Warming

Between the beams it will be necessary to lay insulation on plywood shields. In private houses, foam plastic, mineral wool, polystyrene foam, and sawdust are most often used for floor insulation.

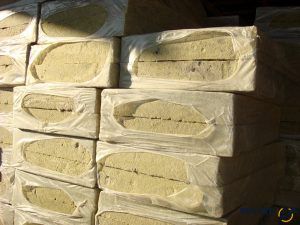

Mineral wool

This material is quite popular for warming floors, walls, facades. Mineral wool does not burn, has good heat and sound insulation. It is sold in the form of slabs or a flexible mat.

Price for 1 square meter min. cotton wool 5 cm thick is about 80-90 rubles. The coefficient of its thermal conductivity is 0.037 W / Mk.

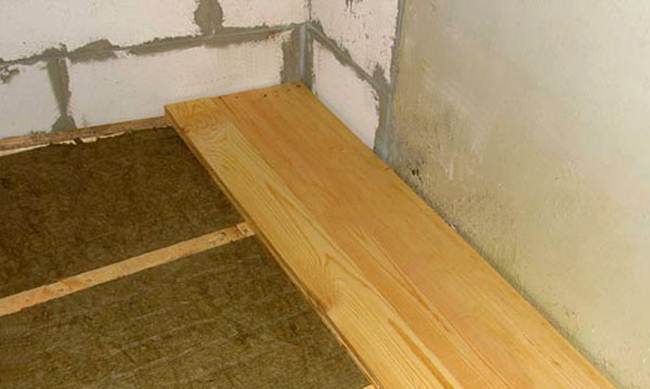

Laying mineral wool between the log

The main thing when using this method is to protect the insulation well from moisture, otherwise it will lose its properties. In some types, a water repellent is specially added to repel water.

Extruded polystyrene foam

Extruded polystyrene foam is the best thermal insulator. This is a synthetic material, so it is not affected by microorganisms, fungus and mold, almost does not absorb moisture and is very durable.

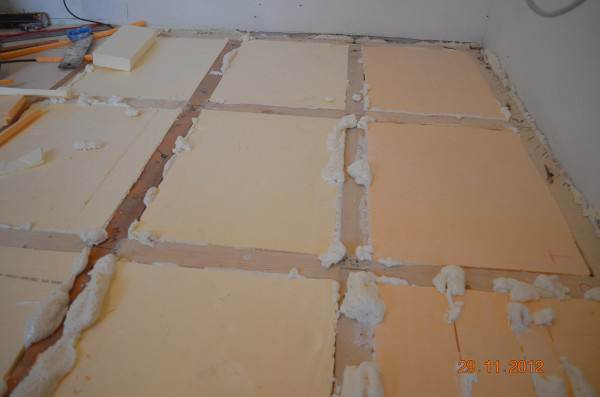

Styrofoam laying between the lag

The price of this material is about 200 rubles per square meter 5 cm thick. The thermal conductivity coefficient is 0.031 W / Mk.

Sawdust

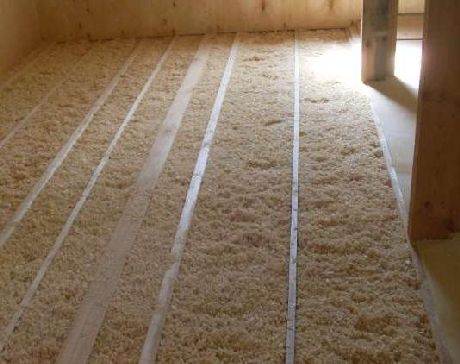

Insulation with sawdust

One of the cheapest and easiest types of floor insulation in the country is falling asleep between sawdust lags.

This option has a high environmental friendliness and almost zero cost, which is very important for giving. Their thermal conductivity is approximately 0.07-0.09 W / Mk

The coefficient increases along with an increase in their density and humidity, so you need to lay them without ramming and protect them from moisture.

Expanded clay

Floor insulation with expanded clay

Expanded clay also refers to economical types of insulation. It consists of fired clay, which becomes very light due to the large amount of air inside. From the point of view of thermal conductivity, this is the least efficient material (0.1-0.18 W / Mk).

