The duration of commissioning work when starting heating in microdomains

- commissioning tests in operating conditions, balance experiments (setting optimal modes, testing valve control in manual and automatic modes, checking automation settings, identifying shortcomings and working out proposals for their elimination), the result is an act of individual tests;

- comprehensive testing (72 hours of continuous operation for all main equipment, 24 hours for heating networks), its beginning is the time when all systems are started at maximum load.

Some companies document all activities related directly to the preparation and testing of devices in a separate document - the Commissioning Methodology, which comes as an addition to the Program. In the Program, they include more general things of an organizational nature.

That is, there is an actual division of the entire complex of works into organizational, legal and technical components.

According to Decree of the Government of the Russian Federation of May 23, 2006 No. 307 “On the procedure for providing public services to citizens”, the requirement for a public heating service is uninterrupted round-the-clock heating during the heating period. The permissible duration of a heating interruption is not more than 24 hours in total within one month.

In case of non-provision of utilities or provision of utilities of inadequate quality, the consumer notifies the emergency dispatch service of the contractor or another service specified by the contractor. A notice of non-provision of utilities or provision of utilities of inadequate quality can be made by the consumer in writing or orally (including by telephone) and is subject to mandatory registration with the emergency dispatch service.

As a rule, the involved specialized organization issues a technical report within one month. proektoved.com Commissioning of heating systems Before commissioning a heating system, it is necessary to perform a number of preparatory work, test and establish the interaction of various units with each other. All this is included in the commissioning of the heating system, the purpose of which is to identify and eliminate shortcomings and errors made during installation, as well as bringing the entire system in line with the standards established for it.

As a result of these works, the client receives a reliable, productive and efficient system. The cost of heating commissioning is fully paid off by the subsequent trouble-free operation and safety of the equipment. Composition of commissioning works

Commissioning works are carried out after installation.

The following types of test work are carried out as part of the commissioning of refrigeration supply:

- verification of the correct assembly of all components and components of refrigeration equipment;

- filling the cooling system with all the necessary working media (freon, nitrogen and oil);

- verification of the functioning of the means of protection and control;

- starting the system and bringing it to the required operating mode;

- instruction (and, if necessary, training) of service personnel.

Important! The last item can be included in the commissioning program only upon agreement with the customer. The procedure for putting heating and heat supply systems into operation heated rooms

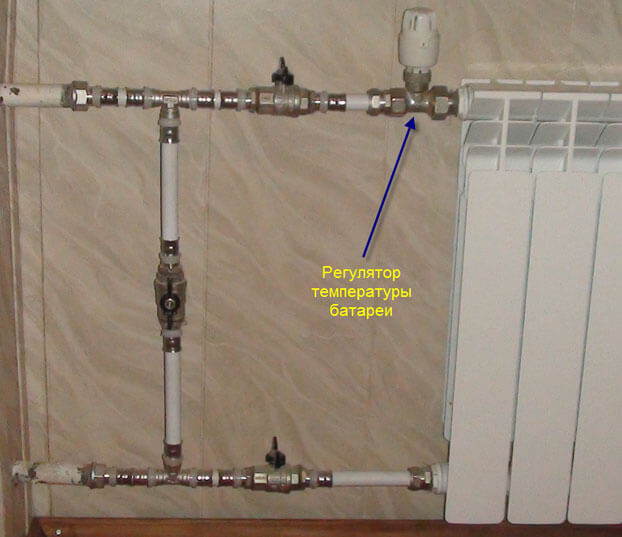

Works on adjusting heating with shut-off valves

Throughout the process, the water entering the system must have a constant temperature. As a rule, regulation is carried out according to temperature differences by changing the volume of water supplied, which depends on the type of heating system and the thermal input.

Temperature drops depend on the volume of water consumed and this value is inversely proportional. Thus, in order to increase the difference to the required value, it is necessary to reduce the flow rate of the coolant. To do this, either cover the valve located at the input, or reduce the flow itself.

The more water passes through the heating devices, the higher the speed of its movement and, accordingly, the coolant cools less. As a result, the average temperature in the radiator rises and the heat transfer of the device increases. After completion of the adjustment in the thermal unit, separate risers of the structure are subject to adjustment. In case of problems, repairs are carried out so that control valves for the heating system on the risers or balancing valves can be used (for more details: “Control valves for heating radiators, valve installation“).

