Types of hydraulic tanks for water supply systems

Hydraulic accumulators, depending on the type of installation, are divided into vertical and horizontal products. In the first case, the devices differ in that it is easier to find a suitable location for their installation. Both vertical and horizontal tanks are supplied with nipples.

Simultaneously with water, a small amount of air enters the device. It eventually accumulates inside and partially occupies the volume of the container. In order for the tank to function properly, it is necessary to periodically bleed the collected air through the nipple.

The way the vertical accumulator is arranged allows the nipple to be used for this very purpose. In turn, with horizontal tanks everything is more complicated. In addition to the nipple designed to bleed air, a shut-off valve and a drain to the sewer system must be installed on the pressure tank. All of the above applies to models that can store more than 50 liters of liquid.

If the tank is smaller, then the device, regardless of type, does not have any special devices for removing air from the membrane. But it still needs to be removed from the hydraulic tank, so water is periodically drained from it, after which it is refilled with liquid.

This procedure is performed in the following sequence:

- First of all, turn off the power to the pumping equipment and the pressure switch.

- Then open the nearest mixer.

- The water is drained until the tank is empty.

- Then the tap is closed, power is supplied to the relay and the pump, after which the water fills the tank in automatic mode.

For autonomously equipped engineering systems, two types of hydraulic accumulators are used for water supply - they are blue and red. This feature allows them to distinguish tanks according to their purpose. The blue tank is used in the arrangement of cold water supply systems, and the red battery is used for the operation of the heating circuit.

When the manufacturer does not designate products with one of these two colors, you can find out the purpose of the purchased device from the product data sheet.

In addition to color, the types of accumulators for water supply differ depending on the characteristics of the materials used for the production of membranes. In any case, high-quality rubber is used, which is intended for contact with products. But in red tanks, membranes are installed that are designed for contact with hot water, and in blue ones - with cold water.

How to properly adjust the pressure in the accumulator

Correct operation of the pumping station requires the correct setting of three main parameters:

- The pressure at which the pump turns on.

- The shutdown level of a functioning unit.

- Air pressure in the membrane tank.

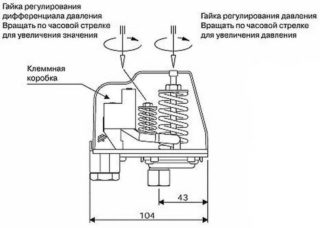

The first two parameters are controlled by the pressure switch. The device is installed on the inlet fitting of the accumulator. Its adjustment takes place empirically, to reduce the error of the action, it is performed several times. The relay design includes two vertical springs. They are planted on a metal axis and secured with nuts. The parts differ in size: a large spring controls the activation of the pump, a small one is required to set the difference between upper and lower pressure. The springs are connected to a membrane that closes and opens electrical contacts.

Adjustment is made by turning the nut with a wrench. Clockwise rotation compresses the spring and increases the threshold for turning on the pump. Turning counterclockwise loosens the part and reduces the actuation parameter. The adjustment procedure takes place according to a certain scheme:

- The air pressure in the tank is checked, if necessary, it is pumped up by the compressor.

- The large spring nut turns in the right direction.

- The water tap opens. The pressure drops, at a certain moment the pump turns on. The pressure value is marked on the manometer. If necessary, the procedure is repeated

- The difference in performance and the shutdown limit is regulated by a small spring. It is sensitive to the setting, so the rotation is carried out by half or a quarter of a turn.

- The indicator is determined with the taps closed and the pump turned on. The pressure gauge will show the value at which the contacts will open and the unit will turn off. If it is from 3 atmospheres and above, the spring should be loosened.

- Drain the water and restart the unit. The procedure is repeated until the required parameters are obtained.

The factory settings of the relay are taken as a basis. They are indicated in the device passport. The average pump start indicator is 1.4-1.8 bar, shutdowns are 2.5-3 bar.

>

How to choose a hydraulic accumulator for water supply systems of a private house

Before buying, you should consider all the parameters of the hydraulic tank

Particular attention should be paid to:

- tank volume;

- location type;

- type of energy storage;

- nominal pressure;

- the cost of the selected model.

