Overview of manufacturers of heating boilers in development

Waste oil burner

Reliable heating on waste oil, reviews of which are mostly positive, is impossible without a factory burner. The safety and efficiency of the heat supply at home will depend on it. Currently, the market is dominated by foreign manufacturers of this type of equipment. This is due to the labor intensity of production and the relatively low demand among Russian consumers for heating boilers for development. Most models are designed for heating large rooms, and their power exceeds 60 kW. But despite this, it is possible to organize heating on waste oil in a private house and with the help of less efficient burners.

Clean Burn Boilers

The American company specializes in the production of powerful waste oil boilers. Its products are in demand in boiler houses for heating 2-3 apartment buildings. The minimum boiler power is 200 kW. A special feature is the unique shape of the heat exchanger, providing 95% efficiency.

Burners Kroll

German manufacturer specializes in waste oil burners

It is important that the company's engineers took into account the specifics of heating a house with waste oil - the burner can be installed on almost any type of solid fuel boiler. In addition, it has a unique fuel heating system so that its viscosity is close to ideal.

A special feature is the mandatory presence of compressed air, which can be generated using a compressor. This is a prerequisite for organizing heating on waste oil with your own hands.

This Russian manufacturer is one of the few who could make truly unique waste oil heating equipment. Their heating boiler "Zhar-20" with a rated power of 30 kW can be installed in a private house. It does not take up much space, and at the same time all the safety measures for waste oil steam heating are taken into account.

The price of equipment from the above manufacturers depends on the power of the boiler (burner), its design features.

Before purchasing a specific boiler model, it is recommended that you read the reviews for waste oil heating. They will help to form an objective point of view on the efficiency of a particular equipment.

Expert answers

grandfather mikhey:

read - .forumhouse /threads/61678/

Marousel:

No

HUMAN:

liquid... warm house

Parfiry Pavlochev:

maybe why do you think the oil does not need to be heated chtoli or one insignificant gram of saving costs people's lives in which case?

Kotofey:

Yes, you can, but keep in mind that it is combustible and that transformers sometimes explode.

Sergey Erofeev:

no fire hazard

Special opinion:

no. the system is not designed for a coolant of such viscosity.

Sergei Sokolov:

it is necessary to recalculate the system and write a will

Anatoli:

In principle it is possible. But it is not desirable to heat the coolant (oil) up to 70 degrees. In place of water, it is now used for heating systems, an antifreeze liquid.

Grandfather Au:

no, you will get an explosion and a fire!

Verik:

it’s possible, it’s even better… BUT THE SYSTEM WILL BE EXPLOSIVE… otherwise, if you think about it, oil gains a higher temperature than water, heats up much faster, cools down more slowly….

f f:

It will be too thick

Airat Sattarov:

The heat capacity of oil is small compared to water and antifreeze. Because of this, there will be overheating of the oil in the boiler heat exchanger, partial decomposition and coking. We have already said about the fire hazard of the system. I’m not talking about dirt during maintenance, spilled water will dry out and that’s it, but what about oil? Why such an extreme? Free oil nowhere to go?

Sergei Zuev:

Transformer oil is not only flammable, but also poisonous. Are you suicidal?

Dmitry Ilyin:

The best heat transfer near water, faster heating. gives off heat faster. Oil slower load and slowly releases heat. Why these difficulties in setting up and servicing. systems? not to mention the above. If you don't want corrosion in the pipes (if it's metal), don't raise the temp. above 70 gr.

██████████████████████████████:

and the water is already a pity

Jabba the Hutt:

And this is a thought!

Antifreeze as a coolant in the heating system

Antifreeze is a development of Soviet engineers in 1971, its abbreviation comes from the name of the department of the Soviet State Research Institute of Organic Chemistry - Technology of Organic Synthesis with the addition of a prefix typical for the name of alcohols.

Although the main component in Tosol is ethylene glycol and it does not visually differ from glycol-based antifreezes, there are the following discrepancies in the composition and technology of their manufacture:

- In addition to glycol and water, Tosol contains nitrate, phosphate, silicate, borate and amine additive components, due to which the liquid boils at a temperature of 100º C and decomposes at 105º C. When used in automotive technology, Tosol is designed for 40,000 kilometers.

