Lighting

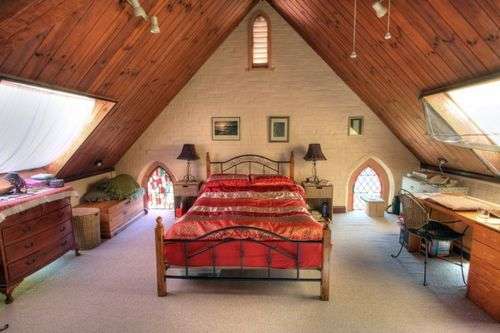

In order for natural light to freely enter the rooms under the roof, translucent structures are needed. In this case, the only correct solution would be the installation of skylights. An important point in the process of preparing for the installation of a window into the roof slopes is the manufacture of a durable wooden frame on the inside, which will help hold the window frames and prevent possible deformation. The frame is installed between the rafter legs, so the width is ordered taking into account this distance and the thickness of the beams. Windows can be installed on the gables or directly on the roof of the house. What are the advantages of roof windows?

- Savings on energy costs. Such windows allow you to increase the throughput of natural light by 40%.

- Exquisite design. Windows help to create a distinctive atmosphere in the room under the roof, organically complement the design, creating space in the room.

- Functionality. Manufacturers offer various configurations and functional loading of windows for attic spaces.

Skylights are a great source of daylight

As for conducting electrical wiring to the attic to create high-quality artificial lighting, there are several proven methods:

- laying wires over the walls, hiding them in special plastic boxes;

- arrangement of hidden electrical wiring, laying the wires under the inner lining.

The first method is the simplest, it can be done quickly and easily with your own hands. The second method is more technically complicated, since the norms and requirements for fire safety of a private house must be taken into account. Hidden electrical wiring is laid at the stage of installation of the frame, wall and ceiling cladding.

When the wiring is carried out to the attic, all sockets and switches are placed in their places, you can proceed to the most exciting stage - interior planning. Here the flight of fancy is only welcome! You can choose classic style solutions, cozy Country or gentle Provence. For young people, you can create an urbanistic room under the roof in the Loft style, and for children - a fabulous island of dreams.

The easiest way to emphasize the beauty of the interior of the attic is thoughtful lighting.

Turning a dusty and dark attic into a cozy and spacious room under the very roof is a time-consuming process and requires financial costs. Knowing the secrets and tricks, following the rules and advice of experts, you can quickly transform a non-residential cold attic under the roof into additional living space.

Transformation of an abandoned attic

1 Features and purpose

Insulation of floors should be given no less attention than insulation of walls or floors. Someone may object, they say, why not concentrate on thermal insulation of floors, if it is much more important to protect walls from heat loss.

Indeed, the walls are almost the main structure that cools the house even with foam and polystyrene. This is due to their large area, length and thickness. The wall in the winter season can freeze through, thereby seriously lowering its temperature, and hence the temperature inside the room.

There is another point that concerns the expenditure of resources for heating the house. Excessive heat from radiators can warm up the wall completely, but it will give off almost half of the heat energy to the outside.

Builders call this process in professional jargon “heating the street”. As you understand, this is at least an unprofitable use of resources.

However, attic floors are no less a priority. To understand why the calculation and installation of thermal insulation for floors is needed, it is worth referring to the laws of physics.

According to these laws, warm air always tends to rise, and cold air is at the bottom. If we are talking about a house or a room, then here the space is closed most of the time, and therefore the air has nowhere to go. As a result, warmer air currents are predominantly under the ceiling.

If your ceiling is cold, then they cool down and sink lower, making room for air with a higher temperature like Technoblock mineral wool heaters. The result is a kind of reverse circulation, when the temperature in the room slowly drops, and all because of the non-insulated ceiling, which has a lower temperature.

Ceiling from beams protected by a vapor barrier film

It is especially important to insulate attic floors. After all, the attic is, in fact, an unused room.

