Separation from the base of the ceramic coating area together with the solution

The most likely cause of such destruction is an incorrectly selected primer mixture or a primer that was not completed at all before laying the tiles. A common mistake in subfloor preparation is priming with concentrated latex, which forms a thin rubber film on the surface that prevents adhesion to cement-based tile adhesives.

Separation of the laid tiles together with the mortar from the base can be caused by deformation of the base

The preserved finish is inspected and tapped in order to identify voids that are fraught with additional destruction of the lining. If the area of the collapsed finish and the existing voids in total exceeds 20% of the total area of \u200b\u200bthe base, then the lining of the wall or floor will have to be redone in full, taking into account the mistakes made, since after partial repair, the destruction of the old tile is likely to continue.

Sheathing the walls of the bath with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with the properties of increased thermal insulation and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall sheathing, consisting of thermal insulation with fireproof properties and a metal coating in the form of a sheet.

Wall insulation with reflective sheathing

Protective cake with reflective materials do so. First, the thermal insulation is fixed with ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since when heated, it is possible to release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow into the steam room, reduces heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-combustible, environmentally friendly;

- asbestos cardboard, which reliably protects against the occurrence of a flame, characterized by long service life;

- minerite, an artificial material made specifically for this purpose.

The protective sheathing assumes the presence of ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close as possible to the wall, make a double sheathing of non-combustible insulation, with the help of ceramic bushings withstand gaps of 2-3 cm and sew up with a steel sheet.

Insulation with cladding

Measures to protect the walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bath. It is based on tiling, which is laid on a refractory lining of GKLO, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-combustible cement-fiber material, moisture resistant and resistant to biochemical attack, LSU, material made of fiberglass bonded with magnesia additives, resistant to impact high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from chamotte dust bound with kaolin additives, designed for tiling stoves, fireplaces, all heated surfaces.

The recommended facing materials are quite diverse, the best of them are:

- terracotta tiles, it is made from special firing clay, which gives increased heat resistance and durability;

- clinker, more dense clay tiles with a surface of various colors, similar to facing bricks;

- tiled tiles, also made of clay, with an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under pressure of 400-500 kg / cm², with imitation of stone, wood, durable artificial material;

- talc chloride, a rock mineral consisting of talc, magnesite and chlorite, is an environmentally friendly natural material that absolutely does not absorb moisture, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use talc chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes, due to the release of vitamin D when heated.

All of the listed tiles are a protection element that rearranges the cake, the basis of which is a refractory material. As well as a screen, the sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tiles should be 20cm.

Protection with cladding decorates the room, creates a positive mood, improves the efficiency of procedures. And most importantly, properly installed insulation prevents the occurrence of overheating of wooden walls, their ignition. Light steam!

Types of violation of the integrity of the finish and defects in ceramics

- Separation of the facing area together with the mortar from the base.

- Detachment of ceramics from the adhesive composition on the surface area.

- Violation of fastening and falling of a separate tile.

- Cracks in firmly seated ceramics.

- Shells and chips on the surface of the tiles.

To determine the causes of the destruction of the finish, it is necessary to examine and analyze both the materials used in the repair and other factors that are not always noticeable at first glance.

Both old tiles and newly glued tiles can fall off

Possible causes of ceramic finish damage:

- incorrectly selected tile;

- incorrectly selected primer;

- deformation of the base under ceramics;

- physical wear of the coating;

- base not primed before laying tiles;

- uneven base under the tile;

- low-quality tile adhesive;

- incorrectly applied layer of adhesive solution;

- aggressive operating conditions (detonation);

- mechanical damage from impacts;

- sealing technological and mounting holes.

Any of these factors or a combination of several circumstances can cause the destruction of a section of a facing coating or individual products.

Consider the methods of repairing a tiled surface, depending on the type of damage.

Step-by-step instruction

Thermal insulation works are carried out taking into account certain rules and safety standards. It is preliminary recommended to decide on the method of warming the furnace. The following elements are thermally insulated in the furnace building:

The first structure is insulated in the following cases:

- reduction of heat consumption - thermal insulation work is carried out with improper design of the fireplace or stove, when all the heat exits through the chimney (due to excessive draft or the use of materials with high heat transfer);

- insulation retains heat;

- elimination of condensate: if the pipe is not insulated, condensate collects in it, it destroys the laying of the pipe or the joints of the welded coating.

