How to install

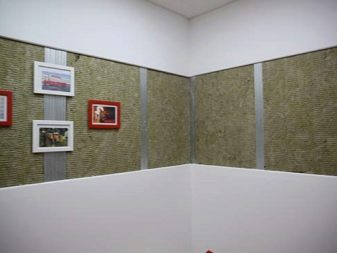

The sequence of work for partitions and ceilings is the same and includes the following steps:

a sealing tape is fixed to the walls and ceiling, which is necessary to reduce the transmission of acoustic vibration through the surface;

rack structures are installed on top of the tape, a step of 600 mm is observed - this is the width of the plate that must be maintained for fixing the plates;

Rockwool “Acoustic” plates are installed in the formed cavities, while it is important to place them as tightly as possible, in other words, by surprise. In order not to damage the material, first one side of the plate is installed in the frame, and then the second edge is carefully tucked into the crate;

depending on the thickness of the plates used (27, 30, 50 mm), they can be installed in several layers;

GKL sheets are mounted, while they are attached in increments of 150 mm

In the case when 2 layers of GKL are mounted, the seams should be offset relative to each other;

gaps and joints between sheets of GKL (GVL) are treated with sealant.

The layer of the Rockwool Acoustic board must be at least 100 mm thick.

To ensure a long service life, a sand-cement reinforced screed is poured over the soundproofing boards as follows:

- the floor slab is covered with insulating material Rckwool "Acoustic";

- a layer of Rckwool "Floor Butts" slabs is laid;

- a layer of Rckwool vapor barrier is laid;

- fittings are laid;

- cement mortar is poured.

Massive prefabricated screed can be installed as follows:

- soundproofing is laid on the floor slabs;

- covering is done with Rockwool "Floor Butts" plates;

- a prefabricated screed is made of two layers of plywood or OSB, which is done “in a row”.

This technology allows you to lay a laminate floor over acoustic "floating floors" without fear of cracking.

What it is

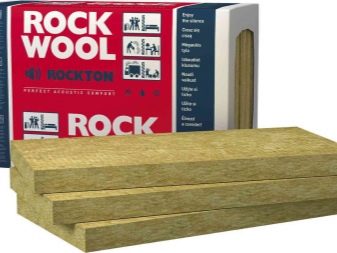

Basalt insulation Rockwool "Acoustic Butts" is a product of the processing of stone rocks, namely varieties of rocks of the basalt group. To be more precise, it is a product of smelting, since the temperature in the melting furnace reaches +1500°C, which makes basalt look like volcanic lava. The hot stream is sent to a centrifuge, where it cools down with constant rotation and blowing, turning into separate fibers, which are then transported for processing with binders and impregnations that enhance the water-repellent and fire-resistant qualities of the material. A carpet of the required density and thickness is formed from individual fibers.

Passing between the layers of fibers, external noise is repeatedly reflected and attenuated, ensuring silence inside the room. The technological process is completed in the heat treatment chamber, where the binder impregnations are sintered, which ensures the strength of the insulation. After cooling, a single carpet is cut into separate plates and packed in a polyethylene film.

Helpful Tips

In order for the sound insulation to be of the highest quality, it is required to follow the manufacturer's technological recommendations.

- When constructing frame-sheathed partitions, it is advisable to take care of soundproofing equipment in advance. In this case, Rockwool "Acoustic Butts" slabs are mounted between racks inside the partition, without affecting the interior space of the room.

- In the case of a partition adjoining a ceiling with a suspended ceiling, the partition should first be erected, the suspended ceiling should be placed on both sides of it, preventing adjoining by laying a damper tape.

- When installing additional insulation on the offset, it is necessary to ensure that the surface lining, if it is made of sheet material, does not adjoin rigidly to the ceiling and floor structures, in order to avoid the transmission of sound vibrations.For example, sheathing sheets should not rest against the floor, it is required to leave a gap of 2–5 mm, which must be closed with a sealant or damper tape should be used.

- Self-tapping screws for mounting are selected based on the material on which they will be fixed. For wood, self-tapping screws with large and wide threads are required, for a metal profile, pointed self-tapping screws with a countersunk head, for a profile with a thickness of more than 2 mm, the use of drill-tapping self-tapping screws is required. For mounting to the ceiling, it is desirable to use plastic dowels that do not transmit sound.

- Soundproof partitions can be used even in damp rooms, for example, in bathrooms. However, do not forget that for their coating it is necessary to use moisture-resistant GVL sheets, laid out in two layers, covered on the surface with waterproofing impregnations and ceramic tiles.

- One of the main conditions for ensuring good insulation is the installation of stone-fiber plates at a distance, that is, as close to each other as possible, which will eliminate the appearance of even thin cracks and gaps between them.

