Long burning wood burning stoves

The main problem of any wood-burning unit is the need to constantly add new portions of firewood. Otherwise, the temperature in the country will begin to fall. Most stoves require refueling every 2-3 hours. Someone likes this fuss, but someone does not like it. If the problem is annoying, we recommend choosing and purchasing a long-burning stove - combustion chambers of an impressive size are used here, accommodating a large amount of firewood.

Separate fireplace stoves for heating dachas work according to the pyrolysis principle, with the afterburning of pyrolysis products in a separate chamber. Firewood here burns in an oxygen-poor atmosphere. The escaping combustion products enter a separate chamber and burn with secondary oxygen. As a result, we get long-term combustion, increased efficiency and increased heat transfer on the same amount of firewood. If you want to choose a pyrolysis stove, then remember that it will greatly simplify the procedure for heating your summer house or country house.

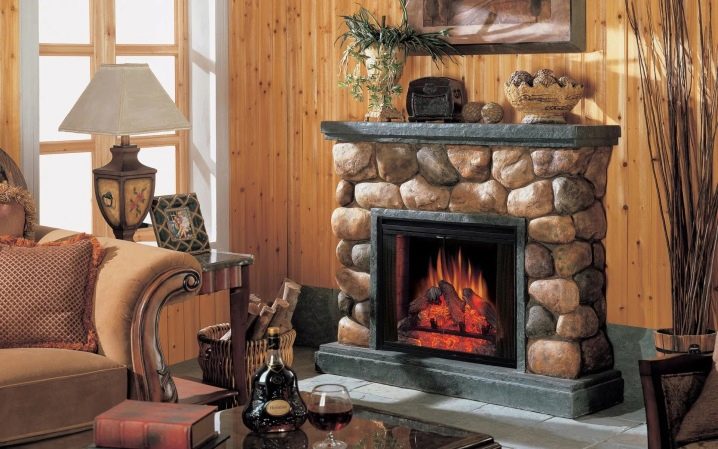

Types of fireplaces for giving

As a rule, the choice of the type of fireplace for giving should be made at the stage of designing a country house. This will greatly facilitate all installation work, and the choice in this case will be wider. Plus, during the construction of the building, the arrangement of the chimney, the design and shape of the fireplace are immediately laid. All this will immediately solve various issues related to installation, as well as provide sufficient traction, high heat transfer and a sufficiently high efficiency.

First of all, you should decide on the type of device: a classic fireplace, an electric or gas firebox, a fireplace stove or a biofireplace. A good option for a country house can be a fireplace stove for a summer residence. The fireplace can be either open or closed. The first option is a classic type of fireplaces. However, direct contact with the hearth requires compliance with increased fire safety conditions and a solid chimney. As a rule, such fireplaces are installed in a special room or area.

Furnace fireplaces or fireplace stoves are distinguished by the fact that direct contact with fire is excluded by installing a door, usually made of heat-resistant glass. Fireplace stoves can be wood, gas or biofuel. (See also: How to learn how to build fireplaces with your own hands)

Cast iron stove for a summer residence

Based on the conditions of a country house, where rapid heating of a small room is required, a cast-iron fireplace stove for a summer residence can be a good option. Such devices come in various modifications, single-circuit (classic) in the form of bourgeois stoves or double-circuit with the possibility of heating and cooking. Thus, fireplace stoves can be classified into three types:

- Heating. Cast iron devices with fast and good space heating. They are quite compact, keep heat for a long time and are easy to install.

Heating and cooking. They differ from the first type in the possibility of cooking. Double-circuit fireplace stoves for summer cottages are an ideal option, especially in conditions of lack of electricity and gas.

(See also: Do-it-yourself Buleryan oven)

Fireplace stoves. The optimal combination of the advantages of 2 devices. At the same time, they warm the room faster than a classic fireplace.

ABX fireplace stoves

Among the numerous models of fireplace stoves on the Russian market, devices of the ABX trademark with an efficiency of up to 80% stand out. Arranging such a fireplace in the country with your own hands is not difficult.

ABX fireplace stoves are equipped with special heat exchangers, which provide heating of a large area. The principle of operation of these devices is based on the convection method, which provides rapid heating. ABX fireplaces are produced in several types: (See.(See also: DIY garden fireplace)

- Classic fireplaces.