- Antifreezes are made using carboxylate technology, the composition includes additives from salts of organic acids, due to which the solution has high anti-corrosion, anti-cavitation and anti-foam characteristics. The boiling point of glycol solutions reaches 115º C, a car filled with antifreeze can travel a distance of 240,000 km. without replacing it.

It is easy to see that the obsolete Tosol is significantly inferior in its characteristics to modern antifreezes for automotive equipment, produced from imported raw materials using carboxylate technology, which is not available to a domestic manufacturer.

Rice. 7 Antifreeze - appearance

What to fill in the heating system of a personal home

At this time, a heating system is considered a significant component of living in a private house. Among modern fuels, gas is considered to be very inexpensive and affordable, due to which heat carriers are heated, and then the heated liquid heats the batteries in the premises. Moreover, this liquid itself can be very different: water, antifreeze or a mixture of antifreezes.

Water - pluses and minuses.

One of the very popular and easily accessible thermal carriers is water, which is not surprising, because it contains a lot of advantages:

- high fluidity (as a result of which it can get everywhere),

- low viscosity,

- non-toxicity,

- ease of access,

- a small price.

And in addition, water transfers heat quite well.

But this heat carrier also has disadvantages.

- Since the heating system of a private house often consists of metal elements, over a period of time they, due to mutual action with water, become unsuitable and become rusty. And where hot water passes (above 80 degrees), scale is also deposited on the pipes.

- The physical properties of water, in consequence of which it freezes at a temperature of zero and below. Therefore, a house where water is considered a heat carrier cannot be left without heat supply in winter, even for a few days. Indeed, when freezing, this liquid begins to increase, which can simply break the pipes.

Therefore, those who use water in their own heating should regularly monitor the efficiency of the latter, and at least once a year wash the system from corrosive destruction and scale.

Antifreeze - pros and cons.

Several types of this liquid are emphasized: propylene glycol and ethylene glycol.

Ethylene glycol is considered one of the inexpensive options for the heating system.

Its positive qualities can be called: low viscosity, good fluidity and resistance to low temperatures (up to -60 degrees).And in addition, this heat carrier does not enter into a chemical bond with metals, therefore, it can be in the system for a long time - without any flushing.

Moreover, unlike water, ethylene glycol has a higher thermal conductivity, which means that the house will warm up faster, and less gas is needed for this heating.

True, this liquid has one most significant drawback - it is toxic, due to which it can only be used for heating industrial areas. By the way, in an effort to remove this drawback, scientists with some period developed a replacement for this liquid - propylene glycol.

It has the same characteristics as ethylene glycol, but unlike it is absolutely non-toxic, thanks to which it can also be used in residential buildings. However, its heat conductivity is much lower (than that of ethylene glycol), the difference is about 15-20 percent. At the same time, propylene glycol costs a lot more than its own ancestor. This prompted the manufacturers to make their mixture.

The perfect solution is a mixture of antifreeze.

This heat carrier has absorbed only the good qualities of propylene glycol and ethylene glycol: excellent thermal conductivity and environmental friendliness. And since water, as a heat conveyor, is already losing its own attractiveness (largely due to the fact that it severely injures pipes with some period), we advise you to take a closer look at the antifreeze mixture.

Pouring antifreeze into the heating system

As noted above, the use of Tosol is justified only in emergency situations, in order to pour Tosol into the heating system, the work is performed in the following sequence:

- The coolant is drained through the filling valve located at the lowest point next to the water heating boiler (this possibility should be provided at the system design stage).

- The mud filter is removed, cleaned and replaced, then, using an inexpensive vibrating electric pump (Kid), water is poured into the system at a standard pressure of not more than 2 bar.

- After filling the pipeline, the inlet valve is closed, the heating boiler is turned on to heat water and the circulation pump. Set the heating temperature to about 60 C. and pump water for an hour, at the end of the time, monitor the condition of the mud filter.

- If too much dirt remains on the filter cartridge, turn off the circulation pump and the boiler, drain the water, clean the filter and repeat the entire washing procedure again.