When buying, you should ask the sales assistant about the availability and cost of replacement membranes or cylinders for the selected model and how affordable they are in principle. It would be useful to check the accompanying documentation and the certificate of conformity, as well as clarify the warranty period for the device.

Important information! If you plan to install it yourself, you need to find out if this is a reason to nullify the warranty. Some manufacturers oblige buyers to hire professional installers - this is prescribed as one of the clauses of the warranty service agreement.

It is quite difficult to understand the range of such products. Today, on the shelves of stores are products of various companies. In order to help the reader, consider the most famous and popular among the population.

Installing a hydraulic accumulator

After acquiring a suitable model of an electric pump for a well or well and connecting it to the pipeline, calculating the volume and purchasing the required hydraulic tank, it is necessary to install it correctly. If the model has a large volume and is installed on vertical legs, you should use the following recommendations:

- It is better to place a volumetric storage tank at the highest point of the house (attic, second floor) - this will create maximum pressure in the water line.

- The floor in the room must be even, the humidity must not exceed the established norms in order to avoid corrosion of the galvanized flange and the surface of the tank.

- It is best to connect the device with a stainless steel braided flexible pressure hose and one inch diameter union nuts made of brass. Avoid supply hoses with aluminum braid and mounting sleeves made of cheap silumin, a brittle aluminum-silicon alloy.

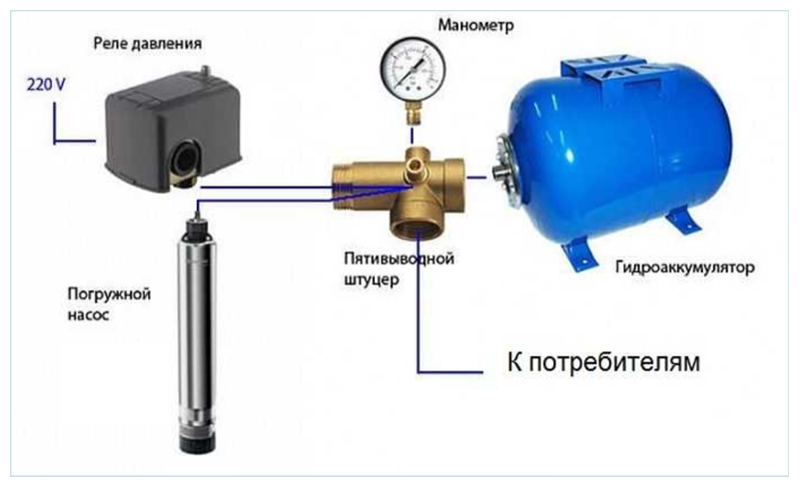

Rice. 10 Connection diagram for a hydraulic accumulator for individual water supply systems

How to check the pressure in the accumulator

To measure pressure, you need:

- unscrew the cap that closes the fitting with a spool located on the tank body;

- connect a pressure gauge to the spool (you can use an electronic or automobile pressure gauge), take a reading and compare with the calculated value;

- in the event of a decrease in the pressure level, pump up the compressor to the optimum value;

- bleed air to relieve pressure.

If the adjustment is carried out before the hydraulic tank is included in the system, it must be left for a day. After this time, after the control measurement, the device is installed.

