Production technology and scope

For the manufacture of stainless steel corrugated type pipes, a special one is used, in which the content of chromium and nickel is increased. It is the combination of these elements in the composition of steel that provides it with exceptional corrosion resistance.

Noteworthy is the production technology of corrugated stainless steel pipes, which consists of several stages:

- forming a pipe from stainless steel tape;

- joining the edges of a rolled workpiece, performed using;

- checking the quality of the welded seam, for which a special laser machine is used;

- transformation of the resulting smooth steel pipe into a corrugated one, for which it is passed through a system of shafts of different diameters;

- heat treatment of the pipe (as a result, it becomes annealed, and therefore flexible);

- cutting the pipe into products of the required length;

- compact roll up.

A mandatory procedure after the completion of all technological operations is the quality control of the finished product. At this stage, it is checked under pressure: it is placed in a liquid medium and controlled for the presence of microcracks in their walls.

Homemade heating radiator from corrugated pipes

All the advantages of corrugated pipes made of stainless steel were fully appreciated by specialists in the construction industry, where these products are used most actively. Thanks to corrugated pipes, it is possible to carry out the installation of serviced communications for various purposes (electrical wiring, water supply and communications for gas supply, a "warm floor" heating system, elements of climate systems and security systems). If earlier, to repair such communications, it was necessary to gouge and then restore the walls, then when using corrugated pipe rolling, the need for such time-consuming procedures does not arise. Corrugated type pipes are no less successfully used as chimneys, elements of gas communications, ventilation, air conditioning and heating systems.

In housing and communal services, corrugated stainless steel pipes, which are connected using special fittings, are also widely used. With their help, they carry out the reconstruction and repair of old engineering networks, perform the installation of new communications, more reliable and durable. The strength of steel and flexibility comparable to the mobility of rubber products, as well as the reliability of the fittings used, have made stainless steel corrugated pipes an indispensable element of equipment for enterprises operating in various industries: chemical, food, medical, agricultural, etc.

Water heated floors from flexible stainless pipes

Criteria for selecting communications and components

Corrugated stainless steel pipe for heating systems is selected based primarily on the diameter of communications, which is laid down in the plan. With properly selected values of this parameter, you can get an efficient system with high throughput. It should be noted that the cross section of the pipes must be related to the power of the equipment.

Additionally, attention is drawn to the steel grade

It is important to consider the manufacturing technology of products. For example, there are flexible communications made of annealed and non-annealed steel.

The difference between them lies in the operating conditions. For example, annealed pipes are good for installing heating systems. It is recommended to use brass fittings as connecting elements

For example, there are flexible communications made of annealed and unannealed steel. The difference between them lies in the operating conditions.For example, annealed pipes are good for installing heating systems. It is recommended to use brass fittings as connecting elements.

Overview of manufacturers and cost of products

There are several popular brands, including Neptun. The product range includes annealed and unannealed products as well as a wide range of fittings. If a corrugated pipe for heating systems is considered, then the price will depend on its cross section. For example, a product with the smallest diameter of 15 mm costs an average of 110 rubles / m.

Alternatively, you can choose products from the Lavita brand. The cost of communications with a diameter of 8 mm will be higher - 150 rubles / m, which is due to the steel grade. In the assortment of this manufacturer you can also find fittings for any requirements.

Expert advice

The pricing of flexible products is simultaneously influenced by three factors: steel grade, product section, manufacturing method. If a pipe of a small diameter from one manufacturer costs less, it means that a different steel grade was used in its manufacture

Therefore, these parameters should be taken into account in the first place.

Accordingly, this type of communication is preferable, especially when it comes to installing a heating system. Since in this case there will be significant loads in two directions: temperature and pressure.

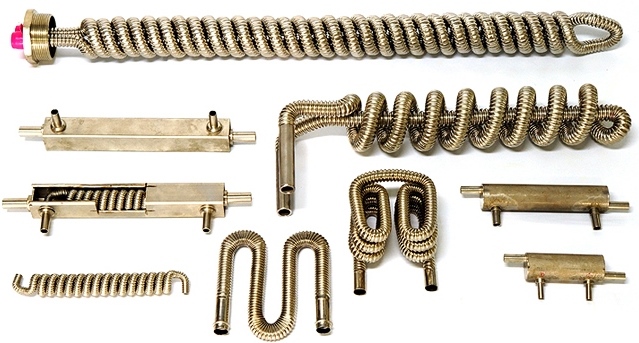

Corrugated Stainless Steel Pipe Fitting

When installing corrugated pipes, there are some nuances that you should be aware of so that they do not become an unpleasant surprise. As is the case with most bending building materials, this quality should not be abused - repeated kinks over time are guaranteed to lead to the fact that the stainless steel corrugated pipe for heating will be deformed.