Tiled stoves-fireplaces.

Steel furnaces-fireplaces.

Structurally, ABX fireplace stoves consist of a plinth, a firebox and an external cladding. The base can be made of cermet, cast iron or tile.

As a cladding, a special type of refractory tile is used, which is produced in Slovakia. The tile is resistant to sudden temperature changes and accumulates heat well.

The ABX firebox can be steel, cast iron or a combination (steel and cast iron).

Advantages of ABH fireplace stoves:

- High efficiency.

Unique design.

Ease and simplicity of installation.

Double combustion of gases.

Adjustment of intensity of burning.

Classification of fireplaces

On the cottage, you can define any of the existing types of fireplaces, because there are no special design features for apartments in the country.

The modern range of fireplaces is divided into three main types, which are fundamentally different:

- Traditional wood baking is a time-honored design solution with which we can see a real dancing fire and emphasize the overall role of the fireplace.

The structured structure consists of a chimney, a frame and a portal. Before building a fireplace in this kind of country, it should be taken into account that regular cleaning of the chimney, removal of ash, continuous monitoring of the furnace and a long building process will be required. In addition, mistakes at any stage can cause smoke to be inside the room.

- Gas with an atmospheric gas burner is a budget and safe solution with a “live fire” effect.

The advantage of such a fireplace is that it is easy to install without worrying about the location of the chimney, since the chimney can be raised directly onto the road or into the chimney. However, with an impressive list of advantages, there are disadvantages: it requires an expensive installation permit, low productivity, the use of explosive propane or natural gas.

- A decorative electric fireplace is a versatile indoor solution that does not involve space heating. Advantages - ease of use, bright effect of "fire", fire safety, lack of a chimney and care for its cleaning.

All options for installing a fireplace can be: built-in wall, separate (island), wall, corner.

The most popular are the corner double-chamber types, which do not require much space and allow you to create a calm space when sitting. To save space, a do-it-yourself fireplace is built into the wall or wall. In addition, convenient models differ depending on their purpose:

- heating furnaces are very efficient heating units and are recommended for installation in the country;

- fireplace grates belong to the outdoor stove and are separated from the main building structures;

- Outdoor fireplaces are located next to the "house", they are made of concrete blocks, stone and brick with a characteristic property - the absence of a damper.

However, such decoration refers to elements of landscape design, and not to stylish interior decoration;

- decorate the space with the effect of "flame" and the illusion of burns. This solution is suitable for those who value easy installation and ease of use.

Depending on the stove, the fireplaces can be closed or otkrytymi.Krome benefits, depending on the performance architecture, the fireplaces differ for the classic t-U-shaped portal, D-shaped member, with nouveau circular or rectangular contours and futuristic high tech, metal, glass, periclase, concrete and fireclay.

