Definition of the concept of pressure

Pump characteristics form.

Different slopes with identical casing and pump impeller (e.g. depending on motor speed)

Various flow and pressure changes

Pump head (H)

- specific mechanical work transmitted by the pump of the pumped liquid.

H=E/G

E

= mechanical energy

G

= weight of pumped liquid

The pressure created by the pump and the flow rate of the pumped liquid (supply) depend on each other. This relationship is displayed graphically as a pump curve. The vertical axis (y-axis) reflects the pump head (H) expressed in meters. Other pressure scales are also possible. In this case, the following relations are valid:

10 m w.st. = 1 bar = 100,000 Pa = 100 kPa

The horizontal axis (abscissa) shows the scale of pump delivery (Q), expressed in cubic meters per hour [m3/h]. Other delivery scales are also possible, eg [l/s].

The characteristic form shows the following types of dependence: the energy of the electric drive (taking into account the overall efficiency) is converted in the pump into such forms of hydraulic energy as pressure and speed. If the pump is running with the valve closed, it generates maximum pressure. In this case, one speaks of the pump head Ho at zero flow. When the valve begins to slowly open, the pumped medium begins to move. Due to this part drive energy is converted into kinetic energy liquids. Maintaining the initial pressure becomes impossible.

The pump characteristic takes the form of a falling curve. Theoretically, the pump characteristic intersects with the delivery axis. Then the water has only kinetic energy, that is, pressure is no longer created. However, since there is always internal resistance in the piping system, in reality the performance of the pumps is cut off before the delivery axis is reached.

Submersible pump power and efficiency

The rated efficiency of the electric motor of a centrifugal pump for water supply is the ratio of useful power to that which is consumed. Designation - η. Distribution formula: η = (Р2/Р1) * 100. The efficiency of an electric motor will never be higher than unity (100%) under any circumstances, since there is no “perpetual motion machine”, and any drives have losses.

Efficiency - this is the name of the ratio of hydraulics to the power that is supplied to the shaft of the downhole device, and their difference reports losses in the unit. Formula: η \u003d (P4 / P3) * 100.

The loss of power in a centrifugal pumping device is also obtained from a number of components, namely:

- hydraulic;

- Mechanical;

- Volume loss Pvset.

Submersible pumps for summer cottages can be bought at any specialized store

Submersible pumps for summer cottages can be bought at any specialized store

The total efficiency is the sum of the efficiency of all losses. The efficiency of the device characterizes the degree of design perfection in terms of mechanics and hydraulics.

Can installation affect the amount of pressure

Given the simplicity, even primitive design of the pumps, as well as the availability of detailed installation instructions, many modern men take up the work on their own, that is, without the help of professionals. This behavior is most often associated with a desire to save money: not everyone is ready to pay not only for a pump or a pumping station, but also for the services of a master. Considering that the pressure of the pump is the main characteristic of its activity, no one is ready to lose. That is why the question arises by itself: how much installation carried out independently can affect the magnitude of the pressure.

It would seem that we connect one pipe to the suction pipe, the other to what is responsible for the pressure, supply power - and you're done. In practice, the slightest mistake can not only adversely affect the pressure of water, but also significantly reduce the duration of work.

Types of device power for a well

During the production of devices at the factory, the designations of the varieties of power are used:

- P1 (kW). Input electrical power is that which the electric motor takes from the mains.

- P2 (kW). On the motor shaft - the one that it gives to the shaft. The pump power input P1 is equal to the motor shaft power P2 divided by the efficiency of the motor.

- P3 (kW). The input value of the hydraulic pump is equal to P2 when the coupling that connects the device shaft and the motor shaft does not consume electricity.

- P4 (kW). The useful power of submersible hydraulic pumping equipment is the one that comes out during operation in the form of water flow and pressure.

Without relevant experience, it is not recommended to independently install the pump

Without relevant experience, it is not recommended to independently install the pump

You can calculate the indicator online, there is a special calculator.