Teploizol

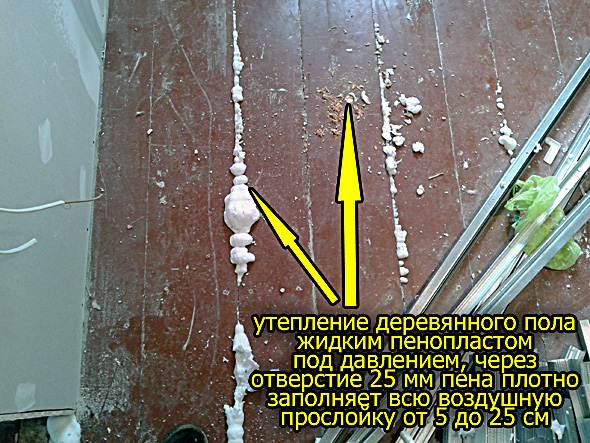

liquid foam

Separately, it is worth talking about another way to quickly and inexpensively insulate a wooden floor - thermal insulation. The main advantage of this option is that you do not even need to remove the floorboard. Thermal insulation (liquid foam) is pumped into the wooden structure through small holes of 25 mm. The cost of such material is 100-250 rubles per square.

Waterproofing for concrete floor

It is difficult to make a concrete floor on the ground because you need to create a single structure in conditions of moving soil. After the “cushion” is made, we make a rough screed. There are two ways.

The first is on the sand, which is the top layer of the pillow, we pour fine gravel. After that, having kneaded the cement-sand mortar, make the consistency liquidish, pour gravel, so that a layer of rough screed of at least 3-5 cm is obtained on top. .

The second way, we put polyethylene 200 microns thick on the sand, level it and glue it with adhesive tape. We make a rough screed on the film, from a solution of normal consistency, 5-7 cm thick. Then we put rolled waterproofing on the rough screed, a heater on it and then a finishing screed.

Floor coverings

- Laminate

- Warm floor

- Linoleum

- Tile

- carpet

- Parquet

- self-leveling floor

- Wooden floor

Floor device

- plinth

- Floor screed

- floor leveling

- Sound and waterproofing

- Floor insulation

- concrete floors

- Floor repair

- Substrate

Calculation of laminate boards

Calculation of paving slabs

Tell about us

SemiGuide 2012-2019 | Information

When copying materials active link to the site is required

Floors in a country house

Good time of the day! Liked your site very much. A lot of useful information for a beginner gardener :).Special thanks for providing information - everything is clear without a translator (specialist) :). And now the question is: when I did the foundation project for the house, I did not take into account the need for additional support for the floor logs, i.e. made a rectangular foundation with axes of 7.4x5.4 without a jumper along the long side of the foundation. Thus, the logs (section of the beam 150x100), lying on the foundation with their edges, have a span of about 5 m. Now I wonder how many columns to put on such a span 2 or 1 will be enough for the log? And the second question is tormenting - is it possible to make them from foam concrete or is it necessary to make them from red brick? I would be very grateful if you could answer my questions.

Hello, Andrey from Kirov!

You can’t do without supports for the floor joists, otherwise the floor under you will shake as you move along it.

Construction literature recommends making pillars under the floor joists in different quantities. With a span of 5 meters, I would make a couple of such supports under each log. If you make one, then if it is damaged (which, however, is unlikely), the lag will remain without support. And if you have 2 supports, then this is almost a 100% guarantee of a stable floor. Especially with the cross section of the beam, the sex lag is 150/100 millimeters.

I believe that the beam is not laid flat, but on a 100 mm side. Then it works to its full strength, or, as the builders say, more rigid.

As for the material of the pillars, the stronger it is, the better. In this particular case, I treat foam concrete blocks with distrust. Practice shows that most of them, with possible prolonged exposure to moisture, are subject to destruction. That is, after a dozen, two decades, they can deform and your lags will sag.

As supports, red brick (but not silicate!) And sand-cement blocks and just concrete poured into a formwork from edged boards or some other options will go.

I am not talking about the fact that the supports must be deepened to the same size as the foundation. Granted. Although here, too, options are possible, which I spoke about on the pages of the site and which, judging by the message, you have read.

Here, very briefly about what you are interested in.

Other questions about gender:

Ask a question to Semenych (the author of the materials)

Wood floor insulation

If the floors in the country house are very strong and even, and there is no desire to open them, you can perform insulation directly on the boards. The disadvantage of this method is that the height of the ceilings will decrease by about 8-10 cm.