Experts recommend insulating the surface of the furnace, located close to the walls of the house. Otherwise, due to temperature fluctuations, cracking of the brick will occur.Thermal insulation in the gap between the wall and the furnace is carried out using the following materials:

- asbestos boards;

- thermal foil (as a heat reflector).

The considered method is used if the space between the stove and the wall exceeds 5 mm. If the distance is small, then asbestos cannot be used (due to the composition of the material).

You can perform thermal insulation work using the following technology:

- strengthening the wall using a suspension of metal sheets;

- installation of ceramic or asbestos insulation boards;

- filling gaps and seams with mineral wool;

- winding the pipe with an external reflector (foil).

Since mineral wool does not tolerate condensation, a special material should be used to insulate this seal. A similar technology is used for furnace thermal insulation. At the same time, the wall does not heat up and does not heat up.

Basalt cardboard characteristics

The main difference of this material is high thermal insulation and sound insulation. It is non-flammable, fire resistant and fireproof. At the same time, basalt cardboard has an extremely low hygroscopicity, in other words, it is not able to absorb moisture from the air. The temperature of use of this material is +500 degrees, while for a short period it is able to withstand up to +700 degrees. Another reason why cardboard should be used in a bath is that it has excellent vapor permeability. It has an increased resistance to microorganisms and rodents, does not crumble, does not rot, is resistant to vibrations and thermal-oxidative aging. The approximate service life of this material is 50 years.

At the same time, basalt cardboard is very easy to cut, it can be done even with a simple knife. The sheets bend well and can take any shape, which makes it possible to make excellent thermal insulation of the bath room. Parts made of such material are able to be fixed with a special adhesive.

Right when cutting, it is necessary to take into account the shrinkage of the cardboard, which can happen from exposure to elevated temperatures. In case of high humidity, the sheet may bend, but after drying it will return to its previous shape

In total, it is able to withstand more than two thousand cooling and heating cycles.

Waterproofing and insulation

It happens when the walls in the bathroom need to be additionally insulated. After all, if you put tiles on concrete and aerated concrete, the surface will still remain cold. In order to properly insulate, it is necessary to use sheets of OSB, chipboard or GVL. These materials are mounted on a pre-primed surface on concrete or aerated concrete, then putty is applied.

Any wooden wall requires preliminary reinforcement. The OSB board is not afraid of moisture, unlike chipboard, due to the fact that it is glued with special resins. Chipboard is not waterproof, because it is pressed from small chips. GVL, or gypsum fiber sheet, is used for surface waterproofing. After insulation of OSB, chipboard or GVL, preparation is required before laying tiles:

- use on a special metal reinforcing mesh on OSB, chipboard or GVL sheets. It is applied with a hammer and a furniture stapler;

- a special cement-based waterproofing is applied to the grid;

- left for some time to dry. How long it dries depends on the temperature in the room;

- primer is applied.

After these works, you need to start laying tiles. On a prepared basis, the tile holds better than on clean sheets of OSB, chipboard or GVL. In some cases, installation is allowed without the use of a reinforcing mesh, but this significantly reduces the quality of the work performed and the tile may soon fall off.

Another way to insulate is to use a material such as foam.The technology for preparing it is the same as for chipboard, OSB and GVL using a mesh on which rotband putty is applied. How long such plaster dries depends on the temperature in the bathroom.

Styrofoam, which has good thermal insulation properties and, together with the positive qualities of tile, is an excellent option for obtaining warmth, strength and waterproofing at the same time. It should be remembered that mechanical methods cannot be used to level the foam. If the penoplex has a good density, then it is attached to the wall with special plastic fungi. They also attach a layer of reinforcing mesh with plaster to the foam. The step between the dowels should be 35-40 mm. In order to more securely fix the tile to the foam, the mesh is coated with putty and cement glue (in a ratio of 2: 1).

In some cases, concrete or aerated concrete uses mineralite, which is a fibrous cement fiber material, to protect against moisture. Minerite has a high rate of moisture resistance and is not susceptible to mold. Therefore, it is important to use minerite for bathrooms with high humidity. Before laying the tiles on the minerite, it is necessary to prepare the surface:

- clean off the glossy layer with a power tool;

- clean the minerite from dust;

- apply special glue to the metal mesh. Let dry. How long the glue dries in the grid depends on the temperature in the room;

- apply another layer of glue on the mesh and let it dry again.

After these works, you can start laying tiles on the minerite.

