For dowels

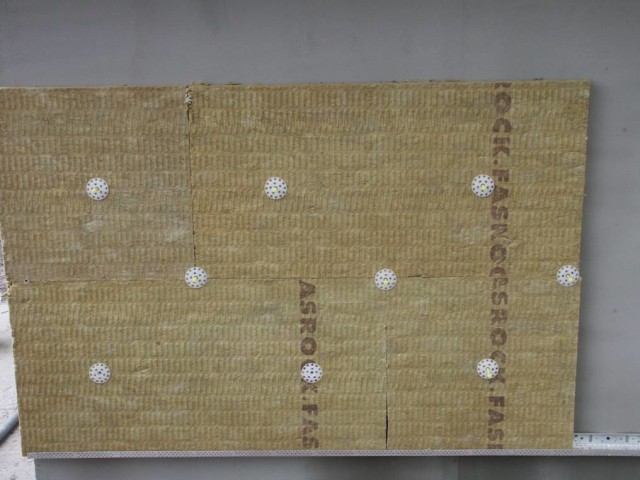

In 90% of cases, mineral wool and other materials are fastened to the wall using dowels.

Now we will simply describe the sequence of work when using this method.

First of all, if an adhesive was first used to fix the heat-insulating boards, they must be well fixed. Most often, fastening with dowels can be carried out 2-24 hours after gluing. A more accurate figure can be found in the instructions for the adhesive composition.

- We select and purchase an umbrella of the desired length;

- We drill a hole into which the fastener will be driven;

- We insert the dowel into the hole;

- Using a hammer, hammer in the anchor (with plastic nails you need to be especially careful when applying force).

Our sheet is securely fixed.

In the case of laying mineral wool, namely its rigid slabs, on the slabs themselves, you will have to pre-drill not only holes, but also round recesses for umbrella caps. Otherwise, these caps will protrude above the surface of the insulation, which will create difficulties when installing the finish.

We discussed the most popular ways to attach insulation to a wall. Thinking about the difficulties and features of installation, they are increasingly choosing another material for insulation - polyurethane foam. It doesn't need to be fixed at all.

Dowels allow you to attach the material to a brick wall and surfaces made of concrete, as well as wood.

Features of thermal insulation of buildings made of wood

When you independently carry out work on the thermal insulation of walls made of round timber or timber, you will notice that these surfaces are not perfectly even. This is a significant problem, since the work on finishing such walls requires non-standard solutions. The existing deviations in the geometry of the walls make their own adjustments to the process of selecting and fastening thermal insulation materials.

Another difficulty that you have to reckon with and consider before you start finishing work is the instability of wooden walls. Natural materials, especially wood, can give minor deformations associated with both the shrinkage process of the house and the operation of the finished building.

The use of materials with low density can only be fixed on the surfaces from the inside, which are located horizontally. The walls, as you know, this does not apply. The way out of a difficult situation can be the use of thermal insulation for facades, produced in the form of plates.

During installation, these plates must be installed close to each other. The installed insulation requires additional protection in the form of a film or nail penofol with foil, which provides wind and vapor protection. This approach will make it possible to secure the space located between the insulation material and the surface of the tree itself.

The choice of materials for thermal insulation

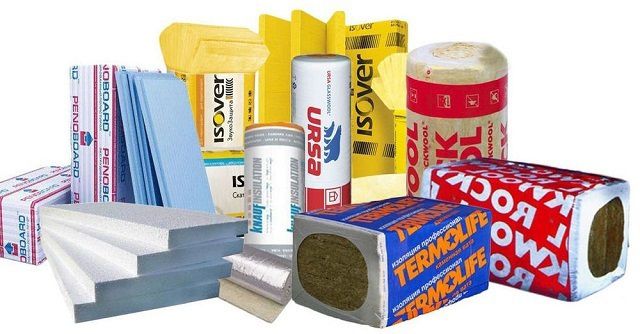

Currently, there are two main types of thermal insulation materials on the building materials market that are suitable for outdoor work. This is foam in sheets or polystyrene foam and mineral wool.

