The nuances of warming

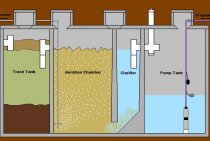

The main problem is the remoteness of the distribution well from the heating of the house. It is not advisable to make a separate line for heating 1-15 m². Therefore, it is necessary to consider other methods of insulation. But before that, you should familiarize yourself with the operating conditions of the pumping station.

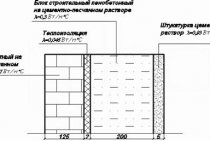

Usually it is a well located 0.5 m below the ground level. Its overall dimensions are 1x1 m with a height of up to 0.7 m. The walls are made of brick or cinder block. In rare cases, the method of pouring concrete is used. These materials have high thermal conductivity, and cannot provide the proper level of thermal insulation. Additional steps will need to be taken to ensure this.

When choosing ways to save heat, the operating conditions of the pumping station are taken into account:

- Ventilation. For a normal level of air exchange, a pipe with a diameter of about 50 mm must be installed. In winter, it is she who is the main source of heat loss. In no case should it be blocked, since as a result of an increase in humidity, the probability of breakdown of electrical equipment will increase;

- Influence on the material of the walls. The most common mistake is installing insulation on the inner walls of the well. As a result of this, the dew point shifts, and as a result, the humidity of the walls increases;

- Flood protection. Care should be taken not only for a good degree of thermal insulation, but also to prevent the ingress of water during the melting of snow or in rainy weather. Therefore, in addition to the insulation, the pumping station must be airtight from the side of the soil and the top cover.

At first glance, the fulfillment of these conditions does not leave the choice of a method for maintaining the desired temperature level inside the station. Therefore, you should use several ways to preserve the microclimate.

How to insulate the pumping station for the winter

Usually the pump is located in a pit on the street a few meters from the house. Often the walls and floor of the pit at the pumping station are left unfinished, using various materials (boards, bricks or concrete) to prevent soil from crumbling. From above, the pit is covered with a lid so that rain and snow do not get inside.

First way

The materials for the pumping station for the winter will be different, depending on the layout of the station. The first method is the construction of a pit below the freezing depth of the soil. This method is less expensive, but is suitable for warm regions where the soil freezes no more than 1 meter, and the groundwater level in the area is low.

However, this method is not suitable for most northern regions - the freezing depth often reaches two meters.

In such conditions, even a deep, but not insulated pit will not provide adequate thermal protection, and the chance that water in equipment and pipes will freeze in severe frosts is quite high.

Second way

The second option for high-quality insulation is the use of moisture-resistant heat-insulating materials.

Consider such heaters for the pumping station as extruded polystyrene foam (foam) and polyurethane foam (PPU). According to their characteristics, mineral wool and polystyrene are not recommended for these purposes.

The use of thermal insulation that is resistant to mechanical stress and moisture is currently a more reasonable solution. The insulation (expanded polystyrene or polyurethane foam) placed on the floor, walls and “cover” will create the necessary conditions that guarantee stable operation of your pumping station even in the most severe frosts.

How to insulate a pumping station for the winter thermal insulation materials

In private homes, owners everywhere face the issue of autonomous water supply and subsequent problems.If the centralized supply of drinking water has bypassed the private sector, holiday village or village, the owners of their own houses get out of the situation by organizing wells, wells and automated water intake using a pumping station.

The pumping station requires insulation for the winter

Such equipment has a number of advantages, but there are also disadvantages. The latter include the fact that the pumping station, submersible, borehole or surface, should not be exposed to sub-zero temperatures.

Pit insulation

Even with the required dimensions of the mine, the lack of insulation will affect the degree of protection of expensive equipment and the entire water supply system. Thermal insulation of both the walls and the protective cover of the well is necessary.

Thermal insulation materials to protect the pumping station

Equipment for a well / well in a country house or in a private house requires thermal insulation using modern materials with increased resistance to moisture. All absorbent materials such as mineral, basalt or glass wool are not suitable in this case. To insulate the pumping station use:

Styrofoam - a material used to insulate a pumping station

- Styrofoam;

- penoplex;

- polyurethane foam.

The use of heat-insulating plate materials resistant to mechanical stress, moisture, rotting is most justified. The use of such insulation on the walls and the cover of the water intake pit guarantees stable operation of the pumping station even in severe frosts.

