Roofing classic mineral wool

By mineral wool, people most often mean:

The latter is highly discouraged. The maximum where you can use insulation from the waste of the metallurgical industry is not residential buildings of enterprises.

Stone wool is used for living quarters. Although it contains resins such as formaldehyde, their percentage is still negligible, moreover, it has undergone a polymerization process. This means that the resin has found and is now in a solid state with a closed molecular structure.

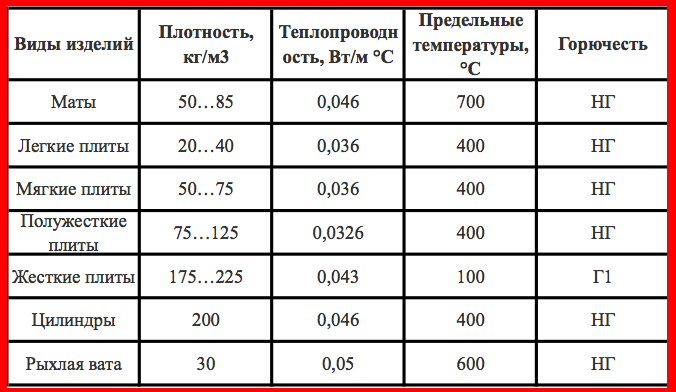

For flat roofs, as mentioned at the beginning, rigid mineral wool slabs with a density of 140-160 kg / m³ are used.

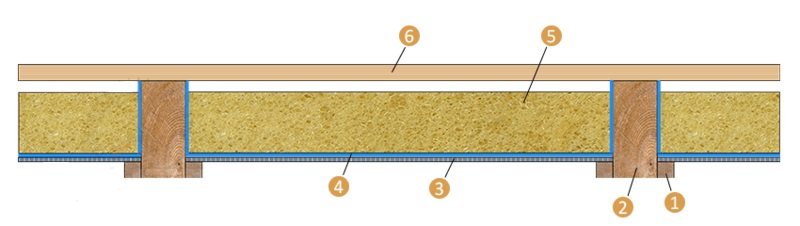

To insulate a pitched roof, soft plates are inserted between the rafters, cutting them. The same plates are inserted between the lags and covered with a protective coating on top in case of overlap. Mineral wool is most often used for roof insulation. This is due to its "breathable" structure. The fact is that any wooden structure should be well ventilated. And if a polymer insulation is adjacent to it, this procedure becomes much more complicated. That's why cotton is used. In addition, cotton wool is a non-combustible material. Being, in its essence, a kind of volcanic lava, cotton wool does not burn, I only melt, and even then at a huge temperature - above 1500 degrees.

However, the insulator is not without its shortcomings. It is associated with poor resistance to moisture. For example, if a cotton slab has a thermal conductivity of 0.036 W / m3 K, then when wet, this indicator can actually change by 2 times! And, as you know, the roof is a place where leaks can occur. In practice, this means that you will have to replace the section of thermal insulation that is wet.

Over time, mineral wool also crumbles, forming dust that can enter the room. Someone does not like this material precisely for this feature of it.

Chip - "plates in rolls"

Manufacturers are increasingly trying to facilitate the installation of insulation. Now more and more often you can find the form factor of mineral wool, which is called "slabs on a roll." Such material has sufficient density to feel good in the frame. In this case, it is enough to fix the roll in the upper part, between the rafters and roll it out below. For example, about Izover Profi, it is even stated that it does not need to be cut (it is clear that we are talking about a not very significant change in the width between the rafters), but simply tighten it and the cotton wool will take the desired shape. It is more convenient to use such rolls than to insulate with plates. Installation of plates takes more time.

When deciding how to insulate the roof of a house, most owners or developers choose mineral wool [flat_ab >

Properties of fiberglass and foam concrete

Fiberglass insulation has almost the same characteristics as mineral wool. These two materials have only two important differences:

- water absorption of mineral wool is much greater than that of ordinary;

- low resistance to high temperatures.

Scheme of roof insulation with foam concrete.

The positive aspects of using materials include:

- lightness of the material;

- low sound absorption.

