Connection with a polyethylene sleeve type MPT

This type of connection is the most common way of joining non-pressure asbestos-cement pipes to each other when laying pipelines for communication cables. This method of connection is acceptable for pipes with a diameter of 300 mm, 200 mm, 150 mm, 100 mm when they are installed in normal dry soil.

Before proceeding to the connection of pipe joints, it is necessary to heat the coupling. To do this, you need to warm it up for at least 10 minutes in a tank of water, which is heated to a temperature of 90-100 ° C.

Before proceeding to the connection of pipe joints, it is necessary to heat the coupling.

The hot sleeve is put on at one end on the previously laid asbestos-cement pipe until it rests against its internal partition. The end of the second asbestos-cement product from the opposite side is also inserted up to the stop of the inner wall of the coupling.

In the case when it is impossible to put a polyethylene sleeve of the MPT type on the pipe, a non-welded metal cuff is used. For example, performing sewer repairs with the need to replace the MPT coupling or using cut (longitudinally) asbestos-cement pipes.

Docking is done using pliers. A gasket made of brizol, metalloizol or hydroisol is placed under the metal cuff. After that, the cuff is tightened with pliers.

The joint of asbestos-cement products, after the cuff is installed, is sealed along its entire length with a cement-sand mortar, the thickness of which should be at least 10-15 mm. An integral positive factor in the use of a non-welded metal cuff is the fact that the ends of the connecting pipes do not need to be carefully processed. After all, often when repairing a sewer pipeline, we have to cut a pipe in order to replace some of its part.

There is also a welded metal cuff, which is used in the construction of horizontal punctures (wells) under railways and roads. The welded cuff has an internal limiter, which excludes the through passage of the connected pipes. These cuffs are able to provide a rigid centering of the joined products.

LLC DESIGN PRESTIGE

Connection with a cast-iron flange coupling of the Gibo type

Connections of asbestos-cement pipes: a - on an asbestos-cement double collar; 6 - on a cylindrical asbestos-cement sleeve; c - on a cast-iron flange coupling; 1 - asbestos-cement pipes; 2 - double collar asbestos-cement coupling; 3 - rubber rings; 4 - working shoulder; 5 - non-working collar; 6 - sealing with cement mortar; 7 - cylindrical asbestos-cement sleeve; 8 - strand; 9 - sealing with cement; 10 - cast iron flanges; 11 - cast iron bushing; 12 - bolt

Cast iron coupling type "Zhibo" / "Jabot" is used for joining asbestos-cement water pipes.

It consists of two flanges, two sealing rings, a bushing and tie bolts, the number of bolts depends on the diameter of the product. The bushings and flanges of the Zhibo couplings are made from cast iron, which has the SCH-18-36 brand. This type of coupling has a permissible deviation of the pipeline no more than 5°.

The advantage of the connection with "Zhibo" type couplings is that their use does not require high-precision processing of pipe ends. Indeed, sometimes when laying a pipeline there is no need to use the whole product and we are forced to cut an asbestos-cement pipe, we also cut it and, if necessary, repair some part of the pipeline. It is in such cases that it is important to use a cast-iron coupling of the Zhibo type.

Throughout its service life, it can be tightened and, if necessary, additionally compacted.

Laying of pipelines on cast-iron couplings of the "Zhibo" type is carried out in the following order:

- a flange, a bushing and a rubber ring of the coupling are put on the end of the previously laid asbestos-cement pipe; a second flange with a rubber ring is put on the end of the attached asbestos-cement pipe; the products are centered; after the alignment is completed, the flanges are tightened with bolts and washers.

However, this method of connecting asbestos-cement pipes has one significant drawback. Bolts that are designed for flange ties are susceptible to corrosion, as a result of which they can collapse.

For joining asbestos-cement pipes with bends, tees, valves and swivel elbows, a special metal pipe is used, which has connecting flanges.

Share this helpful article:

Connection order

The double-breasted asbestos-cement sleeve is first pushed over the end of the already laid product so that its end, which has a less protruding bead, is as close as possible to the end of the product to be connected. First, the coupling is pushed onto the pipe slightly longer than the length of the coupling itself, after that the second pipe is laid and, using a template, the working position of the connecting element is marked with a pencil.

The coupling must have a symmetrical position with respect to the ends of the connected products. Rubber rings must be installed exactly in a plane that is perpendicular to the longitudinal axis of the asbestos-cement pipe.

They must not be skewed or twisted. After putting on the rubber tread and the connecting part, the pipes must be centered. The ease of pulling the coupling will depend on the correct alignment of the products.

Screw jacks are usually used to tension a double-breasted coupling at the joint.