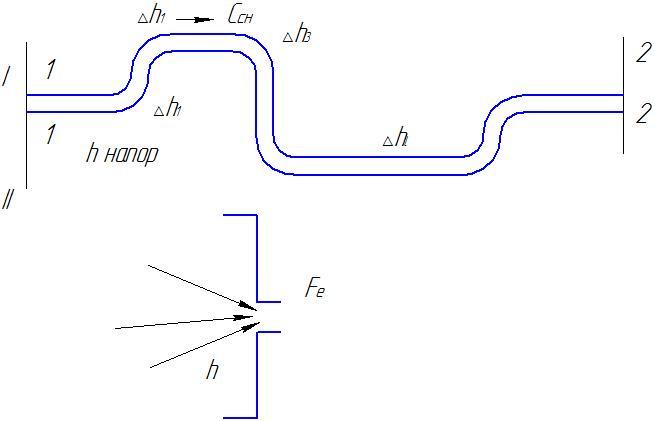

Equivalent hole

If done

hole section Fethrough which such

the same amount of air ,

,

as well as through the pipeline at the same

initial head h, then

such a hole is called equivalent,

those. passage through a given equivalent

hole replaces all resistances

in the pipeline.

Let's find the value

holes:

,

,

(4)

where c is the speed

gas outflow.

Gas consumption:

(5)

(5)

From (2)

(6)

(6)

Approximately because

that we do not take into account the narrowing factor

jets.

is the conditional resistance

convenient to enter into calculations when simplifying

real complex systems. Losses

pressure in pipelines are determined

as the sum of losses in separate places

pipeline and are calculated for

based on experimental data,

given in the handbooks.

Losses in the pipeline

occur at turns, bends,

expansion and contraction of pipelines.

Losses in equal pipeline also

calculated according to reference data:

(7)

(7)

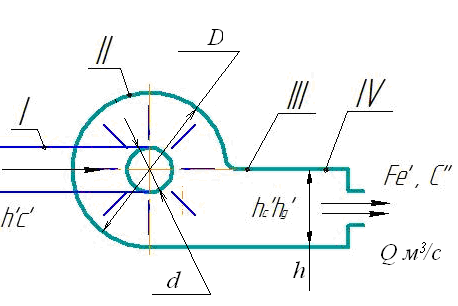

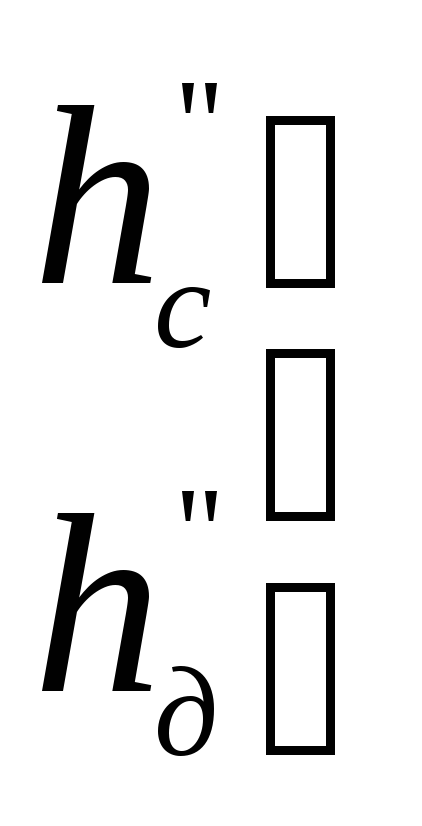

- Suction

pipe branch - Fan housing

- Discharge

pipe branch - equivalent

hole replacing the real

pipeline with its resistance.

- ;

- ;

- ;

- ;

- ;

speed in the suction pipeline;

exhaust velocity through the equivalent

hole;

the amount of pressure under which

gas movement in the suction pipe;

dynamic pressure in the outlet pipe;

full pressure in the discharge pipe.

Through the equivalent

hole

knowing

find

Example

What does

motor power to drive

fan, if we know the previous

data from 5.

Taking into account losses:

where

monometric coefficient of useful

actions.

where

theoretical fan head.

Derivation of Equations

fan.

Given:

Find:

Competent selection of the unit according to the parameters

The selection of a pump for the conditions that are given is an important stage in the design of the installation and station. To select a unit for installation, you need to have the initial values that characterize the pipeline systems, and the requirements that apply to the project.

Such data, which is compiled in the form of a project, should include:

- Information about the purpose and nature of the operation of the device.

- Characteristics of the hydraulics of the pipeline system, including the capacity consumed by the maximum and minimum station Qmax and Qmin consumed head, which corresponds to the maximum and minimum flow rates Hmax and Hmin.

