With or without bypass

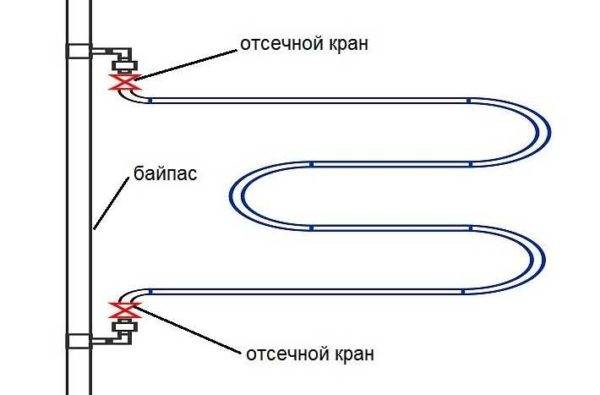

Let's start with what a bypass is. This is a jumper between the input and output of the device, which ensures the circulation of water when the device fails or is turned off.

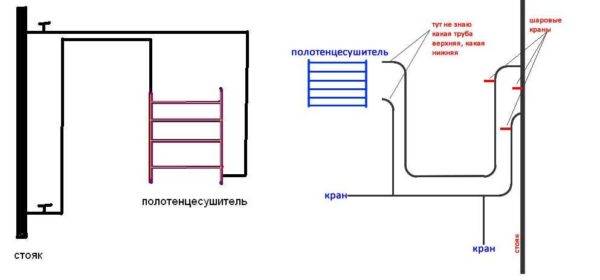

The jumper between the input and output of the heated towel rail is the bypass

If there is a bypass in the circuit, shut-off ball valves can be installed at the inlet and outlet of the device. This is convenient - you can turn it off if necessary (during repair or replacement) and not block the entire riser.

If there is no such jumper, no taps can be installed. In this case, the heated towel rail is part of the riser, by closing the taps you completely shut off the riser.

When connected without bypass, no taps

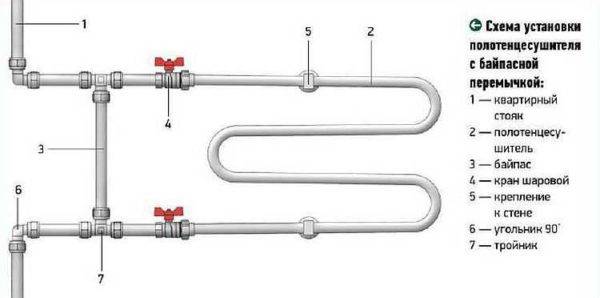

The bypass can be straight (as in the first photo in the chapter) or offset (in the photo below). An offset jumper is placed at the top coolant supply for better performance (circulation improves). With a bottom feed, the offset only interferes. If you do not know where the water is coming from, it is better to do a direct bypass.

Offset bypass at the top coolant supply improves circulation

More bypasses (straight or offset) are made narrower. Tapering, as well as offset, improves circulation, but only in the case of top feed. The narrowing is made with a pipe, which is one step smaller than the main one (if the riser is an inch, a bottleneck is made 3/4 ″). Can't be less. The size of the insert is at least 10 cm.

Categorically it is impossible to put taps on the bypass. Each faucet is a pressure loss, which means that it impairs the circulation of the entire riser, the water flows not so hot anymore. All neighbors above or below (depending on the direction of supply) noticeably worsen the pressure. Sometimes it also falls at the owner of the bypass with a tap. In addition, this is an absolutely unnecessary detail that only brings harm, and there is no noticeable improvement in circulation in the heated towel rail. Well, and besides, this is a violation of SNiP 31-01-2003 (clause 10.6) - interference in general house communications, for which a fine (considerable) can be issued.

Scheme 3 lateral and diagonal connections with narrowed or offset bypass.

The vast majority of plumbers believe that there must be a narrowing between the taps on the substation - otherwise nothing will work. Firstly, this is not so (see diagrams Nos. 1 and 2), and secondly, in the case of a lower water supply in the riser and poor circulation, the narrowing prevents the heated towel rail from working until it is completely cooled, despite the outwardly normal connection. Therefore, it is always worth striving to ensure that the diameter of the bypass is equal to the diameter of the riser.

Figure 21. Connection of a PS ladder, operating on a combination of forced and natural circulation, with a narrowed bypass. Side connection.