After centering and checking the accuracy of the position of the pipes, using a cord and a sight, the products are fixed with backfill and compacted with soil on both sides. When connecting asbestos-cement products using a double-breasted coupling, it is necessary to ensure that the connecting ends of the pipes are dry - this will prevent the sealing rubber rings from slipping over them when the connecting part is pulled.

Screw jacks are usually used to tension a double-breasted coupling at the joint. They are fixed on the element to be attached with such a distance that it is possible to capture the edge of the coupling with the tension legs. The tensioning of the connecting part must be done evenly, without any distortions.

When tightened, the clutch captures the first rubber ring with the front cone-shaped gap, after which it clamps and advances it, and then the second.

After the coupling has taken a symmetrical position with respect to the joint, which is marked with a pencil at the ends of the pipes, the tension of the connecting part stops. Installation of utilities ► using a template, the correct position of the sealing rubber rings is checked. In order to prevent the rubber ring from sticking out of the connecting element, during the hydraulic testing of the pipeline, it is necessary to seal the space between the coupling and the pipe, on the side of the working collar of the coupling, with cement mortar.

LLC DESIGN PRESTIGE

How can you connect products from asbestos cement

The first method of combining is a toothed asbestos-cement coupling. Its name is better known as double-breasted. It is a piece of pipe about 20 centimeters.

Its inner diameter is slightly larger than the outer diameter of the products to be joined. Due to the existing internal fasteners - teeth, the structure with such a connection becomes indestructible and monolithic. These cloves have different sizes, thereby perfectly fulfilling their function - holding the rubber ring.

Before you buy such a product, you need to consider it well and study its external component.Firstly, there should be no damage or splits on the surface on the outside of the product. Secondly, the surface inside the product should look like a regular cylinder, the ends should look like cones with a protruding element.

How is sealing created? This happens with rubber rings, so they must be flexible enough to be able to resist the flow of pressure and not pop out of the joint.

Asbestos cement products must be delivered to their destination before installation.

Installation is done by laying them out parallel to the ditch. Only after careful processing of the ditch can you start laying such products. The bottom of the ditch must be designed with the correct slope so that the asbestos concrete product can be firmly supported by at least a third of the circumference.

In order to avoid damage to the entire pipeline system, it is not necessary to ignore the necessary conditions for the installation of such fragile products, a properly prepared bottom of the ditch plays a crucial role. Where there should be pipe joints, small pits are made, the dimensions of which are approximately the same as the width of the bottom of the ditch. Pits are dug about 70 cm long and about 20 cm deep.

Heating from OOO DESIGN PRESTIGE View water here resant.ruotoplenie-dachi.html

note

Our company LLC DESIGN PRESTIGE is a part of the non-profit organization ANO INTERREGIONAL BOARD OF JUDICIAL EXPERTS. We also provide services for independent construction technical expertise.

In order for the pipeline to serve for a long time and there were no problems with it, it is necessary to initially install the structure in the right way, as well as to connect asbestos-cement pipes as best and as efficiently as possible, using the necessary connecting elements, reinforcing products and devices designed to compensate for various deformations and vibration processes .

In order to make a choice on a certain type of connecting elements, it is necessary to determine for what purposes the product from asbestos-cement pipes will be used

It is important to determine the specific function of the pipeline structure

The manufacturing plants produce asbestos-cement couplings with two teeth, which are similar to the dimensions of the asbestos-cement elements available in the pipeline structure. These connecting elements are widely used in water pipes. The very process of combining parts takes place in a simple way, using a dense rubber ring.

In the case of connecting pipes that will not be subjected to pressure during operation, asbestos-cement couplings are used. They are made of a pipe with thick walls and a large diameter. In addition to it, in water and gas pipelines that are made of asbestos-cement pipes, Zhibo couplings made of cast iron can be used.

For laying cable connections, they are used to fasten asbestos-cement products that will not be subjected to the pressure of a high-pressure polyethylene coupling.

Docking fragment: 1,2 - chrysolite-cement pipe; 3 - clutch; 4 - rubber sealing ring

Such a main element in the product as a connecting node must have the following:

1. In work with significant pressure, as well as in the case of the formation of a vacuum space, it must show stable strength and possess the properties of density.

2. Resist the influence of a dysfunctional environment.

3. To show itself as a convenient and simple material, which is not worth spending a lot of time and effort on.

How are asbestos-cement pipes installed?

Next, we will highlight the most important points that have a direct impact on the process of asbestos cement pipeline installation.

