Properties and features of the use of the material

The main property that determines the effectiveness of a particular insulation is the coefficient of thermal conductivity.

It characterizes the heat loss occurring through a layer of material 1 m thick in an area of 1 m2 for 1 hour at a temperature difference on opposite surfaces of 10 ° C.

For various forms of production of mineral wool, this figure is 0.03 - 0.045 W / (m * K).

A distinctive feature of fibrous insulation is the dependence of their thermal insulation properties on moisture content.

When wet, water droplets envelop the fibers and gradually penetrate into the bulk structure, gradually displacing air from there.

An increase in the amount of water inside, between the fibers, leads to a sharp drop in thermal insulation characteristics. The situation is aggravated by the fact that the water that has got inside is extremely difficult to get out.

Insulation can collect up to 70% of water from its mass. Naturally, under these conditions, the efficiency of its work will tend to zero.

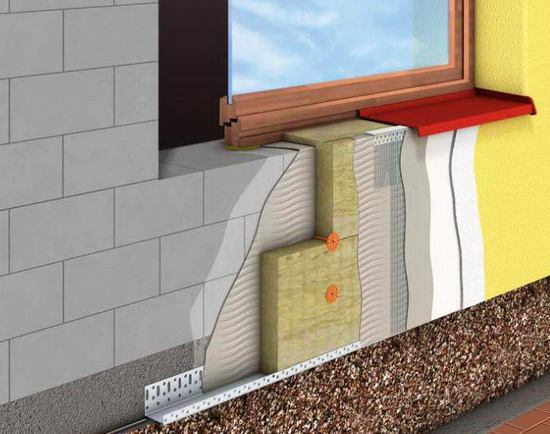

Despite the criticality to getting wet, the scope of mineral wool is extremely wide. When building a house, its use is possible almost everywhere where direct contact with water is excluded:

- Hollow walls (frame and brick, made using the technology of well masonry);

- External surface of wooden or brick walls;

- Internal partitions;

- floors;

- Interfloor ceilings;

- Roof.

Wool protection during installation

To prevent the basalt insulation from getting wet during installation, it is worth protecting the installation site from rain. For this purpose, it is very convenient to use inventory scaffolding. And on these scaffolding, lay boards along the upper rungs of the upper row and stretch the film.

Get cheap and cheerful. Not only building materials will be dry, but also the installers themselves, who work on the walls.

To drain rainwater from film roofs on scaffolding, the easiest way is to use 3-4 drain pipes with a diameter of 110 mm, into which water accumulating on the film will merge. This will allow you not to get wet under an unexpected “waterfall”, when water that does not have a drain bends the film and rushes down in an “unfortunate” place.

Causes of wetting insulation on the roof

First:

during installation, the hydrobarrier or superdiffusion membrane was damaged. That is, the tightness of the film is broken with a self-tapping screw or a nail. Also, quite often, this happens due to excessive tension of the hydrobarrier. According to the norms, it must be installed with a slight sag, so as not to create material stress, and so that condensate water can be collected and discharged at the place of sagging.

The second reason may be

- lack of gluing at the joints of the sheets, which leads to the penetration of condensate moisture by ascending wind currents.

The third reason

is poor fastening at the junction of chimney and ventilation pipes. It should be noted that the edges of the hydro-barrier must be fixed vertically, upwards, to the wall, and a clamping bar must be installed.

fourth reason

it may be the use of low-quality superdiffusion membranes, which are often found in cheap segments.

These are the main reasons that take place when working with hydrobarriers. But water in the insulation, including, may also appear due to poor installation of the vapor barrier.

This happens especially often when wet work is carried out in the house in autumn and winter, and the roof is already insulated. At the same time, the temperature difference between inside and outside is noticeable, and all the condensate, rushing up, gets into the insulation if your vapor barrier is not glued, or the joints are not glued tightly.

Check the tightness of the films until they are completely closed, be sure to glue the joints and junctions to the walls.

And what to do with a heater if it is already wet?

Take out and dry, or purchase a new insulation. But wet, in the rafters, it can not be left - mold can form on the tree.

Remember that only professional builders, or developers themselves who have studied these technologies well, should carry out insulation work.

Rock wool getting wet in the attic can be at least due to several reasons. Due to leakage or damage to the roof, improperly positioned vapor barrier, lack of ventilation or errors in its execution. Regardless of the cause, the result is the same. The mineral wool is wet. Is this wool still fulfilling its role? How to dry it?

Mineral wool, first of all, isolates. Protects from cold in winter, protects from heat in summer. Increases fire resistance, provides sound insulation, thanks to it the house becomes quieter. When choosing mineral wool, it is worth putting on products with increased hydrophobization

. These are materials from which moisture evaporates very quickly.