It is rarely insulated properly, leaving it as a kind of buffer space. Therefore, the temperature in it, although higher than outside, is still quite low.

If you have monolithic or prefabricated attic floors, then you are still very lucky. Concrete, although it does not withstand loads very well, is still a material with a high density. It cools slowly and creates significant barriers to lower temperatures.

However, many buildings have attic floors laid on wooden beams. The device on wooden beams makes it possible to do the work with your own hands, and significantly reduce the cost of arranging the floor, however, its thermal insulation properties can hardly be called acceptable.

The simplest floor of this type consists of beams on which wooden boards are stuffed, and the insides, at best, are filled with a small screed or backfill materials.

The thickness of such ceilings with foil insulation also does not differ in impressive performance. The calculation shows that although they provide sufficient strength for the attic, their thermal insulation is at a very weak level.

The main parameters of the beam for beams

The parameters of the beams directly depend on the geometric dimensions of the premises of the lower and upper floors, their intended purpose. The calculation of parameters is an important stage in the creation of an interfloor overlap, the reliability and durability of the entire structure largely depends on it.

Shape and section

A rectangular beam is seen as the optimal material for the manufacture of beams. Installed on the edge, it has a sufficient margin of safety, high reliability. Sometimes round timber or lumber of specific profiles, for example, an I-section, is used as load-bearing structures.

The exact parameters of the beam directly depend on the expected load, the span length and the distance between adjacent beams. By the way, it is not at all necessary to calculate all the parameters yourself; you can use ready-made tables and diagrams.

Length calculation

Calculating the length of the beam is simple - this is the width of the span plus the tolerances for embedding in the grooves. Regardless of the section, it is not recommended to make spans more than 6 m wide, this will inevitably cause sagging, which can result in an accident. If it is necessary to make a larger wooden floor, you can get out of the situation by installing supports and props in the form of columns from the same beam.

Material quantity

For ease of calculating the amount of material, it would be useful to sketch out a diagram of the future overlap. It should be borne in mind that the distance from the extreme beams to the wall will be approximately 50 mm, and the rest will be evenly laid between them at the same interval (0.5–1.0 m).

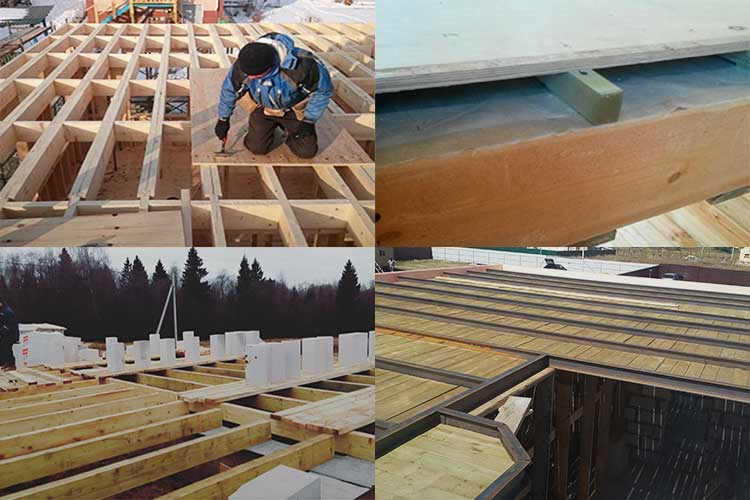

Wooden flooring device

Perhaps this is the best type of flooring, it compares favorably with ease of manufacture and availability of materials. In addition, only wood is used to create it, which ensures environmental cleanliness with sufficient reliability.The device for overlapping on wooden beams is not particularly difficult, its main components are:

- bearing beams;

- guide bars;

- draft ceiling;

- the base of the floor of the upper floor;

- insulation;

- waterproofing;

- decorative coating.

The necessary strength and reliability of the entire structure will give the beam. It can be solid or glued from several layers. A good replacement for timber is solid logs of small diameter. Boards can also serve as the basis for the structure, but such floors have significant limitations in terms of span length and load.