Figure 22. Connection of the PS ladder, operating on a combination of forced and natural circulation, with bypass offset. Side connection.

Figure 23. Connection of a PS-ladder, operating on a combination of forced and natural circulation, with a narrowed bypass. diagonal connection.

Figure 24. Connection of the PS ladder, operating on a combination of forced and natural circulation, with bypass offset. diagonal connection.

Note that the direction of supply in the riser is now unambiguously indicated by the top. With the bottom feed, these options are categorically not recommended to use, the reasons will be described below

With a bottom feed, these options are categorically not recommended, the reasons will be described below.

Cons of this scheme:

Stable operation is guaranteed for top feed only.

The advantages of this scheme:

- Definitely and stably works at the top giving in a strut.

- It is not required to bleed air from the PS after turning off the water.

- The distance from the riser is arbitrarily large.

Conditions for the scheme to work:

- Let us remind you once again that at the bottom supply, the narrowing / displacement between the taps prevents the operation of the PS up to its complete inoperability! At the top feed, it is permissible to narrow the bypass by a maximum of 1 step from the diameter of the riser. Tapering of the offset bypass is never required at all.

- The lower outlet of the riser should be below the bottom of the substation, and the upper outlet of the riser should be above the top of the substation.

- The slope of the supply pipes must be observed (direction shown in the figure). For definiteness, you can take a difference of 3 ... 30 mm per meter. More is better. With small distances from the riser (a couple of meters) and a large diameter of the supply pipes (PPR 32 mm), strictly horizontal laying is permissible.

- There should be no “humps” (completely unacceptable, air will accumulate in them and circulation will stop) or dips on horizontal routes (allowable only within small limits, deep “pits” will interfere with circulation).

- Pipe diameter to ensure maximum circulation - preferably at least DN20 (3/4" for steel, 25mm for good reinforced PPR), ball valves - at least 3/4". The practical maximum distance of the substation from the riser when using a plastic pipe with a diameter of 25 mm is approximately 4.5 meters.

- It is highly desirable to place the supply pipes in thermal insulation. In addition to the fact that it is mandatory when embedding any plastic pipes (provides mechanical protection and compensation for thermal expansion), such insulation can improve the operation of the substation in certain cases (sagging pipes or "pits" on them).

It is strictly forbidden to install any taps on the bypass - this is vandalism and sabotage to yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

- a) Slows down the circulation in the entire riser (hot water temperature drops).

- b) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - and at the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as much.

- c) It does not noticeably improve the efficiency of the above scheme, and with a lower feed, on the contrary, it interferes with the operation of the PS.

How to connect a heated towel rail to a hot water riser

Towel dryers are connected to the hot water supply with a centralized hot water supply year-round. It is allowed to connect the units to independent year-round heating systems. In this case, it is mandatory to install shut-off valves that allow you to turn off heated towel rails in the summer.

Increasingly, in homes, iron pipes (cast iron, steel, copper) are being replaced with plastic ones. Already almost all apartments have polypropylene. Connect the heated towel rail to the plastic pipeline.

This is how the connection node looks like in a closed scheme:

The units are connected to the DHW by means of couplings. They are available in the following sizes:

- 1''×1/2'' or 1''×3/4'';

- 3/4''×3/4'' or 3/4''×1/2''.

Connection node according to the open scheme:

In the direction of movement of the coolant, a slope of the liner to the heated towel rail is made. Along the entire length - from five to ten millimeters. If the eyeliner is less than fifty centimeters, then it can be strictly horizontal.

The axis of the heated towel rail and the supply pipe can be removed from the surface of the facing tiles or plaster on:

- 3.5 centimeters - with a pipe diameter of up to 23 millimeters;

- 5-5.5 centimeters - with a pipe diameter of 40 to 50 millimeters.

The piping and the unit must fit snugly against the supports and be firmly fixed. In this case, the heated towel rail and the supply pipeline are not welded, but placed on brackets or supporting hooks. A "hot" pipe is subject to temperature deformations. Anyway. If you weld, the load on the wall will increase.

The heated towel rail must be clearly aligned horizontally.Otherwise, an air lock may form inside, preventing the coolant from filling the entire unit. To prevent such troubles, Mayevsky taps are added to the connection diagram.

