bedding layer

With a litter layer thickness of 4-5 centimeters, it can be considered a carrier. It is created by pouring a cement-sand screed over a layer of coarse gravel using concrete grades B7.5 or B10. This layer will act as a surface level regulator.

To prevent the mixture from spreading, the surface is limited with rails. It is necessary to wait for the screed to harden and harden, while regularly moistening it. A modern alternative to pouring mortar is the use of profiled membranes, the use of which reduces the time for laying the layer.

Preparatory stage for soil

So, the device of the subfloor on the ground begins directly with the processing of a piece of land

It is important to know the depth of groundwater in order to eliminate the risk of flooding the foundation. To do this, you can prudently install a drainage system that will perform the function of draining water.

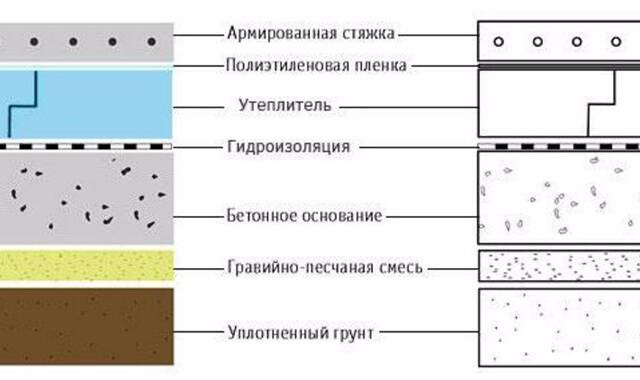

Once the groundwater problem has been resolved, the foundation process can begin. Coarse-grained river sand and gravel with a fraction diameter of about 3 centimeters is used for this. The depth of the layer of these materials should be about 30 centimeters. As soon as it falls asleep, tamping is carried out using a large amount of water. It is unacceptable to use black soil or peat instead of sand, as they are subject to leaching.

If the soil under the house is not saturated with moisture and is dry, a litter layer is laid. Otherwise, it is replaced with a material such as geotextile to prevent groundwater from penetrating above this layer. A mound of gravel or gravel of a large fraction is made on top.

Advantages and disadvantages of underfloor heating on the ground

- Of course, the main advantages of a warm floor on the ground include its reliable protection of the house from cold and frost. Regardless of the temperature, the soil on which the warm floor is placed always has a positive temperature;

- as a floor insulation on the ground, you can choose almost any heat-insulating material. For waterproofing, roofing material or a special film is perfect. And the surface of such a floor can also be finished with any of your chosen floor coverings;

- when installing such a floor, the load goes directly to the ground and you can not make special calculations. In those places where the load will be significant, it is best to increase the thickness of the floor heating cake;

- in addition, you can make the heat-insulating layer thicker yourself, or change something in this design;

- underfloor heating on the ground can be used as the main heating in the house. and as an additional;

- these floors quickly heat up and distribute heat evenly throughout the room, thereby preventing the appearance of drafts, which is fraught with the health of the residents of the house;

- warm floors on the ground have excellent sound insulation;

- excellent protection against mold, dampness and various microorganisms.

- underfloor heating, depending on the design features, can significantly reduce the height of the room;

- in the event of a malfunction of this system, it is very difficult and expensive to dismantle the layers of the floor;

- sometimes it is quite a long and complicated procedure. which is desirable to perform during the construction of the house;

- the need to take into account the position of groundwater.

Underfloor heating pie on the ground laying features

The earthen base on which the heating will be mounted must be prepared. To do this, the soil is leveled, the top layer is compacted. If necessary, a layer of backfill is laid on the ground. It consists of crushed stone or gravel. Most often, the material of the middle fraction is used.This prevents capillary penetration of groundwater into the room. The need to lay such a "cushion" arises only in the case of a high level of groundwater.

