Video of the intricacies of filling a closed system

With caution and start-up rules, you can independently cope with adding water to the old system. At the first start, the check and filling must be done by the masters who installed the heating

If you do not have the skills, do not try to fix the leak yourself or replace the coolant in the circuit. Entrust the work to a specialist - the master will select the optimal carrier, cleaning agent that will not damage the internal surfaces, and correctly fill the system.

The procedure for starting the heating of a multi-storey building.

Starting the heating of a multi-storey building

often associated with troubles arising from ignorance of the rules. To start heating, you must follow a certain order and sequence.

The beginning of the heating season in housing and communal services is often complicated by the problems of uneven heating on the upper floors of a high-rise building, as well as entire risers and apartments.

Such problems are formed due to the rapid start of the heating system. With the rapid filling of the pipelines of a high-rise building, air jams are formed in the system in the heating system of a multi-storey building. which do not allow risers and entire apartments to warm up.

In the summer, after a hydraulic test of the pipeline. the heating system remains stationary, the pressure drops. In order to prevent the system from swallowing air and not collecting air jams at startup, it is necessary to follow certain rules for starting the heating system of a multi-storey building.

How to properly fill the heating system with water in an apartment building, namely:

-

- 1. Perform a smooth start of the coolant into the system. Make-up pumps in the central heating station should be turned on at minimum speed so that the coolant fills the system not abruptly, quickly with a jump, but slowly and gradually.

- 2. The filling of the system must be carried out through the return line of any system of a low-rise and high-rise building, that is, from the bottom up. With such filling, water, the coolant, smoothly displaces all the air accumulated in the system during the summer period, thus displacing the air plug from the system.

-

- 3. After a soft start, you need to release

remaining air from the heating system

—

from air collectors located at the upper points of a multi-storey building

in the attic. - 4. On the air collector, open the drain cock, waiting for the characteristic air whistle to stop.

- 5. After the air stops coming out of the bleed valve, it is necessary to drain the water from the heating system. to release the remaining air.

Drain a small amount of water until bubbles stop coming out. Water must be drained into a bucket or any other container so as not to flood the upper floors. - 6. In houses where there is no attic, for example, in five-story buildings, the air is released independently through the Mayevsky taps on the top floor of the house. Having slightly opened the Mayevsky tap with a screwdriver, the air descends, and the radiator immediately begins to warm up.

- 3. After a soft start, you need to release

Major errors when starting the system.

- 1. Mistake No. 1 is a quick start of the system through the supply line.

- 2. Mistake No. 2 is the drain of water, the coolant, from the system in the basement. An absolutely meaningless thing, since the air rises, and there is no point in lowering it from the lower points, it will not come out anyway.

- 3. Mistake #3 is bleeding air and water from the battery in every apartment in a multi-storey building. When the system starts correctly, this procedure disappears by itself.

See how to bleed air from the radiator:

- When should the system be filled before starting the heating after the summer

- How to properly start the heating system of 5 and 9 storey buildings

- Air lock in the heating system of a multi-storey residential building.

- Should the heating system be filled in September

Social Reviews Cackl

e

We fill the system from below

So, back to pumping fluid into the system. We use a container of a suitable volume (a plastic barrel with a volume of 200 liters is well suited). We lower a pump into it, which creates the pressure required for pumping liquid no higher than 1.5 atm (typical value in the range of 1-1.2 atm). Such pressure requires the creation of a pressure head of 15 m by the pump (for the submersible "Baby" it reaches 40 m).

After filling the barrel with water, we start the pump, watching the liquid level, which should be located above its inlet to prevent "airing". The level drops - add water. Antifreeze should be pumped from a container of a smaller volume (bucket) so as not to immerse the body of the submersible pump in liquid (and then not wash it) - it is enough to immerse the inlet pipe. You will have to add antifreeze often, periodically turning off the pump.

The filling of the system is carried out with open Mayevsky taps on installed heating radiators with substituted containers for collecting water. When the liquid comes out of all the air vents, close the valves, continuing the pumping process.