It was noted above that the use of high-density materials, which is foam plastic, is not recommended for insulating log buildings, since such thermal insulation cannot guarantee a good degree of adhesion to a large area of the insulated wall.

Insulation of wooden surfaces with the use of expanded polystyrene is fraught with an increased likelihood of the development of the process of decay and subsequent destruction of the tree. For this reason, it is worth opting for mineral wool slabs.

This group of heaters is widely represented by a range of goods produced by foreign brands. Insulating material can be produced in the form of plates. If its thickness is small, then the products are formed in the form of rolls.

For processing vertical surfaces such as walls, it is more convenient to use slabs. Their shape and density are more convenient in work, they do not slip and do not change their shape. One of the good options is the Techno Nicole brand, produced in Russia. Particularly interesting is the type of mineral wool for facades, which has dimensions of 1200 * 600 * 50 mm.

Calculation of the required amount of materials

A typical indicator of the thickness of mineral wool is 50 mm. If during the cold season the temperature in the region of residence does not fall below -20 ° C, then laying in one layer will be enough. With more noticeable frosts, it will be necessary to equip two layers of insulation, with a total thickness of up to 10 cm.

To correctly calculate the amount of materials, you need to measure the area of \u200b\u200bthe facade, for this the height of the wall is multiplied by its length. Insulation is also sold with the calculation of the number of square meters, when buying, we focus on the value obtained. In the same way, the required amount of material for wind protection is calculated. Such materials are sold in the form of strips rolled into rolls. When buying them, remember that it will be necessary to overlap the strips on top of each other by at least 10 cm.

To insulate a lumber wall, you will need to take a mineral wool-based insulation with a density of 15 to 35 kg / m3. As well as:

- wooden bars, 3 to 5 cm thick;

- adhesive tape for sealing the joints of insulation boards;

- a membrane film that will protect the insulation from the harmful effects of the external environment;

- moisture resistant composition for sizing a protective membrane film;

- self-tapping screws of various lengths with which the crate will be attached to the wall;

- decorative material for cladding the facade of the house (this can be siding and other types of materials) and all related materials for its installation (guides, self-tapping screws, etc.).

How to properly install

- screwdriver (preferably cordless, as you will have to move a lot);

- self-tapping screws with galvanized coating;

- tape measure, building level and various rulers - corners;

- fastenings - umbrellas for insulation;

- jigsaw with a blade for wood;

- metal profiles and corners.

- It is necessary to attach a frame of wooden (metal) profiles to the wooden walls with a step of at least 50 cm. The distance between the beams dictates the width of the insulation - it must fit tightly into the opening. The frame is erected using a building level and attached to metal corners.

- This is followed by the first layer of ecowool or mineral wool. Install the insulation tightly to the base of the frame. Loose insulation should be laid in a special way: a special membrane fabric is fixed on the finished frame, so that a bag is formed. A heater is thrown from above and fixed with a construction stapler.

Minplates or basalt slabs are the second layer after the membrane fabric. Secure the insulation cake with plastic dowels in the form of a fungus, for structural stability.

Install membrane thermal insulation on the crate. Secure it to the wood frame with construction staples or small self-tapping screws. This substrate prevents the ingress of excess moisture into the insulation, which reduces heat loss.

Now you can start finishing: siding, brick or building boards.

Since siding tends to expand in direct sunlight, do not tighten the screws all the way and leave a small distance between the profiles so that they can “walk” in hot weather. If this is not done, then the plastic will begin to bend, which will lead to depressurization of the facade.

Watch the video in which the user demonstrates in detail the process of attaching insulation to a wooden wall:

Features and secrets of the insulation process

When stuffing the batten, which is made from a 25 mm thick building board, experts recommend using a template rail, which will ensure an equal distance between the batten boards over the entire surface.