One of the ways to adjust the heating system is shown in the video:

When there are only taps on the heating risers, only preliminary adjustment is made. At the same time, it is taken into account that the closer the riser is to the input, the more the tap should be slightly opened. This is necessary so that the shut-off valves for heating at the nearest riser pass a minimum amount of water.

At the same time, on the riser located farthest, you need to open a tap, such as in the photo. First, they check the quality of heating of the farthest riser in terms of location and finish with the one that is closest.

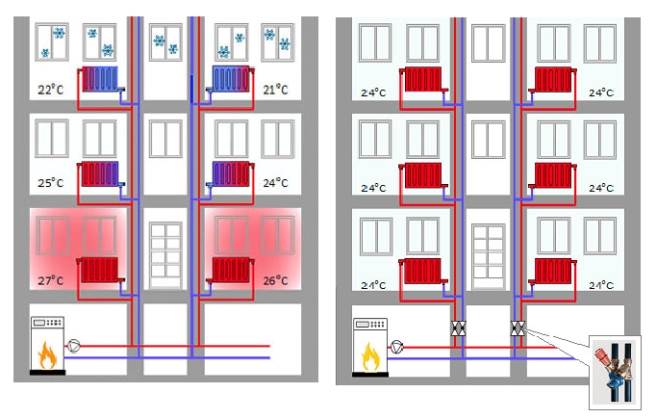

Usually, in two-pipe systems, appliances on the upper floors overheat due to pressure. If this drawback is not present on the lower floor, then adjustment of the upper heating radiators is necessary. In the presence of a double adjustment valve, it is possible to reduce the flow area. In the absence of such taps, the heating batteries are adjusted by installing throttle washers.

In two-pipe heat supply systems, the uniformity of heating of radiators will increase with an increase in water consumption. The most important parameter for heating structures is the operating pressure (read: “Losses and pressure drops in the heating system - we solve the problem“). To lower it, use a pressure regulator in the heating system, and to increase it, use circulation pumps.

The temperature of the heat carrier during the regulation of the device cannot exceed 50-60 °C. After completing the adjustment, the water temperature must be brought to 90 ° C, and the heating of the radiators should be checked again at this temperature regime. It is advisable to seek the service of specialists to adjust heating systems.

Recalculation for heating when adjusting the heating system

The purpose of individual tests is preparation for complex testing in the presence of a working commission.

Complex tests are actions carried out after the acceptance of the mechanisms by the working commission, and directly the complex testing itself. At the same time, the interconnected joint operation of all installed equipment is checked at idle, then under load, after which the technological regime provided for by the project is reached.

Although this is not prescribed by law, in recent years, more and more often, the customer requires that a commissioning program be drawn up for testing work.

This gives confidence that not a single nuance will be missed, and the operation of all systems will comply with the approved standards and project documentation.

Ways to adjust the heating system

It often happens that errors made during the installation of the heating system can only be detected after the equipment is put into operation. Among the causes of failures in the heat supply of the house is the incorrect determination of the required amount of coolant. When there is little liquid in the system, the room will be cold, and if there is a lot, the air overheats and does not pass into other rooms.

To adjust the operation, adjustment of the heating structure is required. If it is not done, then the life of the equipment will be significantly reduced.

The heating system is adjusted using one of two methods:

- in a qualitative way - by changing the temperature of the coolant;

- in a quantitative way - with it, the volume of the liquid is changed.

Qualitative adjustment is carried out on the heat source, and quantitative - directly on the heating structure. Before proceeding with its implementation, the volume of the consumed liquid and the temperature of the coolant are determined using special devices for this - a water meter and a flow meter.

When there are no such devices, then the actual flow rates are compared with the calculated data. Most often, two-pipe heating systems are installed that can provide warmth and comfort in the house. You will also need shut-off and control valves for heating.

What are the types of heating systems in an apartment building

Depending on the installation of the heat generator or the location of the boiler room:

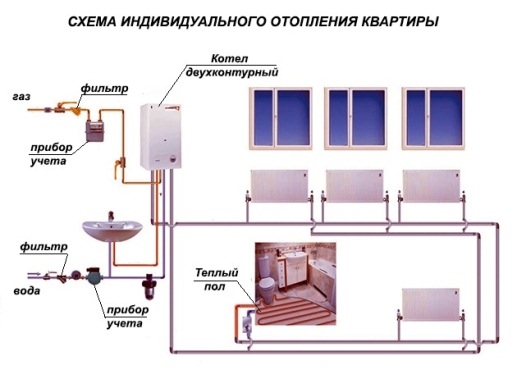

- An autonomous system in an apartment where the heating boiler is installed in a separate room or in the kitchen. The cost of buying a boiler, radiators and related piping materials is returned quickly, since such an autonomous system can be adjusted based on your own considerations regarding the temperature regime in the house. In addition, an individual pipeline does not lose heat, but on the contrary, it helps to heat the premises, as it is laid around the apartment or house. An individual boiler does not need to be adapted for the reconstruction of centralized heating - once drawn up and implemented, the heating scheme will work for a lifetime. And, finally, the already working circuit can be supplemented in parallel or in series with circuits, for example, a “warm floor”;

- An option for individual heating, which is designed to serve the entire apartment building or an entire residential complex, is a mini-boiler room. Examples include old boiler houses serving the quarter, or new complexes for one or more houses on different energy sources - from gas and electricity to solar panels and thermal sources;

A centralized heating scheme in a multi-storey building is the most common working solution to the problem so far.

Heating schemes depending on the parameters of the working fluid:

- Heating on ordinary water, in the pipes of which the coolant does not heat up above 65-70 0 C. This is a development from the field of low-potential systems, but most often old schemes work with a working fluid temperature reaching 80-105 0 C;

- Heating is steam, where not hot water moves in the pipes, but steam under pressure. Such systems are a thing of the past, and today they are practically not used in the delivery of heat and heating of any type of apartment buildings.

Based on the piping diagram:

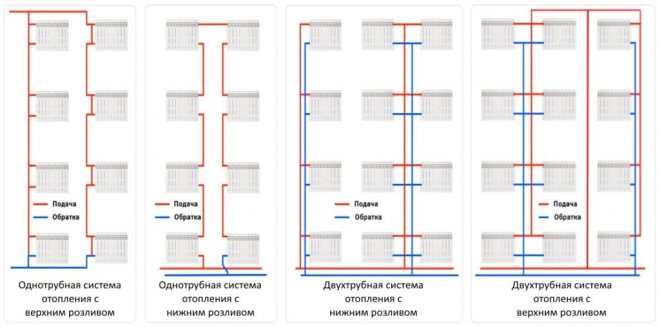

- The most common is a single-pipe heating system for a multi-storey building, where both the supply pipes and the return pipes are one line of the heating main. Such a scheme can still be found in "Khrushchev" and "Stalinka", but in practice it has a big drawback: batteries or radiators connected in series in the circuit do not provide uniform heat transfer - each next heater will be a little colder, and the last radiator in pipeline will be the coldest.For at least approximately the same distribution of heat throughout the premises, each next radiator in the circuit must be equipped with a larger number of sections. In addition, in a single-pipe heating scheme in a five-story building, it is impossible to use radiators that do not meet the design parameters, and devices for adjusting heat transfer - valves, etc. regulation;

- The Leningradka scheme is a more advanced solution, but according to the same one-pipe scheme. In this scheme, there is a bypass (pipe jumper), which can connect or disconnect additional heating devices, thereby regulating heat transfer in the room;

A more advanced two-pipe heating system in an apartment building began its existence with the construction of buildings according to the project of the so-called Brezhnevka - a panel house. The supply and return in such a scheme work separately, so the temperature of the working fluid at the inlets and outlets of the apartments of a 9-storey building is always the same, as in radiators or batteries. Another plus is the possibility of mounting an automatic or manual control valve on each heating device;

The beam (collector) scheme is the latest development for non-standard housing. All heaters are connected in parallel, and given that this is a closed oo system in an apartment building, the piping can be made hidden. When implementing a beam scheme, all control devices can limit or increase the heat supply in a dosed manner.

Commissioning of heat supply

According to the importance of the procedure, the commissioning of heat supply can be compared with the installation of equipment or design. At the time of launch, all its components are controlled, as well as the readiness of the equipment, its effectiveness and productivity.

Crimping as a fundamental stage in the preparation of the heating system

When the main phases of the installation process are completed, you need to do commissioning work - check the heating efficiency, its serviceability, and also bring the equipment to working performance. Crimping is considered one of the initial stages of the NDP of heat supply. This procedure provides comfort for living in a room in which the heating system functions correctly.

Crimping consists of the following sequential steps:

- Checking communications with excess pressure;

- Pump testing;

- Checking the reliability of pipelines is a fundamental stage of heat supply commissioning, which is considered mandatory;

- Monitoring the tightness of pipe coils;

- Hydraulic checks.