It would be much better to bend the pipe to the desired shape and not return to this again.

The installation of corrugated metal pipes is very similar to the usual installation of a pipeline using fittings. The whole difference lies in the absence of a fitting in a fitting for a corrugated pipe, and the crimping is carried out by a gasket. In any case, after installation, a test run must be performed, which will make sure that there are no leaks.

Corrugated stainless pipe for heating is an excellent solution for arranging a heating system. To achieve maximum effect, it is necessary to correctly select materials and carry out high-quality installation work. The resulting heating system will perform its functions properly for many years.

In addition to very good performance characteristics, this material attracts quick and easy assembly of pipelines. You will only need fittings and a key. Connection to all heating devices is made with their help. Choose the required type (corner, tee, cross, etc.) and proceed to the connection.

Cut a piece to the required length with a pipe cutter. The cut must be strictly perpendicular to the pipe. The edges are smooth with no scratches or burrs. Check the completeness of the fitting, fold it. Insert the cut piece into it and tighten the nut. If necessary, tighten it a little with a wrench. That's the whole installation.

Completeness of a fitting for pipes from stainless corrugation. Similarly, there is a transition from an ordinary pipe to a corrugation: first, attach the corresponding fitting to the riser or outlet, and then insert a corrugated stainless steel into its other end and tighten the ring. And no special adapters are needed.

The only thing to consider when installing corrugated stainless steel is that it is still flexible. Therefore, install fasteners more often than when laying the usual shape of pipes.

This will have little effect on the cost - one latch costs a dozen or two rubles, depending on the company, and even if you install them twice as often, the maximum that threatens you is an overrun of 200-300 rubles with an average length of the heating line.

Features of chimneys from corrugated pipes

Application area

Repair of curved brick chimneys

Corrugated steel chimneys are designed to complete heating equipment operating on liquid, gaseous and solid fuels, and can be used with almost any type of boilers, boilers, columns and fireplaces, as they have good tightness and heat resistance.

The installation of such a chimney has a positive effect on the operation of heating boilers.

Corrugated stainless steel pipes can be used for the device:

- internal chimneys;

- external chimneys;

- adapters connecting the outlet pipe of the heater with the main chimney;

- as well as for lining (repairing) brick chimneys with bends.

Clamp for fastening the corrugation to the outlet pipe

Chimney design

Steel corrugated chimneys are made in the form of cylindrical pipes made of individual corrugated strips twisted in a spiral with a thickness of 0.12 mm to 1 mm.

The strips are connected around the circumference with a continuous lock seam, which ensures tightness, flexibility of the chimney and its ability to compress and stretch to a certain length. This may be necessary during installation, for example, to fit a pipe onto the boiler outlet.

Such pipes have different cross-sectional sizes, so it is easy to choose them for any outlet pipe.

To connect corrugated steel pipes, welding is not required; they are fastened together with clamps with simultaneous fastening of thermal insulation. This installation method is very convenient, since if necessary, the corrugated chimney will be easy to disassemble to clean it of soot, and then reinstall it.

Advantages and disadvantages

Corrugated pipes have a lot of advantages, which are often decisive when choosing a chimney.

First of all, they include:

- Flexibility and elasticity. The design allows the corrugated pipe to be bent at almost any angle, which is very convenient when the chimney needs to create a slope, for example, to bypass ceiling beams.

- The possibility of installation without the use of expensive components - corners, adapters, bends, etc. The corrugated pipe for the chimney will bend in the direction you need without compromising its integrity.

Corrugated HDPE pipes

Such pipes are indispensable in the office, country cottage or city apartment. They are used for wiring drainage systems and high-quality cable protection. Corrugated HDPE pipes are tubular channels made on a plastic basis. They have exceptional flexibility, so they can be used to improve and complement older systems.

Corrugated pipes are used specifically for single laying, but it is possible to use an open, hidden or semi-hidden method.

Main technical parameters:

- Wide temperature range - from forty degrees with a minus sign to forty degrees with a plus sign, at which installation can be carried out

- High degree of bending - 360 degrees

- When designing devices that serve as an element for retraction, it is necessary to use a broach made of steel wire of the second class

- From the date of shipment of pipes from the manufacturing plant, the shelf life is at least two years

Types and characteristics of corrugated pipes

There are two main types: single-layer and double-layer corrugated pipes. Two-layer pipes contain outer and inner layers. The outer layer is a rigid corrugated surface, the inner layer is a thin and smooth surface.The layers are connected by special joints. The main property of double-layer corrugated pipes is high resistance to deformation. The corrugation provides strength and protection to the polyethylene material contained in the inner layer.

Advantages of corrugations for pipes:

- Affordable price

- Laying variability: closed or open method

- Easy installation, no need for special machinery or tools

- Durability and long service life