Foam concrete is a fairly new material, which includes a steam generator, concrete and a mixture of sand and cement. Thermal insulation is applied by spraying between the screed and the base. For installation, you will need special equipment that allows you to well process all the cracks, cracks and seams, which will help to avoid the appearance of "cold bridges".

Typically, foam concrete is used in the construction of industrial buildings and residential skyscrapers. The material is lightweight, durable and fire resistant. The thermal conductivity of the material is quite high, so the foam concrete layer must be large enough, at least 50 cm.

The answer to the question of how best to insulate the roof of a house depends on the design of the roof itself. A pitched roof requires a different type of insulation than a flat one. There are differences for the roof of the attic. In addition to the special characteristics of the material, different types of roofs require different ways of installing insulation.

Various types of heaters

The scheme of thermal insulation of a flat roof.

Depending on the shape, heat insulators are rolled or in the form of plates. Each of these types is suitable for a specific task. It is necessary at the design stage to decide which one is best suited.

Roll materials are used for pitched and flat roofs. Roll parameters, its length and width are determined by GOST.

The heat insulator is laid between the rafters as tightly as possible. If your area experiences very low temperatures during the winter, you can apply two layers of sealant.

If the roll compactor is made of mineral material, it is very important to take into account the correct installation, since all defects, even small ones, will sooner or later turn into serious problems. The fiberglass roll seal must be dry

If moisture gets in, its quality deteriorates, and in the future it will no longer retain heat in the room, which will require repairs with the involvement of specialists

The fiberglass roll seal must be dry. If moisture enters, its quality deteriorates, and in the future it will no longer retain heat in the room, which will require repairs with the involvement of specialists.

Tiled heat insulator is made of polymeric or mineral materials. The installed width of the slabs is 61 cm. The length can be different: from 50 cm to 10 m. The slabs must be laid in compliance with all operating rules.

Types of fixing insulation.

For pitched roofs, as well as for flat roofs, there is a warming rule: the step of the lathing should be no more than 60 cm.

It is important to take into account the level of humidity in the room even at the stage of designing construction works - this will help prevent premature deformation of the material

If the installation is done correctly, then the material of the tile insulation itself is not so important: both foam plastic and glass wool are equally well suited.

Tiled insulation is more convenient to use when insulating private houses, the area of \u200b\u200bwhich is small. In this case, all roof insulation work can be done independently.

Criteria for choosing a heater for the attic

High-quality insulation allows you to make the attic suitable for year-round use

When choosing a heat insulator, it is necessary to pay attention to the performance characteristics of the materials, including comparing:

- soundproofing properties;

- ease of installation;

- moisture resistance;

- resistance to biological destruction;

- lifetime;

- profitability;

- environmental friendliness;

- fire safety.

But the main quality by which the material for insulation is evaluated is its coefficient of thermal conductivity, on which the ability to retain heat in the room depends..

From the point of view of ease of installation and use of insulation, preference should be given to universal materials. If the same heat insulator can be used for walls, roofs and floors, the insulation of all structures will last the same period.

Soundproofing properties are a particularly important parameter if the roofing is made of metal (folded roof, metal tiles, corrugated board). Gusts of wind, rain and hail make such a roof “sound”, and staying in the attic will cause discomfort.

Since the roof frame is usually made of wood, it is desirable to use a fire-resistant and non-flammable insulation.Otherwise, an accidental fire will lead to the fact that the entire attic and roof will quickly be engulfed in fire.

So that condensation does not form on the wooden structures of the truss system and gables and the insulation does not lose its thermal insulation properties due to moisture penetration, it is necessary to insulate the attic room with vapor and moisture-proof material, or use reliable hydro and vapor barrier. This affects the speed and complexity of the installation of the insulating layer, affects the preferences when choosing a material.

Insulating a flat roof

The choice of insulation for a flat roof depends on the degree of its operation. If she takes over

certain loads (snow, wind, installation, etc.), then the heat insulator is selected with high moisture resistance and a load limit of up to 250 kg per m2, while additionally a concrete screed is made on top of the heat-insulating layer.