Determination of tank parameters

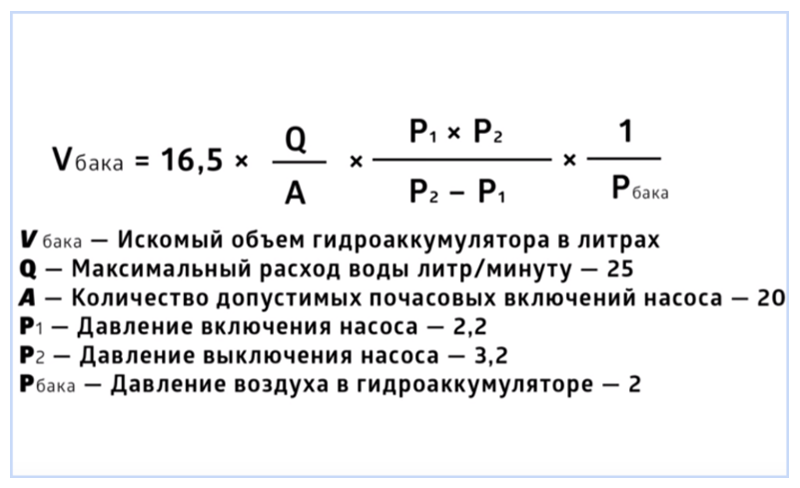

In most cases of inclusions, hydraulic tanks for water supply are installed according to the principle: the larger the volume, the better. But too much volume is not always justified: the hydraulic tank will take up a lot of useful space, the water will stagnate in it, and if power outages are very rare, there is simply no need for it. Too small a hydraulic tank is also inefficient - if a powerful pump is used, it will often turn on and off and quickly fail. If a situation arises where installation space is limited or financial resources do not allow the purchase of a large storage tank, you can calculate its minimum volume using the formula below.

Rice. 6 How to correctly calculate the volume of the hydraulic tank in the water supply system

Another calculation method is the calculation of the required volume of the hydraulic tank according to the power of the electric pump used.

Recently, modern high-tech electric pumps with soft start and stop, frequency regulation of the speed of rotation of the impellers depending on water consumption have appeared on the market. In this case, the need for a large hydraulic tank is eliminated - soft start and adjustment do not cause water hammer, as in systems with conventional electric pumps. Automatic control units of high-tech devices with frequency control have a built-in hydraulic tank of a very small volume, designed for its pumping group.

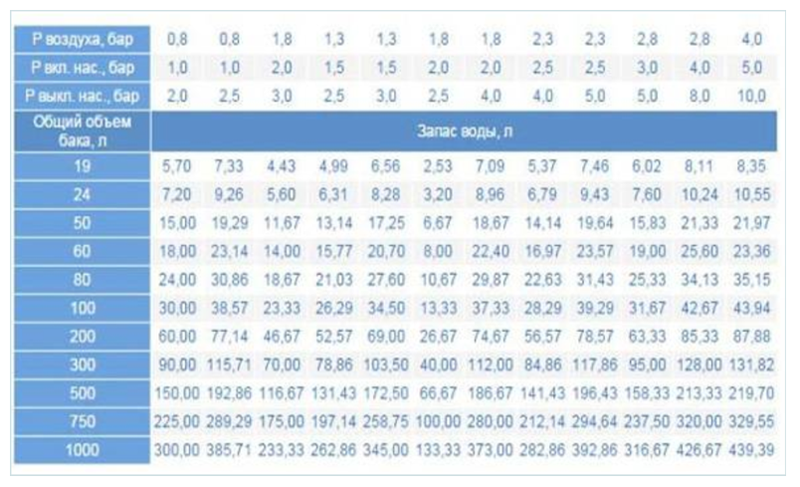

Fig.7 Table of calculated values of pressure and volume of the hydraulic tank depending on the operating modes of the water supply line

The purpose of the hydraulic accumulators

The device of hydraulic accumulators

To provide the house with water, submersible or surface pumps are fully used. From the type of pump, the accumulator can be horizontal or vertical. It depends on the design how air bubbles will be removed from the water. And the choice of a suitable device will depend on the location of the pumping station and the power of the pump.

Devices have differences in types and sizes, but have the same functions, namely:

- Accumulate and release hydraulic energy;

- Suppress water hammer and pulsations;

- Contributes to the normal operation of the entire plumbing system. Hydraulic accumulators are universal and for this reason are widely used in most industries. They are also used in maritime, air and maritime transport.

