composition of antifreeze.

The antifreeze/coolant concentrate consists approximately of the following components:

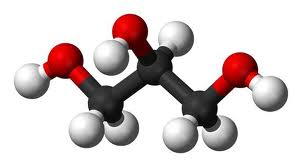

- 93% to 95% ethylene glycol or propylene glycol

- from 2% to 5% additive package

- 1% to 3% percent water

Glycol is present to lower the freezing point and raise the boiling point of the coolant. A small amount of water is either contained in the additives used or added to improve the mixing of the products. It allows the additives to dissolve better in the glycol and prevents sedimentation during storage.

Additives used in the production of coolants have a major impact on the final quality of antifreeze, its properties and service life.

The quality of the additive package components themselves, the correctness and completeness of their selection, and the implementation of technological mixing processes are very important. In cheap coolants, these conditions are often not met.

Gradation of additives according to their functions.

Buffer Additives:

Additives or chemicals - phosphates, borates, or salts of organic acids.

The effect is to maintain proper pH, neutralize acidic materials that enter the coolant.

Corrosion inhibitors:

Additives or chemicals - nitrates, silicates, mercaptobenzothiazole (yellow metal protection additive), tolyltriazole (yellow metal protection additive), and organic acid salts.

The effect is to prevent corrosion of various metals in the cooling system.

Anti-cavitation additives:

Additives or chemicals - nitrites and molybdates.

Advantages and effect - especially effective in cast iron cavitation, corrosion protection.

Defoamers:

Additives or chemicals - Polyglycols and silicones.

The effect is to prevent the formation of stable foam which can lead to heat dissipation/corrosion problems.

Deposit and scale control:

Additives or chemicals - phosphonates and water-soluble polymers such as polyacrylates.

Effect - Prevents the accumulation of scale or deposits on the heat transfer surface.

Antifouling:

Additives or Chemicals - Low foaming surfactants/detergents.

The effect is to prevent the accumulation of oil products and dirt, which block heat transfer and promote corrosion.

What is the difference between G12 and G11, G12 and G13

The main types of antifreezes, such as G11, G12 and G13, differ in the type of additives used: organic and inorganic.

General information about antifreezes, what is the difference between them and how to choose the right coolant

Cooling class G11 liquid of inorganic origin

with a small set of additives, the presence of phosphates and nitrates. Such antifreeze was created using silicate technology. Silicate additives cover the internal surface of the system with a continuous protective layer, regardless of the presence of corrosion areas. Although such a layer protects already existing centers of corrosion from destruction

. Such antifreeze has low stability, poor heat transfer and a short service life, after which it precipitates, forming an abrasive and thereby damaging.

Due to the fact that G11 antifreeze creates a layer similar to scale in a kettle, it is not suitable for cooling modern cars with radiators with thin channels. In addition, the boiling point of such a cooler is 105 ° C, and the service life is no more than 2 years or 50-80 thousand km. run.

Often G11 antifreeze turns green

or blue colors

. This coolant is used for vehicles manufactured before 1996

years and machines with a large volume of the cooling system.

G11 is not well suited to aluminum heatsinks and blocks as its additives cannot adequately protect this metal at high temperatures.

In Europe, the authoritative specification of antifreeze classes belongs to the Volkswagen concern; therefore, the corresponding VW TL 774-C marking provides for the use of inorganic additives in antifreeze and is designated G 11. The VW TL 774-D specification provides for the presence of organic-based carboxylic acid additives and is labeled as G 12. The VW TL 774-F and VW TL 774-G standards mark the G12 + and G12 ++ classes, and the most complex and expensive G13 antifreeze is regulated by the VW TL 774-J standard. Although other manufacturers such as Ford or Toyota have their own quality standards. By the way, there is no difference between antifreeze and antifreeze. Tosol is one of the brands of Russian mineral antifreeze, which is not designed to work in engines with an aluminum block.

It is absolutely impossible to mix organic and inorganic antifreezes, since a coagulation process will occur and as a result a precipitate will appear in the form of flakes!

A liquid grades G12, G12+ and G13 varieties of organic antifreeze

Long Life. Used in cooling systems of modern cars

manufactured since 1996 G12 and G12+ based on ethylene glycol but only G12 plus involves the use of hybrid technology

production in which silicate technology was combined with carboxylate technology. In 2008, the G12 ++ class also appeared, in such a liquid, an organic base is combined with a small amount of mineral additives (called lobrid

Lobrid or SOAT coolants). In hybrid antifreezes, organic additives are mixed with inorganic additives (silicates, nitrites and phosphates can be used). Such a combination of technologies made it possible to eliminate the main drawback of G12 antifreeze - not only to eliminate corrosion when it has already appeared, but also to perform a preventive action.

G12+, unlike G12 or G13, can be mixed with a G11 or G12 class liquid, but still such a “mix” is not recommended.

Cooling class G13 fluid

has been produced since 2012 and is designed for automobile engines operating in extreme conditions

. From a technological point of view, it has no differences from the G12, the only difference is that made with propylene glycol

, which is less toxic, decomposes faster, which means causes less harm to the environment

when it is disposed of and its price is much higher than the G12 antifreeze. Invented based on the requirements to improve environmental standards. G13 antifreeze is usually purple or pink, although it can actually be dyed in any color, since it is just a dye on which its characteristics do not depend, different manufacturers can produce coolants with different colors and shades.

The difference in the action of carboxylate and silicate antifreeze

Types of antifreeze for heating

Antifreeze for heating is based on aqueous solutions of ethylene glycol and propylene glycol. These compounds in their pure form are quite aggressive media for heating systems. However, there are special additives to protect against corrosion, the appearance of foam, scale, damage to individual elements of the network and fittings.

These additives significantly increase the thermal stability, which is provided in the temperature range from -70 to + 110 °C. The absence of thermal degradation is noted even at a temperature of + 165 - + 175 ° С.

Antifreeze in the heating system reacts normally to materials that are used in heating networks:

- rubber;

- elastomers;

- plastic.

Ethylene glycol antifreeze

Domestic antifreezes for heating systems, which are widely represented on the market, are based on ethylene glycol.

They are manufactured in the following versions:

- freezing point in - 30 ° С;

- freezing point at - 65 ° С.

Filling the heating system with antifreeze begins with the preparation of the solution. To do this, it must be diluted with water with your own hands.The price of ethylene glycol is low, so antifreeze based on it is usually not very expensive.

A significant disadvantage of ethylene glycol is its high toxicity both when it comes into contact with the body and when inhaled fumes. The lethal dose of this substance for humans is 250 ml.

This disadvantage limits the use of ethylene glycol based antifreezes in double-circuit heating networks, in which the coolant can enter the hot water circuit. Therefore, the use of such antifreezes is limited only to single-circuit heating systems.

propylene glycol antifreeze

At the end of the last century, non-toxic antifreezes, which were made on the basis of propylene glycol, entered the markets of Western countries. The advantage of these antifreezes is complete harmlessness.

This quality is the most important for double-circuit heat supply systems. These antifreezes also appeared on our market. The instruction allows them to be used at temperatures up to -35 °C.

Propylene glycol is an E1520 approved food additive that is often found in confectionery as an agent that aids in softening, moisture retention and dispersion.

Triethylene glycol antifreeze

At high operating temperatures (up to 180 °C), antifreezes based on triethylene glycol are used. This substance has high temperature stability. However, such coolants are not products for wide use. Typically, triethylene glycol antifreezes are used in special heating systems in which antifreeze heating radiators are also designed for high temperatures.