Thermal engineering calculation

Heating systems are designed to compensate for heat loss through building envelopes: external walls, floors, ceilings. When carrying out heat engineering calculation, the following factors are taken into account:

- average annual temperature and humidity of the outdoor air in accordance with the climatic zone;

- direction and strength of the winds;

- thickness of external building structures and coefficient of thermal conductivity of the material;

- availability of window and door openings, glazing characteristics;

- the presence of attics and basements for the first and upper floors.

It is possible to correctly select the final heat engineering devices only if all the listed parameters are fully taken into account. When making calculations, it is better to slightly overestimate the indicators, otherwise the lack of thermal power may lead to the need to remake the entire system as a whole.

When calculating thermal engineering calculations, the indicators are better dependent.

It is possible to choose the devices necessary for this heating scheme, in particular, radiators, according to the results of a heat engineering calculation. In accordance with SNiP 41-01-2003 "Heating and ventilation", the recommended specific power for residential premises is from 100 W per 1 sq. m. total area with a ceiling height of not more than 3000 mm. This value is adjusted by special coefficients.

How best to take into account all the factors for an accurate calculation of the required power of heating devices? It should be noted that the presence of one or two windows in the room increases heat loss by 20-30%.

If they are located on the north or on the windy side, then the correction can be safely increased by another 10%.

Important! Radiators are designed to compensate for heat loss and their parameters must be calculated with some margin

1 The general sequence of performing thermal engineering calculations

-

V

in accordance with paragraph 4 of this manual

determine the type of building and conditions, according to

which should be counted ROtr. -

Define

ROtr:

-

on

formula (5), if the building is calculated

for sanitary and hygienic and comfortable

conditions; -

on

formula (5a) and table. 2 if the calculation should

be conducted on the basis of energy saving conditions.

-

Compose

total resistance equation

enclosing structure with one

unknown by formula (4) and equate

his ROtr. -

Calculate

unknown thickness of the insulation layer

and determine the overall thickness of the structure.

In doing so, it is necessary to take into account typical

outer wall thicknesses:

-

thickness

brick walls should be a multiple

brick size (380, 510, 640, 770 mm); -

thickness

exterior wall panels is accepted

250, 300 or 350 mm; -

thickness

sandwich panels are accepted

equal to 50, 80 or 100 mm.

Calculation of heat exchangers and various methods for compiling the heat balance

When calculating heat exchangers, internal and external methods of compiling the heat balance can be used. The internal method uses heat capacities. The external method uses specific enthalpies.

When using the internal method, the heat load is calculated using different formulas, depending on the nature of the heat exchange processes.

If heat exchange occurs without any chemical and phase transformations, and, accordingly, without heat release or absorption.

Accordingly, the heat load is calculated by the formula

If during the process of heat exchange vapor condensation occurs or liquid evaporates, any chemical reactions occur, then another form is used to calculate the heat balance.

When using the external method, the calculation of the heat balance is based on the fact that an equal amount of heat enters and exits the heat exchanger for some unit of time.

If the internal method uses data on heat exchange processes in the unit itself, then the external method uses data from external indicators.

To calculate the heat balance by the external method, the formula is used

.

By Q1 is meant the amount of heat that enters the unit and goes out of it per unit of time.

By this is meant the enthalpy of substances that enter and leave the aggregate.

You can also calculate the enthalpy difference in order to determine the amount of heat that has been transferred between different media. For this, the formula is used.

If any chemical or phase transformations occurred during the heat transfer, the formula is used.

Technical requirements for heat engineering devices

How to choose steel or aluminum radiators most suitable for given specific conditions. General technical requirements for heating devices are established by GOST 31311-2005. This document establishes the basic concepts and their nominal indicators. The maximum coolant temperature for water appliances is 70 ° C at a flow rate of at least 60 kg per minute and a pressure of 1 atm.

When buying a radiator, it is important to study its technical documentation. The answer to the question of which devices to choose for heating systems, and in particular radiators, can be obtained after a careful study of its technical documentation.

Passport tests are carried out at the manufacturer, the results of which are reflected in the information official publications of the manufacturer

The answer to the question of which devices to choose for heating systems, and in particular radiators, can be obtained after a careful study of its technical documentation. Passport tests are carried out at the manufacturer, the results of which are reflected in the information official publications of the manufacturer.

Recommendations on which devices are best for specific heating systems can be given by employees of operating enterprises. The presence of a heat-resistant outer coating not only has a decorative value, but also protects metal parts from corrosion. The quality requirements for such coatings are determined in accordance with the standards of the sanitary supervision authorities and must meet the requirements of GOST 9.032-74 (class not lower than IV).

Important! The equipment of building heating systems should not have sharp corners and edges that can injure a person if handled carelessly. Particular attention should be paid to this issue when choosing equipment for schools, kindergartens and hospitals.

Determining the thickness of the wall insulation

Determination of the thickness of the building envelope. Initial data:

- Construction area - Sredny

- Purpose of the building - Residential.

- Construction type - three-layer.

- Standard room humidity - 60%.

