Screed thickness

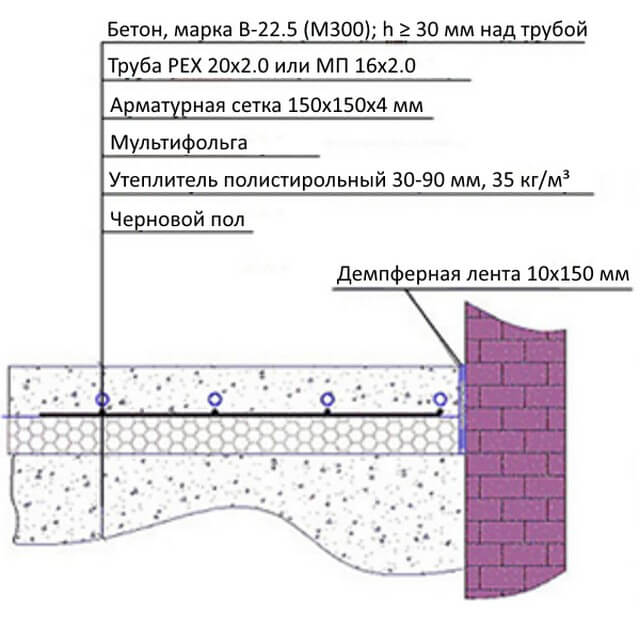

The concrete layer is directly the floor screed. It is strongly recommended to use a concrete screed, and not a cement-sand screed. To achieve the required strength of a slab using a cement-sand mixture, the amount of cement that will have to be used will cause the cost of the floor to greatly exceed the price of a construction of similar strength from concrete. The thickness of the screed should be 30-45 mm above the level of the pipes.

For the manufacture of a concrete layer, concrete of a grade not lower than M300 should be used, and crushed stone should have a fraction of at least 5 mm and not more than 20 mm. With a screed thickness of 50 mm, the mass of 1 m² of such a floor will be about 120 kg, so you should always monitor the sufficient strength of the floor beams in the room where the warm water floor is laid.

The installation process takes place using metal beacons of the PN-28 type, located around the perimeter. The alignment of the mixture is done using a rule.

The ratio of the necessary ingredients is recommended to be strictly adhered to, in order to avoid additional difficulties during the installation process. The optimal composition of the mixture prepared using 12-liter buckets is as follows:

- 1 bucket of cement

- 2 buckets of crushed stone with a fraction from 5 mm to 20 mm

- Water 7-8 liters

Superplasticizer for concrete SP1 - 0.4 liters of a solution prepared in advance. Recipe: pour 2 liters of powder into 5 liters of water and mix well.

If available and at will, 3-4 buckets of granite screenings with a fraction of up to 5 mm are added.

If special plasticizers and granite screenings are not available, then a screed of similar strength can be prepared by increasing the amount of cement from 1 to 1.5 buckets.

After the surface of the concrete layer has dried, the heating system starts up in test mode with a coolant temperature not higher than 25 °C. You can use the water-heated floor in full force only after 30 days.

Difference in heating depending on the thickness of the screed

A competent calculation of the thickness of the layer poured during the screed device is also necessary due to its influence on the process of uniform heating of the room.

If the layer is thin, then it objectively warms up faster, providing, after the start of the water circuit operation, the distribution of heat in the room without a long wait. At the same time, in such conditions, the possibility of cracks appearing in the screed more often arises, negatively affecting the uniformity of heating the floor.

The scheme of laying layers for a water-heated floor

An excessively thick layer has good heat capacity, so it retains heat longer, allowing it to be distributed over the floor plane, but it takes longer to warm up. There is also a large load that affects negatively and can cause a rupture of the screed. To avoid this phenomenon, it is recommended to arrange expansion joints.

When deciding to level the floor with a screed, it must be understood that the thickness of the layer equipped with a wet, semi-dry or dry method will be different, therefore, uniform heating cannot be achieved.