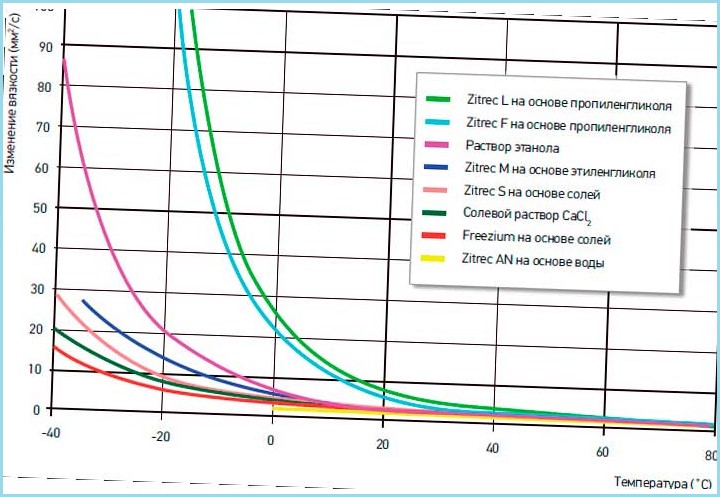

Rice. 12 Graph of antifreeze viscosities

- After making sure that there is practically no dirt in the system, after draining the water, they start pouring Antifreeze. It is poured into a large volume container, a vibration pump is immersed there and pumped into the system at a pressure of about 2 bar.

- Usually, the underfloor heating circuits are connected through collectors, on which automatic air vents are placed to bleed air - they cope with their task without the presence of a person. On heating radiators, air will have to be bled manually through Mayevsky taps. To do this, use a flat screwdriver or wrench to unscrew the slot in the upper part of the radiator and drain the coolant, so all the batteries are bypassed, starting from the upper floors. When the pressure drops after draining the coolant, it periodically pumps it up.

- Bleeding water from the radiators and pumping is repeated again, then the circulation pump and the boiler are turned on at a temperature of about 60º C, and then the batteries are manually checked for uniformity of heating from both sides. If one half of the radiator heats up less, the air is released again and the antifreeze is pumped up.

- With increased foaming during the injection of antifreeze, all equipment is turned off for several hours, giving Tosol the opportunity to settle.

Antifreeze has a short service life, its final phase can be determined visually - if the liquid has a rusty color, this indicates the decomposition of inhibitors and the circuit is urgently freed from the coolant.

Rice. 13 Heating boilers in a private house

Expert answers

Alex Mishin:

Sold special antifreeze for heating systems. At our place of work for many years in one of the rooms there was electric heating with thermosiphon circulation of the liquid heat carrier. No matter how much they repaired, there were problems all the time. If in winter they don’t live in the house all the time, it’s better, I think, not to mess with water heating at all.

Khuliganov Joseph:

Tosol.

Alexander Greshnev:

Problems can arise with antifreeze and other antifreezes, for example, leaks in gaskets. And most likely you have water heating, not steam.

Evil-minded:

pure alcohol will do! And even better cognac ... .

But in fact, very few boilers have the line in the passport “it is allowed to use brand antifreeze ...” As a rule, the manufacturer guarantees the operation of the boiler only on water of a certain quality.

one of my friends poured antifreeze. The house is cold. Antfiriz did not freeze and the pipes did not burst, he turned into a jelly-like mass. PPCC. The pump does not pump it, the gas boiler will turn off from overheating. To start the system, they heated the house with a heat gun and burners until the antifreeze became liquid. Seryoga poured out this muck and filled it with water - and he lives like that.

♆ 54:

antifreeze

Higher intelligence:

vodka

Sergei:

depending on how you heat - if it is constant all winter - then ordinary water, and if at times you jump into the country - then add antifreeze to the water

Dmitry Shestaev:

There are special additives for heating systems that allow you to maintain the integrity of the system during prolonged inactivity in the winter. I agree with the answers of Sergei and the 54th ... the same automobile antifreeze or antifreeze will help ... there is also the Arktika liquid, designed for temperatures below 40 degrees below zero and used only at lower temperatures ... By the way, antifreeze can be found in the form of a concentrate. It is imperative to mix well, otherwise the water will still freeze ... And in severe frost (below -40) there is a risk of damage ...