Insulation is used both outside (well, well) and inside (water intake pit when connecting the house to the city water supply system). In both cases, the well cover is insulated on both sides.

The process of warming the pumping station

Protecting the pumping station from frost and temperature-related breakdowns is easy with a few foam or foam boards (extruded polystyrene foam).

The walls and bottom of the pit, in which the water intake equipment is located, are carefully leveled with a cement screed.

Insulation plates are “sit down” on a special glue and fixed with dowel-fungi. If the walls of the mine are wooden, fungal dowels are enough. The seams between the plates of heat-insulating material must be sealed with sealant or foam.

This will avoid the appearance of cold bridges. It is recommended to use a heater in two layers with a mandatory separation of the seams. The hatch must also be insulated

It is important to avoid cracks into which cold air and snow can blow.

The situation is similar with foam. The only difference is the thickness of the insulation layer. Due to the fact that the foam plastic is inferior to foam plastic in terms of thermal insulation qualities, its layer should be at least 12-15 cm.

Use of polyurethane foam

Polyurethane foam is a widely used material in the insulation of residential buildings, garages, warehouses, technical rooms. It is durable, not afraid of moisture, fungus or mold, does not ignite, has a high level of thermal insulation. And the method of applying the material (spraying) guarantees the tightness of the protective coating.

Polyurethane foam is a durable and widely used material

The walls and floor of the pit / room where the pumping station is located are leveled.

Mount the carrier crate, which will act as a "skeleton" for applying insulation. Usually use a wooden bar and plywood.

The structure is evenly covered with a layer of polyurethane foam, which is supplied under high pressure. It is necessary to cover the manhole cover with insulation on both sides.

Insulation with any of the above materials will protect equipment not only from frost in winter, but also from abnormal heat in summer, working on the principle of "thermos".

Important! It is necessary to insulate not only the pit / room where the pumping station is stored, but also all communication pipes. Especially those that are in unheated rooms or underground on the street

It is necessary to take care of the protection of pipes, taps and connections even at the stage of mounting the system. To do this, use special heaters for pipes, such as energy flex, shells made of expanded polystyrene, foil material, etc.

Especially those that are in unheated rooms or underground on the street. It is necessary to take care of the protection of pipes, taps and connections even at the stage of mounting the system. To do this, use special insulation for pipes, such as energy flex, shells made of expanded polystyrene, foil material, etc.

Methods of thermal insulation of the pumping station

First of all, it is necessary to save the heat that comes from the well. To do this, it will be necessary to insulate the outer walls of the station. As a material, you can use foam or polystyrene foam. The upper revision cover is also made from them.

Additionally, you can equip a wooden frame. It will perform not only a decorative function. Insulation can be installed between its inner wall and the well. But even with a high degree of thermal insulation at sufficiently low temperatures in winter, the probability of water freezing in the pipes is high. Therefore, it is necessary to make a small heating system. It can be implemented in the following ways:

- Installation of resistive heating cable. It is installed on a concrete or brick floor. If the temperature in the well drops below +5°C, the cable is activated;

- Low power electric heater and thermostat. The latter must be adjusted to a certain temperature range. In case of a critical decrease in the level of air heating in the well, the thermostat will turn on the heater. As soon as the temperature stabilizes, it will give a command to turn off.

Some sources advise installing a simple incandescent lamp. However, its thermal energy will not be enough to heat the entire volume of the well. The above technique is costly, since electricity is consumed to maintain the temperature. But passive insulation does not guarantee the integrity of pumping equipment.

Preface. In order not to encounter once in a private house with a lack of water due to freezing of the water supply in the basement or in the ground, not only the pipes, but also the pumping station in the suburban area should be properly insulated for the winter. Consider how to insulate the pump and all communications in the well responsible for the water supply, which is an urgent issue for Russian winters.

Thermal insulation of pipes from the well to the house and the pumping station itself in the well is an urgent issue for residents of country houses and those who like to come to the country house in winter to relax. Frozen water in communications is a serious problem that can cause a lot of trouble, much more than it might seem at first glance. Why is frozen water dangerous and is it worth insulating the pumping station?

Solving the problem of water supply in a country house

Solving the problem of water supply in a country house

As mentioned earlier, autonomous water supply using a pumping substation is the best option for solving the problem of lack of water. As for the price of pump equipment, it is very optimal and quite affordable.