Total thickness of finished subfloor

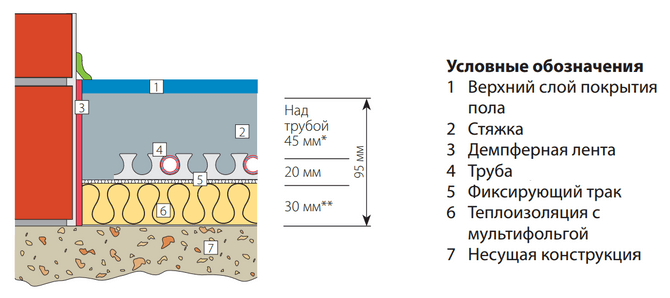

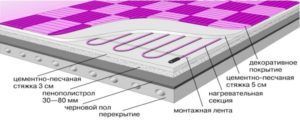

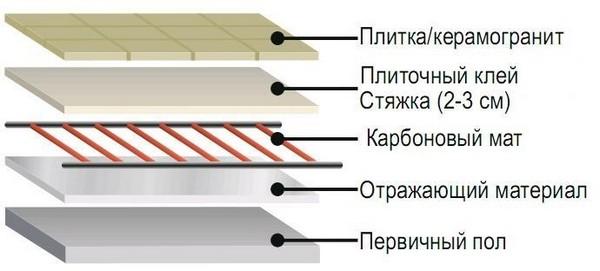

The recommended thickness of each of the layers that make up the cake of a warm water floor. The order of location of each of the layers is shown in the diagram below:

The subfloor must be level and solid. The thickness of each layer placed on top of the subfloor, in order from bottom to top, will be as follows.

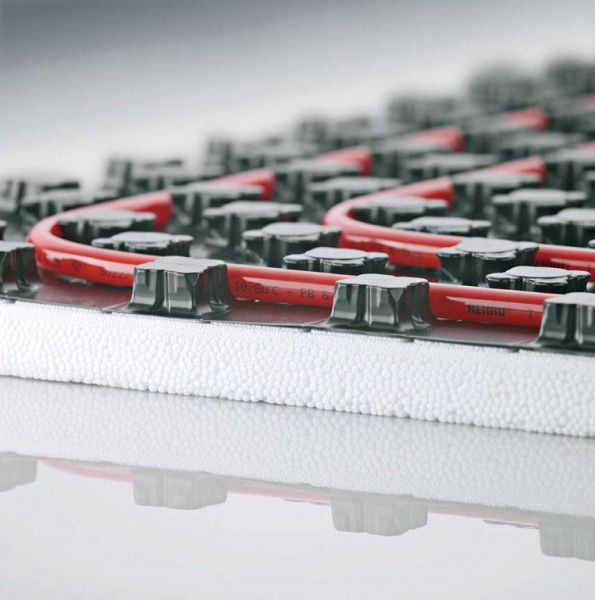

Insulation layer 30-90 mm thick made of fibrous polystyrene rigid boards. They must be strong enough to hold the high load of subsequent layers, and therefore the density of the material is chosen at least 35 kg/m³. The thickness varies depending on how cold the underground space is.If there is a heated room below the floor, then a layer of 30 mm will suffice, and if the floor is laid on the basement of a private house, then it is better to place a layer of insulation with a thickness of at least 90 mm.

A 3 mm thick multifoil is laid on top of the thermal insulation. Its main function is to waterproof the next layers of the floor. If the waterproofing layer has already been laid on the rough concrete floor, no multifoil is required.

Reinforcing mesh 100x100x4 mm or 150x150x4 mm performs the function of increasing the strength of the screed, which, when reinforced, becomes more resistant to tensile loads. For the convenience of laying pipes according to the scheme, they can be fixed at the desired points on this grid.