We control the pressure on the pressure gauge (the boiler device is suitable). When its value exceeds the hydrostatic one, equal to the pressure in the liquid column with a height from the lower to the upper point of the system (a height of 5 m gives a static pressure of 0.5 atm), we continue to fill the system, monitoring the pressure gauge when the pressure reaches the required value.

Pumping antifreeze pump "Kid".

After filling the system, turn off the pump, open the air valves (the pressure will inevitably drop), and then pump up the water. We repeat the process several times, displacing air bubbles.

We complete the filling by inspecting the system for leaks. After the pump is switched off, the hose connected to the outlet is under pressure. If antifreeze was pumped in, first disconnect the hose from the pump inlet and drain the liquid into a container, trying not to pour over the mechanism body.

Replacing the coolant causes and frequency

Replacing water in a closed and open heating circuit is carried out:

During the first start of heating.

After installation, the filling and start-up of the system is carried out

After seasonal drying.

When starting after repair work.

Regular topping up of liquid is required during operation, if there was no drain after the heating season.

Why drain water from a home system

The question to which there is no unequivocal answer is whether it is necessary to drain the circuit annually after the end of the heating season? The decision depends on the type, age and material of manufacture of the main elements - pipes and radiators, as well as on the total volume of liquid.

Each type has its own media replacement frequency

Most often, systems with old cast-iron radiators are drained for the summer. The reason is the appearance of a leak after turning off the boilers. Old cast iron fins are screwed together with old gaskets. When there is hot water inside the batteries, the seals expand to provide a stable seal at the seams.

After the water cools, the material from which the gaskets are made naturally shrinks, and at the junction of the ribs, a leak begins. But a long downtime of old radiators without water is fraught with accelerated corrosion, rust inside the radiator and old pipes crumbles in a dry environment, and can disable the entire riser.

In closed new circuits, filling the heating system is not a costly process. But it is not recommended to completely drain the liquid every year - this is not necessary.

The frequency of replacing and topping up fluid in the heating system

How often do you need to change the fluid in the heating system? A few general rules:

In open-type circuits of private houses, it is enough to simply add water if the system is tight, without exposing old communications to stressful checks in the form of long dry downtime. Replacement is necessary only in case of emergency repair or preventive sealing, after flushing.

Leaks - drain and repair

Closed heating systems need preventive flushing and change of coolant after a few years.

The frequency of filling with new fluid depends on the characteristics of the water, the life of the synthetic coolant, and the general condition of the system. With strong airing of the extreme points, it is recommended to identify the cause - find the place of the leak and check the tightness of the heating network. Typically, water changes are carried out every few seasons.

The choice of coolant what to fill in the home system

Before pouring new fluid into a closed-type heating system, it is imperative to select a coolant. Only 3 options:

- Water.

- Synthetic carrier.

Antifreeze for home systems

Can the system be filled with tap water

Do not try to save money by pouring tap water into the new system. Tap water is "enriched" not only with chlorine, which, when heated, adversely affects the surfaces it comes into contact with. Under the influence of temperature, which can reach 60 - 80 °, plaque begins to form on the inner walls of pipes, connectors, radiators. The deposits resemble scale inside an electric kettle with the same consequences: hard deposits eventually block the internal gaps. As a result, some of the radiators can remain cold even at high media temperatures.

Deposits in the pipe when using tap water

In addition to troubles with water stone, which forms a layer of plaque on the walls of pipes, the use of ordinary tap water can cause problems due to chemical reactions that occur in the media when heated. Aggressive impurities do not have the best effect on the condition of the coating inside radiators, corrode seals, and accelerate corrosion processes.

Conclusion - with a small amount of liquid, it makes no sense to save. It is better to pour distilled water into a closed-type heating system.

Distilled water with surfactants and additives for heating

Advantages:

Low cost.

Reduced viscosity, good fluidity.

No impurities.

No chlorine.

Increased boiling point.

Synthetic coolants: application features

On sale there are ready-made solutions and concentrates based on:

propylene glycol.

Ethylene glycol.

Glycerin.

Concentrate for home use

Despite the imperfect performance of ethylene glycol, it is better not to pour solutions based on it into the home heating network - the substance is dangerous to health.

