Thermostat for gas boiler

Automation of the gas boiler

When heating a room with a gas boiler, the question of automating the process of regulating the heating temperature of the boiler, and as a result, the ambient temperature in the room, appears on the agenda. No matter how expensive and high-quality the boiler is, the change in outdoor temperatures will force you to adjust the boiler again and again. To do this, use a thermostat. Boiler manufacturers, as a separate option, provide the opportunity to purchase a thermostat from the same company. What is, by the way, is a very good option, because due to the variety of standards, different companies may have problems when setting up equipment.

The principle of operation of the thermostat

It is important not to confuse the thermostat for the boiler, or it is also called a room thermostat (room regulator) with standard automatic gas boilers, which is the principle of controlling the temperature of the coolant. This appliance has indoor or outdoor temperature control

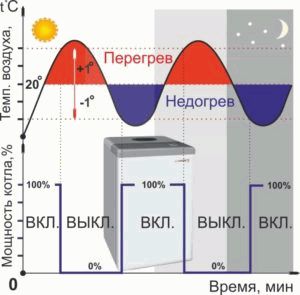

The main principle of operation of the thermostat is to maintain the set temperature in the room, that is, at the minimum threshold value, turn on the gas boiler to heat the coolant, and as a result, heat the room.

when the peak air temperature is reached, turn off the boiler by removing the gas supply to the boiler burner or by issuing a command to the main automation (control unit) of the gas boiler.

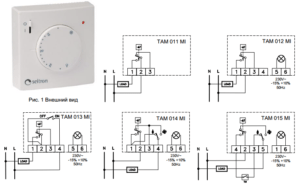

The diagrams for such a thermostat connection are below.

Types of thermostats

Thermoregulators are: mechanical (where you can manually set the temperature mode with the regulator);

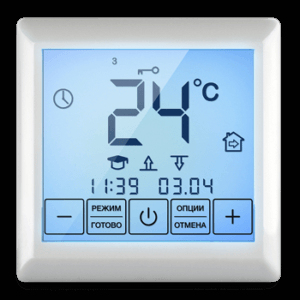

programmable with a digital display or menu;

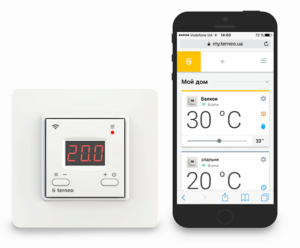

programmable with functionality to control it from mobile devices or the Internet (built-in GSM);

wireless controllers are both autonomous and external (an external one controls the boiler depending on the weather). The last option is the most optimal and effective.

The programmable thermostat allows you to set different temperatures in different rooms of the room, different temperatures depending on whether it is a weekday or a weekend, also depending on what time of day it is, you can also program the sensor to trigger when a person enters the room - there are many variations of programs. The main advantage of this approach is saving resources and achieving a comfortable temperature at the right time in the right place in the room. When using a room thermostat on a gas boiler, savings are achieved up to 20% of gas, with modern insulation standards up to 50%.

Devices of this type are widely represented by many companies such as: Danfoss, Devi, Teplolux, Energy, Vaillant

Danfoss is represented by the so-called radiator thermostat. They consist of two main parts, a thermostatic valve and a thermostatic sensor. The standard temperature sensor setting range is from 5 to 26 °C.

The service life of this device of these companies reaches maximum values.

The warranty for these devices is from one to three years, depending on the brand and model.

How to check valves and other components on a gas boiler

Each gas boiler needs several key components that will monitor the unit for it to work properly. In the event of any deviations, the various components are triggered and the plant simply ceases to function. But at the same time, you need to understand how to check a gas boiler solenoid valve, a thermocouple, or any other component. After all, knowing about the malfunction, in most cases it can be removed by yourself.

This device is one of the few that allows you to measure high temperature.It is both simple and yet reliable. A thermocouple is made up of two conductors of different metals, which are connected at different points. All this makes it possible to use it for different purposes. The main disadvantage can be called an error of one degree. To ordinary people, this seems insignificant. But for such devices, many consider such indicators to be simply gigantic.

The device is used as a fuse. It measures the temperature in the heating pad. If it starts to fall rapidly (say, for some reason, the fire went out or there were problems with the chimney), the system is triggered, in which a signal is sent to the solenoid valve, and the gas supply stops. Therefore, if this component does not work, the equipment is incapacitated.

The sequence of actions to check:

- The thermocouple has two ends, the first of which is heated by an igniter, and the second is attached to the solenoid valve. It is necessary to separate the device from the boiler, whether it is conventional or condensing, having a three-way valve.