It is also important, when installing the insulation layer, to provide a ventilation support bar, which will not only ensure the free passage of air in the ventilation space, but will also serve to drain condensate, if it occurs. Another universal way of laying mineral wool is to lay it under the supporting metal profile, as shown in

Another universal way of laying mineral wool is to lay it under the supporting metal profile, as shown in

The use of mineral wool undersiding

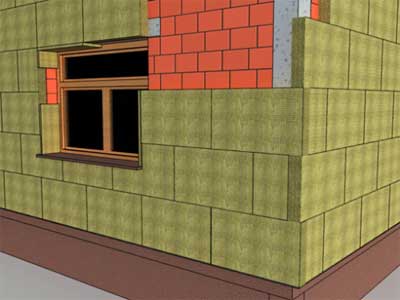

Using mineral wool for siding. The versatility of this method is that the insulation boards are attached directly to the wall.

Before fastening, the walls must be cleaned of roughness and technological irregularities eliminated.

After that, the tiles are laid on an adhesive basis. Also, at the joints, the plates are fastened with a special dowel-fungus

Particular attention should be paid to laying slabs at the corners of the building, which are laid with an overlap, as in brickwork.

It is very important that the laying of the slabs starts from the lower left or right corner of the outer wall of the structure as shown in

Scheme of laying mineral wool on a brick wall

Scheme of laying mineral wool on a brick wall.

Next, metal profile guides are used, which are inserted into the support bar and additional fastening. It is on this additional body kit that a plastic lining for outdoor work is mounted.

You should also carefully approach the issue of choosing a mounting system for lining and arranging a ventilation and condensate drainage system.

This is important, because if a mistake is made in laying the insulation boards, and temperature bridges appear, then the condensate that appears can gradually destroy the integrity of the load-bearing wall, which can reduce the life of the building, or even lead to its complete destruction. Therefore, the issue of laying the plates should be approached thoroughly, because in the future they will all be hidden from the eyes with a decorative layer.

(

Sheathing of walls with siding with insulation under a metal crate.

Wall cladding with siding with insulation under a metal crate.)

Another secret of the quality of laying insulation boards is the treatment of base walls with special deep penetration primers, which, on the one hand, have high surface waterproofing rates, and also increase the level of adhesion of the adhesive base, mineral wool slabs and the base of the bearing wall surface.

Also, when choosing mineral wool, one should take into account the climatic zone in which the building is located, the level of humidity in the environment (houses near a river or lake), as well as the lowest temperature level in winter. This affects the thickness of the sheets used and its density.

The highest quality connection of mineral wool slabs with the base of the insulated surface is achieved by using adhesive bases recommended by the mineral wool manufacturer.

Another unique way to process the insulation layer is to apply a reinforced mesh to the surface of the insulation, on the basis of which decorative plaster or plaster for painting is performed.

Just as practice shows, in the case of installing a drainage system at the corners of a structure, it is necessary to provide attachment points for the drainage system, directly into the load-bearing wall. At the same time, the height of the mounting studs is selected taking into account the thickness of the fastening and further decorative finishing.

Such insulation is elementary to carry out on their own. After all, the laying technology has a simple algorithm.However, before starting work, it is necessary to calculate in detail the scope of work and the technology used, not only for insulation, but also for subsequent finishing. After that, you need to carry out a detailed markup and make insulation.

Necessary tools

To perform the work, the following construction tool is used:

- hacksaw for metal;

- drill with drills;

- hammer;

- Bulgarian;

- wood saw;

- mounting nails with dowels;

- container for the adhesive base;

- putty knife;

- primer brush.

Compliance with the chosen technology of laying the heat-insulating layer in the future will return significant savings on heating the house, and will also keep the morning coolness inside the house on hot summer days without using an air conditioner.

The main types of laying insulation

To insulate the building, it is better to stop at the outdoor installation of mineral wool. Experts recommend this method as the most effective. One of the most common ways is to install plates with the creation of a ventilated gap. This method has been described below.

There are also other ways to insulate walls from the outside:

The wet method consists in the fact that after installing the mineral wool, a reinforcing mesh with plaster is applied to it. After that, the facade of the building is painted with paint. For more information about the wet method of insulation, see the video. On the video, you can more clearly see the correct installation of the sheets, which will help you complete this process without outside help.

