Benefits of using foam

As a floor insulation foam is ideal. Its cost is relatively low, and this is with a large set of the most valuable characteristics of the material:

A screed with a solution with the addition of foam plastic granules gives good results both in isolation from excessive noise and in thermal insulation of the floor.

- The preservation of heat in the room is due to the property of non-transmission of heat by this building material. It's all about the granular structure inherent in foam. Between the round granules there is an air gap, which has excellent thermal insulation properties.

- Isolation from extraneous sounds. It will be possible to walk on the floor without fear of stomping too hard, so as not to disturb the neighbors below.

- Fire resistance. This material is classified by firefighters as self-extinguishing substances. Therefore, in case of fire, if the fire reaches the foam, the floor will not burn for long. The composition of the emitted substances will be the same as during the combustion of wood.

- Long service life. Styrofoam is a unique material. It does not shrink, does not rot and will last a very long time.

The noted characteristics distinguish polystyrene as one of the best materials, making it the best solution for home floor insulation. He will not miss either the cold in winter or the heat in summer. It is lightweight and very easy to handle.

Leveling surfaces and installing waterproofing

Insulation of the floor with foam plastic under the screed is carried out after the surface is leveled. To do this, you can use leveling mixtures or concrete mortar. As an alternative solution, a cement-sand mixture is used. The thickness of such a layer can vary within 5 cm, which will depend on the differences in height. The composition after laying is well dried, only after that you can proceed to further work.

The drying time will depend on the characteristics of the mixture used for leveling. Insulation of the floor with foam plastic under the screed at the next stage involves the installation of waterproofing. This is necessary, despite the fact that the foam is resistant to moisture. In the role of materials for this purpose, special films should be used, which are laid in sheets with an overlap ranging from 5 to 10 cm. The resulting joints are glued with adhesive tape

It is important to foresee the nuance, which is the entry of the material onto the wall, it should be approximately 10 cm. The minimum value is 7 cm

In some cases, the film is replaced with a special mastic. The mixture should be applied with a spatula or brush, the entire surface of the floor must be treated with this composition.

Expanded polystyrene foam and its competitors

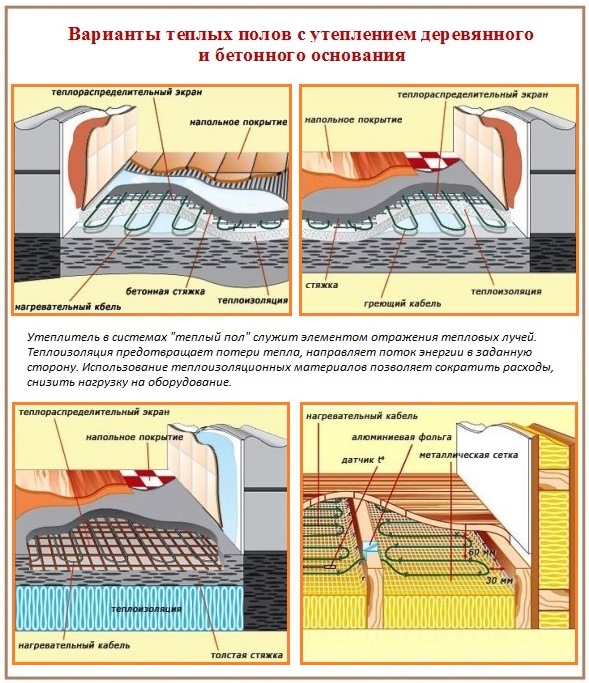

Of the heaters currently used in construction, almost all are applicable for arranging underfloor heating systems. However, there are caveats that put a stop to the desire of professional and independent builders to buy and install:

- cork insulation, the price of which suggests the search for a more affordable alternative;

- mineral wool, which is too sensitive to the action of groundwater, which is why its use in floor structures along the ground and over an unheated underground is highly undesirable;

- foamed polyethylene with or without a foil sheath - a material that decreases three times in thickness under the weight of the screed;

- granulated and extruded foam, attractive in cost and insulating qualities, but not having sufficient rigidity.

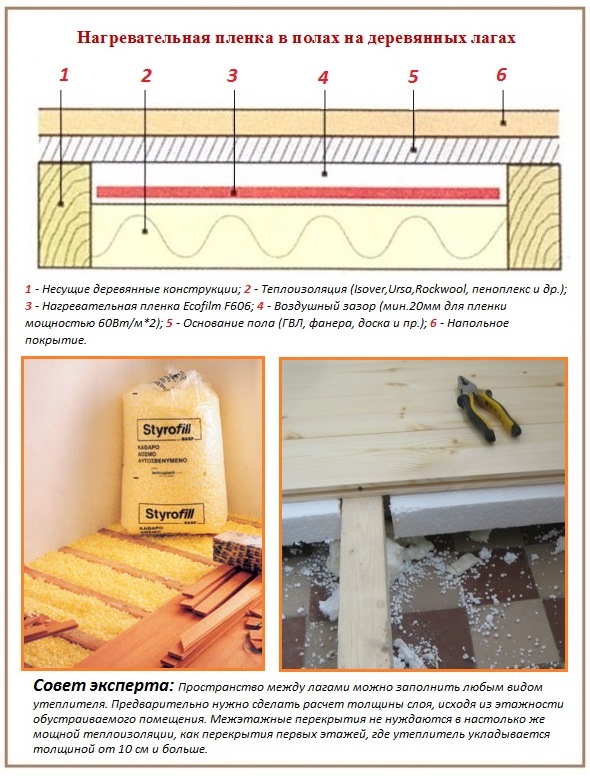

Note that granulated and extruded polystyrene for underfloor heating is a material that is quite suitable if it is not supposed to distribute the load on it. Those.it is cheaper and more practical to find nothing for the installation of heating equipment in the design of a wooden floor with lags and a cold underground.