- Data about power sources or reservoirs.

- Data on the location and conditions of the location of the pump.

- Data about electric motors and energy sources.

- Special requirements. Based on this information, using catalogs and reference books on pumping equipment, you can select a device according to its characteristics and speed coefficient.

Primarily, the type and brand of the pump are selected according to the summary schedule of the working areas of the destination equipment that corresponds to it. The choice is made for averaged flow and head data.When selecting a coordinate with points Qcp and Hcp, it is necessary to ensure that it passes in the middle of the working field of the selected device.

In order for the pump to serve for a long time, worn parts should be changed in time

In order for the pump to serve for a long time, worn parts should be changed in time

Having applied the catalog, it is necessary to find the operating characteristic of the selected device and build a joint characteristic of it and the pipeline (well). By this alignment, the working coordinate is obtained, which corresponds to Qcp and Hav. Knowing Qmax and Qmin, the corresponding efficiency values are found from the curve. If these data are not less than the minimum efficiency, which is accepted, then such a device satisfies the initial data on energy indicators. To build the characteristics of the station, you can also use the universal parameters of the device.

According to the formula, the maximum of the ellipsoidal suction height is calculated, which correspond to Qmax, and then it is compared with the minimum suction height that is set. If the suction geodesy according to the formula turns out to be greater than the specified one, then the selected device satisfies the initial values in terms of its cavitation. It is necessary to write out the geometry, mechanics and hydraulics data of the selected equipment from the reference catalog.

Device selection by speed factor:

- It is necessary to calculate the average values for flow and pressure Qcp and Hcp, taking the number of revolutions according to the standard of a functioning wheel, and calculate the specific rotation frequency ns using the formula.

- According to the specific speed and Qcp and Isp, pumping equipment is selected. Since in such a situation the device is selected using the scaling law for optimal efficiency data, there is no need for another check on the characteristic.

- Knowing the rotational speed, according to Qcp, n and calculated by the formula for the cavitation coefficient Ccr, it is necessary to find the value of the vacuum suction height of the pumping device Hv. Next, using the formula for Qmax, you need to find the maximum value of the ellipsoidal suction height and compare it with the one set in order to reduce the cost of construction work. If the maximum value of the ellipsoidal height is higher than that specified, then the pumping equipment is also suitable for cavitation.

The choice of a pumping device according to the speed coefficient is convenient to perform in a situation where there are no characteristics of the devices, but there are only data that correspond to the optimal mode of operation. It is also mandatory to measure the pressure at the station (example of downhole equipment).

It is important to choose the right pump power and the equipment itself, then the pumping unit or station will function as efficiently as possible

Vane pump working process

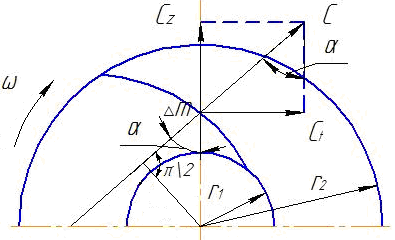

The moment of resistance forces relative to

axis counteracts the rotation of the worker

wheels, so the blades are profiled,

taking into account the feed rate, frequency

rotation, the direction of fluid movement.

Overcoming the moment, the impeller

does the job. Main part,

brought to the wheel of energy is transmitted

liquid, and part of the energy is lost when

overcoming resistance.

If the fixed coordinate system

connect with the pump housing, and the movable

coordinate system with impeller,

then the trajectory of absolute motion

particles will add up from the rotation

(portable movement) impeller

and relative motion in a mobile

blade system.

The absolute speed is equal to the vector

the sum of the carry speed Uare the speeds of rotation of the particle with the worker

wheel and relative speedWmovement along the scapula relative to

moving coordinate system associated

with spinning wheel.