The biggest problem of autonomous water supply is the right choice of equipment, which will be discussed now.

There are two popular schemes for organizing water supply for a summer cottage: using a well and using a well.

For the first scheme, you must first drill a well. It is best to deal with its drilling, selection of equipment and creation of a communication system at the same time as designing the estate and all planned garden buildings.This is necessary in order to be able to easily place water supply elements in different parts of the territory (basement, basement of the house, adjacent buildings, etc.). Also, the advantage of simultaneously building a house and creating a water supply is that with a properly drawn up project, there is no need for additional protection of equipment from freezing in winter. If all the main elements of the pumping substation are located in one place, this will significantly improve the convenience for its maintenance and repair.

Winter is coming. We drain the water

There are many cases when, after the winter, people came to the dacha and found that the system was out of order and it was necessary to ditch the walls in order to change pipes, dismantle and send the pump for repair, there are many. The reason for everything is elementary forgetfulness or ill-conceived decisions when designing a house and a personal plot.

As with other engineering systems, water supply should be taken care of at the design stage. It was then that a fundamental decision had to be made: whether the country house would be operated in the winter or whether it would be conserved before the onset of cold weather. The arrangement of the water supply system and its seasonal maintenance depend on this.

If the owners plan to live in a country house only in the warm season, there should be no problems installing the system. The pump is connected to the electrical network, the hose is lowered into the well, and the pressure pipe is connected to the water supply network.

Before the onset of cold weather, the pump is removed (it is better to take it to the city), the water from all tanks - tanks, water pipes, batteries - is drained, drain taps and plugs should be left open. The drinking well must be cleaned and treated.

This can be done using special formulations, such as chlorinol, which is sold in pharmacies. After treatment, the water from the well is completely pumped out, the well is closed for the winter with a lid.

And by spring it will be filled with fresh drinking water, and all that remains is to use the pump to take life-giving moisture from it. A well that is not operated in winter is not insulated.

If the house is intended for year-round use, quite serious and costly preparatory work will be required. The pumping station must be installed in an insulated room, as it can operate at a temperature not lower than plus five degrees.

Note

The cost of an autonomous water supply system at home, including a well, wiring, a submersible pump or a pumping station and filters, is up to 15% of the cost of the entire house.

The cost of its restoration in case of defrosting can be very high: only the dismantling and re-installation of the pump (excluding repairs) will cost from 500 to 800 dollars, and the replacement of broken pipes hidden in the walls will inevitably entail a major overhaul of the premises.

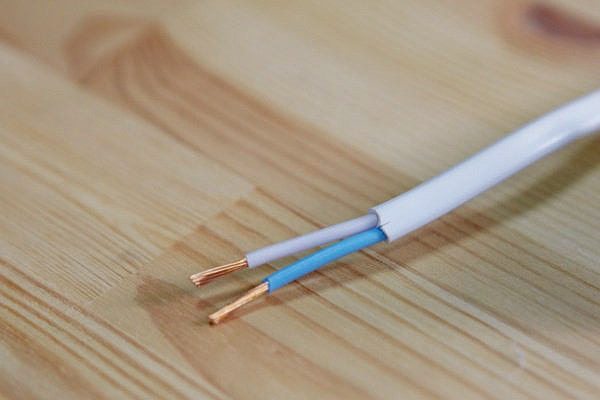

The pipe from the well or well to the house is laid below the freezing level of the soil and insulated for safety - for this purpose, an electric self-regulating two-core cable is usually used, which heats up to 65 degrees. It will be easier for those who have a well under the house, since the pumping station is located in the basement, and not in the open air.

To avoid the formation of frost on the walls of the well and ice on the surface of the water, the head and cover of the well are insulated with any environmentally friendly material. Then there will be a constant temperature in the well - from plus five to plus ten degrees.

The caisson is a metal bunker with a hatch, which is waterproofed from the outside, and coated from the inside with a primer and insulated with foam.

Why insulate

Insulation of water pipes and pumping stations is a topical issue for those people who live in private homes or often come to the country in winter.

The situation described above is actually much more dangerous and serious than it might seem at first glance. It is good if the problem is solved by itself: during the day the temperature will rise a little, and the frozen area will thaw. However, one should not hope for such an outcome - the chances for it are minimal. Alternatively, you can independently identify the part of the pipeline in which the water has frozen and warm it up - however, such a solution is only possible in cases where the pipes and the pumping station are available for inspection.