Tools and materials

For work you will need:

- grinding nozzle;

- jigsaw;

- building level;

- primer;

- putty on wood;

- bars 50x50 mm;

- sheet material, for example, chipboard;

- vapor barrier film;

- insulation;

- self-tapping screws;

- screwdriver;

- construction tape.

The bars will perform the functions of a lag, so they must be even, without defects, and well dried. Since the workflow will take very little time, the bars should be pretreated with antiseptic impregnation and dried.

Floor preparation

Step 1 Carefully remove the baseboards and clean the floor from dust. Check the levelness of the surface with a level gauge.

Step 2. If there are protrusions on the floor, the surface is treated with a grinding nozzle. The gaps between the boards and the recesses are puttied.

Puttying a wooden floor

Step 3. The working surface is covered with two layers of primer mixture, the floor is allowed to dry.

Step 4. The beam is laid out on the floor in parallel rows with a step of 30 cm. From the extreme beams to the walls, the distance is 2-3 cm. Using a level and wooden wedges, the bars are set exactly horizontally and screwed to the base with self-tapping screws.

Laying and fastening lag

Step 5. The space between the bars is filled with insulation. Mineral wool and polystyrene are best suited for this. The formed seams need to be blown out with foam.

Laying insulation in the space between the lags

Step 6The insulation is covered from above with a vapor barrier membrane, carefully spreading the material and fixing the seams between the strips with adhesive tape.

Mineral wool is covered with a membrane

Step 7. The sheet material is cut into squares for convenience and proceed to the flooring. Starting from the second row, the sheets are laid with a joint offset of 20-25 cm. The seams should be minimal, so fit the squares as tightly as possible.

Laying sheet material on logs

Step 8 If you plan to lay boards on top of chipboard, additional processing of the subfloor is not needed. For thinner finishes, it is necessary to putty the joints and sand the entire floor with a sanding attachment. After that, remove the dust, apply a primer and wait until the floor dries.

The described options are the most practical for giving; subject to the technology, it will not be necessary to change the heat-insulating layer for at least 10 years.

Insulated floor in the country will last at least 10 years

Comparative table of floor insulation

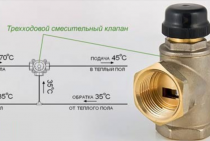

Underfloor heating with the help of technology

Those who wondered how to insulate the floor in the country, probably heard more than once about “warm floors”. This is holding the heating system under the surface of your floor. For this purpose, a cable or flexible tubes can be used, through which water is driven. The source of heat can be any heating boiler - gas or electric. Such a system is laid on top of the insulation layer, distributed under the entire floor, in the form of a circular or parallel fastening of wires or tubes. Such heating will help to feel comfortable and maintain the temperature of the air in the room. In this case, experts will tell you better how to make the floor in the country.

The floor in the country creates an atmosphere. It's one thing when you can safely walk on it in socks, or even barefoot, sit on the carpet in the evenings, allow children to play with toys on the floor, and quite another when it's icy and any contact with it only threatens to catch a cold. For the floor in the country, not so many materials are needed, and working with them is simple and straightforward. Having settled in a new house, or deciding to spend the winter outside the city, be sure to remember about the arrangement of the house, because its most vulnerable places are the floor and roof. The insulated floor in the country will save money on heating and subsequent repairs, so be sure to carry out all the necessary work. They can be done year-round, unless your subfloor is damp.

At a certain stage of the arrangement, the question inevitably arises of how to make the floor in the country with your own hands. The modern market of materials and technologies is replete with many different offers, which are sometimes difficult to understand.

To make it easier for you to choose, we will now try to briefly talk about the most popular materials for arranging a new room, as well as technologies that allow you to do a high-quality repair of the floor in the country with your own hands.

What product to use for floors

The boardwalk of the veranda in the summer cottage can be covered with several coating options. They differ in their cost, external aesthetics and color palette. Let's talk about each next.

Enamel: give the floor a solid color

Enamel compounds are often used for painting metal and wood structures.

This tool has a high density, so it completely hides the natural texture and pattern of natural wood. Therefore, floor enamel makes sense to use if the boards have defects that need to be hidden.

Using this material, you can get wooden floors that are solid in color.

Antiseptic composition: protecting the boardwalk from harmful bacteria

This is a very useful tool that significantly extends the life of wooden structures. It helps to increase the resistance of wood to excessive humidity, prevents the formation of mold, fungus and rot.