You have to remember that you can't install wet mineral wool

. If it happens that the cotton wool gets wet during transport or storage, it should first be unrolled and dried thoroughly. Only after it dries, you can proceed with its installation.

Ventilation without errors

One of the more common causes of damp mineral wool is roof ventilation failure. Good ventilation allows air to circulate above the insulation, which allows condensate to systematically evaporate from it

Therefore, it is so important to carefully manufacture roof ventilation.

Arkady Shchelyunin, Astrakhan. Question: Good afternoon, it's raining, autumn. They did not have time to make cotton wool on the facade of the claydite-concrete house. How to be now? It rains every day. We are afraid that cotton wool will get wet. Then winter. How to dry it?

Sergey Zaitsev, Moscow, specialist.

Answer: Good afternoon, Arkady. In response to your question, I can advise you the following. First, you are right. If it falls under heavy and prolonged rain, then it will absorb moisture. Despite all the advertising assurances of the manufacturers, in the photo with beautiful drops of water on the cotton wool, however, the basalt insulation absorbs moisture and is very excellent.

Therefore, it is impossible to wet it in heavy rain. If during the installation process the cotton wool on the walls gets wet with rain - it's not scary. But if you keep it in the rain for a day, then you really won’t be able to dry it before installation.

So we do 3 things.

Why does mineral wool get wet

The thermal conductivity coefficient of mineral fibers is 0.031-0.042 W / m 2 * K. This means that a layer of glass wool 5 cm thick is equal to the thermal effect of a meter-long brick wall. But the thermal insulation properties disappear when moisture penetrates the fibers.

Reasons for getting wet:

- The waterproofing membrane was damaged when laying the insulation. They pulled the canvas too tight, accidentally pierced it with a nail or self-tapping screw.

- The joints of the film were not glued. As a result, condensate penetrates into the mineral wool fibers.

- Insufficiently tightly fixed waterproofing near the ventilation and chimneys.

- A poor quality diffuse membrane was used.

The risk of getting wet: what threatens raw insulation

Wait to get wet roof insulation

dry on its own - a dangerous delusion. Wet mineral wool does not retain heat. In addition, it becomes a source of unpleasant odor, the spread of mold and bacteria. Well, the "cherry" in the troubles of the roofing pie: the wooden rafters are destroyed, the metal elements of the structure are rusting at an accelerated pace. The result is a major overhaul of the roof.

To avoid problems, check the condition of the insulation:

- if there are streaks or drops on the walls of the attic;

- cracks appeared on the roof, roofing elements do not fit tightly;

- in places where snow accumulated, the roof caved in.

Wet business how to deal with wet insulation

Having discovered that the thermal insulation is wet, there are two options for the development of events. If the fibers are wet only at the top and in a small area, it is possible to dry this place. This requires two conditions: a draft and clear, warm weather.

Wet through insulation URSA experts recommend replacing. The main thing is not to make previous mistakes when installing new material.

How to fix the problem and leave the thermal insulation dry

To protect your newly insulated roof from getting wet, consider these professional tips:

- it is desirable to carry out installation in dry weather;

- before installing the mineral wool, cut the waterproofing film into layers of the desired length;

- after fixing the insulation, immediately cover it with a protective membrane;

- glue the joints of the film, fix it on the rafters with a construction stapler;

- walk only on the boardwalk so as not to tear the waterproofing.

You can select a special insulating material for pitched roofs and waterproofing for it at http://www.ursa.ru/construction-solutions/skatnie-krishi/.

Proven materials, competent installation and the roof will remain dry in any weather!

Question:

Hello. I got wet on the roof of the heat-insulating material -. The firm's builders say it's rock-hard and it dries out quickly. Is it true? What are the consequences of getting Rockwool, a thermal insulation material, wet?

Konstantin

Answer:

Hello Konstantin.

The insulation material could get wet for the following reasons:

1. Roofing leak.

2. The integrity of the vapor barrier layer has been broken.

It is true that mineral wool can dry out after wetting, but certain conditions must be observed. It is necessary to make sure that the air can move freely in the under-roof space. It is thanks to this that moisture will be removed from the insulation material. To achieve this, you need to make a ventilation gap, which can be either single or double, it all depends on the type of construction.

Based on our experience in thermal insulation, we can state that a properly installed and well-ventilated under-roof space will help to dry the wet insulation and the already dried material will not lose its thermal performance.

You need to find out why it got wet and eliminate the cause. If everything is clear with a leak, then most of the cases of wetting of the thermal insulation material is the absence of a vapor-tight layer or sheathing when installing thermal insulation. A common mistake is poor gluing of the seams with double-sided tape or not gluing the overlaps at all. When laying vapor barrier films, it is imperative to glue all 10-centimeter overlaps with double-sided tape.