- The soundproofing effect can be improved by using a double frame, which consists of two rows of racks that are not interconnected.

- In the presence of cracks or cracks on the surface of walls or other bases, do not use mounting foam. The best option would be to use a vibration-proof silicone-based sealant.

- Since sound propagates through cracks, it is necessary to carry out every component of the structure with high quality in order to prevent a sharp decrease in the soundproofing effect as a result of careless work.

Life hack from Rockwool - in the next video.

Analogues

There are materials on the construction market that have the same range of applications as Rockwool Acoustic Butts soundproofing boards, but have a lower price tag. Analogues include Paroc mineral wool.

Two types of such noise-absorbing coatings are produced, such as:

- Parc SSB 1, which is designed for sound insulation for "floating floors" due to the horizontal direction of the fibers;

- Parc SSB 4 used for impact sound insulation.

"Izomin", which is considered a heat and sound insulating material based on basalt fiber, has a wide range of applications. This material is represented by more than a dozen items. TechnoNIKOL, which is also an economy class material, is represented by 8 items based on basalt fiber, among which the most popular are Technoblock and Technovent slabs. Materials such as Izovol, Shumanet SK and Tizol Eurolight have a higher price tag compared to Rockwool slabs.

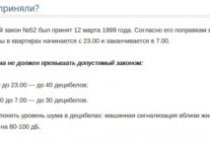

Noise and its types

As you know, noise can be of a different nature. As a rule, a motorist is not less interested in eliminating noise than a resident of a panel building.

Mineral wool rockwool acoustic butts

Noise can be of the following properties:

- Shock, which implies various vibrations of surfaces that receive pressure, shock, vibrations. A typical example of impact noise in a car is the movement of cargo and various tools in the trunk;

- Airborne, which means the propagation of noise through the air. In this case, the thicker the body surfaces, the less soundproofing effect they will have.

- Structural;

- Acoustic.

rockwool butts acoustic

Rockwool Acoustic Butts

What is Rockwool Acoustic Butts? These are special plates that perfectly absorb sound. They are made, as mentioned above, from stone wool. The excellent properties of these plates to absorb sound are explained by the following properties:

- The fibers are arranged randomly;

- The structure of the plates is homogeneous;

- The production technology is unique;

- No shrinkage during the entire period of operation.

As a rule, Rockwool Acoustic Butts is used for soundproofing ceilings, but can also be used for finishing other surfaces.

Acoustic butts rockwool

The manufacturer Rockwool has been producing materials for noise and heat insulation for more than 100 years.It is believed that this is almost the best manufacturer of soundproofing materials today. Many factories in more than 15 countries of the world are already talking about something.

Advantages

The materials of this manufacturer have the following advantages:

These materials do not transmit noise, because the absorption rates are enviable. Noise of 50 dB can be easily reduced by using Rockwool materials. In comparison, powerful acoustic speakers, when they are turned on to their fullest, sound at 60 dB;

butts rockwool acoustic

- Rockwool materials do not burn. Indeed, they can withstand temperatures up to 1500 degrees, while thin TPU films can only withstand 175 degrees Celsius;

- A decent level of Rockwool and thermal insulation. So, in the hot season, the car will not heat up as much as before, and in winter it will be much easier to warm it up;

- Rockwool materials are generally not afraid of moisture. They do not accumulate it, but bring it out, which has a positive effect on the life of the metal surfaces of the car. Provides additional protection against corrosion;

- The materials are completely safe, they are environmentally friendly and made from harmless materials;

- The price of materials is commendable. The cost is acceptable to many.

Butts acoustic rockwool

Unfortunately, Rockwool also has its downsides. Until now, the company has not established a separate production of materials for cars. The purpose of the materials is purely construction, although the use of the latter for soundproofing a car is not excluded.

Soundproofing Acoustic Butts Rockwool

As a rule, the following models are used for car soundproofing:

- Rockwool Lamella Mat 20 mm. This is a mat that can be used to cover any surface of the car, including doors, hood (see Noise isolation of the hood without problems), ceiling and so on;

- Rockwool acoustic butts. An ideal material for soundproofing, only it is recommended to cover only invisible surfaces with it, since there is no foil layer on these plates.

rockwool acoustic butts soundproofing

To learn more about Rockwool acoustic butts, a video review and photo materials will allow. The manual will help you get information on how to work with the material. The price of materials, as mentioned above, is not high.