In the future, the floors should be painted with paint or varnish, because the antiseptic, regardless of its cost, will not visually give the wood any additional aesthetics and will not protect it from mechanical or atmospheric influences.

Lacquer for wooden surfaces

The wooden floor of a country house requires additional protection from external factors that have a negative effect on wood. This is high humidity in the room, small rodents, mold, bark beetles and other insects. And for this purpose, varnish is widely used.

The glossy lacquer composition has a bright sheen, but over time it can rub off from frequent walking on the floor of the veranda.

Matte and semi-gloss varnish does not shine. But such a tool is highly resistant to impact and perfectly protects wooden structures from negative environmental factors.

According to many experts in the field of construction and interior decoration, varnish compositions are more practical to use.

Let's talk in more detail about the species diversity of varnishes for natural wood.

What material to choose

The choice of insulation is determined by several criteria:

- material resources of the dacha owners;

- complexity of installation;

- durability;

- resistance to moisture and rodents.

The last point is especially important, because if the owners live in the country only periodically, dampness and mice are the main cause of floor destruction.

The range of heaters is wide, and along with modern ones, many summer residents willingly use already familiar, time-tested materials. With a limited budget, there are several acceptable options.

Expanded clay - light porous granules perfectly retain heat, mice and insects do not start in them, the material does not emit harmful fumes. For effective thermal insulation, it is necessary to provide reliable protection against dampness and pour expanded clay in a thick layer - up to 30 cm.

How to easily identify high-quality expanded clay

Wood shavings and sawdust are a cheap and environmentally friendly material that can be purchased at any woodworking enterprise. The shavings perfectly retain heat, but are afraid of moisture, so they also need high-quality protection. In addition, insects and rodents can start in it.

Sawdust and shavings

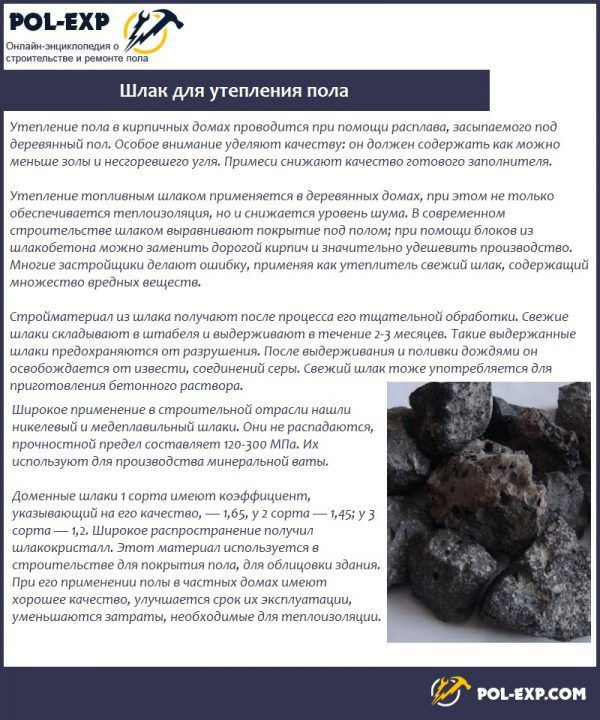

Slag is an affordable and practical way to insulate the ground. He also needs waterproofing, but it is durable, non-flammable and mice do not start in it.

Slag for floor insulation

glass wool

Polyfoam - easy to install, moisture resistant. It has a long service life, but provided there are no mice, since these rodents destroy it very actively.

Floor insulation with foam

The use of modern materials gives an incomparably better result: laying is carried out with minimal labor costs, the efficiency of insulation increases significantly, you can forget about re-repair for at least 20 years. The only negative is the high price, but financial investments fully pay off in a few years, thanks to significant savings on home heating.

Penoplex |

XPS boards are not afraid of moisture, temperature fluctuations, freezing, and due to their high density and special structure, they perfectly retain their shape throughout the entire service life. The insulation is lightweight, in addition, the plates have a convenient connection system, so anyone can handle the installation. |

Mineral wool insulation |

Produced in various modifications, they have increased wear resistance, less hygroscopicity, and last longer. There are mats and plates with a foil coating that reflects heat and increases the effectiveness of thermal insulation at times. |

polyurethane foam |

The sprayed insulation forms a dense and seamless layer of insulation that is resistant to any negative influences.Due to the porous structure, the insulation does not exert heavy loads on the foundation and floors, and is excellent for thermal insulation of floors on the second floor, attic and attic. True, spraying requires a special installation, as well as skills to work with it, so it is problematic to insulate the floor in this way on your own. |