MITRICH:

The choice is small. Either antifreeze or oil (e.g. automotive, transformer, etc.)

HE:

petrol. he's going to freeze!

Dmitry Kusa:

Good afternoon, use professional and trusted sources that will help you very easily. You will quickly achieve convenience and comfort in your home, and most importantly, quality ecommerce.grundfos /

Rules and steps for draining water from the heating system

How to properly drain water from the heating system in a house or apartment? It is necessary to take into account the design features of the heating system and follow the procedure.

Draining the heating system in a private house

The heating system of a private house is usually autonomous and draining does not require any permits and agreements with neighbors. It is recommended to drain the heating system in the following order:

- Disconnect the heating boiler from the network.

- Water in pipes and radiators must be completely cool.

- Close the cold water supply valve.

- Open air valve.

- Open the valves on the radiator and boiler.

- Connect the hose to the drain cock, which is located on the return pipe near the boiler. The other end of the hose must be lowered into the toilet or a large container if the hose is short.

- Open drain cock.

- Pump out water until the pressure gauge shows zero.

- Open the Mayevsky tap and let air into the heating system. The air will push out the rest of the water.

- Move the hose to the supply tap, open it and drain the liquid from the upper pipe.

A compressor is needed to drain the water from the underfloor heating system. It is connected to the inlet pipe, turned on, and the air supply contributes to the movement of fluid in the thermal circuit. A drain valve is installed on the return pipe, which opens to remove water.The compressor builds up pressure gradually and stops draining when air is released at the outlet. Underfloor heating circuits have a small capacity and can hold no more than 10 liters of water.

After the coolant is drained, the necessary actions are taken to repair or reconstruct the system. Or they calmly leave the house for the winter, eliminating the risk of rupture of heating pipes.

Draining the heating system in an apartment building

If the radiators were replaced with new ones in the housing, they are equipped with the necessary fittings. It is easy to drain the water in this case. This is also possible if there are shut-off valves on the way from the riser to the heating radiator. The procedure in this case is as follows:

- Shut off the fluid supply to the battery by turning the control valves.

- Open the drain cock at the bottom of the battery. Instead of a tap, there may be a plug available, then it is unscrewed with an adjustable wrench.

- Place a bucket to drain water or connect a hose.

in an apartment building, you need to open the drain cock at the bottom of the battery

in an apartment building, you need to open the drain cock at the bottom of the battery

Difficulties arise if the battery is old, the valves are missing or painted over. Then the water will have to be drained from the entire system. It is impossible to do this on your own, you will have to apply to the management company. The specialist will turn off the tap in the basement and remove water from a certain riser.

If there is a bypass (a vertical jumper between the upper and lower radiator pipes) in a single-pipe heating system, the course of action is different:

- Open the tap on the bypass.

- Shut off the shut-off valves - turn off the coolant supply.

- Open the outlet valve or plug to drain the water.

This item is written in the contract with the management company. The system must be maintained at a constant pressure and self-draining this pressure can relieve it, which will lead to problems with heating throughout the house. Therefore, to discharge water, you need to call a specialist.

Draining the heating system in an apartment or house is a mandatory procedure before replacing parts of the heating system and carrying out preventive maintenance. During the absence of the owners of a private house in winter, it is imperative to drain the water in order to avoid freezing and damage to the system. To simplify this procedure in the future, the old heating system must be replaced, providing it with all the elements of valves.

Features of using water as a heat carrier

In terms of heat transfer efficiency, water is an ideal heat transfer medium. It has a very high heat capacity and fluidity, which allows you to deliver heat to the radiators in the required volume. What water to fill? If the system is closed, you can pour water directly from the tap.

Yes, tap water is not ideal in composition, it contains salts, a certain amount of mechanical impurities. And yes, they will settle on the elements of the heating system. But this will happen once: in a closed system, the coolant circulates for years, a small amount of replenishment is very rarely required. Therefore, a certain amount of sediment will not bring any tangible harm.