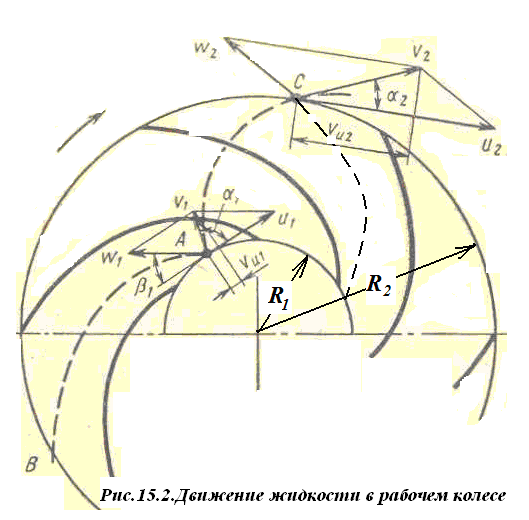

On fig. 15.2 dash-dot line

shows the trajectory of the particle from the entrance

and before leaving the pump in relative

movement - AB, trajectory of the portable

movements coincide with circles on

wheel radii, for example, on radii

R1and R2.

Trajectories of particles in absolute motion

from pump inlet to outlet - AC. Movement

mobile system - relative, in

mobile - portable.

Parallelograms of speeds for entry into

impeller and exit from it:

(15.5)

(15.5)

where i= 1.2.

Relative speed sum Wand portableUwill give absolute speedV

.

Speed parallelograms in fig. 15.2

show that the angular momentum of the particle

fluid at the outlet of the impeller

more than input

V2Cosα2R2

> V1Cosα1R1

Therefore, when passing through

wheel moment of momentumincreases. Moment rise

the amount of motion caused by the moment

forces with which the impeller acts

to the liquid in it.

For a steady flow of fluid

momentum difference

fluid leaving the canal and entering

into it per unit of time is equal to the moment

external forces with which the impeller

acts on the liquid.

Moment of forces with which the impeller

acts on the liquid is:

M = Qρ(V2Cosα2R2

— V1Cosα1R1),

where Q is the flow rate

liquids through the impeller.

Multiply both sides of this equation by

impeller angular speed ω.

M ω= Qρ(V2Cosα2R2ω

— V1Cosα1R1ω),

Work Mωcalled

hydraulic power, or work

produced by the impeller in

unit of time, acting on

the liquid it contains.

From the Bernoulli equation, we know that

specific energy, transmitted

unit of weight of a liquid is called

pressure. In the Bernoulli equation, the source

energy to move the fluid

pressure difference.

When using the pump, the energy or

the pressure is transferred to the fluid by the workers

pump wheel.

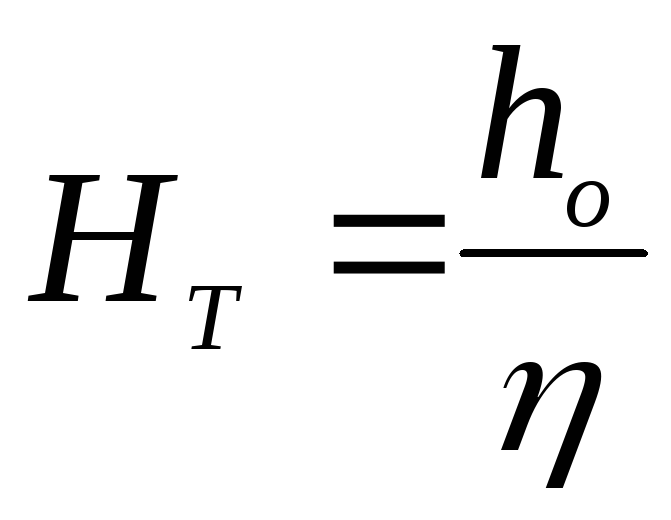

Theoretical impeller head

— HT called

specific energy, transmitted

unit weight of liquid impeller

pump.

N=Mω= HT*Qpg

Given that u1=R1ω

- portable (circumferential) speed

the impeller at the inlet andu2

= R2

ω - working speed

wheels at the output and that the projection of the vectors

absolute speeds per direction

portable speed (perpendicular

to radii R1 and R2)

equalVu2

=V2Cosα2

andVu1

= V1Cosα1,

whereVu2andVu1

, we get the theoretical head

as

HT*Qpg

= Qρ(V2Cosα2R2ω

— V1Cosα1R1ω),where

(15.6)

(15.6)

Actual pump head

less

less

theoretical pressure because it

real values of velocities are taken and

pressure.

Vane pumps are single stage

and multistage. In single stage

pumps fluid passes through the working

wheel once (see Fig. 15.1). pressure

such pumps at a given frequency

rotation is limited. To increase pressure

use multistage pumps

which there are several in succession

connected impellers fixed

on one shaft. Pump head rises

proportional to the number of wheels.

