Significant disadvantages of insulation

Despite the fact that the disadvantages of the material are much less than the advantages, in some cases they become a key reason to refuse to use it.

As it turns out, plastic has not only advantages, but all the disadvantages of XPS are also due to the fact that it has a “polyethylene nature”.

The main disadvantages of extruded polystyrene foam are:

- Weak soundproofing. The material is able to slightly muffle sound waves, but it is not able to absorb them completely, as well as reflect them.

- Sensitivity to ultraviolet radiation. In direct sunlight, without materials specially hiding it, for example, plaster and other finishes that serve it, among other things, as protection, XPS is destroyed.

- Low vapor permeability. In some cases, this can be a plus. But not in all. Therefore, dwellings insulated with extruded polystyrene foam require flawlessly installed and efficient ventilation. Otherwise, condensation will accumulate in the walls, which will contribute to their destruction.

- Low environmental friendliness of the material. No matter how the producers of expanded polystyrene shield their product, plastic always remains plastic. Although it is porous, it will still decompose much longer than any non-synthetic substances.

- The high cost of a heater of this kind also drives some into thought. Moreover, the harder and denser its variety, the more expensive it is.

Separately, I would like to dwell on the fact that, for obvious reasons, this material is very susceptible to attacks from rodents.

If there is open access to the EPPS insulation layer, mice and rats make whole labyrinths of moves in it and even arrange their nests in them.

Therefore, it is advisable to carefully close up the layers of insulation with such finishing materials through which rodents cannot break through to the coveted layer of polystyrene foam.

But the main disadvantage of this type of material is the low degree of fire resistance. One has only to light up the edge of the stove, as the flame instantly eats it completely. Moreover, combustion is accompanied by the release of highly toxic substances into the atmosphere - phenols, which can cause no less dangerous harm to the lungs than the high temperature itself.

Ordinary extruded polystyrene foam is capable of catching fire, depending on the prevailing external factors, at temperatures from 250 to 450 degrees Celsius, which is why it is worth using it to insulate wooden buildings and structures with the greatest precaution. In such cases, experts advise purchasing XPS, flavored during the production process with special refractory additives.

In such cases, experts advise purchasing XPS, flavored with special refractory additives during the production process.

Features of warming the facade of the building with the help of polystyrene with your own hands

Keep in mind that no major delays in work

, otherwise the foam may get wet or bad weather will adversely affect the quality of the material.

The list of tools for work will be as follows:

- hammer;

- smooth and notched spatulas;

- knife for cutting plates;

- dish-shaped dowels;

- foam boards (expanded polystyrene);

- reinforced mesh;

- primer;

- plinth profile;

- facade putty;

- mounting foam;

- for expanded polystyrene - special glue.

The sequence of actions will look like this:

- we prepare the surface of the walls, remove the protrusions and close up the cracks;

- create a basement profile;

- laying the plates;

- close the seams;

- plastering the facade.

And now let's look at all the stages of work in more detail.

Preparatory work and laying the basement profile

using concrete contact. If you use polystyrene plates instead of foam, they need to be processed. On the one hand, they need to be made slightly rough with a special roller.

In order for the installation of plates along the entire facade to be even, it is necessary beat off the zero level in a circle

so that the first row of plates lies in a horizontal position. In addition, the base profile serves as protection and prevents all kinds of rodents from reaching the plates. Do not neglect the installation of the base profile.

It should be installed using a level. Mark the zero point on the facade around the entire perimeter of the profile attachment. Then all points are connected into one with a chopping cord.

Laying tiles on the walls

Laying should begin with door or window slopes, then install the first row, the position of which is guaranteed by the base profile

Then the plates are laid in a checkerboard pattern

, pay attention to the density of their fixation. After completion of work, the polystyrene foam plates are fastened with dowels.

The foam is also fastened with dowels, this is done like this:

- wait at least a day until the glue dries;

- hammer the dowels into the corners, at the joints of several plates, one dowel will be enough to fix three sheets;

- the first dowel must be driven into the center of the plate, and the rest at their corners.

Let's move on to the plaster. If you apply it to a surface without a reinforced mesh, then it will not stick to the foam. The grid needs to be leveled. without a long break

because the glue sets almost instantly. In order for the mesh to be completely covered with plaster, the insulation must be covered up.

The final layer should be applied after the first one is completely dry. A smooth spatula is used for application. Take any paint that is intended for outdoor structures. It is best to apply it to the facade with a foam roller.