Unusual options for decorating the walls in the bathroom

An unusual option is the use of other tiles (Himalayan salt and mosaic) in addition to the usual ceramic. An excellent solution for wall decoration in the bathroom is the use of mosaics. Ceramic mosaic tiles, like tiles, are placed only on a flat surface. In addition to this type, there is a flexible base mosaic, due to which it can be placed on an uneven surface. Such a mosaic finish is made of glass or ceramics. Glass has a large selection both in shape and color and it is performed on a mesh base. Oh, the ceramic mosaic decoration is glued onto paper. But the only thing to remember when working with a mosaic is that it will not work to correct the curvature of the walls and the mosaic will repeat all the irregularities. Therefore, a rotband mixture should be used to level the surface.

Another option for decorating the walls in the bathroom is to use Himalayan salt tiles. It is used to create a modern apartment design. Finishing with Himalayan salt will provide a healthy microclimate due to its beneficial properties. These salts also have antiseptic properties.

A good effect is obtained from Himalayan salt cladding, having beaten all the walls in the bathroom with it. Himalayan salt tile has pleasant warm tones with a translucent matte texture.

Himalayan salt tiles on bathroom walls

Himalayan salt tiles on bathroom walls

Some are wondering about the possibility of sticking tiles on wallpaper. But professionals will answer unequivocally that no. Firstly, due to the fact that the glue on which the wallpaper was glued may lose its adhesive properties. Secondly, the tile is very heavy, compared to how much the wallpaper weighs - they can fall off. It is worth refraining from laying tiles on the wallpaper if you want to get a quality result.

Finally, it should be noted that ceramic tiles are the most common option for wall decoration in the bathroom. The main thing to consider before sticking tiles with your own hands is the material of the wall. If the wall is insulated with additional material, or leveled with a rotband mixture, then this should be taken into account before tiling the surface.Indeed, depending on the base, whether it is wood, polystyrene, OSB, gypsum board, minerite, concrete or aerated concrete, you should adhere to the installation technology. The quality of the work performed and durability depend on this. But it is better to refuse installation on wallpaper or paint. If you want to make the bathroom interior modern with the use of sustainable materials, then you should use Himalayan salt tiles or mirror tiles.

- How to prepare the wall for tiles in the bathroom

- Repair of a combined bath with a toilet

- How ceramic tiles are disassembled

Application of protective screens

Screens are shields made of brick or metal, covering the walls from intense thermal radiation. Similar protection is used when installing metal furnaces.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5 cm.

Advice! When purchasing a metal stove for a bath, you should give preference to a model equipped with a metal casing. Its cost is not much higher, but the issues of wall insulation are removed.

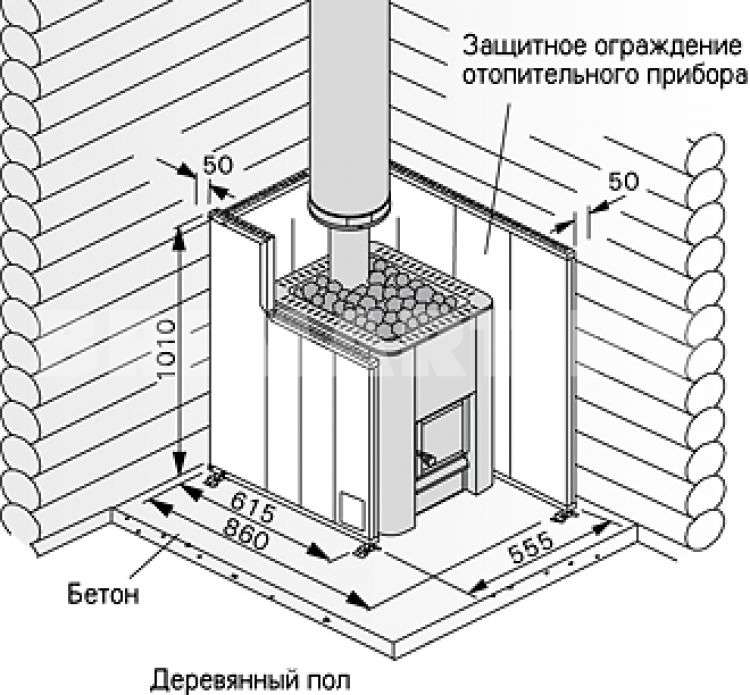

Additional front or front shielding, which is located on the walls, depending on the location of the furnace, will not interfere. Protection guarantees wood from overheating, reducing t ° by 100 degrees or more, and provides an opportunity to save space in the steam room. The oven protected by a casing can be installed at a distance of 50-55 cm from the wall.