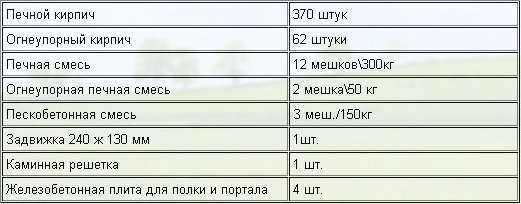

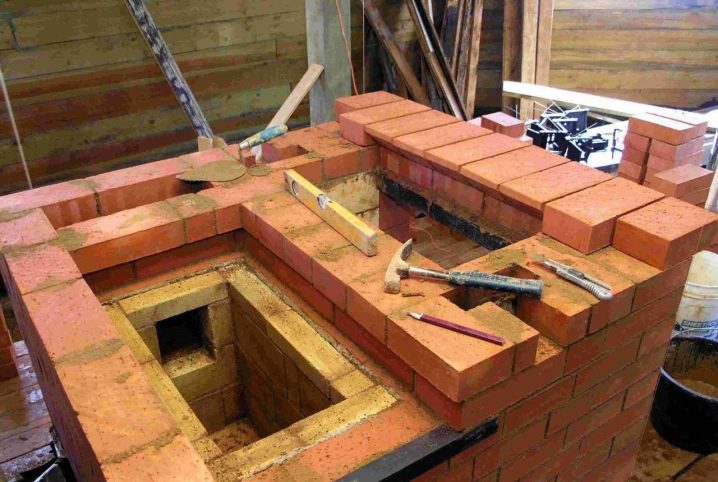

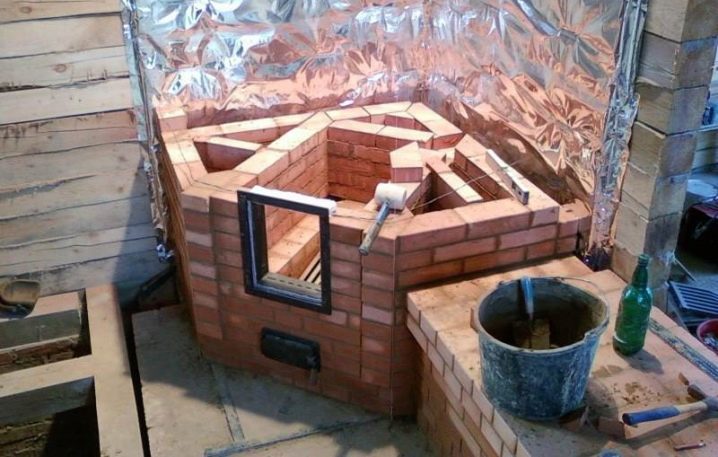

An example of the construction of a small brick oven

- For a small oven, it is not necessary to equip a separate foundation. It is enough to strengthen the floor, lay roofing material, hydroisol or glassine.

Pour dry sand 1 cm thick.

We lay a layer of bricks on the leveled sand. It is very important to level the layer with a level.

Apply a layer of clay on top of the brick and install the blower door.The door must be wrapped with asbestos cord, and preferably with cardboard, after moistening it. The door should be secured with wire.

We lay the second layer of bricks.

The third row of bricks is made of halves.

On the third layer of brick lays a grate above the blower.

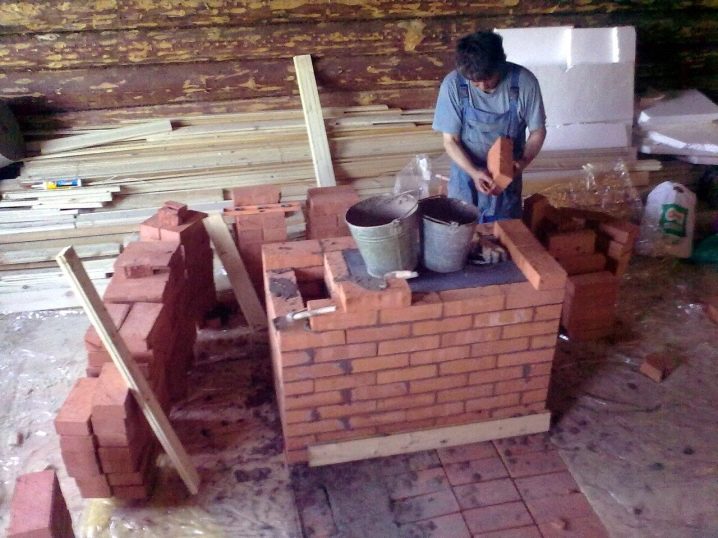

The fourth row of bricks is laid out on edge. For internal partitions inside the chimney, it is necessary to make stands. The back of the stove is made without clay with brick protrusions to the outside (knockout bricks).

We pre-wrap the furnace door with a moistened asbestos cord, then we fix it with wire and two bricks.

We lay flat the 5th row of bricks.

We lay the sixth layer on the edge, and rub the walls of the chimney with a rag.

The seventh layer of brick lays flat. In this case, the bricks of the back wall are laid on the edge.

The eighth row should close the firebox door and end with two bricks above the firebox.

A beveled brick is installed above the firebox to shift the flame towards the center of the hob.

The ninth layer of bricks is laid with a slight offset to the back wall. Before this, a moistened asbestos cord is laid to ensure tightness between the hob and the brick.

From the tenth row, the formation of a chimney begins, which should gradually expand towards the back wall. An iron chimney can be made of attached or nozzle type. A packed brick pipe can lead to a shift in the center of gravity.

In the 11th row, it is necessary to install a valve, sealing it with an asbestos cord.

The chimney is joined to a light metal pipe. If the pipe is diverted to the side, then an overlap of three layers of bricks should be provided.