To summarize, the foam, of course, has more pluses than minuses as a heater. From perfectly keeps heat inside the room, does not create loads on the foundation, does not get wet, has good thermal conductivity and is affordable for everyone.

But at the same time, remember that with the internal use of such a heater it can give off an unpleasant odor

, also foam refers to materials that are unstable in terms of ignition, and in terms of environmental friendliness, this material is not the best.

Therefore, the most optimal use of such material is foam insulation of facades, roofs and non-residential buildings on both sides.

The main stage of construction is the insulation of the house. If you make mistakes in technology or in the choice of material, you can deprive your home of the necessary heat. Styrofoam plates will help to keep the comfort in the house even when it is cold outside. They are famous for their low price and good thermal insulation.

Application area

Given the previously indicated disadvantages, it is possible to choose the use of foam without damage to the building. Polystyrene insulation of wooden buildings (if required) is better done from the inside than from the outside.

This will protect the material from destruction, and the building from defrosting. It is more reasonable to use a vapor-proof material in stone buildings (brick, concrete), but if necessary, you can also insulate wood.

Stone and block buildings can and should be insulated from the outside. But it is not recommended to insulate wooden houses from the outside with foam plastic.

Floor insulation

When used from the inside, the ceiling becomes the main area of application.

Laying in the floor structure is also possible. But when carrying out work, the strength of the material should be taken into account.

- The first use case is common for concrete floors. In this case, the insulation is placed under a cement-sand screed. To prevent foam plastic from prominating, the screed is made reinforced with a thickness of about 50 mm. For reinforcement, special meshes with reinforcement with a diameter of 3 to 6 mm are used.

- The second option is applicable for buildings with wooden and concrete floors. In the first case, the insulation is placed in the ceiling or floor between the beams. In the second case, you will have to make a wooden frame, between the lags of which foam is mounted. In this case, the floor pie increases, eating up the useful height of the premises.

You can also fix the foam to the ceiling in two ways. With or without a frame. The choice of method depends on what material the ceiling is made of and technical capabilities.

When insulating the ceiling, it is worth remembering about waterproofing and vapor barrier.

Polystyrene balls are not afraid of water, but moisture can accumulate between them. Manufacturers are usually silent about this property. The ceiling in this case should contain the following layers (they are listed from the bottom up, from the side of the warm room):

- the material with which the ceiling is sheathed;

- vapor barrier necessary to protect the insulation;

- insulation;

- floor structure;

- waterproofing (sometimes mounted on top of the ceiling);

- the floor of the next floor.

If necessary, insulate the floor, the vapor barrier is also laid from below, and the waterproofing from above

It is important to remember that the first is always located on the side of warm air, and the second on the side of cold air.

In this material: the pros and cons of expanded polystyrene. Simple, detailed and clear. Perhaps this article will change your plans for home insulation. Read and comment. At the end of the article - reader survey

.

Interested in Styrofoam? Decided to apply it to the arrangement of your home? Then now we will tell you what advantages and disadvantages polystyrene foam has.

Technology 3 construction using foam formwork

Technology features

The essence of this technology lies in the fact that hollow foam blocks are used for the construction of walls. Reinforcement is installed in the space inside the blocks and concrete is poured. The blocks have standard dimensions of 950x250x250 mm.

Thus, at the construction stage, the foam acts as a formwork, and after the walls are erected, it serves as a heater.

The construction of a house using this technology is carried out as follows:

| Illustrations | Description |

|

Foundation arrangement. For such a house, it is best to build an ordinary strip foundation. It is built according to standard technology. |

|

Formwork assembly:

|

|

Pouring concrete:

According to this scheme, the walls are erected to the required height. Then the roof is mounted and finishing is carried out. |

Pros and cons

Advantages:

-

Strength.

Construction using fixed foam formwork allows you to get a full-fledged monolithic housing that can withstand any load; -

Durability.

A house built in this way can last more than 100 years;

-

Simplicity and speed of construction.

When compared with conventional formwork, the blocks are installed much easier and faster; - thermal insulation qualities. Unlike a conventional monolithic structure, the walls of a house built using this technology do not need to be insulated.

Flaws.

The disadvantage of such construction is its high cost. The blocks alone cost about 1,000 rubles per square meter.