Screen installation is simple. The casing, equipped with legs, is attached to the floor with side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry, which sew up the oven with

all sides, the same casing, only made of brick. Another way is laying half a brick between the firebox and a wall of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm bricks in a quarter, but it should be remembered that in this case the thermal insulation index is reduced by exactly half. In height, it is recommended to raise the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Important! In the lower part of the masonry, functional holes for heat transfer should be made. Protective screens are effective, they reduce the temperature to a level acceptable when using high-temperature fuel units

The same function is performed by wall cladding made of non-combustible materials.

Protective screens are effective, they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.

Protective screens near or around the oven

Such a system will need to be performed when installing a potbelly stove in the corner of the room. You can mount or lay out of brick several screens installed at a short distance from each other. In this case:

- the first screen protects a person from touching the iron furnace and getting burned. It is customary to make it from refractory or fireclay bricks;

- to protect walls made of combustible material, a second layer of protection is provided. It can be laid out of brick or covered with a sheet steel barrier with a mirrored front surface. In this case, heat waves will be reflected from the mirror and spread faster around the room;

- if the foundation is insufficient in size or it is impossible to manufacture it, it will be necessary to lay a protective screen made of durable refractory material on the wooden floor. It can be a sheet of steel or a decorative layer of heat-resistant clinker tiles or porcelain stoneware. The surface will first have to be covered with a layer of thermal insulation.

Installation of metal screens

This is the easiest way to make surface protection.It is better to use sheets with a polished front surface. Before fastening, the wall surface at the desired level along the height of the screen is covered with a layer of thermal insulation. Thus, we protect the surface of the walls from heat.

You can lay a layer of thermal insulation or fix the metal on self-tapping screws with inserted ceramic gaskets. But it is better to fix the screen on the strips treated with a layer of protection or a metal profile. In this option, the air gap will not allow heat to pass freely to the walls, reliable insulation of the stove from the wooden wall is ensured.

A special gap is made in the lower part of the wall for the passage of cold air, ventilation of the wall and screen. When arranging the wall with a layer of thermal insulation, a number of longitudinal guides are installed on the surface. The space between them is filled with a layer of mineral wool or other material. Then sheets of metal are installed, screwed to the crate with screws.

In this design, the gap in the lower part can not be left. The air will not be able to calmly pass, but the wall will be reliably protected from high temperatures. To protect the floor of the house, a plate made of non-combustible durable material can be used.

brick screens

This protection option is usually installed near the furnace. Thus, it is possible to protect not only the wall, but also a person from burns. By installing a brick wall, you can reduce the distance from the stove to the wall. For laying, it is better to use ceramic or refractory bricks.

The work is carried out in several stages:

- you will need to make a small foundation or remove the boards from the floor along the marking lines for laying the screen and, having drilled holes in the concrete of the base of the building, insert metal rods to fasten the bottom of the wall and the foundation;

- having leveled the floor surface, lay out a layer of mortar and lay the first row of bricks, it is required to place the bricks in the same plane without distortions. It depends on how even your entire wall will stand. Do not forget to make small ventilation slots, for this you can move a few bricks from the bottom row.

- checking the level and pulling the twine for laying each subsequent row, all the bricks are laid on a mortar of clay and sand. Having raised the wall to the required height, the top is sealed with a layer of mortar or covered with a board. So you can make a shelf for decorative ornaments and all kinds of little things.

The brick is laid out no higher than the top of the furnace at a distance of at least 40-100 mm from it.

With the help of protective screens of both types, it is possible to reduce the distance from the furnace to 500 mm.

Examples of installing brick protective screens in the photo:

When the process is not possible

So, we answered yes to the question of whether it is possible to glue the tiles in the bathroom on the old tiles. And in what cases this procedure is impossible? First of all, when more than 40% of the old coating is in poor condition. In this scenario, the work will be meaningless. It’s easier to be a little patient and spend money, but remove the old tile, prepare the floor and walls and lay a new tile floor. You can not use the old tile as a base, and in cases where it seems to be whole in appearance, but when pressed, it kind of crunches. This suggests that there are voids under it. And such a surface will not be able to withstand the weight of the new coating for long.

How to glue tiles on tiles in the bathroom on the floor

And here, too, there are no special rules.