Air in the accumulator

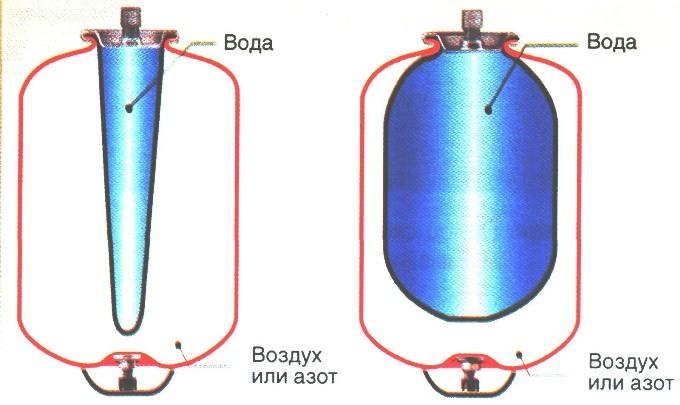

Due to the special design of the hydraulic accumulator capacity, the loads are reduced. The hydraulic tank is divided into two parts (water and air) by a membrane. The pressure that is in the accumulator softens the water hammer that is inevitable during the operation of the station. Also, the accumulator is able to maintain pressure in the pump system.

Purpose of hydraulic accumulators and expansion tanks

Initially, we divide all the considered tanks into two main types. The first type is devices designed to compensate for excess pressure (volume) in heating devices. These are expansion tanks, or "expansomats" from the English word "expansion" - expansion. To imagine why expanders are needed, consider the operation of the heating system. When the boiler is heated, the temperature of the heat-carrier fluid in it rises. When heated, the liquid expands. This leads to an increase in its volume by about 0.3% for every 10°C. Therefore, with an increase in temperature by 70 ° C, the initial volume of the coolant will increase by about 3%. The liquid is practically incompressible, and if the heating system is not equipped with an additional device that allows this volume to go somewhere, then its destruction will inevitably occur.To exclude this, expansion (compensation) tanks are used. The open expansion tanks common in the past had a number of shortcomings and are practically not used at present. Given the Russian engineering conservatism, we will once again describe some of the disadvantages of open expansion tanks:

- The presence of an open tank determines the increased volatility of the liquid and the need for its constant replenishment;

- More expensive open tank installation. It must be installed at the very top of the heating system. It is necessary to provide a special place and ensure its insulation and freezing, while a closed tank can be installed anywhere;

- Increased corrosion in the system due to the access of oxygen to it;

- An open heating system operates at low pressure and is therefore difficult to control.

The second main type of tanks is water tanks (hydraulic accumulators). Their task is to accumulate a certain amount of water and give out this amount under the right pressure at the right time. Like heating systems, water tanks can be open or closed. All the disadvantages listed earlier for open tanks of heating systems apply to water tanks. But in addition, a device is needed to prevent overfilling the tank. The appearance of expanders and hydraulic accumulators is shown in the figures below

Prevention, repair and troubleshooting

Any types of accumulators for water supply systems require comprehensive maintenance and timely prevention.

There are a huge number of reasons for breakdowns of expansion tanks, but the main ones are the high frequency of turning on pumping equipment, water supply through a check valve, low water pressure, low operating pressure in the hydraulic tank, damage to the inner membrane or outer walls of the housing, improperly selected tank volume.

To eliminate serious breakdowns and prevent the emergency condition of the tank, regular checks and preventive maintenance of the device are required.

Some breakdowns are fixed as follows:

- The air pressure is increased by forcing through the nipple hole using pumping or compressor equipment.

- The damaged surface of the membrane or housing is restored in the SC (service center). If there is serious damage, they are replaced.

- The pressure difference is equalized by a significant increase in the differential, taking into account the frequency of operating inclusions of the installed pumping equipment.

- A sufficient volume of the hydraulic tank is determined before the start of installation work.

To ensure the continuity of the system, there should be no air pockets in it. The frequency of checks is 1 time every 3 months. During this period, full control is carried out over the set thresholds for the operation of the pump, the relay settings, the tightness of the housing, the serviceability of the membrane and the absence of leaks.

Incorrect adjustment of any element of the system can affect the performance and durability of the hydraulic tank.

The accumulator for hot water and cold water supply is successfully used in private households. Proper connection and configuration of the device will ensure a long service life and efficient operation of the water supply system.