When buying, you should focus not on the price, but on the degree of concentration of the active substance. Different brands of coolant are diluted in a certain proportion. Before preparing the solution, be sure to read the instructions for diluting the composition.

Synthetic carriers degrade over time, so before you throw away the canister from the concentrate, find information on the expiration date and mark with a marker near the boiler or inlet pipe so that you do not forget to replace the coolant in time.

Helpful Hints

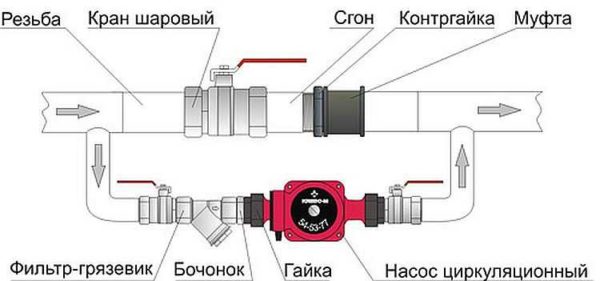

To exclude an arbitrary change in the flow of water, shutoff valves are attached to the inlet-outlet area of the circulation pump. The connecting nodes must be treated with a "sealant", one hundred will increase the performance of the entire heating system.

To quickly and correctly install the pump pump, you need selected connections and threads.To reduce the time of searching for all the necessary parts, look in plumbing stores for a special device with already selected fasteners. After the installation process of the pumping unit is completed, the system is filled with water or other coolant.

Before you start the system, you should open the central valve to remove air pockets - the water that appears will notify you of the complete removal of air from the system.

About quantity and breakdowns

The number of circulation pumps required to heat a private house can be determined based on the entire length of the pipeline. If its length is about 80 m, then one is enough. If this length is exceeded, consider increasing the number of pumps in the system.

The reasons for the failure of circulation pumps can be incorrect installation, arbitrary location of the cable connection and terminal module, as well as non-compliance with the rules for operating the heating boiler

To avoid malfunctions, it is important not to ignore the procedures for regular air release and take care of a good cleaning of the system from mechanical particles.

But it should be remembered that all breakdowns of the circulation pump must be corrected by specialists. Therefore, if malfunctions have already appeared and are detected, it is best to contact the repair service.

How to add coolant

In addition to the instructions for filling the heating system, you need to know the correct procedure for adding coolant. This situation may occur 2 or 3 times during the heating season.

It is important to determine in time that the volume of water has fallen below the critical one. Depending on the type of heating, there are different procedures for filling the heating system.

Closed heating system

The main indicator is the decrease in the pressure level in the pipes. For timely control, several pressure gauges are installed in the system. One of them must be located immediately after the hot coolant exits the boiler. You should also install a pressure gauge on the top air valve. The pressure drop in the system is a consequence of 2 factors - the occurrence of an emergency (leakage) or the natural evaporation of the liquid. If this process occurs very quickly, most likely a pipe burst has occurred. The gradual decrease in pressure points to the second factor.

The method of adding liquid completely repeats the procedure for filling water with any closed heating system. To do this, you can use hand pumps to fill the heating system (antifreeze), or use the central water connection.

Open heating system

Filling an open heating system with water is recommended through an expansion tank. This can be done even at relatively high water temperatures in the pipes. This method has several advantages - level control coolant in the system during filling and improved circulation due to the difference in water density.

There is a risk of failure of the boiler or heating radiators if additional filling of the open heating system with coolant occurs while the boiler is running. Therefore, this procedure is recommended to be performed when the water in the pipes reaches room temperature.

To select antifreeze, we recommend that you familiarize yourself with the video material.

First start of the heating boiler

The procedure for the first start-up of the boiler before the start of the heating season depends on its model and type. But despite this, a visual check of its condition is performed. This is one of the most important stages preceding the final launch of heating in a private house.

The heat exchanger is one of the most "vulnerable" element of the boiler. Its verification is mandatory, because during the operation of the device it is constantly exposed to high temperatures.Along with the task of starting the heating radiator, the preparation of the boiler is one of the most important during the process.