After that, we take out the knockout bricks and clean the chimney.

Then we finish the furnace outside (plaster or whitewash).

Before the stove we equip the pre-furnace sheet.

After completion of all work, it is necessary to dry the oven for one week. At first, it is recommended to fire with wood chips or paper. And after hardening, you can start burning wood.

materials

Refractory bricks in the amount of not less than 300 pieces. The easiest way to choose a good brick is to look at its color: light (underfired) brick crumbles when heated and is completely fragile. Glossy brick, covered as if with a crust (burnt), is very fragile, it is pricked even from a weak load.

The binder material for masonry is based on fireclay clay. Do not use ordinary cement for masonry. A special solution can be bought packaged in bags with instructions for preparation on the package. For an average fireplace, about 100 kg of masonry mixture will be required.

Cement, sand and gravel will be used to strengthen the foundation. If you plan to put a brick foundation, then still a solid brick. You will have to lay out six rows of bricks, set at the end.

Ready-made fireplace stove with a chimney or separate elements: a cast-iron grate, a door (it is possible with glass). Several porcelain stoneware slabs or ordinary ceramic tiles for finishing the space in front of the fireplace.

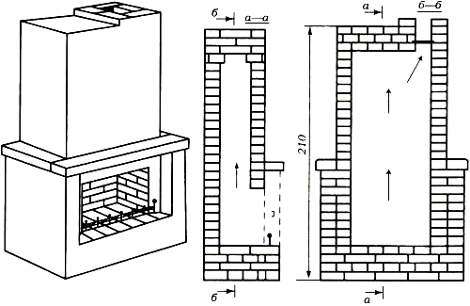

An example of a chimney

Before deciding how to build a fireplace, you need to choose a method of ordering (see. Corner fireplace - ordering). There are two variations of ordering: with and without a spark arrester.

Fireplace draft is regulated by means of a gate valve. The efficiency is 10–15%.

The first three rows or only the contour of the rows can be laid out according to the scheme, filled into the inner part with a backfill of sand and gravel.

The fourth row is laid out with refractory bricks. Immediately, to fix the fireplace grate, embedded L-shaped pins are installed.

simple fireplace

Ordering a conventional fireplace

Masonry of a simple fireplace with a spark arrester

Materials for building a fireplace

Fireplace masonry

The question of how to build a fireplace in the country is not so simple, since not everyone can do the work with their own hands, but controlling the process, understanding what is happening, is a very real task.

fireplace base

Fireplaces of light structures, which are often installed in the country, are placed directly on the floor, large ones (more than 700 kg) are built on a foundation with a depth of about 0.5–0.7 m. In the construction of fireplaces, two types of foundation are distinguished:

-

A poured foundation that uses concrete with aggregates (crushed stone, crushed brick, etc.) or liquid concrete. For especially heavy fireplaces, reinforcement with fittings can be used.

The surface of the flood foundation is usually made at floor level or 10–15 centimeters lower. Formwork is used for pouring.

-

Brick foundation, which is designed for small fireplaces. It is laid out in the form of bricks placed on the ribs.

High-strength cement (M300 grade or higher) is used for mortar. Rows should be from 4 to 6.

To protect the foundation from moisture, roofing material is used, for which the bottom and walls of the formwork are covered with roofing material, and the joints are covered with bitumen. We coat the attachment points, and fill the bottom of the foundation with a thin layer of expanded clay.

If a heavy fireplace is placed on the second floor, the foundation is built anyway, except for the presence of a wooden floor.

In such a situation, a 15 cm layer of refractory material covered with a sheet of iron is placed on the floor. The lower brick layer is laid on a cement-clay mortar.

After making the foundation, wait 5-6 days before it dries.

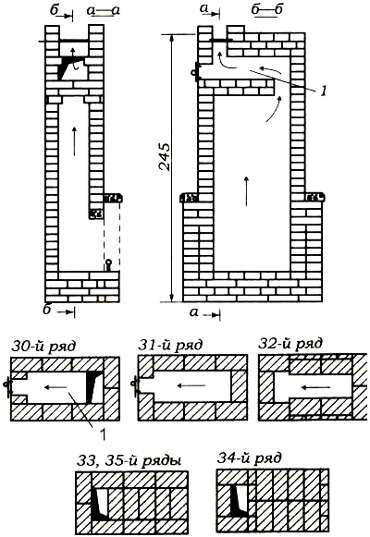

Chimney

Basic moments:

- The walls of the pipe must be thick enough to reduce heat loss. When the fireplace is located against the inner wall, the pipe is laid out in one brick. If the fireplace is next to the outer wall - one and a half or two bricks.