- Then provide a constant flame. A candle is the best.

- We heat the tip above the flame at a distance of 1 cm. Just be careful, as the heat can reach half of the body.

- We take the tester and turn it on for millivolts. One probe is placed on the body, and the second on the output contact.

- After half a minute, a working thermocouple will show an EMF in the range from 17 to 25 mV. If the indicators are normal, then the problem of a non-working system may be different.

Solenoid valve

The solenoid valve is a shut-off valve that directly affects the safety of the unit. It is mainly installed so that in the event of a malfunction, it closes the fuel supply. Emergency situations in the operation of gas heating can occur due to various factors:

- fuel pressure drop;

- lack of fluid in the system (you can check the joints, three-way valve and pipes);

- traction deterioration;

- gas leak.

Each of the above problems is dangerous for human life, and therefore the further operation of the system is unacceptable. That is why the solenoid valve works. Its original position is open. To close it, an electrical impulse is applied to it, coming from a thermocouple installed above the flame in the combustion chamber or on the chimney.

It must be said right away that this element rarely comes out of standing position, since it has great potential for use. Despite this, moments still happen.

There are two ways to check the operation of this valve:

- Fire. The used thermocouple is replaced with a new one. The automatic button is turned on. Next, the igniter is ignited and fire is brought to the end of the thermocouple. In this case, the automation should work.

- Instrumental. The sensor is removed from the housing and a repair contact is inserted. It is supplied with voltage from 3 to 6V. If the solenoid valve is in order, the automation will work. Otherwise, you need to replace this element.

Ignition transformer

This element supplies the burner with a current discharge (spark), which is necessary for igniting the fuel. In addition to other elements that directly affect the operation of the unit, the component can also fail. As a result, all automation will work, but the fire will not appear, since there is no source for ignition.

How can I quickly check the ignition transformer of a gas boiler for operability? Just. You need to do a few simple steps:

- Through a special window, see if the discharge is going on or not.

- Using a tester, check the voltage coming out of the controller during the ignition attempt. Normal is a figure that falls in the range from 187 to 235V.

- If a problem is found, disconnect the power from the transformer and connect it back.

- Check again.

In any gas boiler, many safety elements and sensors are installed to monitor the correct operation of the unit. In the event of situations that clearly threaten human life, a system of complete shutdown of the installation is activated.

Automation for gas heating boilers Dani

By itself, automation for gas boilers is the heart of the system, with its help you start your gas equipment, the boiler provides a stable and very reliable working environment. Also, the automatic system in gas boilers guarantees completely safe and simplified operation of the equipment. The automatic boiler is easy to operate and unpretentious in maintenance. This system will help to ensure full human control of the automatic operation of the boiler. Depending on the type of boilers, there are different types of automation, which are characterized by their distinctive functions and features.

Features of automation for gas equipment

Automation for gas boilers is absolutely indispensable in the gas equipment system. It helps to produce an uninterrupted gas supply to the wick and burner, and also works and shuts off the gas supply valve in such cases:

- When the igniter goes out;

- In case of interruptions in the gas system or the cessation of gas supply;

- If the pressure in the system drops below the maximum allowable rate;

- With a complete or significant absence of chimney draft;

- In the case when the temperature of the heated water in the tank of the boiler itself is +93 degrees and above.

Where is it used and what is the difference between automatics for Dani gas systems

Automation on the Dani gas boiler is installed directly by the manufacturer. If part of the system fails, you must immediately take care of replacing the components and immediately buy the broken part. The most frequently requested parts for the Dani automatic gas boiler system are solenoid valves, thermostats, ignition pipes, thermocouples.

Automation for the Dani gas boiler makes it very convenient to regulate the temperature in the boiler, and also has all the necessary advantages characteristic of this type of product. Reliability and excellent workmanship of Dani boilers guarantee their durability and uninterrupted operation.

If your automation is out of order, you need to contact the specialists and ask them for professional advice directly at the site of the breakdown. It is strongly not recommended to redo and experiment with gas equipment on your own, because otherwise you risk not only the full and high-quality operation of the entire system, but also your health.

It is worth recalling that Dani brand boilers are the undisputed leaders of the domestic market. They have been produced for more than forty years, and during all this time they managed to prove themselves exclusively from the best side. Their automation is simple and easy to use, it allows you to control the boiler as accurately as possible, regulate the heating of water and the temperature in the entire heating system.