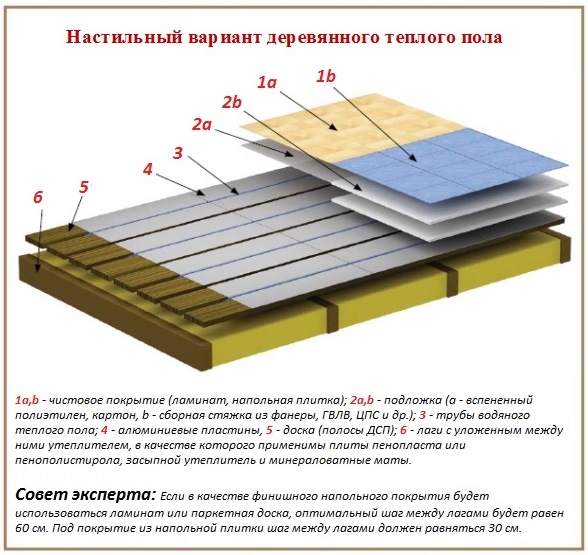

In general terms, the scheme for constructing a warm floor with polystyrene foam or loose polystyrene insulation will look like this:

- Polystyrene granules or cut foam boards fill the free space between the logs installed on a plank or plywood base.

- From above, the insulation is covered with a vapor barrier membrane, then an additional crate is built in the cross of the lags to provide ventilation.

- Plywood or similar sheet material is attached to the crate.

- Install rails from the rails, between which the underfloor heating loops will be laid.

- Further according to the budget. Either only along the path of pipes of water floors or an electric cable, a foil of 30 microns thick is laid, or it is completely covered with foil polyethylene. Or metal profiled guides are installed between the rails, produced specifically for wooden underfloor heating.

After laying pipes or cables, the structure is covered with plywood, OSB boards, GVLV sheets according to the dry screed rules, and then the coating is laid. By default, we assume that this structure is protected from ground moisture and condensate by waterproofing from the side of the underground, or it was already under a plank or plywood draft base.

It is very desirable to protect the material from the side of the basement with a fine metal mesh from rodents. Polystyrene does not cause their appetite, but they should not be given an opportunity for tasting.

Creation of a foam floor screed

To create a floor screed on foam, you will need materials:

- solution;

- mounting foam;

- dry mix;

- Styrofoam;

- waterproofing material.

Tools:

Floor screed tools.

- special cutter or rail;

- level;

- trowel;

- guides.

The first stage is characterized by the implementation of the so-called rough screed. To do this, the surface is leveled with a special dry mix (purchased in the store) or concrete. The thickness of the rough screed layer is 3-5 cm.

After the preliminary filling of the floor has dried, a layer of waterproofing film is spread on it. The material is rolled out around the room, providing for an overlap of 5-10 cm. In addition, the insulation is applied a little to the wall (about 10 cm of the film) to prevent the passage of moisture in the area of \u200b\u200bthe floor plinth.

To do this, you will need to lay slabs of building material over the entire area of \u200b\u200bthe room. Usually sheets of 2-3 cm are chosen. It is not recommended to leave gaps between the plates. The floor is covered with foam plastic so tightly that there are no gaps between the individual elements. Or translucent cracks are sealed with mounting foam. Only insulation without gaps can provide maximum heat in the room.

The scheme of the screed with foam.

After laying the insulation boards, beacons are installed so that the uniformity of the filling can be observed. It is advisable to mount beacons on the narrowest side of the room in order to obtain the highest result in work. Since the cement plaster mixture has a much higher viscosity, it makes sense to install beacons in it. This will be a good help in the implementation of high-precision work.

The mixture is placed in a straight line with large strokes, then a beacon is placed on it and pressed with a level. Similarly to the procedure for leveling the surfaces of the walls, 2 beacons are installed along the edges, between which a rope is pulled. It will help to install the internal beacons more accurately.

After setting, the guides go directly to the pouring of the cement mixture. The concrete mixture is thrown into the gaps between the guide beacons and leveled with a trowel.Then the excess concrete mixture is pulled together (hence the name "screed") with a plaster cutter or lath.

If the flooring chosen is laminate or parquet, then at the end of the drying time of the base layer, a thin layer of self-levelling mortar or ceramic tile adhesive is applied over the screed. Such a technique will ensure that the concrete surface is perfectly even, which will greatly facilitate the laying of the coating in the future.

The floor is insulated with foam, the screed is ready. It remains only to rejoice at the results of the work done and the financial savings on filling the floor on our own.