The normal section of the pipe is 1/10–1/15 of the width of the furnace opening. The minimum pipe parameters are 14 × 25 cm.

- It is not safe to rest a heavy pipe on a light fireplace, so it is better to use ceramic or metal pipes in this case.

They need to be insulated from the outside, lining the pipe with brick and filling the space between the brick and the pipe with expanded clay.

- The quality of traction directly depends on the height of the pipe. The optimal height option is 5-7 meters. On top of the damper, the pipe looks like a tapering pyramid, and the transition at the top into the chimney.

The front wall of the smoke box is raised, tightly joining it with the chimney. The vertical back goes straight into the chimney.

- The chimney provides a damper (rotary or sliding), with the help of which the fireplace is closed for heating. It is also needed to adjust the traction force. The damper should be located 20-30 cm (maximum 80-100 cm) above the opening of the firebox, at a distance of about 2 meters from the floor.

- If the chimney is less than 5 meters, then without a damper, cold outside air will quickly fill the room. If the pipe exceeds 7 meters, the damper may not be installed, although in any case it will not be superfluous.

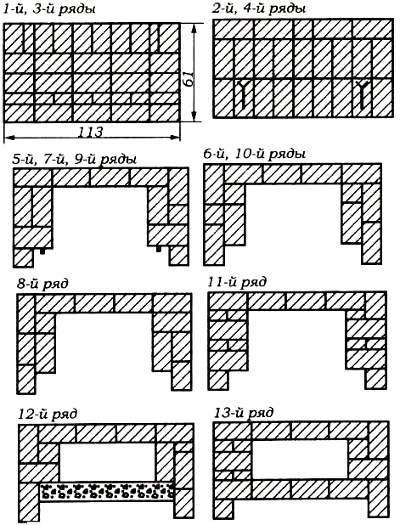

Step-by-step instruction

The first three rows of bricks are very important because this will be the base of the fireplace. They must be placed strictly according to the level, and limiters are inserted between the bricks for more even masonry.

Laying two rows of bricks without mortar, laying subsequent ones on the mortar.

The fourth row is placed around the first three and a hole for the furnace begins to form from it.

In the fifth row, it is worth considering the location of the blower. At the same stage, fasteners for a metal grating are installed in the masonry. You can make them yourself.

The sixth row secures the supports. It also serves as a support for the grate (cast iron or steel grate that holds the fuel. Ash spills down through it).

The seventh row is the basis of the portal for the fireplace.

From the eighth to the thirteenth row, the decorative front part of the fireplace is laid out, which is tied together.From the eleventh row, the formation of a “mirror” begins - the inner back wall of the fireplace, which is located at an angle.

On the fourteenth and fifteenth row, the portals are again tied up.

From the sixteenth row, the laying out of the “mirror” ends and the laying out of the “tooth” begins, which is coated with clay soaked a few days earlier. This is done to prevent a fire in the house.

From the seventeenth to the nineteenth row, the facade of the fireplace is formed.

On the twenty-second row is the creation of a chimney pipe with access to the street. The accepted dimensions for this hole are 15x28 cm. The wider the chimney, the more heat will be retained, the standard size gives good draft and allows optimal removal of combustion products.

On the twenty-third row, a "swallow's tail" is formed - the shape of a smoke hole.

Laid the last layer of bricks.

Step 1 study the design

The two main elements of a fireplace are the chimney and the firebox. The main functional part is the furnace, it is it that ensures high-quality operation. The chimney is necessary to keep the air circulating and keep the flame burning. Additional details of the fireplace:

- a heating element;

- valve;

- smoke collector;

- ash pan;

- lattice;

- protective door;

- flame cutter.

At the bottom of the fireplace is a portal - a decorative design of the firebox, made in a certain style. The finished look is given to the object by the cladding - the final finishing of the portal surface.