Optimal Performance

- The correct choice of the maximum and minimum pressure at which the pump is automatically turned on.

- Proper setting of the air pressure level in the tank.

When performing self-checking and adjusting indicators, you should follow the recommendations of specialists. As a general rule, the air pressure in the pressure storage tank must be below the minimum start pressure of the pump. The difference in indicators is 10-12%.Compliance with the recommendation allows you to save a small amount of water until the next start of the unit. Example: if the pumping station starts automatically at 2 bar, the air pressure should be 2-0.2="1.8" bar.

The air pressure in the storage tank does not depend on its volume. The average for containers with a size of 24-150 liters is 1.5 bar, 200-500 liters - 2 bar. The initial factory air injection of 1.5 atmospheres in conditions of low water consumption of a one-story building can be reduced to 1 atmosphere. Low pressure in the pipes reduces the wear of the system, but limits the use of plumbing fixtures. Reducing the pressure to less than 1 bar will cause the rubber bulb to overstretch. There will be contact between the membrane and the metal case. Contact will cause accelerated wear of the rubber.

Excessive air pressure (more than 1.5 bar) is also not desirable. It will take up most of the tank, reducing the amount of water taken in. There will also be an increased load on the pipes and components of the plumbing system.

Pressure calculation

To calculate the optimal air pressure in the tank, there is a formula: P \u003d "(Hmax + 6) / 10," where

- P is the air pressure in atmospheres;

- Hmax is the distance to the highest point of the domestic water supply network.

The top point of analysis is the shower on the last floor of the building. The distance from it to the installation site of the pressure vessel is measured. The larger the gap, the higher the pressure required to lift the water. The use of numbers will add clarity to the calculation. For a building with a height of 2 floors, the value of Hmax will be 7 m. The pressure will be P \u003d "(7 + 6) / 10 \u003d 1.3" atmosphere. For a height of 10 m, a pressure of 1.8 atmospheres is required.

Before buying a hydraulic accumulator, the volume of the device is calculated. The calculations take into account:

- maximum water consumption;

- number of pump starts per hour;

- air pressure in the tank;

- lower and upper pressure limit for pump operation;

- coefficient related to pump power.

After installing the membrane tank, you will need to set the minimum and maximum threshold for the operation of automation (pressure switch). The volume of water coming from the hydraulic accumulator depends on the difference between the maximum and minimum indicators. Increasing the parameter increases the efficiency of the device, but leads to rapid wear of the membrane. For private houses, a difference of 1-1.5 bar is recommended.

The indicator of the minimum pressure in the membrane (Pmin) must be 10% higher than that of the air in the tank cavity. For stable operation of the system, the differential pressure must be 0.5 bar or more. This value is taken into account when calculating Pmin. The upper limit of operation (Pmax) is calculated based on the characteristics of the pump - the head is divided by 10. The calculated value does not correspond to the real one due to changes in the declared parameters of the unit associated with wear. It is recommended to take the upper level indicator 30% less than the pressure characteristic.

Pressure in the accumulator

In the accumulator air chamber, the pressure must be 10% lower than the pressure when the pump was turned on.

An accurate indicator of air pressure can be measured only when the tank is disconnected from the water supply system, in the absence of water pressure. Air pressure must be constantly kept under control, if necessary, adjusted, which will add life to the membrane. Also, to continue the normal functioning of the membrane, a large pressure drop should not be allowed when the pump is turned on and off. Normal is a difference of 1.0-1.5 atm. Stronger pressure drops reduce the life of the membrane, greatly stretching it, moreover, such pressure drops do not allow comfortable use of water.

Hydraulic accumulators can be installed in places with low humidity, not subject to flooding, so that the flange of the device can successfully serve for many years.

When choosing a brand of a hydraulic accumulator, it is necessary to pay special attention to the quality of the material from which the membrane is made, check the certificates and sanitary and hygienic conclusions, making sure that the hydraulic tank is intended for systems with drinking water. You also need to make sure that you have spare flanges and diaphragms, which should be included, so that in case of a problem you do not have to buy a new hydraulic tank.