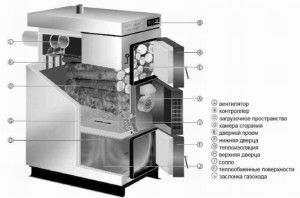

solid fuel boiler

Before the start of the heating system has not yet taken place, a comprehensive monitoring of the state of the solid fuel boiler is carried out. Its surface is cleaned of rust, the performance of the pressure gauge and thermometer is checked.

Then follow these steps for the correct start of the heating system:

- Sedum firebox and ash pan from soot. This can be done with a metal brush;

- Checking the condition of the chimney. Its pipe must be securely connected to the boiler nozzle.

For pyrolysis and pellet models, the operation of the electronic control unit, fans and nozzles is tested. When the heating system starts up correctly, the improper functioning of these elements can lead to sudden temperature fluctuations, which directly affects the condition of other components.

Gas boiler

Before you start the gas heating boiler, you should read its instructions. For different models, the order of the steps may vary slightly. This is due to the different types of construction. In particular, this applies to condensation models, in which during operation it is necessary to trace the correct formation of condensate. Without it, heating the secondary heat exchanger will not be possible.

How to properly start heating with a gas boiler? After filling the system with water, you need to do the following:

- At the bottom of the boiler there is a valve that shuts off the flow of water into the circuits. After the end of the heating season, it can be closed. Therefore, you need to open it - while the pressure gauge readings will change. The pressure value should not exceed 3 atm;

- After heating the coolant, you need to open the make-up valve again. If there are air plugs in the system, you can remove them using Mayevsky taps. The pressure in the system during this stage may decrease slightly;

- In fact, you will have to start the sinking radiator 2 times. The first - during filling with coolant, and the second - when the boiler is turned on;

- The correct functioning of the boiler is controlled by the values on the dashboard.

The result of starting heating in a private house should be a stable temperature regime of the entire system, as well as the absence of pressure surges in the pipes.

Filling the heating system with coolant

It must be recalled once again that before starting the heating system at home, a visual inspection of all elements is performed. If necessary, individual components and components are replaced. Only after that you can proceed to the procedure of filling with coolant.

In the absence of water, a slight rust coating will inevitably form on the inner walls of the radiators and the heat exchanger. Therefore, before the coolant is filled, it is recommended to clean the system.

Flushing the heating system

If there is still coolant in the pipes, you need to remove it. This can be done through a special pipe located at the lowest point of the system. There should also be a recharge node. Only after that you can continue to solve the question - how to properly start the heating system.

For closed heating circuits with forced circulation, hydrodynamic flushing is recommended. To do this, you should purchase (or better, rent) a special pump with filtration and a chamber for cleaning fluid.

Flushing procedure:

- Connecting the pump nozzles to the system;

- Start-up and visual control of the degree of contamination of water that has gone through a full cycle through the pipeline;

- If necessary, replace the fluid with a new one;

- Do several flushing cycles until the water is completely clear.

After that, pressing is performed. Before starting the heating radiator, you need to check the condition of its connection to the pipeline.It is recommended to replace the gaskets, as well as to check the integrity of the couplings.

To start a closed heating system, an increased amount of coolant (or air) is injected into the pipeline. This is necessary to check the reliability of the connecting elements of the system. The pressure value must exceed the nominal value by 1.2 times.

Adding coolant to heating systems

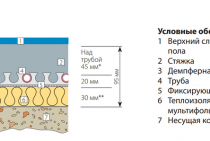

As a coolant, you can use ordinary distilled water or antifreeze. Filling is done through the sub-picture node located at the lowest point.

This is important, because if you try to add water through other nozzles located above, the likelihood of air pockets will increase. In order to make the correct start of the heating battery, it is recommended to check the presence of Mayevsky taps and their performance

To do this, open each of them. Then you need to follow the following procedure:

The air and drain valves located at the highest point of the system open;

The faucet of the file unit opens smoothly. The water pressure should be small so that air jams do not form;

After the coolant flows from the nozzles of the air and drain valves, they should be closed;

Mayevsky's taps remain open until coolant starts to flow from each instead of air

This is important, since starting the heating boiler in the presence of air pockets can damage the entire system.

