Classification of gas regulators

Before using a pressure reducer, you should familiarize yourself with its varieties and the main parameters by which these devices are classified.

Principle of operation

In direct-type gearboxes, the gas passing through the fitting acts on the valve with the help of a spring, pressing it to the seat, thereby blocking the entry of high-pressure gas into the chamber. After the valve is squeezed out from the seat by the membrane, the pressure gradually decreases to the operating level of the gas appliance.

The principle of operation of the reverse type device is based on compressing the valve and blocking further gas supply. With the help of a special adjustable screw, the pressure spring is compressed, while the membrane is bent, and the transfer disc acts on the return spring. The service valve is lifted and the flow of gas to the equipment is resumed.

When the pressure of the system (cylinder, reducer, working equipment) increases in the reducer, the membrane is straightened with the help of a spring. The transfer disc, going down, acts on the return spring and moves the valve to the seat.

It should be noted that domestic reverse-acting gas cylinder reducers are safer.

Mounting Features

Ramp gas regulators are needed to reduce and stabilize the pressure level of gas supplied by a single source. Devices tend to lower the working pressure of the gas supplied from the central line or a number of sources. They are used for large volumes of welding work. Network stabilizers hold the low pressure value of the gas supplied from the distribution header.

Types of working gas

Devices working with acetylene are fixed with a clamp and a stop screw, while for others they use a union nut with a thread identical to the thread of the fitting at the valve.

Housing color and regulator type

Propane regulators are painted red, acetylene regulators are white, oxygen regulators are blue, and carbon dioxide regulators are black. The body color corresponds to the type of working gas medium.

Pressure stabilization devices are available for both flammable and non-flammable media. The difference between them lies in the direction of the thread on the cylinder: in the first it is left-handed, in the second it is right-handed.

How does a cylinder reducer work?

1 Direct reducer

The usual simple gas pressure reducing apparatus consists of two chambers with an area of high and low pressure separated by a rubber membrane. In addition, the “reducer” is equipped with an inlet and outlet fitting. Modern devices are designed so that the bellows liner is screwed directly into the gearbox. Increasingly, you can find a gas reducer with a third fitting designed for mounting the monomer.

After gas is supplied through the hose and then through the fitting, it enters the chamber. The generated gas pressure tends to open the valve. On the reverse side, a locking spring presses on the valve, returning it back to a special seat, commonly called a “saddle”. Returning to its place, the valve prevents the uncontrolled flow of high-pressure gas from the cylinder.

Membrane

The second operating force inside the reducer is a rubber membrane that separates the device into a high and low pressure area. The membrane acts as an “assistant” to high pressure and, in turn, tends to lift the valve from the seat, opening the passage.Thus, the membrane is between two opposing forces. One surface is pressed by a pressure spring (do not confuse with a valve return spring), which wants to open the valve, on the other hand, the gas that has already passed into the low pressure zone presses on it.

The pressure spring has a manual adjustment of the pressing force on the valve. We advise you to buy a gas reducer with a seat for a pressure gauge, so it will be easier for you to adjust the spring pressure to the desired output pressure.

As the gas exits the reducer to the source of consumption, the pressure in the chamber of the working space decreases, allowing the pressure spring to straighten. She then begins to push the valve out of the seat, again allowing the device to be filled with gas. Accordingly, the pressure creeps up, pressing on the membrane, reducing the size of the pressure spring. The valve moves back into the seat narrowing the gap, reducing the gas filling of the reducer. The process is then repeated until the pressure equalizes to the set value.

It should be recognized that direct-type gas cylinder reducers, due to their complex design, are not in high demand, reverse-type reducers are much more widespread, by the way, they are considered devices with a high degree of safety.

2 Reverse gear

The operation of the device consists in the opposite action described above. Liquefied blue fuel is fed into the chamber where high pressure is created. Bottled gas builds up and prevents the valve from opening. To ensure the flow of gas into the household appliance, it is required to turn the regulator in the direction of the right-hand thread.

On the reverse side of the regulator knob is a long screw, which, by twisting, presses on the pressure spring. By contracting, it begins to bend the elastic membrane to the upper position. Thus, the transfer disk, through the rod, exerts pressure on the return spring. The valve starts to move, begins to open slightly, increasing the gap. Blue fuel rushes into the slot and fills the working chamber at low pressure.