- The temperature of the internal air is 18°С.

|

layer number |

Layer name |

thickness |

|

1 |

Plaster |

0,02 |

|

2 |

Masonry (cauldron) |

X |

|

3 |

Insulation (polystyrene) |

0,03 |

|

4 |

Plaster |

0,02 |

2 Calculation procedure.

I carry out the calculation in accordance with SNiP II-3-79 * “Design standards. Construction heat engineering”

A) I determine the required thermal resistance Ro(tr) according to the formula:

Ro(tr)=n(tv-tn)/(Δtn*αv) , where n is the coefficient that is chosen taking into account the location of the outer surface of the enclosing structure in relation to the outside air.

n=1

tн is the calculated winter tair outside, taken in accordance with paragraph 2.3 of the SNiPa “Construction heating engineering”.

I accept conditionally 4

I determine that tн for a given condition is taken as the calculated temperature of the coldest first day: tн=tx(3) ; tx(1)=-20°C; tx(5)=-15°С.

tx(3)=(tx(1) + tx(5))/2=(-20+(-15))/2=-18°C; tn=-18°C.

Δtn is the standard difference between tin air and tin the surface of the enclosing structure, Δtn=6°C according to the table. 2

αv - heat transfer coefficient of the inner surface of the fence structure

αv=8.7 W/m2°C (according to Table 4)

Ro(tr)=n(tv-tn)/(Δtn*αv)=1*(18-(-18)/(6*8.7)=0.689(m2°C/W)

B) Determine RO=1/αv+R1+R2+R3+1/αn , where αn is the heat transfer factor, for winter conditions of the outer enclosing surface. αн=23 W/m2°С according to the table. 6#layer

|

Material name |

item number |

ρ, kg/m3 |

σ, m |

λ |

S |

|

|

1 |

Lime-sand mortar |

73 |

1600 |

0,02 |

0,7 |

8,69 |

|

2 |

Kotelets |

98 |

1600 |

0,39 |

1,16 |

12,77 |

|

3 |

Styrofoam |

144 |

40 |

X |

0,06 |

0,86 |

|

4 |

Complex mortar |

72 |

1700 |

0,02 |

0,70 |

8,95 |

To fill in the table, I determine the operating conditions of the enclosing structure, depending on the zones of humidity and the wet regime in the premises.

1 The humidity regime of the premises is normal according to the table. one

2 Humidity zone - dry

I determine the operating conditions → A

R1=σ1/λ1\u003d 0.02 / 0.7 \u003d 0.0286 (m2 ° C / W)

R2=σ2/λ2=0,39/1,16= 0,3362

R3=σ3/λ3 =X/0.06 (m2°C/W)

R4=σ4/λ4 \u003d 0.02 / 0.7 \u003d 0.0286 (m2 ° C / W)

RO=1/αv+R1+R2+1/αn = 1/8.7+0.0286 + 0.3362+X/0.06 +0.0286+1/23 = 0.518+X/0.06

I accept RO= Ro(tr)=0.689m2°C/W

0.689=0.518+X/0.06

Xtr\u003d (0.689-0.518) * 0.06 \u003d 0.010 (m)

I accept constructively σ1(f)=0.050 m

R1(φ)= σ1(f)/ λ1=0.050/0.060=0.833 (m2°C/W)

3 I determine the inertia of the building envelope (massiveness).

D=R1*S1+ R2*S2+ R3*S3=0,029*8,69+0,3362*12,77+0,833*0,86+0,0286*8,95 = 5,52

Conclusion: the enclosing structure of the wall is made of limestone ρ = 2000kg / m3, 0.390 m thick, insulated with foam plastic 0.050 m thick, which ensures the normal temperature and humidity conditions of the premises and meets the sanitary and hygienic requirements for them.

Classification of equipment for heating systems

Steel radiators are the most common and they have an affordable price.

In order to choose the right quality heating appliances, you need to get an idea in this matter. The construction industry offers a wide range of heating equipment. Heat transfer from devices to the environment occurs due to radiation and convection.

There are several types of equipment used in different heating systems. How to choose high-quality radiators? Classification of equipment is carried out according to various criteria, including materials used in production, design, installation method and other features.

Professional sales consultants from building supermarkets will help answer the question of which heating devices are better. The most widespread are steel heat engineering devices, which are characterized by relatively low cost and acceptable strength characteristics.

They are manufactured in accordance with the requirements of GOST 19904-90.

Batteries made of extruded aluminum profile or cast have proven themselves well. The technology of their production is determined by GOST 8617-81. the minimum wall thickness must be at least one and a half millimeters. This must be taken into account when selecting equipment for space heating.

At leisure

Thermotechnical calculation of heating systems

The need for thermal engineering calculation of heating systems (as well as other elements and structures) arises in the event of a major overhaul and modernization of buildings.

The relevance of carrying out such work at facilities has increased in recent years due to the high wear and tear of buildings built back in the Soviet years. The heating systems that buildings were equipped with ten years ago, and are still being equipped, are designed in such a way that they do not allow efficient distribution of heat between floors and individual elements of systems inside the building.