But the consequences of freezing (besides the fact that there will be no water in your house) will certainly make you think about the insulation of the entire plumbing system of every owner of a private house. As we remember from the school physics course, frozen water tends to expand, and the force of its impact will be enough to damage even a metal pipe - it will simply crack. The same applies to pumping equipment. And in this case, you will have to carry out much more significant repairs to identify and replace it - you see, it’s not a very pleasant and easy task if it’s twenty degrees below zero outside, and the frozen area is on the street.

For this reason, the insulation of water pipes and pumping stations is a topical issue for those people who live in private homes or often come to the country in winter.

Recommendations and installation instructions

Closing the water supply with thermal insulation is not as difficult as connecting heating cables, so we will consider the technical nuances of installation relating specifically to electrical equipment.

External installation of the heating cable

Fastening along the outer surface of the pipe is often practiced when it is necessary to heat open sections of the water supply located in the basement, basement, caisson.

There are two ways to fix the wire on the pipe:

- stretch along the surface along the entire length;

- wrap in a spiral.

The first option is more economical and practical if the cable power is enough to heat the pipe. In particularly cold areas, you can apply the second method, but the wire consumption will increase.

Fastening takes place in the following order:

This is the easiest way to install a heating cable.

Device Recommendations:

- To heat a polypropylene water pipe with a diameter of up to 32 mm, it is enough to fix the cable along one side - it does not matter which one. However, if it is necessary to insulate the sewer, the wire is fixed exclusively from below.

- If there is a choice of insulation, then you need to take a thicker one. Overheating of the self-regulating cable does not threaten, but the heat loss will be significantly reduced. The thicker the “fur coat”, the less electricity the samreg will spend, the greater the savings.

- Aluminum self-adhesive is the best material for attaching to the pipe. Acrylic adhesive does not collapse under the influence of heat, which is evenly distributed over the entire heated surface.

- The sun's rays destroy some types of insulation and fasteners, so for open areas it is better to choose black clamps and adhesive tape that does not react to UV radiation.

If the cable is not fixed in a straight line, but in a spiral, then the insulation will occur according to the same principle - putting on a “fur coat” and fixing it with clamps. Without a heater, part of the energy will be wasted on heating the air.