The installation of mineral wool according to the “Well” type is carried out according to the following technology: the insulation is mounted between the double wall of the building. To do this, sheets of material are mounted to the brick wall, and then cladding is made of concrete, brick or other materials. Thus, the insulation lies in the gap of the double wall of the building.

Varieties of materials for external insulation

Mineral wool is a fibrous heat-insulating material on a synthetic basis. Contains formaldehyde adhesive.

Advantages:

- has a high temperature threshold;

- does not melt or burn.

Flaws:

- does not protect the tree from mold;

- releases toxic substances at high temperatures.

Glass wool is a type of mineral wool that contains components such as quartz sand, recycled glass.

Advantages:

- has strength;

- does not burn.

Flaws:

- melts at high temperature;

- releases toxic substances;

- encourages fungal growth.

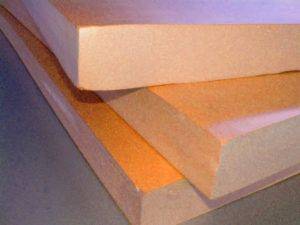

Penoplex is a heater with a cellular structure, and is made of expanded polystyrene.

Advantages:

- strength;

- retains heat well;

- low moisture absorption;

- environmental friendliness;

- not subject to decay;

- fire resistant;

- ease of installation;

- durable.

Flaws:

- easily destroyed when exposed to solvents;

- difficulty in fitting and cutting;

- vapor tightness is often a disadvantage rather than an advantage.

Styrofoam - insulation consists of a large number of balls filled with air.

Advantages:

- excellent sound insulation;

- ease of installation;

- withstands temperature changes;

- density;

- not subject to swelling and decay;

- durability.

Flaws:

- low vapor permeability;

- not fire resistant;

- is not environmentally friendly.

Ecowool is a modern insulation material, made of 80% cellulose and 20% antiseptic, a substance that protects it from rodents and mold. They can insulate any room.

Advantages:

- reliability;

- inedible for rodents;

- prevents the formation of mold and fungi.

- low thermal conductivity;

- environmentally friendly.

Flaws:

- installation requires special equipment;

- undergoes shrinkage;

- smolders when exposed to high temperatures.

There are other heat-insulating materials that can be used to insulate wooden houses from the outside.

Varieties of mineral wool

The type of raw material from which mineral wool is produced, as well as the processing method, affects its type. Depending on the material from which the insulation is made, mineral wool is divided into:

- Stone.

- Glass wool.

- Slag.

Stone is the safest, due to the fact that its fibers do not prick. It is extracted from rocks, then melted and torn into separate thin fibers (density 30-220 kg / m 3, thickness 3-5 microns, length 16 mm). The addition of a binder to the resulting fibers allows the finished sheets to be pale yellow in color.

Glass wool is made from limestone, sand, soda and etibor, which are melted and then passed through special devices and inflated with steam. As a result, thin glass filaments are formed, which are then processed with polymeric materials. The output is amber-colored layers.

Slag wool can be obtained from slag waste from blast-furnace metallurgy. The raw material for the finished product is melted and torn into separate threads to obtain fibers (density 75 - 400 kg / m 3, thickness 4 - 12 microns, length 16 mm).

Insulation of external walls

Consider the most popular:

- Polystyrene. This material is very light and compact. Affordable price, ease of installation and environmental friendliness are the main advantages of expanded polystyrene (polystyrene). Due to the production technique, it has a small thermal conductivity. The only negative can be considered low vapor permeability.

Please note: you should take into account the fact that a wooden house breathes and allows moisture to pass through, and polystyrene foam attached close to the tree will prevent the removal of fumes, which can lead to dampness and mold.

Due to the presence of impregnation from an antiseptic and glue, rodents and other insects are not afraid of ecowool. Studies have been carried out on the thermal conductivity of wool: a layer of 10 cm of wool is equal to a wooden beam 40 cm wide. The advantage of wall insulation from the outside is obvious - saving space inside the house is about 10% of the total area.