For an unused roof, the load limit is determined by lower values, but the insulator must have good moisture resistance.

Most often, it is insulated with expanded polystyrene (ordinary foam or extruded material), foam concrete, expanded clay. Fibrous mineral heaters are used much less frequently for these purposes. As a rule, the latter are used if the installation of polymer insulation is not possible with high fire safety requirements.

Since expanded polystyrenes are characterized by flammability, in order to avoid the occurrence of fire situations, a non-combustible sand-cement screed is applied to them.

The flat roof insulation system includes:

floor slab;

vapor barrier;

insulation material laid in one or two layers;

hydrobarrier;

concrete screed (if necessary);

sloping waterproofing.

Flat roofs can be insulated both from the outside and from the inside.

The best insulation for any roof, as many years of installation practice shows, are light, non-combustible, heat-intensive, safe and durable materials. A wide range of heat insulators that meet all these requirements makes you choose the right insulation as responsibly as possible, because silence, warmth and comfort in the house depend on the right choice and high-quality installation.

Good Rockwool insulation. I've been using it for roof insulation for a long time. Similar manufacturers do not match the quality of Rockwool.

Many people advise to insulate the roof with polystyrene foam, I disagree! Styrofoam does not have sound insulation, although installation is easier than mineral wool! The only drawback of cotton wool is that it is afraid of moisture, so you also need to think about vapor barrier! And yet, cotton wool is denser than foam, but its cost is higher!

Abroad, for a long time, not all of this is used for roofing, but rigid slab polyurethanes - if about the latest generation, then these are PIR panels. For operated roofs, it’s the most durable material, even put a helicopter on it)))) not to mention the fact that it’s like a person there to clean the snow and / or service some equipment. There are still few manufacturers in Russia, the most famous brand is probably PIRRO. But people got the hang of it pretty quickly - at least those who think about the long-term benefits.

But can you tell me, if you are of course aware, are such plates suitable for facades under plaster? If they are suitable for exploited roofs, then this is also probably good for facades - such strength.

The main properties of insulation for pitched roofs

In the past, sawdust and straw were used for thermal insulation. Nowadays, there is a wide variety of heaters on the market. If manufacturers are added to the list, then there will be a huge number of names

But each development has its place, so it is important to learn how to choose the right material

To do this, pay attention to the following characteristics:

The thermal conductivity coefficient should not exceed 0.05 W/m*K.

A low density is important so that the insulation does not weigh down the roofing cake. It is allowed to use mineral wool with an indicator of 45-50 kg / m³. There are also lighter materials, such as fiberglass with a density of 14 kg / m³.

The insulation should not strongly absorb moisture, the ideal material repels liquids. For example, water does not affect the characteristics of the foam at all. But if mineral wool gets wet, then it should be replaced immediately. Wet mineral wool loses 60% of its thermal insulation properties.

Since the roofing constantly heats up in the summer and cools down at night. Such temperature changes should not affect the life of the insulation

In addition, it is important how the material tolerates severe frosts.

During heating and normal use, the thermal insulation must not emit fumes harmful to health.

One of the key requirements for insulation is fire safety. It is better to give preference to the option that does not ignite when in contact with an open fire.

The material must retain its shape over time and not fall off, leaving gaps.

The longer the insulation can last without replacement, the better.

Give preference to options designed for a period of at least 25 years.

Features of materials and devices

On a note

So, a roofing insulation must be able to maintain its thermal insulation properties for a long time, be fire, bio- and water-resistant, and not have toxic or unpleasantly smelling fumes.

How to insulate a roof with expanded clay

Warming technology - standard:

- vapor barrier layer

- insulation,

- waterproofing,

- roofing.

If there are reinforced concrete floor slabs on the roof, the implementation of thermal insulation is greatly simplified:

- gravel is poured onto the prepared slabs,

- the resulting insulation layer is compacted and covered with a screed. On the one hand, it levels the surface, on the other hand, it gives rigidity.