Step 2: preparatory activities

At this stage, you need to decide on the location of the fireplace, draw up a project, choose building materials and evaluate your financial capabilities. The following factors affect the value of an object:

- the number of floors in the cottage;

- ceiling height;

- materials used;

- type of fireplace;

- finishing;

- the specifics of the foundation of the building, etc.

Step 3: buying building materials

In order to build a fireplace in the country with your own hands, you need to purchase the following items:

- special oven brick;

- clay;

- sand;

- cement;

- rubble stone;

- crushed stone, etc.

Clay should be soaked a few days before laying. A mixture for masonry is made from prepared clay and sand. Bricks are also pre-soaked.

Step 4: building the foundation

You need to choose a place for the foundation in accordance with the location of the rafters and ceiling beams. First you need to dig a pit. The dimensions of the pit should exceed the parameters of the foundation by 10-15 cm.

The depth of the pit should be such that the erected foundation can withstand the load of the future fireplace. Usually the depth is 60 cm less than the foundation of the house itself. The foundation can be laid out of ordinary brick or special rubble concrete.

Step 5: laying the fireplace

Before you start laying, you need to sort normal bricks from non-standard blanks. On the surface of the foundation you need to lay several waterproofing layers. Soaked clay acts as a binding material.

We lay out the first row of bricks using the “edge” method, do not forget to add a little cement to the solution. In the course of the work, it is necessary to carefully monitor the "geometry" of the structure, using a triangle or twine. You should also use a level and a plumb line to determine horizontal and vertical.

Each brick is soaked before laying - kept in water until bubbles stop emitting. A trowel is usually used to build a solid wall, and when laying out a chimney, it is better to level the solution by hand. Excess solution can be removed with a wet cloth. In the place where the pipe goes to the roof, you need to use a cement-sand mortar (proportion 1 to 3).

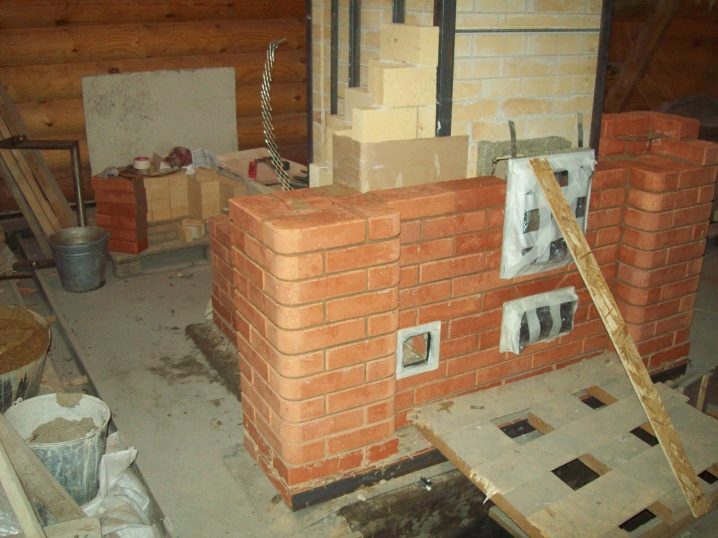

Step 6: Finishing the fireplace

After the completion of the laying work, they proceed to the final finishing of the fireplace. The seams need to be processed, the brick itself can be painted in any natural shade.To paint a faded brick, you can use ordinary gouache. The fireplace shelf is made in accordance with your own preferences and the general style of the interior.

Thus, building a fireplace for a summer residence with your own hands is not so difficult. However, if you are not confident in your building abilities or are afraid of making mistakes that could lead to an emergency, it is better to use the services of professionals.

(Visited 679 times, 1 visits today)

Kitchen interior in country style of the 30s

Types of office partitions and their comparative characteristics

Country house interior design

Art Nouveau renovation

Recommendations for choosing a bathroom cabinet

Do you want to decorate the stairs? Choose the right railing!

What interior would a leather sofa fit perfectly into?

Blinds: the most common types

Recommendations for the construction of a country fireplace with your own hands

After the choice is made in favor of one or another type, you can begin to equip country fireplaces with your own hands. If you are going to buy a ready-made fireplace or fireplace stove, then there will be practically no problems with installation. Another thing is if you decide to build everything yourself. Laying a fireplace or stove with your own hands can save a lot of money, provided that you have at least minimal knowledge and skills.