Vane pump can work with

different modes, i.e. at different feeds

and rotational speeds.

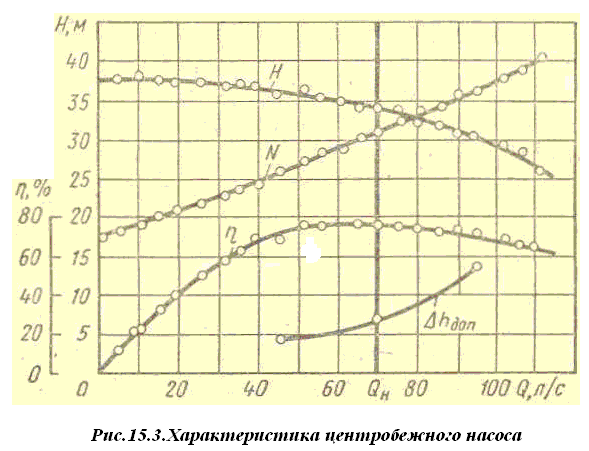

Covering the valve installed on

pressure pipe of the pump, reduce

feed. It also changes the pressure

developed by the pump. For operation

pump needs to know how it changes

head, efficiency and power consumed

pump, when its supply changes, i.e.

know the characteristics of the pump, under which

refers to the dependence of pressure, power

and efficiency of the pump from its supply at a constant

rotational speed (Fig. 15.3).

The mode of operation of the pump, in which it

Efficiency is at its maximum

is called optimal.

Basic installation errors

Let's take a look at the most common mistakes many of us make:

Suction pipe diameter. Quite often, the diameter of the pipeline in practice is less than the diameter of the suction pipe. This design, when connected, increases the resistance on the side of the suction line, thereby reducing the suction depth.In simple terms: a pipeline reduced in diameter is simply not able to pass the size of the liquid that the pump easily sucks in and pumps.

Direct connection to a regular hose. Such a system is not particularly critical if a pump of small capacity is used. Otherwise, under the influence of the high pressure created by the pump, the hose will shrink, its cross section will be significantly reduced, and water simply cannot pass through it. At best, this will lead to a cessation of the water supply, at worst, to a breakdown of the pump without the possibility of its subsequent repair.

A large number of bends and turns in the pipeline. This installation option does not increase the resistance value, respectively, reduces the performance and the pump head

That is why it is so important to reduce the number of bends and turns to a minimum value if you want to use the purchased and installed pump at 100%.

Sealing. It is due to insufficient sealing in the suction section of the pipeline that significant water losses can occur.

Poor sealing not only reduces the water pressure, but also accompanies the pump operation with excessive noise.