The maximum pressure of the accumulator, for which it is designed, must not be less than the maximum pressure in the water supply system. Therefore, most devices can withstand a pressure of 10 atm.

Operating recommendations

After the accumulator is installed, it must be properly maintained. Approximately once a month, the pressure switch settings should be checked and adjusted if necessary. In addition, it is necessary to check the condition of the housing, the integrity of the membrane and the tightness of the connections.

The most common failure in hydraulic tanks is a rupture of the membrane. Constant cycles of tension - compression over time lead to damage to this element. Sharp drops in pressure gauge readings usually indicate that the membrane has torn, and water enters the “air” compartment of the accumulator.

To make sure there is a breakdown, you just need to bleed all the air from the device. If water flows out of the nipple after it, then the membrane definitely needs to be replaced.

Luckily, these repairs are relatively easy to make. For this you need:

- Disconnect the hydraulic tank from the water supply and power supply.

- Unscrew the bolts that hold the neck of the device.

- Remove damaged membrane.

- Install a new membrane.

- Assemble the device in reverse order.

- Install and connect the hydraulic tank.

At the end of the repair, the pressure settings in the tank and the pressure switch should be checked and adjusted. The connecting bolts must be tightened evenly to prevent warping of the new diaphragm and to prevent its edge from slipping into the tank housing.

Replacing the accumulator diaphragm is relatively easy, but care must be taken to ensure that the new diaphragm is the same as the old one.

To do this, the bolts are installed in the sockets, and then literally a couple of turns of the first bolt are alternately made, moving on to the next one, etc. Then the membrane will be pressed against the body equally around the entire circumference. A common mistake newcomers make to repairing a hydraulic accumulator is the incorrect use of sealants.

The installation site of the membrane does not need to be treated with a sealant, on the contrary, the presence of such substances can damage it. The new membrane must be exactly the same as the old one in both volume and configuration. It is better to first disassemble the accumulator, and then, armed with a damaged membrane as a sample, go to the store for a new element.

Optimal parameters

The main factors on which the operation of the water supply network and the service life of hydraulic equipment depend are as follows:

The main factors on which the operation of the water supply network and the service life of hydraulic equipment depend are as follows:

- Competent calculation of the maximum and minimum pressure values at which the pump should turn on (turn off).

- Correct pressure setting in the receiver.

The air pre-injection pressure is 1.5 - 2 bar (depending on the volume of the tank). The determination of the air pressure value for working in tandem with a specific pumping station is based on the factory parameters of the pressure switch. The average value of the pressure at which the pump turns on is from 1.4 to 1.8 bar. The shutdown threshold is usually in the range of 2.5 - 3 bar. The optimum value of air pressure should be 10-12% less than the pressure to turn on the pump.

If these requirements are met, after turning off the hydraulic pump, a certain amount of water is guaranteed to be stored in the accumulation tank, sufficient to create a stable pressure until the next pump start.

Hydraulic accumulator device

The hermetic case of this device is divided by a special membrane into two chambers, one of which is designed for water, and the other for air.

Water does not come into contact with the metal surfaces of the case, as it is in a water chamber-membrane made of strong butyl rubber material that is resistant to bacteria and meets all hygienic and sanitary standards for drinking water.

In the air chamber there is a pneumatic valve, the purpose of which is to regulate pressure. Water enters the accumulator through a special threaded connection pipe.

The accumulator device must be mounted in such a way that it can be easily disassembled in case of repair or maintenance, without draining all the water from the system.

The diameters of the connecting pipeline and the discharge pipe should, if possible, match each other, then this will avoid unwanted hydraulic losses in the system pipeline.

In the membranes of accumulators with a volume of more than 100 liters, there is a special valve for bleeding air released from the water. For small-capacity accumulators that do not have such a valve, a device for bleeding air must be provided in the water supply system, for example, a tee or a tap that shuts off the main line of the water supply system.

In the air valve of the accumulator, the pressure should be 1.5-2 atm.