Pressurized communications are left under pressure for a day

It should be noted that during a temperature drop, the load in them will slightly decrease - do not be afraid of this. This is a traditional physical process when, when a substance cools, it contracts.

Even a person who does not have much knowledge in this area can cope with the commissioning of heat supply - the procedure is simple and does not require specific abilities.

Test run for commissioning heating systems

The heating system is tested before the heating period begins. Before filling the pipes with water, they must be washed. During the process, very small particles of metal and polymeric materials are removed, stuck during pipe processing.

The run of the liquid during the commissioning of heat supply is done according to the schedule for the start of work on heating. The test is performed at a temperature of 60-70 degrees, depending on the period of the year: frozen pipes must be warmed up in advance.

The duration of the test is 7 hours, and the test of the equipment should show good results. All fittings must withstand the test load: this means that the pipes are ready for continuous operation.

Having launched test testing, the basement floors of the building are controlled. Specifically, problems may arise due to the difference in pressure indicators.For the release of air during the commissioning of heat supply, specialized opening devices are used, by means of which the remnants of the emerging substance are removed.

The final step is to check the boiler and adjust it, after which we proceed to the use of heating in full.

Commissioning of electrical equipment

The need for heating

The need to heat your own home has always existed, but the ways to achieve this goal were very different. For more than one hundred years, classic Russian stoves have been used in Russia, and fireplaces appeared a little later. Traditional heating structures have been replaced by modern devices and heat supply systems that surpass their predecessors in quality and efficiency.

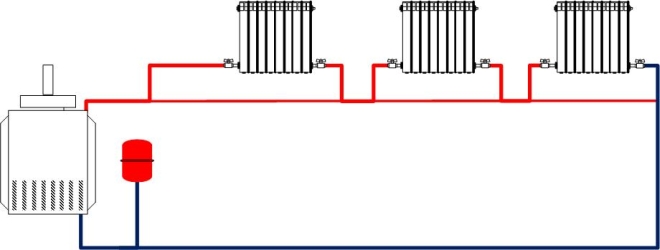

Currently, the heating system is a structure, which, as a rule, consists of the following main elements:

- heating boiler;

- pipeline;

- heating appliances.

Inside the heating system is a coolant. In most cases, water is used to heat private households, since in the event of a leak, it does not pose a danger to people and the environment from an environmental point of view. Of all types of liquid heat carriers, it is water that accumulates heat best of all and, when cooled, gives it away.

In addition, it flows well and moves almost instantly inside the elements of the system. Water is always available in the water pipes and can be added to the heating structure at any time.

The operation of the system is to move the hot coolant through it with the help of a circulation pump. Water is first heated in the boiler, and then distributed through pipes, from which it enters the radiators.

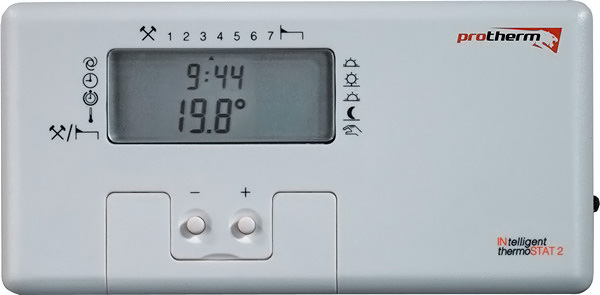

How to adjust the temperature

Important! It is impossible to adjust the pressure using thermostats, since they limit the flow of water only in one section of the system, without affecting its general condition and heating of the remaining risers

Adjustment Methods

- Adjustment of each valve and temperature measurements after each adjustment of their position;

- Dividing the system into modules and adjusting them separately. In this case, each section of the room receives its share of the total heat given off by the system.

Before balancing, the heating system is diagnosed by opening all shut-off valves and a test run; in this way, it will be determined in which part of the circuit the imbalance has occurred.

- Coolant flow and pressure regulators;

- Balancing and bypass valves.

The necessary adjustment components are installed based on the type and complexity of the system. So, with a single-pipe circuit, ordinary taps will suffice. Balancing the heating system in this case is carried out by simply twisting them until the desired temperature is reached. Two-pipe circuits require balancing valves. Firstly, they provide more precise adjustment, and secondly, they allow you to connect a special device to measure the characteristics of the coolant supply - pressure, flow and temperature.