In the working chamber, in the gas hose and in the cylinder, the pressure begins to increase. Under the action of pressure, the membrane is straightened, and a constantly compressing spring assists it in this. As a result of mechanical interactions, the transfer disc is lowered, weakening the return spring, which tends to return the valve to its seat. By closing the gap, naturally, the flow of gas from the cylinder into the working chamber is limited. Further, with a decrease in pressure in the bellows liner, the reverse process starts.

In a word, as a result of checks and balances, the swing can be balanced and the gas reducer automatically maintains a balanced pressure, without sudden jumps and drops.

Boiler connection diagram

The cylinders are connected to the system through a special reducer, which converts the gas from a liquid state into a gaseous state for further supply to the boiler.

Gas cylinders with separate reducers

Note! The gas flow rate through the reducer should be 1.8-2.0 cubic meters / hour, a conventional gas reducer with a flow rate of 0.8 m

cube / hour is not suitable for this system.

When connecting cylinders to the boiler, two options are used: one common reducer for all cylinders or a separate reducer for each. The latter option is safer, but also more expensive.

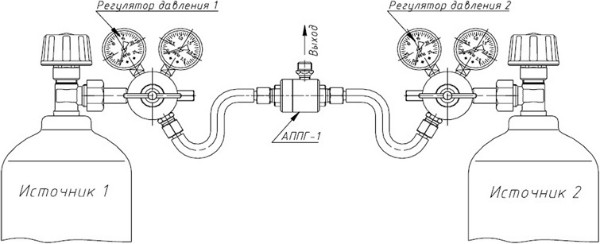

Several cylinders can be connected to the gas boiler at once, which allows you to increase the time between their refueling. For this, a ramp is used - a two-arm collector that distributes the capacities of the cylinders into two groups, the main and the reserve.

First, gas is selected from the cylinders of the main group, and when it runs out, the ramp automatically switches the boiler to the reserve group. The moment of switching is accompanied by a signal.After connecting already filled cylinders to the ramp, the boiler automatically switches to work from the main group.

Scheme of connecting cylinders to the ramp

Note! Gas cylinders are installed at a distance of at least 2 m from the boiler, but the best option for their placement is in a separate non-residential premises or an insulated gas cabinet on the north side of the house. Gas cylinders must not be exposed to direct sunlight

Gas cylinders must not be exposed to direct sunlight.

The wall thickness of the metal pipes of the gas pipeline must be at least 2 mm. In places of passage through the walls, the pipe is placed in a special case and foamed. The boiler is connected to the gas pipeline using a flexible connection, and a rubber-fabric sleeve (durite hose) is used for the reducer.

Calculation of the number of gas cylinders for heating

Types of cylinders for heating

One of the significant disadvantages of such heat supply is the constant replenishment of fuel reserves. Therefore, it is necessary to calculate in advance how many cylinders are needed for the boiler. There is no exact methodology for this. But there are a number of ways in which you can determine the approximate fuel consumption.

To determine the flow rate when heating with gas cylinders, it is necessary to familiarize yourself with the technical documentation of the boiler. It shows the fuel consumption for both natural and liquefied gas. Usually in the latter case, manufacturers give the consumption in kg / h. For boilers with a capacity of 24 kW, it is about 3.5 kg / h.

In addition, the intensity of fuel consumption is taken into account. On average, to maintain a normal temperature in winter, the heating of a private house with bottled gas works from 12 to 16 hours a day. If the heating season is about 100 days, the total consumption for a 24 kW boiler will be:

Those. on average, 1 cylinder for a heating boiler with a capacity of 50 liters per day will be needed. This is the maximum fuel consumption that can be reduced as follows:

- Installation of automation for gas supply;

- Acquisition of modern models of boilers with high efficiency;

- Insulation of the house to reduce heat loss.

But even these measures will not greatly affect fuel consumption. Almost all reviews of heating with gas cylinders indicate the relevance of installing this type of heat supply only in houses with a small area and non-permanent residence.

The table shows how many cylinders are needed for a heating boiler, depending on the area of \u200b\u200bthe house.

Number of cylinders 50 l, pcs.

These are not final numbers. For each heating system, an individual calculation is made of how many cylinders are needed for the boiler. It is also necessary to take into account the correct filling of the container. All liquid is previously removed, the weight of the empty cylinder is measured.

When filling the cylinder, you can check the level of its filling by measuring the temperature level. The area where there is a gas mixture will cool the balloon.