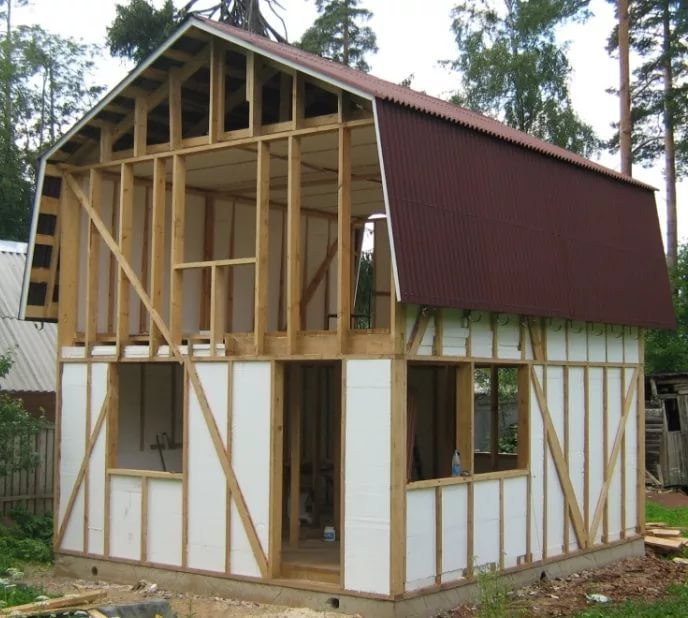

Technology 1 frame construction

Technology features

Frame construction is far from a new technology. However, in our country it has become widespread only in the last two decades.

The essence of this technology is the construction of the frame of the house from a wooden beam. In this case, the space of the frame is filled with foam. Outside, such walls are sheathed with OSB boards, and from the inside with drywall, clapboard or other finishing material.

Thus, the foam in this case performs the function of a wall filler, which is responsible for wall insulation and sound insulation.

Pros and cons

We will not go into the details of the frame construction technology itself, since it has already been repeatedly mentioned on the pages of our portal. Therefore, further I will only talk about the pros and cons of insulating a frame house with polystyrene foam.

Advantages:

-

Efficiency.

Due to the low thermal conductivity of the foam in central Russia, a thickness of a layer of insulation of 150-200 mm is sufficient. At the same time, housing will turn out to be warm and energy-saving; -

Thrift.

Styrofoam is one of the cheapest materials that can only be used in frame construction;

-

Environmental friendliness.

This material is hypoallergenic and does not cause irritation upon contact with the skin, unlike mineral heaters. Therefore, it is comfortable to work with him; -

Form stability.

Styrofoam does not shrink, which eliminates the appearance of cold bridges in the walls; -

Durability.

Subject to the insulation technology, the material will last more than 50 years.

Flaws:

Zero vapor permeability.

For this reason, the walls from the inside need a hermetic vapor barrier. Otherwise, all moisture will accumulate at the joints between the wooden frame parts and polystyrene foam, which will lead to rotting of the frame.

Hydro-vapor barrier, in turn, turns housing into a sealed "thermos". Therefore, such buildings need high-quality ventilation;

Fire hazard.

Foam manufacturers very rarely add flame retardants to its composition. As a result, the material burns well, and at the same time emits dangerous toxic substances.

For these reasons, polystyrene foam is rarely used to insulate a frame-type house. Most often, mineral wool is used.

I must say that instead of foam, you can also use foam in a frame house. This material is an improved version of foam.

Penoplex is more effective in terms of thermal insulation, as well as more durable and durable. In addition, flame retardants are usually contained in the penoplex, which makes it a low-combustible material.

The disadvantage of penoplex is its low vapor permeability. In addition, the price of foam plastic is 2-3 times higher than that of foam plastic.

The benefits of foam

One of the thinnest insulation

If we compare the foam with all other heaters, then it is unique because of such a quality as a low coefficient of thermal conductivity, in which no one can surpass it.It follows from this that it will have a minimum thickness, unlike other materials. This fact clearly confirms the list of known insulators with an indication of the value of their thermal conductivity:

- Penoizol (50 mm).

- Polyfoam insulation (75 mm).

- Mineral wool (125 mm).

- Wood (340 mm).

- Brick wall (900 mm).

- Concrete (2132 mm).

The lightest insulation

Even during the choice of foam, you can find out how much the foam plate weighs. Just look at the packaging, which contains information about the density of the material:

The value of density, which corresponds to one cube, should be considered the mass of the product. This nuance will help you determine how high quality the material offered to you is. If the description for the foam plastic indicates a density of 25 kg / m3, and weighing shows a different result, you can be sure that something is wrong with this material.

