Expert answers

Michael:

Shitty plumbers tried .... but in general it was necessary not to metalloplastic, but to put plastic (cook it without threaded connections). . what is the question then? if nothing can be done, everything is sewn up and you don’t want to unzip, what are you asking? You can connect, that's all I can say ...

******:

Certainly. I have so. Stand is polypropylene. And I myself redid the wiring to metal-plastic. Advice to you - let the place of the leak be more carefully wound with a fum tape (or replace the rubber gasket) and tighten it well. Something dawned on me - perhaps you have a leak not at the place of the mechanical connection, but simply the polypropylene pipe itself is soldered to the marriage. (here it oozes)

Mongolian muzzle:

it all depends on the connection, if the so-called "American" then it's just a disease due to thermal expansion, otherwise my advice is to change everything to polypropylene, less hassle,

Vladimir Yakovlev:

Of course you can and the problem is in the connection itself

Michael:

select the necessary adapters and connect, it flows due to an incorrect connection, and not because of the pipes

Nikolay Ermolovich:

It is possible but through the adapter PIPE METAL - PIPE PLASTIC this is for water, but we must remember that for hot water and for a cold pipe they are different, that is, they are marked with their markings. For sewerage, their own adapters with rubber seals, even for different diameters. for ventilation, without any problems at all, if the pipe connection is closed with gypsum, that is, so that the connection cannot be reached later, then it is better to connect it also through a special insert using clamps. if the connection is easy to reach, then it is wrapped with a wide electrical tape; if it comes off from time to time, then it can be rewound. Gutters are also like ventilation, but one must keep in mind pipes made of plastic, according to the certificate, they must have a temperature difference, for example, from -50 to +35 degrees C and resistance to sunlight. I could also answer how to lay pipes in the ground along the roof and. etc. but I think that's enough. If it's easy, rate the answer.

Vlad Ternovskiy:

if the joint is metal plastic flows, change the oring or tighten it, and if it's plastic - plastic, then you need to resolder

Grandfather Au:

you need to call a plumber if the fitting is long, let it stretch - if under pressure testing - let it change the fitting and a piece of metal-plastic pipe

Celestial slug:

So they connect. Even before the replacement of the risers, the wiring was done by a metal-plastic. From the riser there is a corner-adapter, a ball into it, then a counter and up to the mixer.

Belogurov Nikolay:

when does it cool down? when does the heat stop?

Kungurtsev Andrey:

The disadvantage of metal-plastic pipes is that their connections are unreliable and the collet (metal-plastic connection) is not airtight. When using a metal-plastic in a heating system, over time, these pipes begin to flow at the junctions. What can be done? Only if you tighten the joints, drill drywall so that a hand with a key crawls through, and then putty this place. But of course you need to use polypropylene for heating systems. otopleniedoma.ucoz

Artyom Lobazin:

It is better to change the entire system or gradually in sections. Just take not junk like metal-plastic and polypropylene, but a metal-polymer pipe made of pert type 2. And it will serve for a long time and it will be easy to lay. nanopipes there and there is a video

Can't find the fire?

GEBO coupling, if you don't mind the money:

goga ivanov:

kaneshna ... insert one into the other and wrap it tightly with tape ... :)))

Dr. Zilberman:

Certainly. Plasticine. If you don't plan to use

vve-67@mail :

A piece of rubber hose and clamps.

Vladimir Petrov:

If not for a long time, then you can, as mentioned above, with the help of clamps. But it’s better to still find a soldering iron and solder and then connect with fittings. There is still pressure and a clamp somehow not reliable

Alexander:

It is possible to try for water supply with low pressure. It may be possible to put on propylene an adapter for HDPE on a water thread, then a fitting for a metal-plastic. Not suitable for reinforced polypropylene. Reliability is questionable, in an apartment building it is not worth the risk.

Cat smile:

... Look for a fitting that matches the diameter of the polypropylene. Next is a matter of technology and watch the video explanation)… s .youtube m/watch?v=cbHKD038MCM — fitting for HDPE.

Best Answers

Oleg:

diameter does not match there will be no reliable seam

BASIL:

buy adapters, why solder if you can connect, unless you have to solder the adapter to polypropylene and that's it

Online magazine Tips for hosts:

Theoretically possible. But it's like a hedgehog and a snake to cross and hope that you get barbed wire. ) Such a "joint" will not have a real application.