- a layer of roofing material is laid,

- you can lay, if desired, an additional layer of waterproofing. lay a layer of

Ventilation ducts must also be taken into account, due to which excess moisture generated during temperature changes is eliminated.

Minvata - a classic among heaters

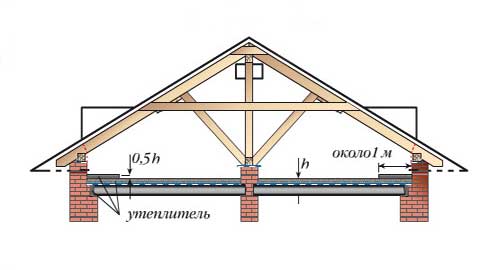

Mineral wool slabs will be securely held in the inter-rafter space if they are 2 cm wider. However, with

Then the insulation is covered with a vapor barrier film, which is pressed against the rafters with slats. To preserve the ventilation gap, which is highly desirable, the slats are nailed along the rafters. You can nail the slats and across. But in this case, in order to avoid the formation of cold bridges, an additional heat-insulating layer is installed. To do this, with a step that is 2 cm less than the width of the insulation, slats are nailed across the rafters with a thickness equal to the thickness of the insulation layer. Insulation is laid between them - mineral wool or expanded polystyrene sheets, and a vapor barrier layer is laid.

We use polyurethane foam

How to insulate the roof with foam correctly

The popularity of this material is associated with its properties:

- low weight - you can not resort to strengthening the supporting structures, installation is noticeably facilitated;

- environmental safety - hypoallergenic, there are no favorable conditions for the reproduction of mold and bacteria;

- low thermal conductivity, etc.

You can often hear doubts about whether it is possible to insulate the roof with foam. This is due to the prevailing opinion that the toxic fumes of polystyrene foam under the influence of high temperature can cause certain harm to health. However, proper insulation of the roof of a residential building requires the use of a certain brand of foam - PSB, which is considered a fireproof, self-extinguishing material.

https://youtube.com/watch?v=IVk4TePjmZU%3F

Viewing the video “How to insulate a roof with polystyrene foam”, a video tutorial, will help to more clearly present the process of insulation.

https://youtube.com/watch?v=MTIMaoYuL_A%3F

2019 stylekrov.ru

Pitched roof insulation technology

The insulation of mansard gable roofs is very different from the thermal insulation of single-pitched roofs. Because the latter have a small attic space, hence the difficulties of carrying out work from the inside. They are transferred outside from the side of the roofing. At the same time, we immediately indicate that polyurethane foam is not used in a single-pitched structure.

Thermal insulation of a pitched roof

So, how to properly insulate a shed roof:

- Along the rafters, along the ends, at the lower edges, the so-called cranial slats are stuffed along.

- Between the rafter legs, boards or any durable slab or sheet material are laid on the slats: plywood, chipboard, OSB, etc. The legs are fastened with self-tapping screws. Niches are formed.

- A vapor barrier membrane is laid on the rafter system. Installation is carried out in strips with an overlap of 10-15 cm, after which the joint is closed with a self-adhesive tape. Laying should be carried out so that the film covers the niches, emphasizing their shape.

- Insulation is being installed in niches.

- A waterproofing film is laid on top of the rafters in the same way as a vapor barrier, only stretched without sagging. Fastening to the rafters with staples from a stapler.

- Lathing installation.

- Installation of roofing material.

As you can see, warming a shed roof is not the most difficult process, so it’s realistic to do it yourself even for a person who is far from the construction industry.

Gable roof insulation

There are two possible situations here:

- The roof is already covered with roofing material.

- Not yet covered.

Let's start with the second case because it's easier.

- A waterproofing film is laid on top of the rafter legs in strips. Laying method - overlap with additional fastening of the joint with adhesive tape. The laying direction is horizontal from the eaves to the ridge. It is not necessary to pull strongly, a slight sag will provide thermal expansion or contraction of the material.

- A counter-lattice is stuffed along the waterproofing - these are bars laid along the rafters (along). They create a ventilation gap between the roofing and the insulation cake.

- The crate is stuffed.

- Roofing material is being installed.