The rough screed layer, which was mentioned above, also has certain nuances. The thickness should be between 50 and 100 mm. Used brand of concrete - M100 or M200. It is advisable to reinforce the sole in the case when the soil was poorly compacted. Also, its use is justified in the case when there are discrepancies in the density of the base.

Rough screed for warm floor on the ground in a private house can be laid on the ceiling of the basement. This is done in order to level the plane. The thickness of such a layer should not be less than 3 cm.

There is also such a phenomenon as a dry screed. Its use has gained popularity due to the fact that there are no wet concrete works. It is advisable to use technology only for arranging a rough screed.

When laying a warm floor on the ground, you should also take care of the deformation layer. A damper tape will help here. The material will negate the likelihood of a thermal bridge. It also compensates for the load generated by the heating of the concrete pavement. This prevents the screed from expanding and cracking. The damper tape is laid on all sides of the external enclosing structures. But this is done only after applying the plaster and preparatory work for the final finishing of the building.

Floors on the ground - a universal way to build a warm and reliable foundation in the house. And you can do them at any level of groundwater and the type of foundation. The only limitation is the house on stilts. In this article, we will describe in detail all the layers of the "floor pie" and show how to organize it yourself.

Concrete floors on the ground, imply no basements or gaps for ventilation in the underground.

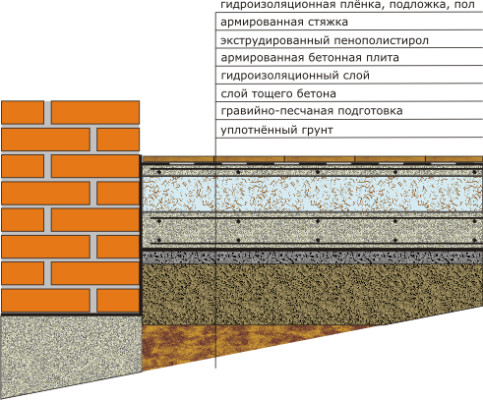

At its core, this is a multi-layer cake. Where the bottom layer is the soil, and the top layer is the floor covering. At the same time, the layers have their purpose and a strict sequence.

There are no objective restrictions for organizing the floor on the ground. High groundwater is not a hindrance in this. Their only weak point is the production time and financial costs. But on such floors you can put brick or block walls, and even heavy equipment.

Water heated floor on the ground

Surface heating design is an excellent solution for living rooms and work areas with a large area (more than 20 m2). Here you can use electric heating or water. In small rooms (bathroom, balcony or loggia), it is quite difficult to place pipes. Therefore, the use of electric underfloor heating is allowed (and even recommended). As a rule, everyone strives to provide comfort in the first place in large rooms. It is worth considering the water floor on the ground, its features.

Based on this, it should be understood that to connect heating, it is worth considering the presence of an autonomous heat source. And for this you need to apply to the relevant government agencies for permission.

There are several methods for installing water systems. But for each of them you need to provide the following:

- When laying on the ground, it is worth taking care of organizing a kind of “cushion”. The first layer of sand is laid (thickness 5–7 cm), then comes the fine stone (layer thickness 8–10 cm).

- The second stage is waterproofing. You can use almost all available materials. Suitable bitumen-rubber or bitumen-polymer mastic. Alternatively, a pasting type can be used. This option has reinforcement in the form of fiberglass.

- You can not do without thermal insulation. You can use polystyrene foam. The thickness of this layer is variable and depends on the calculations being carried out.

- An additional layer of foil-coated roll-type insulation can be used (this is an auxiliary structure, so this step can be skipped).

- Laying underfloor heating pipes on the ground.

- A screed is made over the pipeline. Reinforcing it with a mesh will also be required. The height of such a structure, together with the heating elements, should be 50–70 mm. This is done to quickly warm up the coating. Reinforcement is carried out over the design of the warm floor. This is done in order to evenly distribute the load on the system.

- Finish coating. Here it is allowed to use materials that are not amenable to the thermal effects of the underfloor heating system.