Heating a country house with bottled gas

To create a well-functioning piping of the heating system of a private house, as a rule, gas boilers are used. Compared to alternative heating devices, they are the most cost-effective and easy to operate. But what about those who do not have the opportunity to connect a private house to a centralized gas pipeline? In this article, you will learn whether it is possible to heat a house with gas from cylinders and how to properly set up safe heating with gas cylinders.

- What is more profitable - to use a convector or a balloon?

- Proper storage is the key to safety

- Advantages of gas-balloon heating

- Disadvantages of heating with liquefied gas

The design and principle of operation of the gas reducer.

Any propane reducer includes the following components:

- valve;

- working chamber;

- locking spring;

- pressure spring;

- membrane.

The throughput of this device depends on the degree of opening of the valve, which is affected on the one hand by the membrane and the pressure spring, and on the other by the gas and the locking spring. The higher the pressure of propane in the cylinder and the lower the flow of gas-using equipment, the closer the valve is located to the seat. Conversely, as the chamber pressure drops and the flow increases, the valve opens more. The operating parameters of a household propane reducer are determined by the stiffness of the springs and the elasticity of the membrane. Some models are additionally equipped with a valve whose shaft is connected to a pressure spring, which allows you to manually adjust the gas supply in a certain range.

The principle of operation of the device:

Modern propane reducers are sometimes additionally equipped with a safety mechanism that is triggered if the propane-butane inlet pressure is exceeded. In order to increase the level of safety, such gearboxes are usually installed on gas tanks and group cylinder installations used to gasify one or more houses. You can learn more about how autonomous heating is implemented in private households in the article: Autonomous heating with propane butane.

Types of gas reducers.

Reducers, which are used to control and regulate the pressure of various gases and their mixtures, are divided into numerous types. These devices are classified according to different criteria.

So, according to the principle of operation, two main types of these devices are distinguished:

- reverse action;

- direct action.

Depending on which containers the gearbox is mounted on and what tasks it performs, there are such types as:

- balloon;

- network;

- ramp.

Different types of reducers are used with different gases. So, there are reducers:

- for acetylene

- hydrogen;

- for oxygen;

- methane;

- propane-butane.

Different reducers not only have different operating principles, but also provide working gas pressure in different ways, have a different number of reduction degrees. So, allocate:

- single-stage devices with a spring mechanism;

- two-stage also with a spring mechanism;

- single-stage gearboxes with pneumatic mechanism.

It is worth mentioning that externally the reducers differ in color (depending on the gas for which they are used), fasteners, etc. So, for example, reducers, with the exception of acetylene, are supplied with union nuts, the thread of which is identical to the thread of the valve fitting. A feature of fastening acetylene reducers is a clamp with a stop screw.

Direct reducer.

In the case of a direct acting reducer, the gas that enters the high pressure chamber does not close, but, on the contrary, opens the valve. He, in turn, is pressed against the locking spring. The reducer membrane here plays the role of a "keeper" of the balance between the two forces: it is necessary to divert the valve from the spring and open access to gas into the low pressure chamber.

In practice, it is the gearboxes that work on the reverse principle that have achieved greater popularity. Since these devices have proven to be more reliable and easier to use. Reverse action reducers can be found on many gas cylinders.

The gas reducer in the gas supply system performs an important stabilizing function. Due to it, variable and high pressure is smoothed out to more or less constant, which ensures the normal and safe operation of the equipment.

Gearboxes are used almost everywhere when it comes to gas equipment, whether they are devices operating on combustible (methane, hydrogen, etc.) or inert (nitrogen, helium, etc.) gases. A typical household example is the gas cylinder reducer, also known as the "frog".

It is familiar to almost all owners of individual (autonomous) sources, who are forced to purchase them due to their remoteness from highways and the lack of connection to a centralized gas supply for this reason. must remain at a pressure of about 15 bar, while for consumer devices it is normal from 10 to 36 mbar.

If you do not first pass propane through the reducer, then the results of a direct connection may come as a complete surprise to you.

This applies even more so to compressed gas cylinders (eg methane at a pressure of 250 bar). "Frog" is inexpensive, and it's easier to get it than to spend money on eliminating the consequences of the disaster.

Motorists who have equipped their cars with economical gas-balloon equipment are also familiar with this device. Liquefied (or compressed) gas in such systems is also first sent to the propane-butane mixture (or methane) reducer, and only then enters the carburetor or injector.