- The rest of the processes are transferred to the attic (attic).

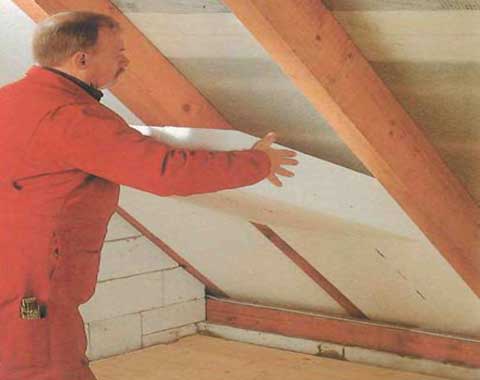

- A slab insulation is laid between the elements of the truss system. The layer (thickness) of the latter should be equal to the width of the rafters.

- The entire pitched plane is covered with a vapor barrier membrane in the same way as with a waterproofing film on top.

- Panel or sheet finishing is mounted: plywood, drywall, lining, etc.

If polyurethane foam is chosen as the heat-insulating material, then all work from the inside of the attic comes down to applying foam to the pitched plane of the roof structure. The main task is the uniformity of the applied material.

If ecowool is chosen as thermal insulation, then first a vapor barrier layer is installed from the side of the attic along the rafter system. Then holes are made in it, where a hose is inserted, supplying insulation into the space between the rafters. Thus, all areas between the rafter legs are filled. Subsequently, the holes made are sealed with tape.

I would like to draw your attention to the fact that the installation of ecowool is carried out using wet and dry technology. The first is when water is added to the material

In the case of pitched roof insulation, dry technology is used.

Styrofoam and polystyrene boards

Foam roof insulation (expanded polystyrene) is a biologically safe white material. Its advantages:

- chemically neutral;

- has high rates of air permeability (breathes);

- low coefficient of thermal conductivity, water permeability and sound permeability;

- low weight and the possibility of gluing;

- subject to the installation rules, it can last several decades;

- resistant to alcohol, alkalis and acids, not damaged by microorganisms and insects,

- work does not require special clothing.

The disadvantages of polystyrene include its flammability and high cost.

Insulation materials from plant materials

In Germany, France, Finland, Poland and the Czech Republic, insulation has long been made from hemp, flax and wood fibers bonded with polyester or starch. Recently, a similar production has been established in Russia. Insulators of this type have a capillary structure, therefore they pass both air and steam.

Properties of insulation from vegetable fibers:

- safe for health;

- have high fire resistance;

- have excellent sound and heat insulation characteristics;

- in most cases, vapor protection is not required, which makes the insulation system breathable;

- the capillary structure allows both absorbing and releasing moisture, regulating the microclimate in the room, an additional bonus is the ability to avoid wetting beams and rafters;

- these materials do not dust and do not prick;

- plant fiber material is easy to install - it fits snugly to the structure and does not require special skills during installation;

- during work there is no need for overalls;

- does not shrink during operation;

- service life - up to 60 years.

Price

The structure of the attic insulation system from the roof side remains almost unchanged when using any material - you need bars for the crate, waterproofing and vapor barrier, inner lining. This means that the cost of the entire system directly includes the cost of insulation for the attic.

The cheapest are mineral wool (from 400 rubles per cubic meter). Styrofoam is much more expensive - a cubic meter costs from 1100 to 3000 rubles. The most expensive heaters are made from vegetable fibers. A cubic meter of such material can cost more than 10 thousand rubles.

Everyone has the opportunity to choose the most suitable material, based on their own preferences and material capabilities.

2019 stylekrov.ru

Modern roof insulation

The best roofing insulation:

1. Knauf roof insulation

Knauf manufactures environmentally friendly heat and sound insulation insulation using a special ECOSE technology. The range also includes mineral wool, glass wool and expanded polystyrene.

The advantages of these building materials:

- naturalness;

- ease of use;

- no foreign smell;

- during installation emit 70% less dust;

- have a small weight;

- keep their shape for a long time;

- increase the life of the roof;

- have increased sound insulation, vapor permeability, etc.