In principle, the beam can be made of any wood, but it is better to choose larch or pine. Hardwood has a slightly different structure and less resistance to bending. Such an overlap may not withstand constant load.

On the supporting structure of parallel beams, the base of the future floor and ceiling is mounted, respectively. It can be a prepared board or wood-based sheet material. A floor covering is laid on the finished base (on the second floor), and a full-fledged ceiling is made from below.

A feature of this design is the free internal space that must be used. It is filled with any material with heat-insulating or sound-absorbing properties. This will help keep the heat in the rooms and provide a sufficient level of sound insulation.

Overlapping of the second floor on wooden beams installation stages

The walls with landing nests are ready, the wood and auxiliary materials are purchased, the tools are ready - we begin the installation of floors:

- One day before installation, the tree is smeared with antiseptic mixtures and fire-resistant compounds - with the exception of the ends, no “chemistry” can be applied to them. The choice of such compositions is now very large, you can name brands Finesta

, Seine

well, Neomid, Pinotex

and others with a wide selection of antiseptics and flame retardants. All primer should dry well; - We measure the beams and saw off with a sharp wood saw with a margin of 35-45 centimeters from the size of the room for reliable support on the walls. The cut should be at an angle of 60˚, so that when viewed from the side, the overlap element looks like a trapezoid with a wide lower part. The ends recessed into the walls are coated with resin and wrapped with roofing paper after it dries;

- Installing the end beams. We work from a high, wide and reliable "goat", it will not be possible to manage with ladders alone. Carefully set them in level and on the horizon. As linings, wide sections from the same floors are used, and in advance with antiseptic and fire-fighting compounds. Make sure that the ends of the beams do not rest against the walls, there should be a gap for ventilation of at least 3-5 cm in depth;

- When there is no doubt about the accuracy of the installation of the side beams, they are fixed with dry gravel in the landing nests. Lines are pulled tightly between the extreme beams. On these auxiliary fishing lines, other elements of the beam frame of the floor are installed;

- The installed beams are again carefully measured and adjusted, after which the landing nests are concreted with a solution of cement and crushed stone.

When planning the construction of a country cottage, the owner has to solve the difficult issue of choosing floors. Some contractors advise him to use reinforced concrete panels, others insist on using wooden beams as a ceiling.

We decided to help beginners get out of a difficult situation. In our article you will find an overview of the advantages and disadvantages of wooden floors.

Useful tips for their installation and important nuances of doing this work will also not be superfluous. We hope that the information received will be useful to you at the construction site and help you avoid serious mistakes.

There is a stereotype in the minds of citizens that precast concrete panels are the only possible solution for any building. It is not difficult to overcome it.

It is enough to list the advantages of wooden beam ceilings:

- Minimum cost (1 m3 of timber is several times cheaper than 1 m3 of hollow core panels);

- The load on the walls is 2-3 times less than from the panels. This allows you to significantly reduce the consumption of reinforcement and concrete when laying the foundation;

- On small spans (up to 4 meters), wooden beams can be laid manually using the simplest devices (winch or lifting block). Mounting heavy slabs without a powerful crane is an unrealistic task;

- Low labor intensity and high speed of work (compared to pouring a monolithic reinforced concrete floor);

- Environmental friendliness (granite gravel is used in concrete, the radiation background of which can significantly exceed the norm).

As you know, there are no advantages without disadvantages. There are few of them for wood floors:

- Increased deformability. It manifests itself in the effect of vibration during walking and the formation of cracks at the junction of plasterboard partitions;

- Low fire resistance (without special impregnation);

- Relatively small length (does not exceed 6 meters). For reinforced concrete panels, it reaches 7.2 meters.