Ecowool |

Cellulose insulation with very low thermal conductivity. Environmentally friendly, has high soundproofing properties. The insulation is blown into the underground space using the installation, since it is quite difficult to manually evenly distribute and compact the layer. |

As a bulk insulation, many use expanded vermiculite - a granular material with a scaly structure. It is lighter than expanded clay and retains heat better, serves as excellent sound insulation. Unlike XPS and mineral wool, vermiculite is completely environmentally friendly, but it is not affected by fungi, putrefactive bacteria, insects and mice do not live in it. Well, the disadvantages include only the high cost, which is why vermiculite is inferior in popularity to cotton wool insulation and polystyrene.

expanded vermiculite

Floors in the country

The floors in a country house can be very different, but most often it is a wooden flooring or a concrete screed. Today, to create a beautiful and original design of the room, you can use other, more modern and beautiful materials.

Which gender to choose?

In the building materials market today there is a huge variety of materials that will decorate the house and make it more comfortable. With the right material, you can create a stylish interior and predetermine its future design.

In the country, it is better to mount a simple, durable and inexpensive floor, which will be highly durable and reliable.

But in order for the crazy to still be beautiful and stylish, you need to pay attention to the appearance of the materials. Today, several types of floors are very popular:

- concrete,

- wooden,

- from parquet,

- from laminate,

- linoleum,

- ceramic tiles.

Concrete floor

A concrete floor has little decorative effect, because it is an ordinary screed that is covered with a special paint, but despite this, it can look very nice if everything is done correctly and with high quality.

If the concrete surface is constantly looked after and monitored, it will look like new. Once every few years, the floor needs to be tinted and updated - it does not require more attention to itself. In addition to the advantages, the concrete floor also has its drawbacks - it is considered cold, even if it is covered with carpets or paths.

Wooden floor

Wood flooring is a classic option that goes well with any interior and design. Wood is a natural material, so it is warm and natural, making the house more comfortable.

The wooden floor is durable, resistant to temperature extremes, to low humidity, but you need to take care of it all the time and monitor its condition. It must be treated with special fire retardants, paints, varnishes, and also sanded if necessary.

Such a floor cannot be used in rooms with high humidity, because it will quickly become unusable, and it will be necessary to completely change the coating.

The advantage of laminate flooring is that it looks very nice and rich. Due to the variety of colors, you can choose a stylish option for any interior. The texture, shades and color of the laminate can be very different, so when choosing it, you should first of all decide on the interior of the room and think over the whole environment and layout.

The advantage of laminate is that it is resistant to pressure, stress, abrasion. If you take care of the surface, then no traces will remain on it, even from furniture.This material does not accumulate bacteria, so its care is quite simple - wet cleaning.

Other materials

In the country, you can also use other coatings - linoleum, parquet, ceramic tiles. Each of these materials has its own advantages and disadvantages. Parquet looks very rich, beautiful, it gives the house a special charm and style. Linoleum - the material is quite inexpensive, but practical and easy to install. Ceramic tiles are a versatile material that can be used in any room, even in the bathroom. This material is not afraid of high humidity, high temperature, household chemicals and fats, so it is quite easy to care for it.

When choosing a floor for a summer residence, you need, first of all, to focus on your personal preferences and wishes. Each house is unique, just like a person, so the choice of floor must be taken very responsibly and look for the option that will best meet the requirements and characteristics of the cottage.

Floor construction elements

If the flooring is arranged on the ground, then its pie should look like this:

- The soil must be leveled, leveled and compacted.

- Next, an underlying layer of crushed stone, slag, gravel is arranged, sand can be laid (10 cm thick). The layer is leveled and compacted with rollers.

- The waterproofing layer prevents water from reaching the structural elements. It protects the structure of the overlying deck from rising groundwater levels. It can be two layers of roofing material, all kinds of waterproofing films, membranes.

- If the base is insulated, then the next layer is heat-insulating. If this cottage is only for summer holidays, then you can do without it. Thermal insulation, as a rule, is made of expanded clay, slag with a thickness of approximately 150 mm.

- Concrete preparation device grade 100 - 150 100mm thick.

- Leveling screed from a solution of brand 100-150 with a thickness of 25 - 30 mm.