A metal-plastic pipe is a metal "screen" lined with polyethylene on both sides. The outer layer is thin, it will spread when heated, and the “alloy” of polypropylene and polyethylene will not give a strong seam, despite the similarity and closeness of the formulas, the materials are still somewhat different.

In addition, it is not realistic to choose the appropriate diameters.

The connection of these pipes both with each other and with metal pipes is provided by appropriate adapters.

White Oleg:

No, it will not work - different polymers do not solder together. Better through combined threaded couplings. By the way, compression fittings from the HDPE pipe work great on polypropylene - I needed a detachable connection between polypropylene and HDPE. For 20 pipes of metal-plastic and Pp-r, you can try this method ...

Igor Shkurny:

Why such difficulties in life? No!! ! These two pipes fit perfectly and without soldering!

Similar posts

- cost of steel pipes

- Metal-plastic pipes and their features

- Which metal-plastic pipes to choose

- Characteristics of metal-plastic pipes

- Methods for laying metal-plastic pipes

- Installation of fittings for metal-plastic pipes

some kind of tow, but you don’t need to clean the metal-plastic tube from aluminum, don’t write nonsense if you don’t know

Nikolai Dorokhov How to connect pipes made of different materials, for example, polypropylene or metal-plastic with metal? Metal pipes are gradually becoming a thing of the past. They were replaced by durable and reliable products made of polypropylene and metal-plastic. But in the process of construction, modernization or repair of existing water pipelines, it may be necessary to attach polypropylene or metal-plastic pipes to metal ones. How to connect pipes from different materials?

In what cases is connection to metal pipes required?

Situations with the joining of pipes made of different materials during construction work occur quite often. The most typical cases include:

- attaching plastic pipes to metal parts of equipment;

- implementation of various sections of communications by different organizations without agreement in the choice of one type of material;

- replacement of only a rotten section of the pipe with another, more modern material;

- repair work within the same apartment with the replacement of pipes and their connection to the old system of neighbors.

What types of connections are there?

It is possible to connect pipes that are made of different materials in only 2 ways:

threaded - using a variety of fittings, it is used for joining pipes not of large diameter, but of medium or small diameter;

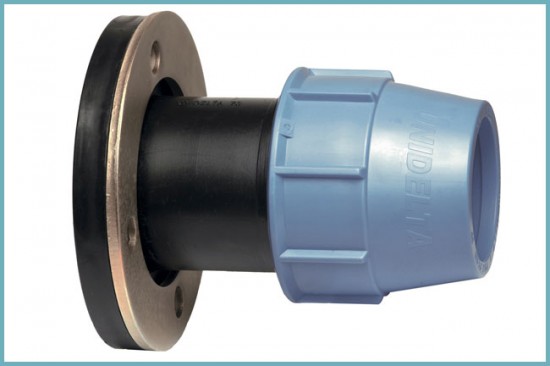

flanged - this type of connection is collapsible, used for pipes of large diameter, made using flanges.

Threaded connection with fittings

Fittings are adapters, on one side of which an external or internal thread is wound, designed to be connected to a metal element. On the second side there is a coupling for connection with metal-plastic or polypropylene by crimping or soldering, depending on the material. Installation of the system is not too complicated:

- The coupling on the metal pipe at the connection point is unscrewed, and the thread is cleaned.Or a piece is cut neatly and evenly, and carved using a special tool.

- To seal the joint along the thread, a little plumbing tape or tow is wound, all this is smeared with a silicone compound.

Flanged pipe connection

Metal pipes with plastic are often interconnected using flanges. Before starting work, the required type and size of elements is selected, corresponding to the diameter of the pipes. It turns out a collapsible structure, which can be disconnected on occasion, if necessary, to access any area. Flanges before work are carefully inspected for the presence of burrs, from which damage to the plastic pipe is possible, and, if necessary, are eliminated.

The technology of this connection, like the threaded one, is also not very complicated:

- the pipe at the intended joint is neatly and evenly cut;

- the flange is put on the pipe, then a rubber gasket is installed;

a flange is carefully pushed onto this seal;

the flanges of both pipes are fastened together with bolts, which must be tightened without undue effort, evenly and without displacement of the part.

Both of these methods of connecting pipes from different materials are reliable and durable. The installation process is not too complicated. For high-quality work, you just need to carefully consider each stage, follow the instructions and act carefully.