If pressure testing has not been done before, it can be done while filling with water. Pressure control at the start of heating at the stage of filling with water is carried out using pressure gauges installed on the boiler, safety group and collectors.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until the moment when water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above.However, one should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

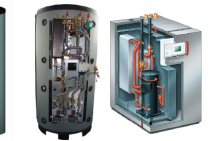

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Crimping

The main purpose of pressure testing is to check the strength of the connections and the reliability of the system as a whole. Usually, the craftsmen who installed the heating system demonstrate to the customer the quality of the work performed during pressure testing.

- If the heating is done by hand, and there are no hidden installation areas in the system, for example, a warm floor, you can not do pressure testing.

- If you decide that you cannot do without a strength test, pump the coolant into the system, raising the pressure to 2.5-3 atmospheres and observe it for 15 minutes. In this case, the pressure in the system must remain constant.

- If the pressure level drops, you need to find a leak, eliminate it, and carry out pressure testing again.

- If the pressure is at a constant level, the boiler can be started.

Where to put

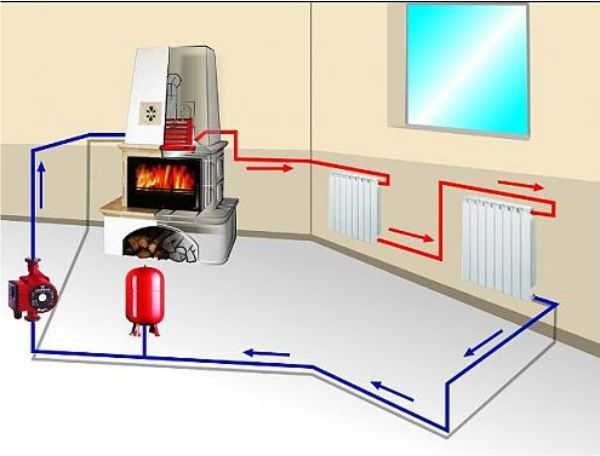

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler.Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branching in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer-mud filter is necessarily placed in front of the unit.

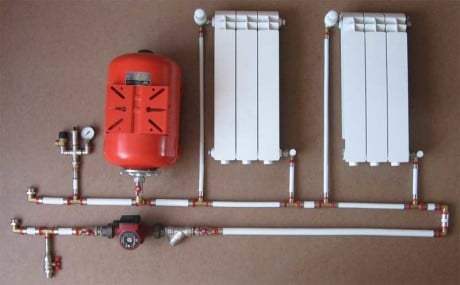

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

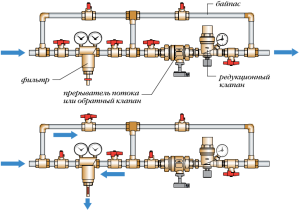

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

If the radiator does not heat up.

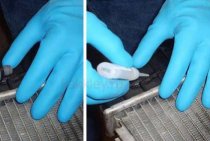

If water comes out of the radiator, but the radiator still does not heat - what is the reason? In case of inaccurate installation, debris can get inside the pipes and accumulate in thin places, for example, in valves. Will have to clean up. Close both valves on a cold radiator. Loosen the union nuts on the valves

Drain the water carefully from the radiator

If the pressure in the system is working, then you can abruptly open the valve on the supply pipe, while the jet of water should take out the garbage. We put the radiator in place, open both valves, poison the air again through the Mayevsky tap ... well, I suppose everything is already clear enough. After such manipulations, two positive results should appear:

1) heat all radiators;

2) you have a habit of working carefully, preventing debris from entering the pipes.

Also: the difference between supply and return for a normally operating system is 15-20 degrees. Not more. But this also depends on the ambient temperature during the start-up period. In the cold season, the system will need to, so to speak, “accelerate”. And it makes sense to observe the difference between supply and return when the temperature is established in the room.

That's all, nothing complicated. If the heating system is assembled correctly, then there should be no other problems, and the heating system should start without problems.

What determines the normal functioning of the heating system? There are several objective factors that directly affect the efficiency, reliability and maintenance of its performance. Therefore, first of all, you need to know how to properly start the heating system in the house. It is best to consider this procedure on the example of an autonomous system of a country cottage.