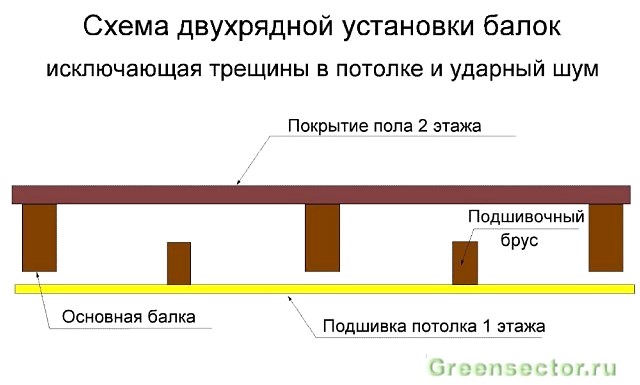

Among the disadvantages of these designs, some authors of feature articles include the formation of cracks in the plaster of the ceiling and poor impact sound insulation. However, with a competent approach to installation, these two problems are solved simply and reliably. To do this, a number of less thick beams are laid below the load-bearing beams, specially designed for filing the ceiling (drywall, OSB, lining, board).

Attic space definition Security Portal

If there is a pitched roof in a residential building, then a space is formed under it, which can be called an attic or attic. You need to know what is the difference between an attic and an attic.

This is necessary not only to understand the functionality of the under-roof space, but also so that you do not have problems during the registration of the house, since the total and living area of the house can differ significantly depending on the purpose of the space under the roof.

- Attic floor

- Attic space

- Differences

The difference between an attic and an attic

The completion of the house in the upper part can be an attic or an attic. Each of these types of premises has its own characteristics. What are these features and how does the attic differ from the attic? Let's consider the issue in detail.

articles

Attic - an attic used as a residential building, the facades of which are at the same time the slopes of the roof of the building.

Attic

Attic - the space between the roof and the ceiling of the last (or only) floor.

Attic

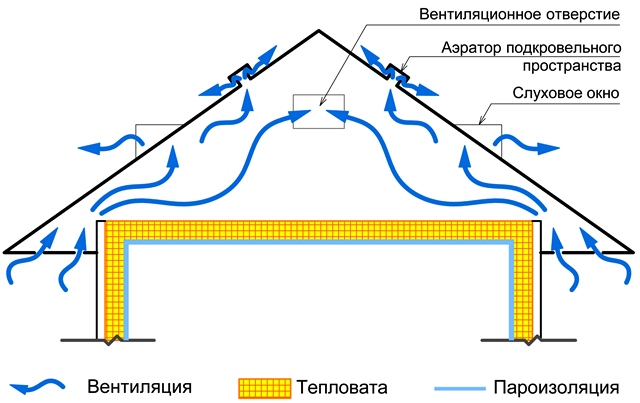

Attic ventilation through dormer windows

Ventilation with dormer windows

Only dormer windows can be used as attic ventilation, without equipping a system of vents and vents. This option is not very effective, since air can stagnate under and above the windows.

To improve air exchange and reduce the volume of stagnant places, the size of the dormer windows is 60 cm x 80 cm. They are mounted in opposite gables. First, wooden frames are made, attached with racks to the rafters. The roofing material is attached to the frame. Windows look better, decorated with the same materials as the roof. Lining is well suited as a finish for openings around windows. The window frame in the opening is installed last. All gaps between the window frame and the roof should be carefully closed.

Rules for the placement of ventilation windows:

- windows are placed at equal distances from the ridge, cornice and sides;

- between windows there should be a distance of more than one meter;

- the design of the window should harmoniously fit into the general appearance of the building;

- you can install a ventilation grill for the attic in the window, painting it to match the roof.

How to make an attic floor Features of the device

October 29, 2016

The arrangement of the attic in a private house is one of the final stages of construction. This room can be used for a variety of purposes. But most often this space is allocated for various engineering communications and equipment. Depending on the method of operation of this room, the attic floor is also equipped.

Inside such a room, the temperature usually does not differ much from outdoor indicators. Therefore, the living space must be qualitatively separated from it with the help of ceilings. How the whole process takes place, you need to know before starting work.