Water as a heat carrier for heating systems is almost ideal

If the heating is open, the requirements for water quality, as a heat carrier, are much higher. Here there is a gradual evaporation of water, which is periodically replenished - water is added. Thus, it turns out that the concentration of salts in the liquid increases all the time. And this means that the sediment on the elements also accumulates. That is why purified or distilled water is poured into open-type heating systems (with an open expansion tank in the attic).

In this case, it is better to use distillate, but it can be problematic and expensive to get it in the required volume. Then you can fill in the purified water, which is passed through the filters. The most critical is the presence of a large amount of iron and hardness salts.Mechanical impurities are also useless, but it is easiest to deal with them - several mesh filters with a cell of different sizes will help to catch most of them.

In order not to buy purified water or distillate, you can prepare it yourself. First, pour and stand to settle most of the iron. Carefully pour the settled water into a large container and boil (do not close the lid). This removes hardness salts (potassium and magnesium). In principle, such water is already well prepared and can be poured into the system. And then top up with either distilled water or purified drinking water. This is no longer as costly as the initial fill.

How to prepare water at home

There are several ways to reduce stiffness. For example, boiling removes carbon monoxide, reducing calcium hardness, but a more aggressive cleaning option is required to remove salts and other compounds. If you need to find a quick way to soften water for heating with your own hands, then you should choose an inhibitory filter that neutralizes scale. This is an effective softening option that removes sodium, lime, soda ash from the coolant.

You can use non-reagent options, for example, magnetic softeners. The aggregates act on the liquid in such a way that magnesium and calcium salts lose their ability to precipitate and are eliminated from the composition of the liquid due to separation.

However, this method is not suitable for a coolant with a temperature index of up to +70 C, you will have to look for another way to soften the water for the heating system. For example, take rain, melted liquid and pour it into the system as needed. This is a composition with sufficient softness, which must be left for several days to infuse before being used as an antifreeze.

You can soften the coolant by using filters with slaked lime, soda ash and sodium hydroxide, and devices based on fine-grained ion-exchange resin also help. All devices work on the principle of binding magnesium and calcium ions dissolved in the liquid and preventing the elements from entering the purified water.

The settling technique helps to eliminate excess iron from the liquid. Iron removal is necessary to prevent the oxidation of the coolant when interacting with oxygen and the appearance of a rusty precipitate. The easiest way is to defend water for a heating boiler in a tank of 200-350 liters. A compressor will come in handy for pumping oxygen, and if the level of iron content is too high (up to 5 mg per 1 liter), a special filter must be installed. Water, passing through membranes and purification systems, will get rid of manganese, hydrogen sulfide, iron and will be suitable for filling into the system.

Chemical reagents cannot become a practical alternative to filtering equipment, since all mixtures cannot quickly adjust to an increase or decrease in the hardness of the coolant. For example, when using polyphosphates, the risk of scale formation can be eliminated, but you will have to ensure that the reagents are present in the system at all times.

The method of preparing the carrier for the heating system should be chosen only after a chemical analysis of the water, such as the design itself.

If you take an anti-freeze, what brand

Liquids for heating systems

Today's market offers a variety of offerings for these specific products.

However, there are also leaders here. Liquid for heating called "Warm House" is in great demand among consumers. This product is produced in Russia.

"Warm House" has been successfully used for many years, so we can say with confidence that the liquid has stood the test of time. And best of all, this antifreeze is characterized by reviews from homeowners who have considerable experience in operating heating systems using antifreeze.

According to them, this brand does not lose its characteristics for ten heating seasons.

This fully corresponds to the service life declared by the manufacturer. As you know, satisfied customer reviews are the best proof of quality.

Also known are such brands as Energos Universal, Energos Lux, Thermagent, Dixis, etc.

On the basis of ethylene glycol, Russian manufacturers produce antifreezes in two versions: with a freezing temperature of up to -30°C, and also with a freezing temperature of up to -65°C.

The above manufacturers are actively expanding the range of non-freezing coolants made on the basis of food-grade propylene glycol, an environmentally friendly raw material. And this is not in vain, because the demand for heating antifreeze is growing, which means there should be an offer.