3. Mineral wool. Mineral wool is a natural insulation, which is in the form of plates. It is convenient to mount it, however, you should wear a construction mask during work, since the mineral wool insulation has small dust particles.

It should be remembered that an additional strip foundation is required for bricks around the entire perimeter of the house.

Between the wooden house and the brickwork, it is necessary to leave a distance of 20 cm to ventilate the facade, in order to avoid the appearance of black fungus.

Please note: since brick or stone is the heaviest facade material, a mesh of reinforcement is fastened to the foundation.

5. Basalt insulation. Natural insulation, having long and elastic fibers glued to each other. It has good thermal conductivity and low flammability. Flexible and lightweight basalt, well protects a wooden house from drafts and freezing.

Do-it-yourself step-by-step instructions for insulating walls from the outside

After preparing the materials, the insulated area of \u200b\u200bthe house is calculated. Step-by-step instructions for warming a house with a ventilated gap are presented in the video

The video contains recommendations that will help you easily perform building insulation.

When everything is ready, the installation of mineral wool is carried out using the following technology:

- The walls are being prepared.

- A vapor barrier is installed.

- Wooden or metal slats are mounted.

- Insulation is placed in the installed rails.

- Installed waterproofing film.

- A ventilated gap is set up.

Preparation begins with cleaning the walls from peeling plaster, if the wall is concrete or brick. The wooden surface is impregnated with an antiseptic to protect against mold. Slopes of windows and platbands are dismantled.

The vapor-tight membrane is installed with the smooth side facing the insulation. Its installation is carried out to remove vapors from the wall of the building. Insulation can be mounted without the use of such hydroprotection, but only if the surface is perfectly flat.

Then, vertical rails on self-tapping screws are mounted to the wall of the building.

A heater is installed in the gap between the rails. If necessary, the mineral wool is cut with a knife to the desired size. If the installation is made on a wooden wall, then the material is fixed with dowels. And if on a concrete surface or on brickwork, then the use of glue is allowed.

If necessary, you can use a second layer of insulation. It is necessary to ensure that the seams of the 2 layers of insulation do not coincide in order to avoid the occurrence of an air gap.

Installation of a waterproofing film is made from above on a heater. It provides moisture removal from the material. The film is fixed on the rails with the help of dowels. The seams are additionally glued with a special metallized adhesive tape.

The ventilated gap is mounted on top of the rails. For this, additional counter-rails are stuffed. Various finishing materials are then installed on them: block house or siding.

On glue

As the only method of fixing with an exclusively adhesive mass, it is rarely used and only for ventilated facades. For plastering work, additional reinforcement with dowels-umbrellas is needed. However, this method has its own characteristics that need to be considered separately.

First, there are two types of adhesives:

The dry mix is sold in bags and requires dilution. Glue-foam is sold in cans and does not require prior preparation. The latter costs a little more, but the convenience is worth it.

Exposes the bottom bar, which will be the starting point of thermal insulation. The dry mixture is applied to the plate itself.

In the case of a dry mixture, you need to apply glue to the plates in several pieces and evenly distribute it over the entire surface with a comb. After that, the insulation board is fixed on the wall. Usually, the installation of mineral wool or other materials starts from the corner and always from the bottom row.

Adhesive foam is applied around the perimeter of the slab and in several strips in the middle. After applying, press the plates to the plane. The foam hardens from 30 minutes to 2 hours. During this time, it is possible to slightly correct the position of the plate using a level.

From dry mixes often used:

- EK THERMEX;

- Ceresit CT 190;

- Ceresit CT180.

Popular foam options:

- Ceresit CT 84;

- Soudabond EASY;

- InstaSTIK.

The cost of one cylinder is from 200 to 500 rubles.

We discussed the basic principles of how to fix the insulation on the wall using an adhesive composition. You can decide what exactly to use by reading a couple of opinions.

With large differences in the walls, it is recommended to use polyurethane foam, specifically for foam. It is also called "liquid foam". If the curvature of the wall is one to three centimeters, this is not a problem at all. I bought it at the Epicenter a year ago, glued a sheet for the sake of interest - a year has passed, everything is holding on, the sheet cannot be torn off. Styrofoam breaks, but holds.