In simple terms, in some parts of the heating system, too much heat can be given off, while in others not enough. As a result, some of the apartments receive an oversupply, which allows residents to live with open windows even in winter. And vice versa - some apartments freeze because they do not receive enough heat.

To eliminate these shortcomings will allow thermal engineering and thermal imaging of the structures of buildings and structures http://www.disso.spb.ru/?item=9.

At the first stage, measurements are made - a survey is carried out and specialists-engineers receive something like this map. It shows areas with different thermal conditions of buildings and allows you to fix the existing defects.

The next step is to conduct a heat engineering calculation, which allows solving the issue of uniform heat distribution in the house. Each facility handles this task differently. In some cases, it is necessary to insulate the house - to conduct sheathing with insulation. In other cases, it is necessary to balance heating systems, modernize existing engineering systems from ITP.

Thermal survey will reveal heating defects and indicate to engineers and designers which structural elements require recalculation. In the future, modernization is carried out using modern technologies and modern heating equipment.

Views: 787

Date: February 25th, 2014

When choosing radiators, it is worth considering all the factors affecting them.

Maintaining a comfortable temperature and humidity regime in residential or other premises in the climatic conditions of our country is impossible without heating systems. The most widespread schemes with an intermediate coolant, which can be both centralized and autonomous.

The final devices in such systems are heating devices that carry out heat exchange processes in the premises.

The question: how to choose heating radiators, taking into account all factors, is quite complicated and requires detailed consideration.

2 Example 1

Calculate

thickness of the outer wall of a residential building,

located in the city of Topki, Kemerovo

areas.

A.

Initial data

-

Estimated

temperature of the coldest five

days

tn=

-39 оС

(Table 1 or Appendix 1 of this manual);

-

Medium

heating period temperature

tfrom.per.=

-8.2 °C

(see ibid.); -

Duration

heating period zfrom.per.=

235 days (ibid.); -

Estimated

indoor air temperature tv=

+20 оС,

relative

indoor air humidity φ=

55%

(cm.

appendix 2 of this manual);

-

Humidity

room mode - normal (Table 1

); -

Zone

humidity - dry (app. 1 *); -

Conditions

operation - A (app. 2).

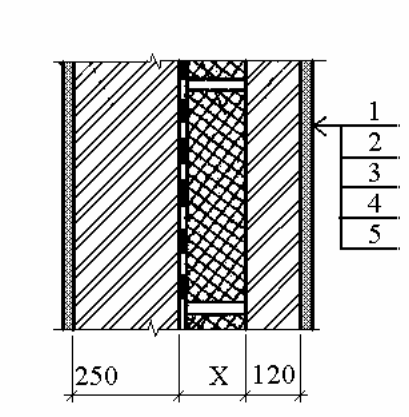

Rice.

2. Wall design sketch

table

7. Thermotechnical

material characteristics (on

adj. 3*, subject to operation A)

Name

materialγ,

kg/m3

adj.3*

δ,

mλ,

W/(m °C),

adj.3*,

|

m2 |

|||||

|

1. |

Cement-sand |

1800 |

0,02 |

0,76 |

0,026 |

|

2. |

Brick |

1400 |

0,12 |

0,52 |

0,23 |

Name

materialγ,

kg/m3

adj.3* δ,

mλ,

W/(m °C),

adj.3*,

|

m2 |

|||||

|

3. |

Plates |

50 |

δ3 |

0,052 |

δ3/0,052 |

|

4. |

Brick |

1400 |

0,38 |

0,52 |

0,73 |

|

5. |

Lime-sand |

1600 |

0,015 |

0,7 |

0,021 |

B.

Calculation procedure

1.

In accordance with clause 4.1. and 4.2 required

resistance to heat transfer of a given

buildings should be determined from the conditions

energy saving depending on

heating degree days

according to formula (5a):

GSOP

= (tv—

tfrom.per.)zfrom.per.

GSOP

= (20-(-8,2))·235 = 6627.

.

Required (reduced) resistance

heat transfer from energy saving conditions

determined by interpolation according to the table. 2 (or

tab. 1b)

ROtr=

3.72 (m2

oC/W).

.

Total thermal resistance

enclosing structure is determined by

formula (3):

;

where

αv=

8.7 W/(m2 °C)

(Table 4*, see also Table 4 of the manual);

αn=

23 W/(m2 °C)

(Table 6 *, see also Table 5 of the manual).

RoROtr

RO

=

1/8,7 + 0,026 + 0,23 + δ3/0,052

+ 0,73 + 0,021 + 1/23 = 3,72

δ3=

0.13 (m)

.

Taking into account the modular thickness of the brick

masonry accept

thickness of mineral wool insulation

plates equal to 0.14 m.

Then the total thickness of the outer walls without

accounting for finishing layers will be 0.64 m

(2.5 bricks).

Let's spend

verification calculation of the total thermal

structural resistance:

RO

=

1/8,7 + 0,026 + 0,23 + 0,14/0,052 + 0,73 + 0,021 + 1/23 =3,85

RO

=

3,85 > ROtr

=

3,72

Conclusion:

accepted design of external walls

meets thermal requirements.