To give a foundation for a fireplace, it is built to a depth of at least 60 cm. If the country house is two-story, then the depth should be 80-110 cm.

Lightweight fireplace designs are usually mounted on a brick foundation. At the same time, the brick is laid in 4-6 rows, on the edge. Strong cement (M400 and above) is used as a binding element.

For overall and massive fireplaces, it is recommended to use a flood foundation, additionally reinforced with fittings. To equip such a foundation, liquid concrete filled with crushed stone, brick chip, etc. is used.

Be sure to pre-make the formwork. The bottom and walls of the formwork should be covered with roofing material to protect against moisture. The joints of the roofing material are smeared with bitumen. The lower part of the foundation is covered with a light layer of expanded clay.

The top of the foundation is carried out at a level of 10-20 cm below the floor level, and then the clay solution is laid to the floor level. After the foundation has been built, it is necessary to allow time for drying for one week.

The main points of the arrangement of the fireplace.

To reduce heat loss, it is necessary to make the walls of the chimney thicker. At the inner wall, the pipe can be laid in one brick. And at the outer walls, the pipe is laid out in 1.5-2.0 bricks. The optimal cross-section for the chimney is the ratio of diameter and length equal to: 1/10 - 1/15. For high stacked chimneys, ceramic or iron pipes should be used. Outside the building, the chimney must be insulated. Chimneys with a height of at least 5-7 meters provide good draft.

The front wall of the chimney, as a rule, rises and fits tightly with the chimney. The back wall is strictly vertical, with a transition to the chimney.

The damper in the chimney is installed at a distance of at least 20-30 cm from the furnace opening and about 2 m from the floor.

Premier fireboxes

Professionals do not advise to heat the fireplace during the first month after its assembly. And this is understandable: cementing mortars gain strength and dry with natural humidity. Why test them at such a crucial moment?

The next stage - trial fireboxes

The next stage is trial fireboxes:

- Within 10 days, 2 times a day, short-term (up to half an hour) heating with a small amount of firewood is carried out. At the same time, the blower hole (on the front of the ash pan) should be ajar.

- It is best to lay crumpled paper on the grate, and on top of it - chips and finely chopped firewood.

- Then set fire to the paper, close the door and open the blower. Although if there are difficulties in kindling, you can leave the firebox door ajar for a while.

What kind of wood to prefer for a fireplace insert?

As practice shows, it is better to use dry hardwood firewood (maple, oak). They will give an even and calm flame. Birch firewood will bring a lot of soot. And alder and aspen, on the contrary, will help burn soot out of the chimney. You can read more about the types of firewood and their pros and cons in the article Firewood - good and different.

So you can only visually effectively store firewood

Readers can easily share their experience of giving fire additional romantic attributes. So, to get a flame of a beautiful pattern, you can add chopped stumps and roots to the logs, and to get a pleasant smell - cherry and juniper branches. Of course, dry wood must be used, as damp wood leads to poor combustion and fouling of the fireplace components.

The duration and intensity of burning depend on:

- quality and quantity of loaded fuel;

- air supply to the furnace, regulated by a blower valve;

- for vigorous combustion, logs of small diameter are used, but in large quantities;

- "slow" mode, on the contrary, is provided by a small amount of firewood of large diameter. And this is understandable: after all, the intensity of combustion depends on the area of \u200b\u200bcontact of wood with oxygen. If you take a large log, when else will fire reach all of its wood?

The intensity of combustion depends on the area of contact of wood with oxygen.

From the same conditions of the need for effective contact of wood with oxygen, various tips for laying firewood in a fireplace follow. I will not repeat the well-known truths about laying a wood-burning well at about 1/3-2/3 of the firebox height. After a few fireboxes, you will succeed by experience. The main thing is that when laying the logs should not be placed very tightly - in this case, a lack of oxygen may occur. About what negative effect it gives, it is written above.

The fireplace in the country house creates a charming atmosphere of comfort. A solid, well-built hearth, taking into account fire safety rules, will delight you with the beauty and warmth of a living fire for many years.

A solid, well-built hearth, taking into account fire safety rules, will delight you with the beauty and warmth of a living fire for many years.