What you should pay attention to? The floor, as a rule, is subjected to much greater loads than the walls, which is quite understandable, but we walk on it every day. Therefore, be careful when applying glue to the surface of the base.

It should not be allowed to leave places untreated with the composition, otherwise it is fraught with the fact that cracks may appear on your new beautiful tile over time. In addition, it would be advisable to consider such an option as laying diagonally.This method is good because the new coating will be more durable due to a different arrangement of the seams.

And this is done very simply. Mark up by dividing your bathroom floor into equal rectangles or squares (depending on its configuration), find the center. Lay the tile so that its corners are aligned with the axes you have drawn. In the future, it will serve as a guide for the following elements. True, there is a lot of trimming with this method of performing work, but on the other hand, the strength of the base will not cause concern. When you're done, let the tile dry, and then seal the seams too.

We ensure the durability of the future coating

Since it is unlikely that it will be possible to glue tiles on tiles in the bathroom on an old glossy coating, it should be pre-treated. How? There are three ways to solve the problem.

It is necessary to remove the gloss from the old tile. It's long, hard, besides there will be a lot of dirt. Then you need to make notches on it (the same disadvantages) or treat it with a special compound. The third method involves the purchase of a primer, which is quite expensive. But since even the most economical owner will not be able to stick tiles on tiles in the bathroom at all without financial costs, it is wiser to stop at this option. But the process will not take any time or effort. And this miracle remedy is called "Concrete-contact". The primer will roughen the old tile and provide excellent adhesion to the substrate. The composition is applied with a brush or roller. The main thing is to withstand the exposure time, that is, to give the primer a good grip and dry. Which will take six hours, no more.

When it's required

It happens that there is no need to protect the walls. If the furnace is located at a safe distance from the wall in terms of fire safety, the arrangement of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source is different:

- A stove laid out in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal furnace without a lining should be placed a meter away and not closer;

- A metal one with a footed crucible can be installed 70-75 cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² hardly accommodates the necessary set of items for the soaring procedure. Therefore, the need to isolate the walls with special skins is relevant.

Advantages of basalt cardboard

Heat-insulating basalt board is used during the treatment of areas of thermal equipment that are extremely sensitive to elevated temperatures, such as, for example, insulation of heating and thermal furnaces, insulation of dampers, boilers, pipelines, and doors. Basalt sheets are used for a heat-resistant layer between the stove and the floor, the chimney and the roof, where other materials cannot be used. It is also used for thermal insulation of drives of any kind, thermal boxes, mixers and ladles. Basalt cardboard is used as part of a variety of structures, for example, a “sandwich”, which is assembled from layers of paper and cardboard. It can also be used to isolate joints in building structures of various purposes.

Due to its environmental friendliness, this material can be used as thermal insulation for heaters, boilers, and other household equipment.

- High degree of thermal and noise isolation.

- Fire resistance.

- Environmental Safety.

- Does not affect the corrosion resistance of metals.

- Biologically stable (does not attract rodents and microorganisms).

- Retains properties at high temperatures (up to 700°C).

- Not resistant to moisture, so additional protection is needed.

Thermal insulation of heat pipelines, oil pipelines and gas pipelines, other types of communications subject to the influence of temperature extremes and other aggressive factors.

As a heat-insulating and soundproofing material in the construction of structures for various purposes (industrial and residential).

As a heat-insulating material for various containers, reservoirs, boilers, etc., provided that the surface temperature is between -180 degrees, +700 degrees.

Thermal protection and insulation of refrigeration units.

As fire protection of air ducts and other structures.

As a heat-insulating and soundproofing material in interfloor ceilings, wall partitions.

Basalt cardboard with foil is one of the varieties of basalt cardboard, the main feature of which is the presence of foil on one side. Like other types of similar cardboard, the material is made of basalt rock fibers, which are formed into dense sheets that can provide a significant thermal insulation effect. Thanks to the foil layer, this effect is doubled, since the thermal energy is reflected inside the room and is stored even better. In addition, basalt foil board can also be used as sound insulation, as it has excellent sound absorption capacity.

It is a non-combustible, fireproof and fire-resistant material that practically does not absorb moisture from the air. Foiled basalt cardboard fits perfectly under the screen and pre-furnace sheet to provide maximum thermal protection for wooden surfaces in the sauna. Able to withstand temperatures up to 1000C. According to its characteristics, basalt cardboard is superior to the widespread asbestos cardboard, it has improved sound absorption, thermal conductivity, and service life.