The gas reducer finds application also in the industry. In places of transition from large highways to local networks, a significant reduction in pressure is required. Powerful and dimensional products are used here. Another example is the gearboxes for gas tanks involved in the supply of industrial facilities or human settlements.

Disadvantages of gas heating on cylinders

Like any other heating method, this one also has its drawbacks:

- if the cylinder is outside, in case of severe frost, the system may turn off - the condensate will freeze and prevent the gas from escaping;

- do not place cylinders in unventilated areas;

- since the gas is heavier than air, if it leaks, it can go down (into the basement, underground), and if there is a strong concentration, serious consequences will occur.

Thus, heating with gas cylinders, if certain conditions are not met, can be very dangerous. Therefore, they should be stored only in ventilated rooms, under which there is no basement. It is even advisable to place them in a separate extension on the site. The room must be warm so that the system does not turn off in frost. If it is cool in the annex, then you will have to make an insulated metal or plastic box for the cylinders. For insulation, the walls are sheathed with foam plastic 5 centimeters thick. Ventilation holes must be made in the lid of the box.

How to choose a household propane reducer

The choice of a device for supplying a propane-butane mixture to gas-using equipment is based on two key parameters:

Sample passport for a gas stove

The operating mode of most household propane appliances is 30 mbar, 37 mbar or 50 mbar. Based on this indicator, an appropriate gearbox is selected. If its output pressure differs from the operating parameter of a gas stove, boiler or, for example, a grill, this may lead to improper operation of the equipment and even create an explosive situation.

The characteristics of the propane reducer can be viewed on it - 3 kg / h and 29mbar

30 mbar, 1.5 kg/h (kg/h)

For stable and safe operation of the gas consumer, it is also important that its consumption does not exceed the performance of the gas reducer. At the same time, the upper level of the reducer flow rate is not standardized.

That is, for a boiler with a power of 24 kW with a mass flow rate of 2 - 2.5 kg / h, it is permissible to install a gearbox with a capacity of 3 kg / h and above - the automation of the boiler or stove will still not let the "extra" gas through.

0.45 m3 (for propane-butane)

1000 Pa - 1 kPa - 10 mbar

30 mbar - 0.03 bar

Some owners of autonomous gas supply systems make a mistake when they purchase industrial gearboxes instead of household ones, considering them to be more reliable.Firstly, such devices are much more expensive, and secondly, they are designed to work with more powerful gas equipment, so they are not always consistent with household appliances.

You should also pay attention to the type of thread of the device. Gearboxes designed to work with non-flammable gases are equipped with a right-hand thread, and with combustible gases they have a left-hand thread and a risk on the nut

Rules for the installation and operation of a gas reducer

To connect a propane reducer to gas-using equipment, two methods are used: using a herringbone fitting or using a threaded connection. The first option is considered the simplest and is often used to connect a cylinder to a gas stove. The second method is more reliable and aesthetic, in addition, it allows you to connect one propane tank to several consumers at once.

Connection via fitting

Whichever option is chosen, in the process of connecting the gas reducer and starting the system, you must follow the following instructions:

- Make sure that there are no cracks and depressions on the body, check the integrity of the pressure gauge (if any).

- Connect the device to the cylinder (gas holder). For better tightness of the threaded connection, flax or FUM tape should be additionally used.

- Connect the gas line to the outlet pipe of the reducer. When using a herringbone fitting, fix the pipe at the attachment point with a clamp.

- Slowly open the bottle valve, then turn the valve on the gas consumer.

It should be noted that the device is intended for operation in a temperate climate, therefore its use is permissible at temperatures from -15 to 45 degrees Celsius.

An example of connecting a propane reducer in a group cylinder installation

A well-made household propane stabilizer can last more than one year without serious repair intervention. Only rubber materials that lose their elasticity over time are subject to periodic replacement. You should also inspect and, if necessary, clean the bypass valve 1-2 times a year. The degree of clogging of the gas reducer directly depends on the purity of the propane-butane mixture used. For example, here you can get acquainted with the standard forms of delivery of this high purity mixture in accordance with GOST. If high quality gas is used, then the service life of shut-off and control valves and gas-using equipment will increase significantly, and the probability of sudden failures of the autonomous gas supply system will be minimized.

How a gas reducer works

Direct reducer

The diaphragm responsible for pressure regulation, under the action of the spring, begins to displace the valve from the seat surface. The pressure is reduced due to a small passage and reaches a safe, serviceable.