In order to avoid heat loss through the roof of the structure, KNAUF recommends using products of the KNAUF Insulation brand Pitched roof. It is a highly effective mineral wool insulation with minimal water absorption.

The building materials of this company have various thermal technical parameters, sizes and are made in the form of plates and mats:

- Plate 037 A;

- Roll 037 A;

- Plate 034;

- Thermo Roll 034 A.

Application:

- objects of the agro-industrial complex;

- health care;

- catering establishments;

- industrial, residential and public buildings.

2. Ursa roof insulation

URSA is a European manufacturer of roofing heat-insulating building materials that never ceases to improve its products. Produces materials based on extruded polystyrene foam and staple fiberglass.

The advantages of this product:

- ease of use;

- practicality;

- profitability;

- environmental friendliness;

- versatility of application;

- resistance to chemical and mechanical influences;

- materials adhere as closely as possible to the surface;

- have a low coefficient of thermal conductivity;

- excellent sound and thermal insulation, etc.

Varieties:

- URSA M-15;

- URSA P-15;

- URSA M-11, M-11(F);

- URSA Pitched roof, Glasswool, etc.

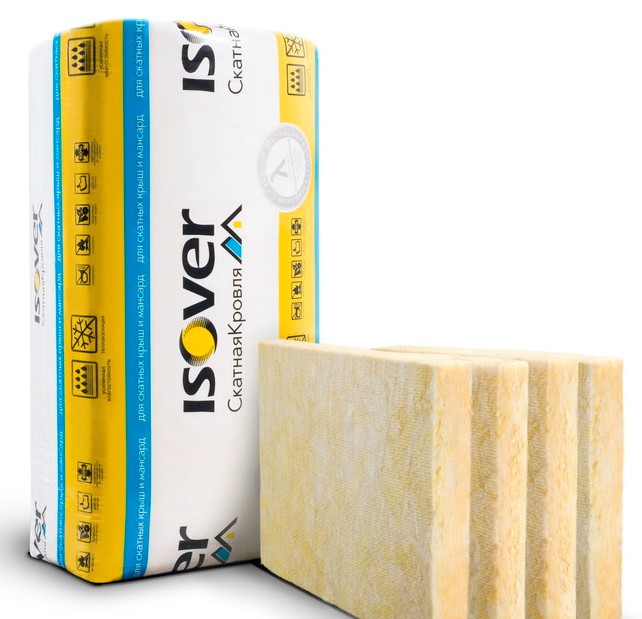

3. Izover roof insulation

ISOVER Pitched Roof is a fairly lightweight sound and heat insulating mineral wool slab, made on the basis of top quality fiberglass. The material has increased moisture resistance and is designed for buildings with a difficult humidity regime.

Advantages:

- fits quite snugly to any design configuration;

- does not involve fasteners, as it is fixed by surprise;

- is environmentally friendly;

- light and elastic;

- convenient for transportation;

- easy to install;

- durable;

- has excellent thermal insulation and low thermal conductivity;

- increased moisture resistance;

- reliable sound insulation;

- incombustible;

- bioresistant (does not rot, etc.).

Scope of use of Izover materials:

- industrial equipment;

- engineering communications and systems;

- ceilings and floors;

- suspended ceilings, wall cladding, partitions;

- roofs (flat and pitched);

- facades and walls.

Varieties:

- ISOVER Sauna;

- ISOVER Floating Floor;

- ISOVER ConcreteSlab;

- ISOVER Karkas-M, Karkas-P;

- ISOVER Stucco Facade;

- ISOVER VentFacadeBottom;

- ISOVER VentFacadeTop;

- ISOVER SoundProtection;

- ISOVER Pitched Roof;

- ISOVER Classic.

Usage of Isover Pitched Roof:

- noise and heat insulation of structures made of metal element-by-element assembly;

- sound insulation of partitions;

- sound and heat insulation of interfloor ceilings;

- sound and heat insulation of floors along the lags;

- noise and heat insulation of walls in cottage and low-rise construction;

- sound and heat insulation of mansards and all types of pitched roofs.