Advantages of Basalt cardboard:

Environmental friendliness. Basalt cardboard is an absolutely environmentally friendly material. It does not contain or emit harmful substances even under the influence of high temperatures. It is used in industries such as microbiology, food industry, pharmaceuticals, which require more stringent environmental control of production.

Heat and sound insulation. Due to the light fibrous structure and the chaotic arrangement of fibers, basalt cardboard has enhanced heat and sound insulating properties. Its use will allow you to effectively perform high-quality insulation, reducing the level of noise and heat loss.

Fire safety. The use of cardboard prevents the spread of flame, which minimizes your risks. Products belong to the group of non-combustible materials (NG). The melting point of the fibers is over 1000C.

Durability. In the absence of mechanical damage, the service life of the material is unlimited.

Ease of installation. The material is easy to handle, allowing you to do the installation yourself.

The price is for 1 sheet of basalt cardboard.

Reclaimed tile installation

The laying of ceramics is carried out from the bottom up, maintaining a given gap between the tiles by inserting fixing crosses. A layer of tile adhesive is applied to the back surface of the product, slightly thicker than under the boundary tiles. The sheet is applied to the surface at the installation site and pressed to the level of the old cladding. Excess glue squeezed out from under the tile is immediately removed. In order to properly glue the last tile, a layer of glue is placed on its back surface more accurately, since it is difficult to squeeze out its excess through narrow joints with adjacent products.

The tile can fall off the wall or floor along with the adhesive and from the adhesive

After 1-2 hours, when the glue sets, the tile joints are cleaned of mortar to perform grouting, which can be done the very next day.

If the wall or floor cladding was repaired in the kitchen, bathroom or toilet, then the tile adhesive and grout should be selected from the “moisture resistant” group, which also contains antifungal additives.

So that the repaired section of the wall or floor does not stand out against the general background, it is possible to partially remove the old grout from the seams on the old cladding and wipe the joints with fresh grout used for repairs.

Cleaning loose tiles

If there is a supply of facing material, then use it, or buy the same ceramics, if not, the fallen off finish is cleaned of the solution. To do this effectively, in a way that is gentle on ceramics, use a grinder with a dry cutting disk. The tile is soaked in water for half an hour to soften the glue and reduce the amount of dust. Then the ceramics are laid face down on a flat wooden surface, pressed with a clamp through a rubber pad and the old mortar is cut off or grinded off at an acute angle to the surface. The edges of the tile are cleaned of grout with sandpaper.

The use of basalt cardboard

The fibrous material was developed exclusively as an environmentally friendly insulation. However, due to its high physical characteristics, it began to be used not only to reduce heat losses, but also for other purposes.

Carrying out thermal insulation

Basalt cardboard is an environmentally friendly and absolutely safe insulation, which is recommended for use in residential premises. The material is sheathed with loggias and balconies, door leafs. Almost zero hygroscopicity allows the use of fibrous insulation sheets in stainless steel screens for saunas and baths.

The heat insulator is suitable for external and internal insulation of building envelopes of houses built from timber or chopped logs. Basalt cardboard is used for sheathing interfloor ceilings in industrial and residential buildings. Often, a fibrous heat insulator is also used for floor insulation, performing assembly according to the “warm floor” system.

As a soundproofing material

The structure of basalt cardboard provided the heat insulator with the ability to absorb low, medium, high sound range noise. Fibrous sheets are often laid between GKL and GVL. This allows for a good level of sound insulation. Fibrous cardboard is included in many noise-absorbing materials, especially panels. It is also laid when equipping floating floors. Thus, this type of insulation is used for soundproofing the surface of the floor and walls.

Application for household equipment

Fibrous material is used for insulation in various types of cooling and heating structures to protect against the temperature influence of the environment. Basalt cardboard has become a safer alternative to asbestos sheets. It does not contain harmful substances and does not lose its operational properties when used in lining chimneys and pipelines. Heat-resistant substrates are also made using fibrous sheet cardboard. They are involved in furnace structures, as well as in the arrangement of the floor, ceiling and walls. The insulator wraps heating elements in boilers for both industrial and domestic purposes. A dense basalt sheet is used for thermal insulation of frying ovens, kitchen gas and electric stoves, refrigerators and cold rooms. The material is also used to wrap water pipes and air ducts in supply ventilation systems.