You can perform insulation work with any foam, regardless of its density. An important point is that with its decrease, the strength of the material will deteriorate. The decision to insulate the first floor of the building will not be the best, since any mechanical impact will lead to damage to the facade. Therefore, you should choose a material that has a maximum density value.

One of the cheapest heaters

One of the most important advantages of polystyrene should be called its low cost. Today in construction, such types of it as:

- sheet foam;

- foam chips or balls.

Moreover, these materials almost do not differ in cost. It can be assumed that this was influenced by an increase in demand for balls, which are needed during roof insulation. They are introduced into the composition of the cement-sand mixture, after which a layer of the required thickness is created on the floor. This option allows not only to save money, but also to keep warm and provide the necessary strength.

Styrofoam is a very versatile insulation

Polyfoam has become widespread in the performance of such works as:

- wall insulation;

- roof insulation;

- floor insulation;

- insulation of the basement of the house.

Most often, foam is used for wall insulation.

It is important that, in addition to all other qualities, this material has a long service life, even when under a layer of plaster. According to the manufacturers, the facade, which is made on the basis of polystyrene foam boards, is able to do without major repairs for 30 years.

Rumor has it that if Styrofoam was used to insulate a house in Germany, then the owner can count on longer insurance than usual, which can reach up to 100 years.

Material Advantages

Thermal insulation of a building using expanded polystyrene (the second name of polystyrene) has the following positive aspects:

- Low cost. Compared to other thermal insulation materials, this one will be inexpensive, and you can buy it in almost any store.

- Good thermal insulation performance. Styrofoam insulation gives the same effect as the popular mineral wool and Penoplex. The thermal conductivity of all these materials is similar.

- Ease of use. The material is easy to cut. You can work with it without the use of special tools or protective clothing. In addition, the insulation is easily attached to glue and special fungi.

- Light weight and dimensions. Transportation of polystyrene foam will not be a problem. The material is easy to transport by yourself. This option allows you to reduce the cost of insulation.

The advantages of insulating a house with polystyrene foam do not end there. The material does not pose a danger to humans. It can be used both inside and outside. But when applying it is worth remembering the shortcomings. Cons are listed below.

Benefits of insulating your home with styrofoam

- Styrofoam is a foamed solid mass, which is sold as plates of different sizes. Due to foaming, the foam contains a huge amount of air, and, as you know, air is a poor conductor of heat. This means that polystyrene is rightfully a good heat-insulating material, which is used everywhere in construction.

- Due to the large amount of air contained in the material, the foam is very light. It can be carried alone, without anyone's help. In addition, the material is quite easy to cut, so you can easily "fit" the foam in size right at the installation site. To fix the plates, you may need special mixtures designed for gluing plates to walls. They create an additional heat-insulating layer at the installation site of the foam.

- In addition to heat-insulating properties, the foam has good sound-proofing properties. That is, it is a poor conductor of heat and noise, therefore, in a house insulated with foam plastic, it will be not only warm, but also quiet.

- With the help of polystyrene, you can insulate various parts of the premises: roofs, ceilings, walls, facades, attics, basements, foundations. However, when insulating the internal surfaces of the walls, it is worth remembering one rule. The wall that faces the street should not be insulated with foam from the inside. There is a simple explanation for this. A wall that is heated from the inside by heating devices stops warming up if it is covered with foam plastic, since foam plastic is a poor conductor of heat. Such insulation will contribute to the active destruction of the walls, due to the fact that the dew point will be shifted and will be located between the wall and the foam. Constant exposure to moisture, strong temperature changes, and even possible freezing of moisture between the wall and the foam will lead to the destruction of the wall. Such walls are recommended to be insulated from the outside.

- Polyfoam is not afraid of moisture and does not absorb it, does not require additional waterproofing during installation. It is also resistant to fungus and mold.

- It has a low cost in comparison with many other heat-insulating materials.

The higher the density of the foam, the less air is contained in its structure, the lower the level of its thermal insulation. However, with an increase in the density of the material, its resistance to mechanical damage and strength increase.

Styrofoam features

The structure of the foam is a foamed mass, where the bulk of the mass of the plate is air. Thereby the density of this material is much lower than the density of the raw material

from which it is made. A huge amount of air in the structure of the material is its undoubted plus, in addition:

The material has a different density depending on the raw material, and this also affects the level of mechanical strength. The greater the density of the structure, the less air inside the material, respectively, thermal insulation properties will be worse

, but the material will withstand more mechanical loads.