Cases in which it is strictly forbidden to use antifreeze

When not to use antifreeze

It is not difficult to get acquainted with all the advantages of antifreeze from any manufacturer.

This information is actively advertised by trademarks. On the other hand, we should talk about the features of this liquid, which manufacturers try not to emphasize:

- It is forbidden to use antifreeze in double-circuit boilers. After all, the features of the device of this heating system are such that the coolant can leak from the heating cone into the water supply circuit. And according to its chemical properties, non-freezing liquid is poisonous.

- It is strictly forbidden to use antifreeze in open systems, in which case it may evaporate.

- Also, antifreeze should not be used in heating systems with galvanized pipelines. When interacting with them, loss of original properties and chemical changes is possible. It is not recommended to pour antifreeze into cast iron boilers. At the very least, you need to make sure that paronite gaskets are present in your unit, which can prevent the harmful effects of antifreeze. The technical data sheet of the product will help you with this.

- The heat capacity index of antifreeze is lower than water, as a result, more powerful radiator batteries are needed.

- Since the viscosity of the non-freezing liquid is higher, more powerful circulation pumps will be required.

In any case, the final decision is always yours. It is impossible to say unequivocally which is better, water or non-freezing liquid.

It all depends on the individual heating parameters. Before making a final decision about the choice of a particular coolant, you should seek the advice of specialists.

Best Answers

Kostya Komar:

THEORETICALLY, you can. But it's unnecessary. Moreover, you do not have a boiler, but a THERMOBLOCK. What is the difference between a boiler and a thermoblock? Yes, in the heat transfer system from the flame to the coolant. There is a heat exchanger in the thermal blocks, similar to a gas water heater in a communal apartment. And when using liquids more viscous than water and with lower heat capacities, burnouts in the heat exchanger are POSSIBLE. And the viscosity of the transformer oil will come back to haunt the entire system. There are no calculation methods for the oil of individual heating systems. You will not be able to pick up a super pump for pumping this, possibly, “free” coolant. EVEN ANTIFREEZE for the thermoblock is NOT RECOMMENDED!! ! EVEN!! ! But I would still fill it with diluted antifreeze and forget it for 10 years.

Eric 29Rus:

oil smell. flood antifreeze

Valyushka Maksimova:

I don’t know about oil, we have antifreeze filled in.

IGOR KOVALENKO:

The pump in the boiler is designed for water ...

Rost:

So there's a transformer somewhere nearby, right? Oil has a worse viscosity than water. Of course, you can fill it in, the system will work, the only question is how. After all, the oil can heat up over 100 degrees, due to poor viscosity, overheating can occur in areas close to the boiler. Such a system is more likely to fail.BUT, you can use oil, you just need to prepare the system for it in advance, you need thicker pipe diameters, smoother bends, etc., if this is foreseen in advance, then it will work fine on oil, and on water too. And so, all enti boilers are not designed for antifreeze and water.

nikita:

boiler pump well, in the passports of most pumps there is a note about oil

submariner:

In no case. Earn such a hemorrhagic. Transformer oil corrodes gaskets (rubber). After some time, a flood will occur from all joints where there are rubber seals.

Vadik Stepanov:

thanks for the advice in this case, another question is how to clean the system from working out

Procedure for draining water from the system

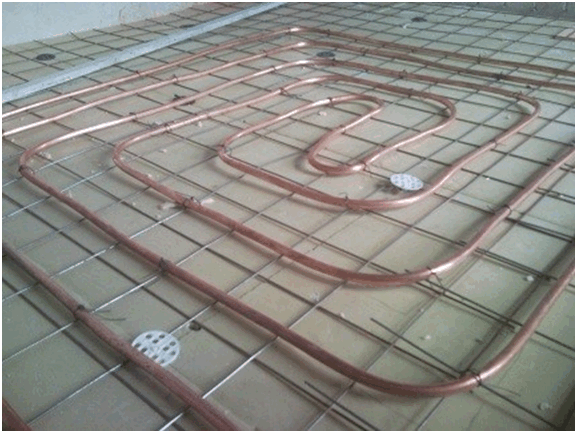

Underfloor heating is a closed system, so you need to take care of the drain taps even at the installation stage. The number of valves must match the number of water circuits.