We set up the heating system of a country house on our own

In my previous article, I wrote that one of the effective ways to upgrade heating systems in private buildings is to switch from an open heating system to a closed one. The heating system of a residential building improved in this way has many advantages, which together ensure its simple operation, you just need to turn on the boiler at the beginning of the heating season and turn it off at the end. Everything!

However, in order for the heating system of a country house to work in this mode (turned on, “forgotten” for six months, turned off), you need to correctly configure and adjust its operating parameters. This is what will be discussed in my article. I will make the main calculations, conclusions and calculations using the example of my heating system, but the reader can always use this information by drawing an analogy with his specific case.

NDP heating systems

Commissioning of the company you have chosen;

- whether they have relevant experience;

- terms of service and warranty.

In this case, the following requirements must be met:

- Activities related to the commissioning of engineering systems (including the commissioning of air conditioning systems) must be carried out within the time limits established by the standards.

- The commissioning of the equipment is carried out under strict control by the contractor's specialists.

- Upon completion of the entire commissioning complex, you should receive a documented guarantee of their high-quality implementation.

- The guarantee for them is provided from the moment of the final commissioning of the facility.

Commissioning tests are understood as works performed on already installed (mounted) equipment, ready for start-up and commissioning.

Attention

Home » Heating » Commissioning of heating systems Commissioning program During the implementation of many projects, capital construction or reconstruction of buildings and structures is carried out with the installation of new equipment or specialized processes. Such works include the installation of fire extinguishing systems, power supply, air conditioning, ventilation, fire alarms.

1. Responsibilities of the customer

Implementation of general, operational and technical management of the quality of construction, installation, adjustment and testing of equipment; carrying out pre-launch and launch operations on equipment, units and unit; work of acceptance commissions; elimination of defects in equipment, construction and installation.

Ensuring the organization and conduct of pre-installation inspection of equipment and apparatus.

Ensuring commissioning works at all stages:

— financing of works;

— qualified operating personnel (starting with unit testing);

- working means and materials in the required quantities;

— exemplary devices, design and factory technical documentation.

Ensuring the safety of equipment and installations, the experimental control system, as well as documentation, equipment and apparatus of organizations involved in commissioning at the power unit and a regime that excludes access by unauthorized persons.

Provision of personnel of commissioning and research organizations with service and laboratory premises, housing and other household services.

Development, together with the general contractor, of measures to ensure safe working conditions, and the adoption of a general measure for safety and fire safety at the power unit.

The duration of commissioning work when starting heating in micro-districts

Important

Flushing of heat consumption systems is carried out annually after the end of the heating period, as well as installation, overhaul, maintenance with the replacement of pipes (in open systems, systems must also be disinfected before commissioning). Systems are flushed with water in amounts exceeding the calculated flow rate of the coolant by 3-5 times, while complete clarification of the water should be achieved.

When carrying out hydropneumatic flushing, the flow rate of the air mixture should not exceed 3-5 times the calculated flow rate of the coolant. For flushing, tap or process water is used.

Connection of systems that have not been flushed, and in open systems flushed and disinfected, is not allowed. Diaphragms and nozzles of hydraulic elevators must be removed during flushing of the heating system.

After flushing, the system must immediately be filled with coolant.

Commissioning of heating systems

Before you put the heating system into operation, you need to do a number of preparatory work, carry out checks and establish the mutual action of a variety of units with each other. All this is included in the commissioning of the heating system, the purpose of which is to detect and remove the minuses and errors made during installation work, and also bring the entire system in accordance with the standards established for it. As a result of these works, the customer receives a good, productive and effective system. The cost of adjustment and start-up of heat supply is fully reimbursed by the next trouble-free operation and safety of the equipment.

Scope of work on commissioning and start-up

- Commissioning works are done after installation work has been carried out. They include:

- Connecting the boiler to the gas main (if a gas boiler is used);

- Setting up security systems;

- Installation of an electric voltage stabilizer and connection of the boiler to it;

- Coordination of the operation of the boiler and indirect boiler (if used);

- Connection of thermal converters and their adjustment;

- Testing and pressure testing of heating systems;

- Filling the system with a heat carrier;

- Bleeding air from the system and balancing it;

- system start-up;

Upon completion, a report is drawn up on the commissioning of the heating system, which lists the scope of work performed and draws conclusions regarding the subsequent operation and improvement of the equipment.