Further, the straightened spring allows the valve to open access to the flow of a new volume of gas from the cylinder, and the regulation process is repeated. On non-adjustable gearboxes, the spring force is set at the factory, acting as a pressure regulator.

Reverse gear

Here the principle is somewhat different. Incoming gas from the source presses the valve against the seat, preventing it from escaping. The design contains a screw, with the help of which the spring compression force is adjusted.

By compressing the spring with a screw (regulator), the safety diaphragm is bent, passing a certain amount of gas. The support disc actuates the return spring, after which the valve rises, freeing the way for the fuel.

The working chamber has the same pressure as in the cylinder. The membrane under the action of the spring returns to its original state, and the support disk moves downward, while pressing on the return spring. As a result, the valve is pressed against the body seat.

It is worth saying that many note the great popularity of reverse action gearboxes. They are safer to use.

Gas cylinders in winter

If gas cylinders are outside the house, then in winter at negative temperatures, the pressure of liquefied gas decreases, and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-combustible materials. Also for this purpose, stand-alone non-residential buildings with minimal heating are suitable. When using cylinders, the following safety precautions must be observed:

Special cabinet for installation of cylinders

- It is forbidden to warm gas containers with an open flame;

- There should not be a basement or cellar near the cylinders, since liquefied gas descends when leaking, has no smell and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the dwelling;

- Storage of empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

How and why gearboxes are used

The gas ones look no different from each other. It is customary to manufacture them, depending on the type of gas. All gases used are divided into two groups:

Many gardeners have noticed that if you need to replace an empty container to power the stove, the nut is unscrewed in the opposite direction.

Gas reducers are found in almost all spheres of our life. From industry to medicine. For welding works are used: oxygen, acetylene, argon, carbon dioxide and others.

Builders, in addition to welding equipment for roofing, use propane. All household cylinders are also equipped with propane reducers.

Medical institutions, in addition to oxygen, use nitrogen and the recently popular “laughing gas”.

We are used to seeing that gas storage tanks are made of metal. They are of considerable size and weight. But they are being replaced by containers made of composite materials.

Unlike metal cylinders, they are safer and lighter. Manufacturers claim that in case of an emergency, it does not scatter to the sides, forming a large number of traumatic fragments.

Accordingly, composite cylinders require a dedicated gearbox. Among their characteristics it is worth noting:

- the nut is screwed on with ease;

- for the gasket, a service life of 10 years is declared;

- the design ensures complete sealing.

At the moment, reducers for household gas equipment have entered our lives so tightly that we treat them with some disdain. And they are responsible for the integrity of the living space, and you can buy them at a low price.

Before buying, you should pay attention to the following:

- type of gas used;

- type of gas cylinder;

- connecting dimensions;

- is there a regulator to change the pressure;

- price.

Choosing a boiler for cylinder heating

LPG boilers

Currently, manufacturers do not produce narrow-profile heating boilers for bottled (liquefied) gas.However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing the boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if it is provided for by the design.

There are several types of gas-fired heating boilers for bottled gas, which differ in operational and technical indicators:

- Burner type - open or closed. It is best to purchase heat supply boilers on a gas bottle with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Mounting - wall or floor. Most models up to 24 kW are wall mounted;

- The number of contours. To supply heat to the dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If permanent residence is planned in the house, it is recommended to buy a two-circuit model with hot water supply.

You can pre-calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, manufacturers often give the maximum flow rate at the maximum power of the equipment. The lower the intensity of the burner, the less fuel will be consumed.

The best performance indicators are gas-fired heating boilers on bottled (liquefied) gas with a cast-iron heat exchanger. It will last much longer than steel.

Gas connection

If you are an amateur, your actions can lead to a serious accident.

What you should pay attention to when connecting to the gas supply:

- installation of shut-off valves - a gas valve that will shut off the supply;

- a gas filter is installed behind the tap according to the relevant standards;

- through the filter, a pipe from the boiler, strictly metal, is connected to the line. It is preferable to use a flexible corrugated stainless steel pipe in this capacity;

- the pipe is connected to the corresponding boiler outlet using a union nut with a paronite seal;

- the joints of the elements must be hermetically sealed. To seal these areas, tow and paint or their modern counterparts are used. Synthetics are excluded.

To check the tightness of the gas connection, the connections are moistened with soapy water and look for bubbles.