What designs are

Towel warmers come in different shapes. When choosing them, people are often guided solely by aesthetics, which is not entirely justified. These devices work normally with good water circulation, but not all models provide such circulation. With some you have to be smart for a long time, looking for the right connection scheme, otherwise they simply refuse to work.

So, all heated towel rails can be divided into four groups:

- U-shaped or U-shaped. The simplest models, elementary connection (side). Ideally, when replacing the old one, you find a model with the same center distance. Then, if you're lucky, you can even not redo the bends.

- Ladder. Modern designs with a number of crossbars. Also a good option in terms of hydraulics. The connection can be bottom, side or diagonal. But it is not chosen arbitrarily, but according to a set of conditions (where the supply comes from, location relative to the riser).

-

snake. Another classic model with side connection. Installation of this type of heated towel rail, as a rule, does not present any problems.

Types of heated towel rails

- Complicated form. There are very unusual heated towel rails. They can even be an interior decoration, but their proper connection is a problem. As a rule, consultation of a competent specialist, a plumber who is well versed in hydraulics, is required. As you can imagine, finding one is not an easy task.

It often happens that after installing a heated towel rail, it simply does not work. If the error is serious, the riser to which it is connected also stops working. Therefore, it is necessary to know and follow the connection rules.

Where to connect and where to hang

You can connect a water heated towel rail to both the hot water riser and the heating. If both of these options are available, DHW is usually chosen.

There are three reasons for this: less hassle with permission to connect, you can connect at any time of the year (agree with the management company to turn off the riser and that's it) and, most importantly, such a heated towel rail is heated all year round

If there is no hot water in the house, you will have to connect to the heating riser. This requires permission from the Criminal Code and a project. You buy a heated towel rail (preferably of a simple design), go to the housing office with his passport (copy), write an application. If permission is given, order the project (you will also need a copy of the passport with connecting dimensions). Then, according to the project, you do it yourself or hire performers (plumbers from the Housing Office, as an option). Call the representatives of the Housing Office for acceptance.

To ensure that the “towel” is always warm and without problems, all supplies are straight, without arcs and pockets

When determining the installation location of a heated towel rail, questions may still arise about at what height it should be hung. If there is a choice, it is most convenient to position it so that it is at head level and below. This is if you put a U-shaped or a snake. If we are talking about "ladders" of great height, the upper bar is placed not at the level of the glow of the hand of the raised hand (about 190-200 cm).

When choosing a place to install a heated towel rail, one must also take into account the distance from the riser. In principle, the closer to the riser, the better - more chances that it will work. But, it can be attributed to a meter or so, only if the following conditions are met:

- low hydraulic resistance of the heated towel rail (simple shape and section 1″ or 3/4″),

- sufficient pressure (2 atm or more)

- drainage with pipes of normal diameter (one step less than the riser).

In this case, be sure to follow other connection rules. Then there will be chances that such a “remote” device will work normally.

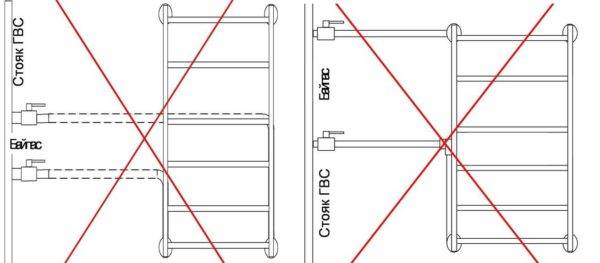

How not to do

All the above schemes work stably. As you can see, all the bends go straight, without bends in the form of an arc or rings. This is not accidental - air accumulates in all the irregularities, which interferes, and sometimes completely blocks the circulation.

This scheme does not work

In the photo, the installation of the heated towel rail is incorrect. Made at least two mistakes:

- the taps are made narrower than the center distance of the heated towel rail;

- they are made of a metal-plastic pipe with loops.

Such a connection simply cannot work. Metal-plastic pipes are an excellent material, but not for connecting heated towel rails. Their fittings have a very strong narrowing of the lumen, which has a bad effect on circulation. Plus, air accumulates in the loops, and the flow through the upper loop, even when supplied from above, will not go - too much hydraulic resistance to water must be overcome.