The essence of the processes of checking the system and its launch

As you can see, commissioning consists of a huge number of operations, very important of which are related to testing the heating system. Let us consider in more detail one of the main stages of commissioning - pressure testing of the system. It should be performed to detect all suspected areas of leakage. The essence of the procedure is to inject water or air into the system under pressure, a couple of times higher than the working pressure. During crimping, all connections must be checked very carefully.If air is used during the test, the joints of the pipeline must be smeared with a soap-based solution.

Another stage of verification is thermal testing of the system. Its purpose is to warm up all radiators with water at a temperature of 60-70 0C for 7 hours. At the same time, the degree of heating of the radiators, the temperature of the heat carrier at the outlet and inlet to the boiler, and the air temperature are monitored. If all the indicators are as close as possible to the design ones, the system has successfully passed the thermal testing. If not, then the next adjustment is performed. Before filling the system with test water, it should be flushed to remove equipment preservation agents and other debris from the pipes.

To start the system, you need to fill it with a heat carrier, bleed the air and put the boiler into operation. To fill the system with a heat carrier, a make-up valve is opened, the location of which can be found in the documentation for the equipment for the boiler room. When the system pressure can reach the required value, the valve is closed and the boiler is started for the first time. After turning on the circulation pump, air should be bled from it by slightly unscrewing the screw in the very center. When water flows from under the screw, it must be rolled up to the end. Then the electronics will start up all the boiler systems, and for some time the air will be removed from the system, which will be reported by gurgling sounds. When the system is getting better, you need to check the pressure, and if necessary, bring it to normal by replenishing the amount of heat carrier.

After the first start-up of the heat supply, you can adjust the system using taps to adjust the heaters. It is necessary to ensure that the energy of the heat carrier is sufficient to heat the last heater in the circuit. Such an adjustment can take a couple of days and is carried out already during operation. There is no need to worry about this, because in general the system has already been debugged and does not stop working in normal mode.

2. Responsibilities of the lead commissioning organization

3.2.1. Ensuring the implementation of their volumes of commissioning work on equipment in accordance with the agreed distribution of volumes between the involved commissioning organizations.

3.2.2. In addition to performing your scope of commissioning:

- distribution of the volume of adjustment work (when drawing up a coordination plan);

— coordination of actions of all participants in commissioning works: development of engineering support for commissioning works, participation in the development and approval of a combined schedule of construction, installation and commissioning works, development or coordination of work and technical programs for commissioning works in accordance with the instructions in Annex 3, participation in the formation of consolidated commissioning teams, including selection from its composition of a number of node foremen;

— monitoring the results of commissioning by all participants, participation in the work of acceptance committees;

- ensuring round-the-clock duty of leading specialists to provide operational technical assistance during the start-up operations on the equipment;

- submission for consideration of the launch headquarters of questions and proposals relating to the organization and progress of construction, installation and commissioning;

- generalization, together with co-executing organizations, of the results of commissioning and, on their basis, prompt issuance to the customer, design organizations and manufacturing plants (in a copy - to the relevant central offices) of proposals for improving the technology, schemes, modes and designs of equipment and monitoring their implementation;

- summarizing the experience of operating similar equipment and issuing a proposal to the customer for implementation;

– development together with the customer of instructive and technical documentation.

Head commissioning organization together with the customer bears the main responsibility for the timing and quality of commissioning and commissioning of equipment.

3.2.3. The instructions of the head commissioning organization regarding the technology and the timing of commissioning are obligatory for all organizations involved in the admission of equipment.

3.2.4. The main form of activity of the head commissioning organization is the conclusion by it of a single contract for the implementation of the entire complex of commissioning works with the involvement of other commissioning organizations on a subcontract basis.

3.2.5. Additional performance by the commissioning organization of the functions of the "head" is paid in accordance with the "Regulations on the relationship of organizations - general contractors with subcontractors", approved by the Decree of the USSR Gosstroy and the USSR State Planning Committee dated 03.07.87, No. 132/109 and the contract with the customer.

3.2.6. In the absence of a head commissioning organization, its functions in terms of distribution, control and coordination of work are performed by the customer or, when the facility is delivered on a turnkey basis, by the general contractor.

Conclusion

When drawing up a project for heating, do not forget that the estimate for the installation and connection of centralized heating to an apartment building differs from the cost of organizing an autonomous system downwards.

Without high-quality installation of heating equipment, it is impossible to create conditions for staying in the building during the cold season. Each owner of a private house should have an idea of how the heating system is adjusted, otherwise it will not be possible to provide comfortable conditions for rest and sleep for family members.