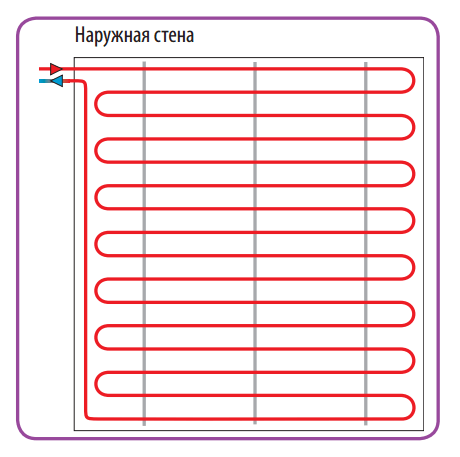

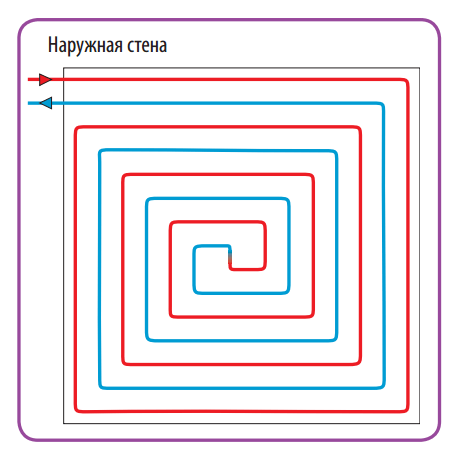

The pipe is laid according to one of the diagrams shown below. These circuits are called "serpentine" and "spiral". The first is classic and suitable for any room, and the second is not recommended for use on wooden floors and is most effective for rooms that require particularly intensive heating. The allowable distance between the pipes is from 10 to 30 cm. The presence of joints inside the floor is unacceptable, the pipe is laid in a single piece, the ends of which enter the collector. The layer thickness is on average 20 mm.

Before moving on to the screed, it must be said about the damper tape. It is pre-laid around the perimeter of the walls in order to avoid creating unnecessary stress on the walls. The fact is that when heated from the heat of the pipe, the concrete screed will expand and create pressure on the walls, and in order to prevent this, it must be protected along the perimeter with a special “spring” material. The minimum thickness of such a tape is 5 mm, the optimal one is 10 mm.

As a result, taking into account all the described requirements for the arrangement of a water-heated floor screed, the thickness of all layers and a separate concrete screed will be as follows:

- The entire floor is 80-135 mm, taking into account the thermal insulation layer and the thickness of the concrete layer

- The screed thickness is 50-65 mm, depending on the selected layer height above the pipe surface.

Mounting Recommendations

If you decide to use a film construction, then the use of a screed compound is not advisable. Here you should use a special adhesive for tiles. On it, the elements are fixed. Naturally, the layer thickness should be minimal, and the upper part of the film floor should be visible. Next, you can lay the tiles. First you need to wait until the previous layer of glue dries. This method of installing tiles will avoid peeling the flooring.

https://youtube.com/watch?v=fY3jneItmIs

Related Materials:

Do-it-yourself dry screed - advantages and disadvantages of technology, step-by-step work plan

How to make a rough floor screed - a guide to work technology

Overview GVL for the floor - advanced material for dry screed

Semi-dry coating

Today, many of us prefer a dry mix for laying screed. It is less problematic to fill than a cement-sand mixture. This styling method has its own characteristics. The semi-dry mixture is considered to be stronger than conventional cement. After pouring, the drying period is much shorter, which makes it possible to finish laying underfloor heating faster.

Experts say that the material does not crumble and does not collapse under the influence of heat emanating from the pipes. It is easier and more convenient to work with this type of mixture.

Before laying a semi-dry mixture, the base should be carefully prepared. All debris is removed, the base is laid with vapor barrier material. If there are deep cracks or depressions, it is recommended to fill them with a viscous cement mortar. Roll materials are laid with an overlap, it must also go on the walls. The seams are treated with special adhesive tape. A semi-dry mixture is poured onto the finished base.