Ways to create attic ventilation

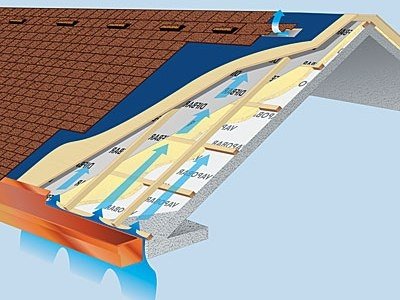

First of all, they provide air flow, as a rule, in the eaves of the roof. To do attic ventilation with your own hands, in most cases, perforated spotlights are used. They are installed at the bottom of the roof eaves, and perforation allows air to freely penetrate, but delays the possible ingress of various insects.

Attic ventilation in a private house also needs air outflow. For this there are the following elements :

- ventilated skate;

- inertial turbines;

- electric fans;

- roof aerators.

The roof around the entire perimeter must have a ventilation gap of at least 40-50 mm. This distance is often provided by the width of the lathing laths, which allows air to circulate freely under the roof. This method, for example, is suitable for roofs made of metal tiles, corrugated board or ondulin. The shape of these roofing materials makes it easy for air to pass under them and provide ventilation.

The area of ventilation ducts should be 0.2% of the total area of the ventilated room.

When using soft materials for roofing, the counter-lattice is made not continuous, but with gaps. This allows air to bypass the most problematic and difficult areas of the under-roof cake. .

Space layout

Often the roof is attached close to the Mauerlat, so the use of this space is almost impossible. In such cases, the walls of the attic room are shifted to the ridge of the roof from the walls of the building. Often, this technique deprives the room of visual space, so the walls in the attic are not installed. Installing furniture in such a room is more difficult, but it looks very interesting.

To make the attic a full-fledged living space, install additional windows. Most often this is done in the gables of the house, but if there are transverse walls in the attic, this is impossible. In such a situation, windows that cut into the roof slope are used. Such techniques are often used in Western architecture and allow you to give the house an unusual look.

When planning an attic, it is often difficult to organize an entrance area. For this, compact folding or spiral staircases are used.

Embedding beams into the wall

The depth of entry into the wall for the wooden beams of the attic floor should be:

- for timber - 150 - 200 mm (length of support on the wall);

- for boards - from 100 mm.

The end parts of the beams are wrapped in a waterproofing material for a length of 250 mm. Most often, ruberoid is used for this. But the end of the beam is not insulated to ensure steam exchange.

The end of the beam is beveled by a value of about 30 mm and an air gap is necessarily left between it and the wall.

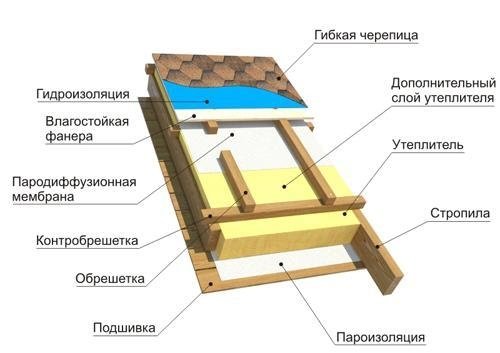

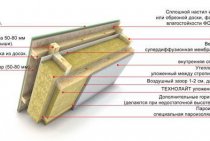

Scheme of embedding the floor beams into the wall Insulation of the attic floor with a counter-lattice 1 - inner lining; 2 - counter-lattice; 3 - vapor barrier; 4 - load-bearing beams; 5 - transverse bars; 6 - ECOVER insulation; 7 - crate

The design with a counter-lattice and the use of mineral wool of the specified thickness as a sound absorber is also a good sound insulator of the attic floor from airborne noise (according to the standards, the insulation index Rw for the attic floor should be at least 45 dB).