Underfloor heating is actually a long hose laid in the floor. Laying method - the configuration of the contours may be different, but the principle of operation of the water circuit is the same - the coolant gives off heat to the surrounding space by heating the floor surface.

Before starting the operation to drain the coolant, the heating system is turned off, after which the time required for the complete cooling of all its elements is waited.

Given the fact that the water circuit is connected to the main pipeline, and the connection point is located above the floor level, the water is drained forcibly using an air compressor.

Note: the power of a household vacuum cleaner is not enough to empty the underfloor heating system.

Drainage is carried out through a return line equipped with a drain valve, and the compressor is connected to the manifold on the inlet pipe, so the check valve may create some interference when blowing the pipe. After connecting to the collector, the compressor for displacing the coolant from the circuit is turned on, and the air supply pressure is gradually increased - to a value after which the liquid began to flow out at the outlet. It should be remembered that the volume of water in each of the underfloor heating circuits is insignificant, therefore, an ordinary bucket with a volume of 8-10 liters is sufficient to receive it.

The compressor should work until air begins to flow continuously from the pipe following the water.

Water or antifreeze advantages and disadvantages of using

What to choose - water or antifreeze?

The vast majority of heating routes for communal use and in autonomous heating systems of private houses are filled with ordinary water.

However, recently this statement is not entirely true, as many people decide to use alternative coolants, despite the huge financial costs.

Is it really expensive to use antifreeze in heating systems?

To answer this question, it is necessary to consider all the advantages and disadvantages of using both water and non-freezing liquid as a coolant.

The vast majority of heating elements, in particular heating boilers and fittings, were designed with the condition that water would circulate in them.

Do not forget that water is an affordable and inexpensive heat carrier. And in case of leaks, environmentally friendly media will not harm your health.

Disadvantages of water:

- Regular circulation of water in pipelines contributes to the formation of scale after a certain period of time. In turn, scale leads to energy overruns by 30%. It is not difficult to conclude that the cost of heating a house will increase significantly.

- The probability of rupture of the heating boiler and pipes during the sudden onset of frost, when the system has not yet been started.In this case, material damage will be significant.

- In metal pipelines, the water coolant will provoke rust over time.

Advantages of antifreeze:

- It is not required to drain from the heating system after the end of the heating season. After all, even at very low air temperatures, all functional characteristics of assemblies, pipes and equipment will be fully preserved.

- The additives included in the heat carrier contribute to the fact that the antifreeze does not cause corrosion, does not foam, does not form scale on the inner shells of the heating elements, and does not cause dissolution or swelling of seals.

Disadvantages of antifreeze liquid:

- The anti-freeze liquid is very viscous, its viscosity exceeds that of water by 20%, which creates hydraulic loads on the circulation pump. That is why, when choosing a pump for a heating system with an antifreeze coolant, the power reserve should be taken into account.

- Antifreeze made on the basis of propylene glycol emits vapors that are harmful to human health when leaking.

- Antifreeze liquid is more aggressive to taps, pipes, fittings and other heating components.

Boiler Manufacturers Warning

It should be noted that the use of anti-freeze is not an uncontested method of dealing with freezing of pipes and a heating boiler; you can use power outage warning systems or automation that starts an emergency gasoline generator in the absence of electricity.

This is logical, because if restrictions are imposed on the water itself (it must be clean, colorless, without sediment, with a carbonate hardness of 3 mol/cu. have identical properties - antifreezes do not fit into any standards in terms of their chemical and physical properties.

Usually, a warning from the manufacturer is written in the instructions and informs the consumer that he disclaims all responsibility for the incorrect operation of the boiler, along with a maintenance guarantee, if anti-freeze is poured into the system.

Rice. 14 Examples of the negative impact of antifreeze on the heating system

Being faced with the choice of which is better in the heating system, water or antifreeze, many choose the second option, although its use is associated not only with financial costs, but also with problems arising during operation and termination of warranty obligations for boiler equipment.

The use of Tosol for heating is the worst option, not only in terms of its efficiency, but also the expenditure of funds, its use can be justified only with very rare use of the heating system.