What mixing proportions should be used is indicated on the packages with the semi-dry mixture. The consistency of the material should not contain much water. If you squeeze it in your hand, you get a tight lump. Moisture should not flow down the hand. Thus, the correct mixing of the ingredients of the mixture is checked. Very often, fiber is added to the dry mix to make the coating even more stable. The fiber is well distributed throughout the structure in all directions.

The minimum thickness of the screed will be 4 cm. Its height also depends on the method of laying the pipes themselves, on what material they are laid. The floor and its maximum height can reach a mark of 20 cm. If the base for pouring has significant irregularities, the height has to be raised significantly. In general, the thickness will be at least 4 cm and not more than 20 cm.

The coating can be destroyed by the wrong drying method. If you can walk on the floor, it doesn't mean the grout is really dry. A liquid cement-sand mixture 4 cm high dries for at least a month. A mixture prepared from dry materials dries out within a few days, depending on the height of the coating. In order for the material to harden correctly and without crackling, the surface should be moistened with water and covered with a film. As a result, the base will not sag, dry well and will not crack.

The size of the water cover depends on the type of filling and the characteristics of the base. The more significant irregularities on the surface, the higher the structure will be. This happens due to the imposition of several layers - this is a necessity to reach the zero level.

Based on experience, experts say that the relative total height of a warm water cover is 10-15 cm, absolutely all materials used are taken into account, including flooring.

Base thermal insulation

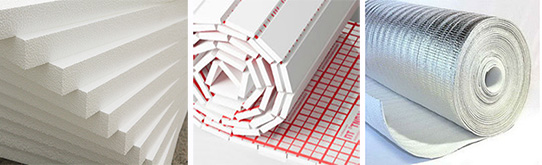

Before installing the heating system, it is necessary to insulate the base. The heat-insulating layer will protect the water circuit from heat loss leaving the basement or foundation of the house. As a heater is used:

- Styrofoam;

- extruded polystyrene foam;

- foil-coated backing.

These materials are characterized by high strength to mechanical stress, resistance to moisture and temperature changes. The thickness of the insulation is 30-50 mm, it is laid on a layer of waterproofing polyethylene film. The canvas is laid with an overlap on a clean, dry base, it will become a protection against getting wet for the insulation. Thermal insulation slabs are laid end-to-end, the joints are smeared with glue or blown with foam, the excess of which is cut off.

Penofol or a similar sheet of reflective insulation is placed on top. A layer of aluminum foil is directed upwards, this will reflect the bulk of the heat back towards the room. The joints of the foil insulation are glued with special adhesive tape. Penofol will protect the insulation from the aggressive effects of concrete. A metal reinforcing mesh is laid over the thermal insulation. This element evenly distributes the high load from the water circuit system and the concrete structure.

Types of plasticizers, features of their use

Plasticizers (surfactants) are surfactants. Surfactants are produced in liquid or powder form, with antifreeze additives and reinforcing polyamide fibers.

During the development process, the composition is endowed with the property of modifying and improving the quality of floor screeds:

- Ensuring the plasticity of the solution;

- Increasing the degree of mechanical strength and moisture resistance;

- Improvement of surface smoothness;

- Exclusion of possible damage to electrical devices by corrosion.

Laying a warm floor with your own hands, using hardening active substances in the screed, makes its use comfortable and safe.

Sometimes modern plasticizers for screeds are classified as environmentally friendly products.

But still, do not forget that they contain chemicals that have the ability to change the structure of the concrete mixture.

Therefore, in the process of preparing do-it-yourself screeds for an electric or water floor, it is recommended to include in their composition the amount of additives corresponding to the information indicated on the package.

Some manufacturers of surface-active additives for cement-sand screeds, in order to get ahead of competitors, keep their composition and recipes secret.

In addition to unknown individual components, the composition of plasticizers includes the following ingredients:

- Sulfuric concentrated acid (strong oxidizing element);

- Phenolic production waste (phenolic resin, water);

- Concentrated sodium hydroxide solution;

- Defoamer, formalin and water;

- Plastic reinforcing fibers (present in some surfactants).