Under the insulation to protect against steam, a polyethylene film is laid with overlaps from 200 mm and a thickness of more than 0.15 mm. A steam-diffusion membrane is laid on loose mineral wool. On top of the counter-lattice, a flooring is made of boards, DSP, chipboard. for the possibility of movement on the floor.

Also, in order to ensure the durability of wooden structures, a general increase in humidity in the attic should not be allowed. For ventilation, the total area of vents in the attic should be 1:2000 - 1:5000 of the area of \u200b\u200bthe room.

If the attic is residential, then the insulation is laid in the roof, and the interfloor (attic) floor is soundproofed. Floor beams are significant sound bridges, therefore, in order to achieve a significant level of insulation from airborne and impact sound, it is necessary to use a floating floor - a layer of sound absorber between two layers of sound reflector. Then the overlap should be designed for laying a dry screed over a layer of sound absorber of rigid mineral wool boards with a thickness of 40 mm or more.

Floors ↓

Arrangement of ventilation of a cold attic

Since it is very important that the ventilation of a cold attic is regulated, it is not necessary to close the crate and rafters. This can be ensured, for example, if sewing with gaps is made

If ondulin or slate was used as a roofing material, and films for vapor and wind insulation are not used, then nothing else needs to be done for ventilation, since the air will pass between the roof waves.

Scheme of the movement of air in an unheated attic

If the roof is gable, then the ventilation holes are made in the gables. Here you can make a loose fit of the lining of wooden overhangs, while the holes must be made evenly. If the linings are fitted tightly or the fronts are stone, then in this case holes are made in the wall. The total area of the ventilation ducts should be equal to 0.2% of the floor area.

There is another, more economical way - to put the usual ventilation grilles. One grate is turned down with holes, and the other is made with the possibility of adjustment.

The arrangement of ventilation of the hip roof is different. Here they make an inlet at the bottom in the filing, and an outlet at the top of the ridge. If the overhangs are wooden. It is enough to loosely place the bars with a gap of several millimeters. Holes should be provided in the plastic lining.

Attic ventilation can be arranged differently depending on the type of roof. So, if slate and euroslate are used, a classic ridge is installed, with a flexible roof - a turtle (valve). A special valve is also needed when using a ceramic roof. The use of metal tiles involves the use of a conventional ridge, which will save on the valve.

Do-it-yourself floor in the attic

When converting the attic into a living space, it may turn out that the heat insulator located in the ceiling has become unusable and has lost its heat-insulating properties. The reasons for the loss of performance can be very different: from local leaks to poor ventilation of the attic and, as a result, wetting of the insulation from the resulting condensate. Wet, rotting boards can also cause an entire floor to be refurbished.

Alteration of the ceiling begins with the installation of an additional crate between the floor beams. As a crate, most often, pine bars are used, which are fixed perpendicular to the beams using metal corners or in another convenient way. To prevent the penetration of condensate from the lower room, a layer of vapor barrier membrane is laid. Stone wool slabs are often used as insulation, which, depending on the required thickness, can be laid in two layers.

A second layer of vapor barrier is laid on top of the plates. The membrane is fastened with a construction stapler. The basis for the subfloor can serve as slabs of tongue-and-groove moisture-resistant chipboard. They are tougher and stronger than conventional boards, and are also environmentally friendly. Thanks to the longitudinal protrusions and grooves, it is easy and convenient to mount the plates, and the surface is perfectly flat. For the final floor use laminate or linoleum.

Roof insulation in the attic

Roof insulation is the most important step. When insulating with your own hands, it is necessary to perform a heat engineering calculation to select the thickness of the heat insulator. Most often, ready-made tables and climate maps are used to select the thickness of the insulation. For pitched roofs, basalt materials with a density of at least 35 kg/m3 are used. Such a minimum density is necessary to hold the insulation when it is spread between the rafters.

From the side of the room, a vapor barrier film is laid. From the side of the roof, it is better to put a superdiffusion membrane on the insulation, which allows moisture to pass from the heat insulator.