When insulating, foam boards, depending on the level of strength, are used in this way:

- plates with a minimum strength indicator should be combined with a maximum level of protection against mechanical damage during insulation;

- plates with low strength are best installed for insulation with a frame method of installing load-bearing structures;

- if the plates have greater strength, protection against mechanical damage will be provided even without a frame, but it must still be installed in addition to the insulation.

Mice start in foam

And one more fact that must be indicated when evaluating the pros and cons of foam insulation is that mice start up in the material.

Expanded polystyrene is an ideal habitat for them, because it is warm and soft. Therefore, when insulating with polystyrene foam, close the access of mice.To do this, you can finish the places where rodents can enter with mineral wool, which mice do not like.

Therefore, although polystyrene foam has a number of positive qualities, one should not forget about its disadvantages. Therefore, it should be used thoughtfully and according to all the technological features of the material.

The main stage of construction is the insulation of the house. If you make mistakes in technology or in the choice of material, you can deprive your home of the necessary heat. Styrofoam plates will help to keep the comfort in the house even when it is cold outside. They are famous for their low price and good thermal insulation.

Technology 2 construction of domed houses

Technology features

Unlike frame houses, domed houses are made entirely of foam. Moreover, even the roof, if it can be called a roof at all, is made of foam. The fact is that the walls of such buildings have an arched shape, i.e. smoothly into the roof.

For the construction of domed houses, ready-made parts are used, which have recently been manufactured by various companies. The material for them is a dense foam brand PSB-S-50. As a result, the house is assembled as a constructor.

I must say that the first such house was built in Alaska back in 1984. However, interest in such construction in our country has arisen only in recent years.

To make it clear to you what this construction technology is, then we will briefly consider the procedure for erecting a domed house:

| Illustrations | Description of works |

|

Foundation arrangement. |

|

Construction assembly. Blocks are assembled as a constructor. They are connected to each other according to the thorn-groove principle.

The joints of the blocks must be coated with glue-foam. It is not advisable to use polyurethane foam, as it expands greatly. |

|

Finishing. This procedure is performed according to the standard scheme for foam plastic:

|

|

Decorative finish:

|

The size of such a house can be from 6 to 12 meters in diameter.

Pros and cons

Advantages:

-

Cheapness.

This method of construction is one of the most budgetary; -

Speed

. You can build houses from polystyrene foam and finish it in a week, without taking into account the construction of the foundation; -

Seismic resistance.

As tests have shown, the dome structure is not afraid of any earthquakes;

-

Easy assembly.

Every beginner can build a house with his own hands. -

Minimum heating costs.

Due to the low thermal conductivity of the material, such houses are very "warm" and energy-saving; -

The possibility of expanding the area.

Extensions can be added as needed.

Flaws:

-

Suitable for temporary residence only.

Styrofoam houses can only be considered as temporary housing; -

Low strength

. Styrofoam walls, even reinforced ones, are not able to fully protect housing from intruders.

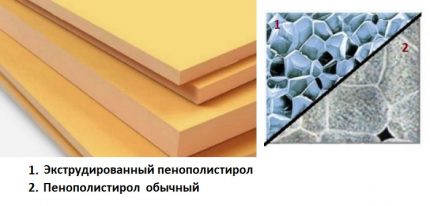

What is EPPS

In everyday life, this material can be found under the name "styrofoam", but this is fundamentally wrong. These two materials differ significantly from each other. For example, extruded polystyrene foam (EPS) is one of the most resistant to deformation and durable varieties, and its heat-shielding properties hardly suffer from this.

High-strength XPS is made on special production lines by chemical extrusion of the original raw material, which is pure polystyrene granules.

With the help of special equipment, the raw material is converted into foam, from which, in turn, small granules are produced. During the solidification process, these granules are pressed into layers of the desired shapes and sizes, after which they can be used not only for insulating houses, but also for other purposes.

The main difference between extruded polystyrene foam and press foam lies in the characteristics of its granules. They are smaller, which makes this building material more resistant to physical stress. The size of the granules of the heat-insulating material produced by extrusion does not exceed 0.1 mm, while the granules of the non-pressed material can reach up to 10 mm.

In foreign interpretation, EPPS can be referred to as XPS. It is produced in several varieties. After the abbreviation "XPS" in the markings of this material there are numbers from 25 to 45, which indicate its density.

The higher the value, the higher the density of the material. Particularly dense extruded material can even be used to insulate asphalt pavement, for example, Penoplex products.