Do not forget to inspect the truss system, what happened to it when wet. Wooden structures also dry out, but not as quickly as mineral wool insulation. To ensure the best safety of the rafter system, all wood parts must be treated with an antiseptic, it will help the tree not absorb water so quickly.

Protecting wool from rain before installation

We store the finished cotton wool in bales right next to the walls, preferably indoors. In this case, you can apply for mounting on the walls in the windows of the first or second floor, as it is more convenient.

Further, if the wall is deaf, we make a temporary canopy of boards and film next to it. Nothing global is needed, the main thing is that the water flows to the ground, and not to cotton wool. Although it is packed in film bales, it is not protection from heavy rain.

Further, we understand that in heavy rain, especially during a protracted autumn storm, all the water is underfoot, the earth does not have time to absorb such an amount of water. We do not put cotton wool in bales and sheets on the ground, even under a canopy. It is best to use the most ordinary wooden pallets. Their height, 15 cm, is enough so that the cotton wool does not get wet from the ground.

When you need a ventilation gap ventilation gap in a frame house

So, if you are thinking about whether you need a ventilation gap in the facade of your carousel house, pay attention to the following list:

- When wet

If the insulation material loses its properties when wet, then a gap is necessary, otherwise all work, for example, on home insulation will be completely in vain - Steam pass

The material your home's walls are made of allows steam to pass through to the outer layer. Here, without the organization of free space between the surface of the walls and the insulation, it is simply necessary. -

Prevent excess moisture

One of the most common questions is the following: do I need a ventilation gap between the vapor barrier? In the case when the finish is a vapor barrier or moisture-condensing material, then it must be constantly ventilated so that excess water does not remain in its structure.

As for the last point, the list of such models includes the following types of sheathing: vinyl and metal siding, profiled sheet. If they are tightly sewn onto a flat wall, then the remnants of the accumulating water will have nowhere to go. As a result, materials quickly lose their properties, and also begin to deteriorate externally.

Do I need a ventilation gap between siding and OSB (OSB)

When answering the question of whether a ventilation gap is needed between the siding and OSB (from English - OSB), it is also necessary to mention its need. As already mentioned, siding is a product that insulates steam, and OSB does consist of wood chips, which easily accumulate moisture residues and can quickly deteriorate under its influence.

Additional reasons to use a vent

Let's analyze a few more mandatory points when the gap is a necessary aspect:

-

Prevention of rot and cracks

The wall material under the decorative layer is prone to deformation and damage under the influence of moisture. To prevent rot and cracks from forming, it is enough to ventilate the surface, and everything will be in order. -

Condensation Prevention

The material of the decorative layer may contribute to the formation of condensation. This excess water must be removed immediately.

For example, if the walls of your house are made of wood, then an increased level of moisture will adversely affect the condition of the material. The wood swells, begins to rot, and microorganisms and bacteria can easily settle inside it. Of course, a small amount of moisture will collect inside, but not on the wall, but on a special metal layer, from which the liquid begins to evaporate and be carried away with the wind.

Protection of basalt insulation after installation

And, of course, immediately after installing a section of basalt insulation on the wall, this section is closed. This protects the already installed wool on the walls from slanting rain.

The membrane itself does not tolerate ultraviolet light very well, so you should not hesitate with the subsequent decorative coating - siding or some other that you have chosen.

If you are not doing a ventilation facade, but, then you should not particularly worry here. The plaster layer will calmly close the cotton wool, anyway it will get a little wet during the installation process.

- The question is asked by Andrey Sukhorukov, Perm: Hello, dear colleagues! Would you like to clarify how you can protect vinyl siding from the sun and frost? Looking at the neighbors...

- Do the rising prices for electricity and gas make you think about saving energy resources? Try to answer this question honestly. If yes, then this article...

Mansard roof insulation - three benefits in one solution. First, the house becomes noticeably warmer. Secondly, heating costs are reduced by 30-50%. Well, and the third: there is a residential floor. They finished the walls - and instead of a cluttered attic, they got cozy rooms under the roof.

A popular roofing insulation is mineral wool.Material with excellent performance, non-flammable and affordable.

When you still need a ventilation gap

In what other cases will you need a ventilation gap between the wall and the decorative coating:

- The material of the decorative layer contributes to the formation of condensate.

- The wall material under the decorative layer can deteriorate from moisture (rot, cracks, etc.).

Otherwise, all the moisture that will condense on the inner surface of the profiled sheet will be absorbed, which will be destroyed from this.

In the case of a ventilation gap, moisture, of course, condenses on the inner surface of the profiled sheet - this is metal. But it does not have direct contact with the surface of wooden walls. And the current of air, which is present in the ventilation gap, carries away this moisture in the form of steam and removes it from the space between the decorative layer and the wall.