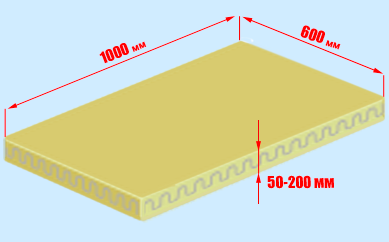

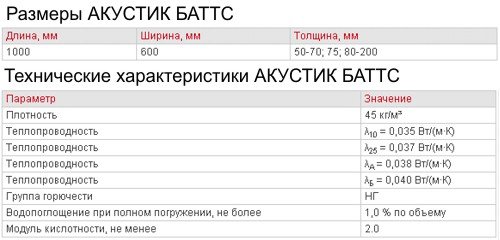

Specifications

All Rockwool Acoustic Butts boards have good noise reduction, strength and hydrophobicity, making this material a leader in this segment of the domestic construction market. To date, there are plates on the market, the size of which can be 1000x600x27 mm (ultra-thin), 1000x600x50 mm and 1000x600x100 mm.

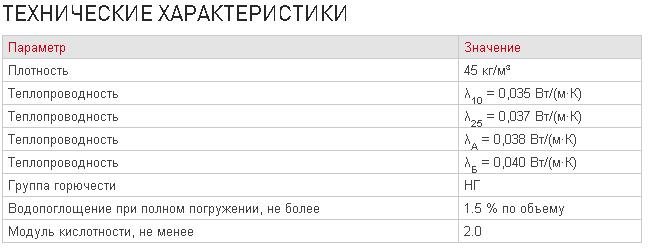

Plates Rockwool "Acoustic Butts" and Rockwool "Acoustic Butts PRO" have the following characteristics:

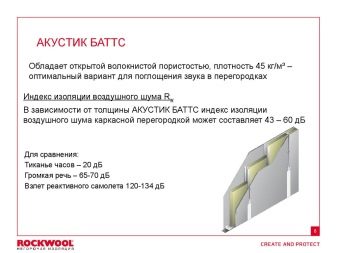

- the sound absorption index depends on the type of slab: for the Rockwool Acoustic Butts PRO slab, it corresponds to class A (1 - the absolute level of noise reduction), and for the Rockwool Acoustic Butts slab - class C (0.7 - partial noise reduction), especially effective absorbs medium and high frequency sounds;

- density is 37 kg/m³, 45 kg/m³, 60 kg/m³;

- weight varies from 125 kg to 150 kg per 1 cubic meter;

- thermal conductivity has a coefficient λ10 = 0.034 W / (mK), which is a rather low value;

- water absorption during short-term immersion is no more than 1.0 kg / m²;

- vapor permeability coefficient - 0.3 mg / mh Pa, which is a low indicator and allows the use of this material on wooden structures;

- combustibility group - NG (the material is not subject to combustion and can be used when surfaces are heated up to + 750 ° С);

- environmental friendliness is confirmed by the EcoMaterialGreen sign;

- chemical resistance corresponds to the class of inert materials;

- biostability completely excludes damage to the material by fungus, mold and rodents;

- resistance to compression and deformation ensures no shrinkage during the entire period of operation.

Advantages and disadvantages

When evaluating the pros and cons of various Acoustic Butts Rockwool slabs, it is worth starting from user reviews, since this material has been used in construction for quite some time. The manufacturer notes that when creating a "working" sound insulation, it is not enough just to use basalt fiber mats. Sound insulation is the arrangement of a sound-absorbing material fixation system that meets certain technological requirements.

Those of the consumers who have equipped such a soundproofing system and successfully use it note the following advantages of using Rockwool Acoustic Butts boards:

- good price compared to similar materials;

- light weight, easy to transport;

- ease of use: the material is elastic and does not crumble as much as other types of mineral wool, allowing you to perform work quickly and cleanly;

- the material does not impose any special requirements on the surface on which it is mounted;

- when arranging home theaters, the following effect is noted: inside the room, the sound does not “press on the ears”, since it is not reflected from the walls and ceiling, partially absorbed by the material of the plates;

- when using basalt fiber for wall insulation, there is no background noise in the room;

- the main advantage is the preservation of good soundproofing characteristics even with a small thickness of insulation. This is especially true for the latest varieties, called ultra-thin and having a thickness of 27 mm;

- the material "breathes" unlike synthetic analogues, therefore it is suitable for wooden construction;

- biostability and incombustibility;

- along with the soundproofing effect, this material is also a heater.

The downsides include a few things.

- The installation of Rockwool slabs, as well as other soundproofing options, leads to the loss of free space inside the room. The use of an ultra-thin variety of Rockwool "Acoustic Butts" can partially help in this.

- Builders-practitioners do not recommend the use of fiber boards for soundproofing floors, since the material is compacted over time from walking and other loads, which leads to a loss of the sound-absorbing effect and the appearance of subsidence of the floor. However, the manufacturer notes that this defect is due to non-compliance with the technology and, when soundproofing floors and installing “floating floors”, recommends applying a cement-sand reinforced screed over insulating slabs or a prefabricated screed of at least two layers of sheet material.

- The material requires the most hermetic coating with GKL sheets and the treatment of seams with a non-drying sealant.