Is polystyrene foam good as a heater

Scheme of thermal protection of various materials for insulation.

Styrofoam (polystyrene), due to its characteristics, has found very wide application in construction. It has low thermal conductivity, relatively good vapor conductivity, and also low weight, which does not additionally burden the building structure.In addition, it has the ability to withstand high mechanical loads, while having a low density.

Other positive qualities of polystyrene include its good interaction with other building materials, resistance to moisture, rather low thermal conductivity (or high thermal resistance), low noise resistance, extraordinary ease of processing and relatively low price.

Today, many argue: will it be good if we insulate a wooden house from the outside with foam

They pay attention to its low vapor conductivity, which allegedly leads to moisture and rotting of wooden walls. Therefore, it is not advised to insulate with polystyrene, and when choosing a heater, it is recommended, if possible, to replace polystyrene with other heaters

But the approximate indicators of vapor permeability of materials given by them show that polystyrene foam has approximately the same vapor permeability as pine wood.

Therefore, the use of polystyrene as a heater for buildings with high internal humidity (for example, baths) is not recommended. And if inside the wooden house the humidity is normal and controlled, then the use of polystyrene foam as a heater will fully justify itself.

Scheme of insulation of the foundation with foam.

There is an opinion that it is better to use penoplex as a polystyrene insulation. Let's consider this question. Penoplex is extruded polystyrene foam. That is, most of its characteristics are similar to the characteristics of polystyrene (heat and sound insulation, resistance to aggressive substances, specific gravity, ease of processing, etc.). It is characterized by greater density, increased mechanical resistance to stress, as well as the ability to self-extinguish when ignited.

The downside of foam plastic is its low vapor and air conductivity, besides, it has a high cost compared to foam plastic. The shortcomings of polystyrene before foam are eliminated by work on protecting the foam from fire with facing fire-resistant materials and putties. In addition, the vaunted fire safety of foam plastic approaches zero during the fire itself, since the combustion of the insulation will be supported by the burning of the wood of the walls. Thus, the use of foam plastic for warming a wooden house is more profitable than foam plastic.

The procedure for warming the house with mineral wool

Before starting work on warming the house, it is necessary to prepare the surfaces of the walls: clean them from dust, various contaminants and treat them with an antiseptic.

The procedure for warming the outside of the house with mineral wool involves five stages:

- The first stage is the laying of a vapor barrier, which provides ventilation and prevents the house from rotting. For vapor barrier use a special film, roofing material or aluminum foil. It is impossible to lay vapor barrier material directly on the wall, so as not to expose the walls to fungus or mold. To do this, it is necessary to leave a ventilation space between the wall and the vapor barrier material.

- Stage two - involves the manufacture of a wooden frame for insulation material. The frame is made of wooden slats, which are attached vertically to the wall and should be 1-2 cm smaller than the size of the mineral wool slab.

- The third stage consists in laying a layer of insulation. Insulation with mineral wool is recommended to be laid in two layers in such a way that the joint of the first layer lies in the middle of the second. No cracks are allowed. For reliability, the insulation is fixed with metal or plastic anchors.

- Stage four consists of waterproofing, which prevents water from entering the insulation and walls.

- And the final fifth stage is the cladding of the house from the outside. Sheathing material is attached to a wooden crate made of a 4 × 5 cm bar.Thanks to new modern technologies, a wide range of exterior coatings are presented on the market, which will give the house an aesthetic look.

Application and characteristics of penoplex

Penoplex, like polystyrene, is a type of processed polystyrene foam. It is produced in the form of a plate and has good protection against mechanical influences and the influence of external factors.

In addition to all this, such material can be used for finishing rooms with a high moisture index. Often it is used for room insulation.

You can lay such a heater in any conditions, both inside and outside the house. It is used to finish the foundation, walls, ceiling or floor. The material will be the best solution for thermal insulation of a balcony or rooms with high humidity.