Unstable Circuits

The next two schemes may work, but not always. In the lower part of the heated towel rail, water stagnates and, with some difference in height, cannot rise. No one can say specifically when it will work and when not. Depends on the pressure in the riser, on the diameter of the pipes and the design of the dryer itself.

Unstable wiring diagrams

With such a connection, even a working connection may suddenly (usually after a stop) stop working. It's simple: the pressure has changed, the pipes are clogged, the water does not “push through” from below, the heated towel rail does not heat.

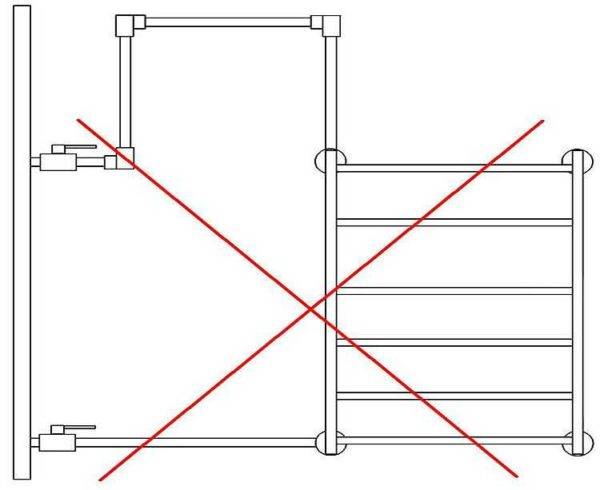

Another option for an unstable circuit is with a loop on top. Again, it will work under certain conditions. But sooner or later, the highest point will become airy and block the circulation. Trouble can be helped if an automatic air vent is installed at the highest point, but if the pressure drops, it will not save.

With a loop at the top

Completely wrong

The photos below are examples of what not to do. Schemes without a tap on the bypass are inoperative. What it threatens is known. In addition, after several years of operation, they will generally cease to function. Most likely this will happen after the next shutdown - the system will become clogged with dirt. This is because the entire flow of hot water is started up through the heated towel rail. After repair, the water carries a huge amount of dirt, which safely settles in the bends (in the lowest areas in the first place). In a few years, everything is clogged completely. For good, everything needs to be redone and connected correctly, but only flushing can help grief.

Very bad idea

It is necessary to rinse both the heated towel rail and the supplies to it. To do this, we remove the dryer and wash it in the bathroom, and wash the outlets one by one by connecting a hose to the vacated outlets, the second end of which is connected to the sewer. By manipulating the taps, pass the flow of hot water through one outlet, then through the other. After washing, everything is installed in place. It may be possible to start the system after that.

Branches from the DHW riser for heated towel rails.

Over time, developers began to use more modern technologies and, instead of a terrible bent pipe, they began to make two branches from the riser to connect the substation at the choice of the residents themselves. However, unfortunately, neither the type, nor the height of these taps from the floor, nor the distance between them is in any way standardized. This leads to massive problems when connecting the PS, which will be discussed below.

Figure 7. Riser taps, unbiased and unrestricted bypass.

Figure 8. Branches from the riser, narrowed bypass.

Figure 9. Riser taps, offset open bypass.

Between the taps there is always a bypass - a pipe section with a diameter equal to the diameter of the riser or 1 step less.

The bypass at the heated towel rail solves several problems:

- Maintaining the normal circulation rate throughout the hot water riser (HW).Forced circulation in the riser ensures the supply of evenly hot water (according to the norms - 60 degrees) to any apartment, on any floor, regardless of its distance from the start of supply to the riser.

- Only part of the total flow of the coolant (water) passes through one substation, the other part goes by, keeping more heat for the next bathrooms. After all, one or two dozen heated towel rails can work from one riser.

- It is possible to completely turn off the substation or adjust its temperature by residents without affecting the rest of the apartments (the latter requires the installation of an additional control valve on one of the outlets, since it is impossible to regulate anything using a ball valve).

Conclusion

The heated towel rail seems to be a complex plumbing product in terms of its connection to the hot water supply system. In the process of performing work on its installation, it is necessary to perform many different operations that can affect the quality of installation and the reliability of the plumbing product itself. Therefore, only a qualified specialist with practical experience is able to most efficiently connect a heated towel rail to a hot water riser. If you do not have such skills, you should not take unnecessary risks, but it is best to entrust this work to the personnel of the service organization.

Sobolev Yury Alekseevich