Consider which of the above cases is yours, and choose whether you need a ventilation gap or not. See what kind of wall material you have.

- Question: Good afternoon, ladies and gentlemen! Please tell us how best to decorate the outside of a house of expanded clay concrete blocks (KBB), what kind of facade would be appropriate here, what materials can be used? ...

- Recently, people began to give preference to wooden houses. The first thing that attracts this natural material is its ecological purity. On top of that, the wood is very good…

- This page shows a frame wall in section along with a heater, which is mounted between the racks of the frame. Simply put, a frame wall in a section is like this ...

- If you look at the history of the construction of residential buildings in cold regions, then the insulation of walls with sawdust began to be practiced not so long ago. Sawdust as wall insulation during construction ...

- The simplest design of the walls of a frame house is vertical posts connected by upper and lower strapping and tied with jibs for additional structural rigidity. When using a plate...

The ventilation gap in a frame house is a moment that often raises a lot of questions from people who are engaged in warming their own home. These questions appear for a reason, since the need for a ventilation gap is a factor that has a huge number of nuances, which we will talk about in today's article.

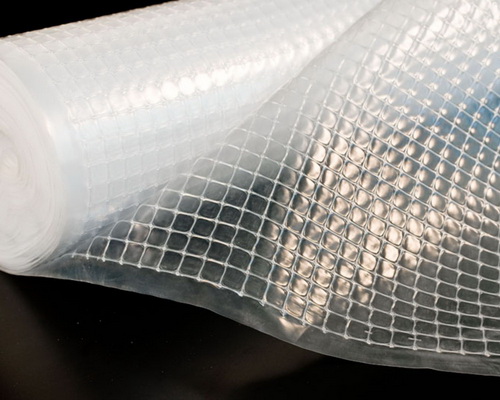

The gap itself is the space that is located between the skin and the wall of the house. A similar solution is implemented by means of bars that are mounted on top of the wind protection membrane and on the exterior trim elements. For example, the same siding is always attached to the bars that make the facade ventilated. A special film is often used as insulation, with the help of which the house, in fact, turns around completely.

Many will rightly ask, is it really impossible to just take and strengthen the skin directly on the wall? Do they just line up and form the perfect area for the skin to be installed? In fact, there are a number of rules that determine the need or uselessness of organizing a ventilation facade. Let's see if a ventilation gap is needed in a frame house?

When is vapor barrier needed?

It is definitely enough to simply formulate the condition whether a vapor barrier is needed. When insulating with mineral wool, protection against water vapor will be needed when there is a possibility of contact with air coming from the room.

To ensure efficient operation, each layer of the heat-insulating “pie” must pass air to one degree or another. In the direction from the room to the street, this ability should increase.

Thus, warm air from the room seeps very slowly between the fibers, displacing cold air from there.

These can be vertical racks of the frame, floor logs or rafters.From the outer (external) side, a wind-waterproof barrier is arranged to protect against the effects of precipitation and strong direct wind.

Such a scheme is valid when making frame walls, floors, attic roofing, ceiling of a residential floor in the presence of a cold attic on top.

Internal partitions and ceilings between living spaces require a slightly different approach. Humid air in this case can penetrate the mineral wool from any direction. To maintain the thermal performance of the structure, a vapor barrier is installed on both sides.

Excess moisture is removed through the ventilation gap left under the outer decorative facade.

Use of other heaters

Despite all the noticeable advantages of mineral wool, other insulating materials are often used. For example, ecowool is a fairly new material in our country (it has become widespread only in the last decade, although it has been used in the USA since the 70s of the last century). How does this material differ from mineral wool and is vapor barrier necessary when insulating with ecowool?

Ecowool consists of fluffy cellulose fibers that absorb moisture from warm air, however, the air between the fibers remains dry. Unlike mineral wool, it is able to withstand a 24% change in humidity and still retain its insulating properties.

Thus, insulation using ecowool does not require vapor barrier.

Consider another popular insulation - polystyrene foam, or simply polystyrene. They can insulate the room both outside and inside.

When performing external insulation in a vapor barrier, there is not much point: the foam itself insulates it quite well. The only thing you have to do is to maintain the correct technology for attaching polystyrene foam, depending on what material, breathable or not, your structure is made of.

Do I need a vapor barrier when insulating with polystyrene foam from the inside? Yes, it is necessary, since the “dew point” shifts inside the room, the walls are likely to get wet and, as a result, mold and fungus develop on them.

With high-quality vapor barrier, warm air will not reach the walls, and, therefore, there will be no risk of getting wet. It is also necessary to ensure good ventilation of the room.

The video below explains in detail why a wall vapor barrier is needed. An example of a heat engineering calculator is given, the influence of the arrangement of wall layers on the dew point and thermal insulation is shown.