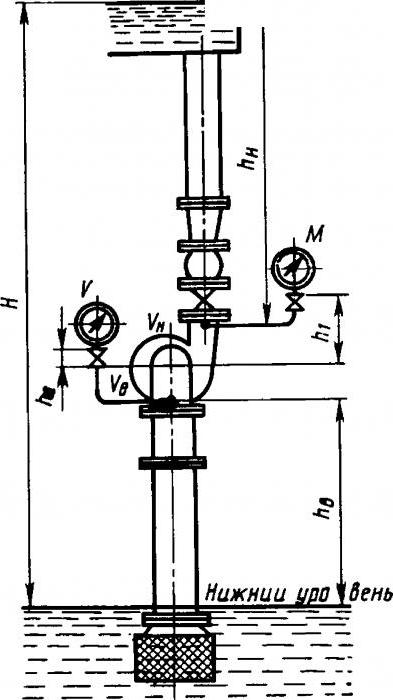

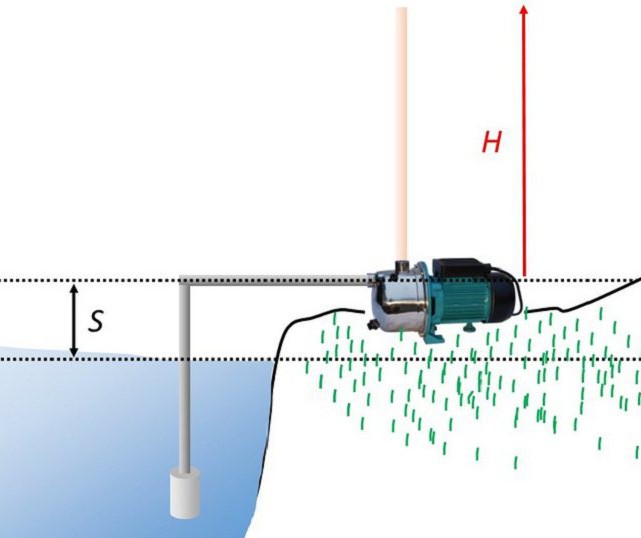

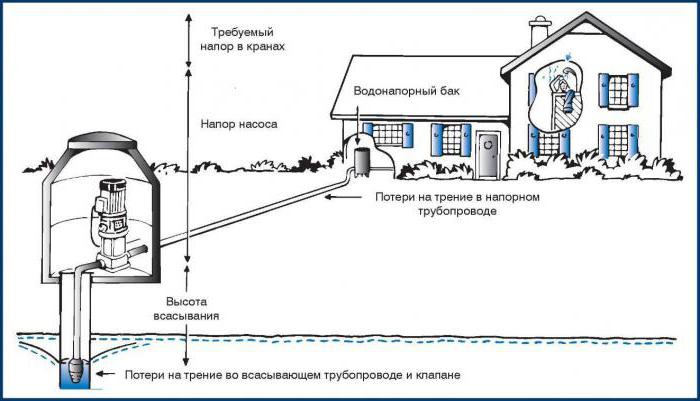

Submersible pump head

That is why one of the safest and most reliable is the submersible pump. Its pressure is calculated by the formula:

H = H height + H loss + H spout where:

H height - height difference between the location of the pump and the highest point of the water supply system;

H losses - possible hydraulic losses that occur when the fluid moves through the pipe, they are primarily associated with the friction of the fluid against the pipe walls;

H spout - the pressure on the spout that allows you to use all plumbing fixtures (usually in the range of 15-20 meters).

We have already established that the head of a pump is the pressure required to push a liquid to a given height. Circulation pumps have found themselves in heating systems, it is with their help that uninterrupted circulation of the heat source in the system is ensured

Of course, the choice of a circulation pump must be approached more consciously and demandingly, understanding that the efficiency and uninterrupted operation of its use largely depend on this, which is so important for apartment buildings. Such pumps are reliable, efficient and have proven themselves even in apartment buildings.

Of course, such a pump should also be selected based on the pressure. The pressure of the circulation pump has no connection, and, accordingly, dependence on the height of the building. The main thing here is the hydraulic resistance of the track. And here the following formula is required for the calculation:

H = (R * L + Z sum) / (p * g) where:

R - losses;

L is the length of the pipeline, measured in meters;

Z sum - the total number of safety factors for the structural elements of the pipeline (for fittings and fittings, this value is 1.3; for thermostatic valves - 1.7; and for mixers - 1.2);

p is the density of water, we remember from the school physics course that it is 1000 kg/m3;

g is the free fall acceleration, the value of which is taken as an average value - 9.8 m/s2.

It turns out that, knowing all the basic parameters, it is quite simple to determine the water pressure that you need in a particular situation, for this you do not have to involve specialists.

Why in meters

A pump for the pressure of water and any other liquid is a very popular device, without which it is difficult to imagine life in a private house. Many consumers still do not understand why the pressure is measured in meters.

The pressure of a centrifugal pump, however, like any other, is usually measured in meters. Of course, such a system raises many questions. First of all, it happened historically, everyone has long been accustomed to such a designation and does not intend to change anything.And, of course, it is convenient, because you do not have to resort to using other units of measurement, to perform complex mathematical calculations. The head value, calculated in meters, gives us information that the pump can lift the liquid to a given height.

Conclusion

"Hydraulics" on

a specific methodological example of calculation

volumetric hydraulic drive it is shown that

to select the required devices (pump,

hydraulic motors, hydraulic devices, filter,

working fluid conditioners, hydraulic lines

and their elements, electric motor) and

efficient operation of the hydraulic drive

need to calculate

Very

it is important not to make mistakes in calculations

and units of measurement, because on error

You can select a device that

during operation of the hydraulic drive

will not meet the requirements

applied to the unit as a whole.

The results of the work performed allow

make a conclusion about sufficient accuracy

performing calculations and choosing

hydraulic equipment