When arranging the base on the floor slabs, the cake will be a little different. As a rule, this is the attic floor:

- The soundproofing layer is not always performed, since this is a cottage and there are no neighbors from above. But if you decide to arrange a bedroom for relaxation there, then, if desired, you can also make a soundproof layer.

- Leveling layer of cement, polymer-cement or other compounds with a thickness of 20-25mm.

We made a tour of the main elements of preparing the base for flooring. According to the project, some of the structural elements may be added or absent - everything is individual.

The base is ready, we proceed to the choice of the finishing floor covering.

Let's talk about the finish

Before laying the finish coat, you should decide what kind of material you need. After all, each room has its own load and humidity level. In addition, when planning the installation of floors in the country, you need to take into account that in winter the room will not be heated.

Floor varnishing.

concrete pavement

The concrete floor for a summer residence can theoretically also be equipped independently. If it is made perfectly even and painted, then it will have a fairly good appearance. Such a coating is strong and durable, you will need to refresh the paint every few years and the floor will be like new.

But no matter how hard you try, concrete is concrete, it will be cold, if you cover it with carpet or bedding, the cold will still be felt. Even in the summer, doctors do not recommend walking barefoot on concrete.

This option may be suitable for a summer kitchen, garage or outbuildings. In residential premises, a concrete screed is made as the basis for a finishing coating.

We use natural wood

The arrangement of floors in the country house made of natural wood is a classic. People have been making them for hundreds of years. The price of such a coating will be average, but wood is a natural material and requires careful processing and care.In particular, a good waterproofing of the wooden floor in the country must be provided. Indeed, otherwise the tree can quickly deteriorate.

One of the schemes for installing a wooden floor.

This coating is also convenient because on a good basis and well-equipped waterproofing, you will not need powerful insulation. A tongue-and-groove board with a thickness of at least 40 mm is used for the coating, which in itself is quite warm.

When deciding how to paint the floors in a wooden cottage, experts advise paying attention to acrylic varnishes and paints. In the old days, the floor was traditionally painted with oil paint, it is of course practical and durable, but with such a coating, the tree does not breathe and the whole meaning of naturalness is lost.

The classic wooden floor is mounted exclusively on logs, because it requires constant ventilation from below. DIY installation instructions are quite simple. Initially, waterproofing is covered, wooden logs are mounted on it, onto which a tongue-and-groove floorboard is already nailed. Insulation is placed between the lags.

Laminate

Laminated coating appeared about 20 - 30 years ago, it is currently one of the most popular. The appearance of the laminate can be anything, the range of colors here is one of the widest. As a rule, it emits natural wood.

Among the advantages can be called a low degree of abrasion, ease of installation and durability. If we talk about the minuses, then this coating requires a perfectly even, waterproofed base. The price of expensive species bites, and budget options are afraid of moisture and cannot withstand heavy loads.

Linoleum

This material can deservedly be called the king of floors, not only in the country, but also in most other residential or office premises. It can be thin or thick. Smooth and corrugated surfaces with varying degrees of stability are produced. Linoleum behaves well in a humid environment and is not afraid of temperature changes, plus laying linoleum does not require high professionalism.

There are few downsides to linoleum. In fact, experts consider the ability to push through the material to be the most sensitive place. Linoleum is afraid of sharp heels and heavy furniture. Plus, it requires a perfectly flat surface for installation.

Linoleum in the lobby.

Tile

Tiled or ceramic tiles are classified as completely environmentally friendly, versatile materials. It is strong, reliable and beautiful, but it is not customary to mount it in the living room or bedroom. Ceramic floors are more suitable for country kitchens, bathrooms and hallways.

You can lay tiles with your own hands, but you will need a certain skill. There are few disadvantages of tiles, the main one can be called its coldness, the ceramic coating is akin to concrete, so now it is customary to mount warm floors under it, in the country version it is better to mount a floor with electric heating.

There are many more interesting tips in the video in this article.

Conclusion

Of what to make the floor in the country, of course, you decide. There are many more beautiful materials, such as parquet, marble or 3D self-leveling floors. We have given only those materials with the help of which it is really possible to lay the floors in the country house with our own hands without having fundamental knowledge.

But for most summer residents, a dacha is a small building, so let's look at the simplest and not too expensive coating options.

You need to start work only after you calculate the thickness of the base pie, take into account the thickness of the flooring, in order to eventually reach the desired mark.

The base is:

- On the ground

- Overlapping (for example, attic floor)