Now that we have figured out what EPPS is, we will discuss in detail all its pros and cons.

Advantages of styrofoam foam

1. Low price

Perhaps this is the most important plus of this material as a heater. Now there are many other heaters on the market that are superior to polystyrene in a number of properties. However, in many cases, it is the cost of insulation that occupies a paramount place. As a result, in many cases, the choice falls on the foam. The amount of money that can be saved by using this material is very attractive.

2. Good thermal insulation

This is also an important advantage of expanded polystyrene. In terms of thermal insulation, it surpasses most other heaters.

Due to this, when using foam, you can get by with the smallest thickness of insulation. Whereas when using other materials, their thickness (to achieve the same thermal insulation value) can be several times larger.

Closely related to this is the following feature.

3. Light weight

This is a very light material (thanks to its manufacturing technology). And due to this (as well as high thermal insulation properties), for example, when insulating a house, a minimum load is created on the foundation and walls.

This is also an important advantage of foam. It is of particular importance when insulating multi-storey buildings.

There are many floors, but the foundation is one!

4. Multi-functionality and wide scope of application

This material is used to insulate a wide variety of objects. So, if we talk about houses, then it is used to insulate walls, basement, floor, ceiling.

At the same time, there are several options for warming certain objects.

This feature makes expanded polystyrene an almost universal insulation. The exception is the insulation of the house from the inside - it is better not to use polystyrene for this.

5. Durability

The service life is really very high. This has already been tested in practice. Of course, provided that this material is protected from exposure to sunlight, rodents and other negative factors.

Subject to the appropriate insulation technology, this material can last 30 years or more. Especially if high-quality foam is used, from honest manufacturers.

It is no secret that low-grade material is also found on the market, which is made without observing all the necessary standards. In this case, of course, there is no need to talk about high durability.

However, if we take into account high-quality polystyrene foam, then its service life is quite high. In this indicator, it surpasses some other heaters.

6. High resistance against fungi, various microorganisms

What is good about polystyrene is that it is of artificial origin.This means that it does not attract any microorganisms. That is, they do not start in it and do not multiply, as in the same wood. And, for example, from the mold, which will be located in close proximity, the foam will not collapse.

Another plus for this heater.

7. Easy installation

Any builder who has ever worked with Styrofoam will tell you that it is easy to work with. This material is easily cut, adjusted to the desired shape, size. For example, insulating the walls of a house from the outside with foam is done simply and quickly. What can not be said about some other types of insulation.

However, this is where the advantages of polystyrene foam end. And now we proceed to consider the minuses - the shortcomings of the foam. Unfortunately, there are not so few of them.

We emphasize right away: we are not producers of expanded polystyrene. Therefore, we will tell you the whole truth, hiding nothing.

Flammability and release of hazardous substances

The main disadvantage of expanded polystyrene is its combustibility. Therefore, with its help it is impossible to insulate rooms in which there is a high probability of a fire.

That is why it is not recommended to insulate a ventilated facade with foam plastic. The voids between the material and the facade surface create optimal conditions for combustion. In addition, voids additionally work as air draft.

Over time, polystyrene foam begins to emit an unpleasant odor. This is due to the natural aging process of the material. The toxic substance that causes the unpleasant odor is styrene monomer. That is why foam can only be used for external insulation.

Detailed information in the video:

In addition, when warming the bath, it is also necessary to ensure that toxic fumes do not get inside the room. When expanded polystyrene is heated above 90 degrees, the amount of hazardous compounds that are released from the material increases tenfold.

Conclusion

Expanded polystyrene or polystyrene is a product obtained from polystyrene and other components.

The main advantage of this material is that it is very cheap. Of the thermal insulation materials, it is by far the cheapest.

Other benefits of Styrofoam:

- It can be used both for insulation inside buildings and outside.

- Great for insulating foundations.

- Not afraid of moisture, has a small specific gravity.

- An excellent heat insulator, for example 1 cm of polystyrene foam replaces 23 cm of brickwork.

- Works well with other materials.

- The cheapest material from heaters.

Styrofoam is also the thinnest insulation, and only penoizol, which is sprayed on the surface, can compete with it. However, only professional builders can work with penoizol, while any person can install polystyrene as a finish on their own.

In addition, the material is very light, which will not affect the severity of the building as a whole and will help save on the foundation. Also in construction, sheet foam is more often used, but sometimes balls and crumbs are used.