Liquid plasticizers are added to the dry mixture: with the calculation of 1-1.5 liters per 100 kg; before use, the substance is thoroughly shaken, poured simultaneously with water, in the course of kneading.

Powdered - take with a calculation of 1: 2 (surfactant / water); mix thoroughly, let stand for a couple of hours (the further mixing procedure is the same as with liquid).

Features of the floor screed of various thicknesses

The thickness of the screed for a water heated floor is the most important component in organizing space heating. There are 2 types of covers used, characterized by thickness: thick and thin screed. Each of these types has its own specific advantages and recommendations for use (depending on specific conditions). How to make a screed over a warm floor, see this video:

https://youtube.com/watch?v=fY3jneItmIs

Thin screed of a warm water floor

At least 4 cm there must be a layer of concrete above the pipe

To determine the minimum thickness of a warm floor, there are certain requirements that are enshrined in special documents (SNiP).

It is worth saying that many of the prescribed sizes in official documents are ambiguous.

So, for example, in SNiP it is indicated that the minimum thickness of the screed for a warm cover can be at least 20 mm, but this applies to a cover made on a cement-metal basis.

When calculating the height of the floor, do not forget to add the thickness of the laid coating

What thickness of the screed should be when using other mixtures, this is not mentioned. But it is indicated that the minimum layer of the pipe cover should not fall below 4 cm.

This means that together with the pipe (average section 20-25 mm), the thickness of the solution can reach 60-65 mm. Most often, this is exactly what the screed is obtained (SNiP recommends 6-7 cm).

Many people think about how to highlight the thickness of the screed if a leveling mixture is poured on top or a tiled floor is laid. When organizing the cement mixture under the tile, one established postulate should be followed, the mortar should exceed the level of the pipes by 1-1.5 cm. See this video for details:

Since the tile is laid on an adhesive base with a thickness of 8-20 mm, the total height of the flooring above the pipe will reach 6 cm (taking into account the thickness of the tile). By the same principle, a cover is created with a leveling mixture, on which a laminate or wooden floor is subsequently laid.

Thick floor screed

An increase in the amount of mortar will not only lead to an increase in the cost of work, but also to an increase in the load on the base

The maximum permissible values of the thickness of the underfloor heating screed are not mentioned in the SNiP, but its unreasonable increase can lead to certain consequences:

- an increase in material consumption leads to an increase in the cost of the structure;

- to heat a thick coating layer, a longer period of time and increased energy consumption are required;

- reduction of space in a heated room;

- may lead to the dismantling of the doorway (the door does not open).

But, nevertheless, quite often they resort to events, organizing a thick flooring, related to leveling the floor and comparing it with the zero point.

The process of leveling the surface is organized on the rough floor, but if this is not done for some reason, it can be done at the expense of the pipe layer of the solution.

The total thickness of the flooring can reach 15 cm.

Based on what has been written, it is worth saying that each owner, choosing the thickness of the screed for a warm water floor, will rely on his own considerations.

But you should not refuse the above recommendations, they can be useful for any builder who has decided to install a warm water floor in the room.

Features of installation of a rod infrared floor

This type of underfloor heating consists of rods, which are interconnected by flexible wires. When current is passed through the rods, they generate heat. This type of heating can self-regulate the temperature, so it can be used without a thermostat.

The installation sequence of the rod infrared floor:

- creation of a laying scheme;

- ground preparation;

- laying thermal insulation;

- preparing a place for the sensor;

- laying out the strips and connecting the cable in accordance with the drawn up diagram;

- fixing the strips to the base with mounting tape;

- installation of a thermostat;

- connecting the sensor and cable to the thermostat;

- connecting the thermostat to the network;

- system testing;

- pouring screed;

- laying tiles.

For such a floor, ceramic tiles are also the best finish, it is laid in a screed, the thickness of which should be more than 2-3 centimeters.