The nuances of connecting a self-regulating cable

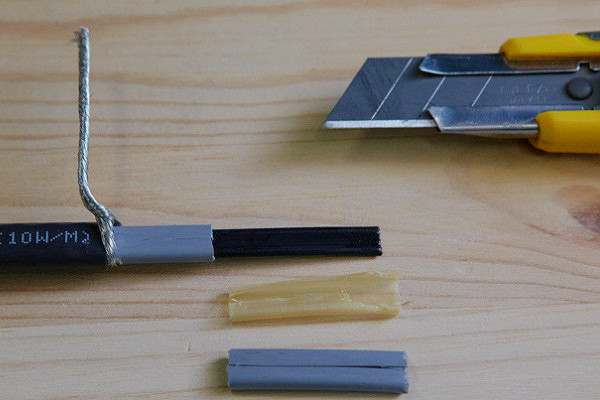

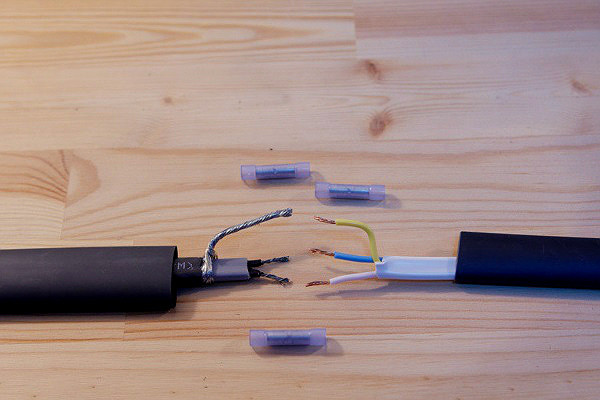

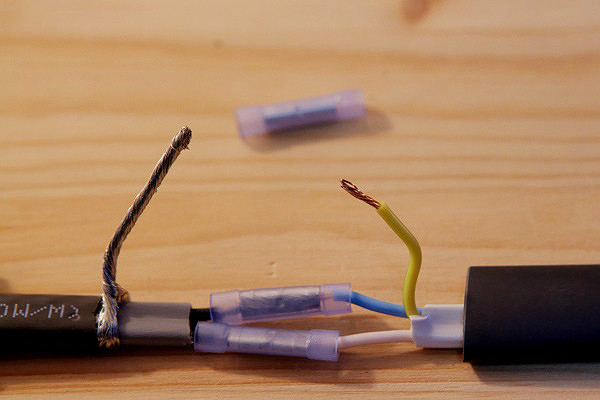

It is impractical to pull the wires to the pipe from the shield, so the samreg is connected to the power cable, which, in turn, is simply plugged into the outlet if necessary. To work, you will need a building hair dryer, a knife, a set of heat shrink tubing for crimping and sleeves for connecting contacts.

It should be remembered that electrical equipment becomes more dangerous in a humid environment, so special attention must be paid to tightness. Photo instructions for connection:

Photo instructions for connection:

As you can see, there are no difficulties with the internal installation of the cable, it’s just that all manipulations must be performed very carefully and consistently.

When choosing a power cable, consider the location of the outlet. If it is next to the pipe, you can buy the shortest product, but more often you have to purchase a 4-5-meter cord.

It remains to compress the end of the samreg:

With a sealed end, the cable is completely ready for use. So that the water pipe does not freeze, it remains to fix the samreg along the entire length of the line, insulate it and insert the plug into the outlet.

In some cases, the installation of an external cable is considered unsuccessful, for example, if it passes through floor slabs or concrete blocks of the well. Then apply internal installation.

If it is better to use a flat-type product for outdoor heating, then a special cable with a round cross section and especially reliable waterproofing is suitable for indoor heating.

The internal installation of the heating cable requires special care and compliance with certain rules. For example, do not pass the cord through knots where threaded connections protrude from the inside - sharp edges can damage the protective sheath

How to insulate a well for the winter preparing a pumping station, water supply, column, caisson, crane in the yard for the cold

As soon as the thermometer crosses the zero mark at night, there is immediately a risk of water freezing in the water pipes.

Not only can water not be used, there is a high probability of pipe destruction, which can be eliminated only after the onset of heat or in emergency mode.

If there is no need to use the well during the cold season, then we drain the water from the system, and all the frosts are unaffected. If there is a need for water all year round, you need to think about how the well will be prepared for winter.

Warming methods

So that in the cold season the house is not left without water, you need to think about how to insulate the tap in the yard for the winter, the upper head of the well and the pipe through which water is supplied.

Such insulation can be a caisson device, the pipe-in-pipe method or a heating cable.

It is important to choose the right insulation material and its design features.

The use of modern materials and technologies will make it possible to prepare the cottage for the use of water all year round.

Heating cable

Well insulation with heat-resistant materials is referred to as passive protection. But there are other, more modern ways. The use of a heating cable is an active method and often becomes the only right decision when preparing a water supply system for winter in a country house. This will be especially true with rare use of the well in the cold season.

The heating cable is laid in two ways:

- inside the water pipe;

- outside the heated pipe.

The cable that is used for indoor installation is sanitary, non-toxic and meets higher electrical safety requirements than other heating or simple wires.

The connection of such a cable to the water supply is carried out through a special tee, which must be built into the existing network. Then measure the length of the pipe that will be heated by this cable.

This size is measured on the cable and fed through the tee into the pipe.

This method of heating has a high efficiency and is very effective. The big disadvantage is that the curved sections of the network cannot be passed with this cable.

Usually two heating cables are used for heating. They are placed along the pipe or laid in a spiral around the pipeline. The more turns of the spiral will be on the same sections of the pipe, the better the heating will be.With a high risk of freezing pipes, external cables are laid in a combined way: two equity wires are supplemented with several spiral ones.

To ensure economical operation of the system, when performing such insulation with an internal or external heating cable, a thermostat is installed. The sensor of this regulator is mounted directly on the pipe and the on and off temperature is set within 3-5 ° C. This setting will avoid frostbite on the pipes and, in the absence of frost, will allow the system to remain off.

The considered method is convenient, but the cost of heating cables, especially internal ones, is very high. In addition, in winter, not all summer cottages are constantly provided with electricity. Therefore, the relevance of using this method is considered individually.