- In order to obtain the required parameters and the desired roughness, the diameters of asbestos-cement pipes are turned. When connecting such structures, special couplings are used.Please note that on the inner surface of the structures there are grooves with elastic rubber rings with a complex glow that resembles cuffs. This allows you to get a reliable and complete system. At the point of docking with the coupling, a radial gap is provided, which provides elastic deformation of the rubber seal. The presence of a mounting gap allows you to get rid of the use of temperature compensators. steel coefficient.

Asbestos and asbestos-cement chimney pipes were very popular in our country during the Soviet years. This was due to a number of reasons.

Firstly, the country had an excellent raw material base for the production of such products. Secondly, pipes made of these materials had a low cost and high profitability. Thirdly, they had good technical characteristics and did not need insulation or additional insulation.

And if there are no alternative technologies

If you do not have an angle grinder, you can use a cutter or hacksaw. Consider these technologies for cutting pipes from asbestos cement.

- Hacksaw. It is quite possible to cut the pipe with an ordinary hacksaw, but it will take quite a lot of effort and time. Initially, the pipe should be wetted, since in the raw state the asbestos cement is cut much easier, and if the pipe is cut dry, the process will become extremely tedious and inefficient. Then it is necessary to outline the cut line, moisten the rags in water and lay them for several hours along the intended cut site. Wet asbestos cement will be much more elastic and will be easily cut. Do not press hard on the pipe when cutting so that it does not split.

- Cutter. To do this, you need a cutter similar to a plastic cutter, but large and made of high-quality metal. The pipe should be laid on a flat plane and scratched on the cutter in the form of a straight line along the ruler. Then deepen it a millimeter and further. Under the scratch, you can put a small rail inside the pipe and break it along the cut line. This process does not generate much dust.

The above methods for cutting asbestos cement are the most popular, but if they do not suit you, you can use alternative technologies:

Classic axe. You need to take an ordinary ax and cut the pipe along the marked lines with it. It should be understood that many blows must be applied to the same place in order to initially break through the pipes, and then the process will go much faster. Of course, it will not work to cut the pipe evenly, but it will work out efficiently and quickly.

Circular. You can cut an asbestos cement pipe using a circular saw. Instead of the usual disc, you need to install a disc with carbide teeth on it.

Slate nail. If you do not have all the listed tools at hand, you can use the most primitive method. First, a cut line is drawn on the pipe, then a slate nail is taken, with which a line is pierced along the entire circumference. The more holes there are, the better. It is best to place a thin oblong object under the pipe, for example, a block of wood. At the end, you need to carefully break the pipe along the line with the holes. The cut line will not be perfectly even, in any case, it all depends on the number of holes made and the accuracy of the break.

Types of asbestos-cement pipes

Asbestos-cement products are divided depending on their purpose into:

- gas pipelines; water pipelines; sewerage.

Depending on the mode of operation, the design is:

Pressure and non-pressure BNT products are regulated in accordance with GOST 539-80, GOST 1839-80, GOST 11310-90.

The pressure pipe has a diameter on the inside from 50 mm to 600 mm. It can withstand pressure ranging from 6 to 9 atmospheres.The pressure pipe is characterized by resistance to wear, as well as slight hydraulic resistance, which allows it to be used for solving construction problems.

A pressure pipe is used when setting up a pressure water and gas pipeline, as well as for arranging irrigation and reclamation systems. It is suitable for arranging wells, as well as overlapping household buildings.

Non-pressure asbestos-cement pipes or BNT are available in lengths from 2.95 m to 5 m. The inner diameter can range from 50 to 500 mm.

BNT are suitable for setting up non-pressure engineering structures: sewers, air vents, etc. They are characterized by the fact that they demonstrate high electrical resistance.

Connection of pipelines with a polyethylene tee

The material of BNT products is not afraid of corrosion. BNT products are used as supports when laying fences, as well as other fences.

Expert answers

Grandfather Au:

They didn’t write the size, with a grinder, but if the pipe is large there is reinforcement, and if it’s large and from the end, then the “bottom” is made from the boards, it deepens by 5 centimeters, then the reinforcing mesh is cooked, then the pegs are put on the outside, the board is poured, the mortar is added, the board is added again, until flood... it's all so simple))

wasilich:

Bulgarian, with a diamond circle.

Oleg Losev:

and maybe not concrete, but asbestos ???. but grinder faster

GRUMMER (unstoppable):

did you decide to drop a pole on someone?

Heinrich Mont:

Damn, along! It will turn out a great chute for a water attraction!

lenOK!:

diamond circle. and all things.

infection:

you want to stop the plant???

pyrokant free:

It seems that Valentina herself wants to do this work.

Victoria Lyzhina:

f-1 grenade and there will be no pipe at all. puncher, the grinder will not take it, but the chob did not flow - pour concrete

Tata:

cement, a building material made from an aqueous mixture of cement and asbestos. For 100 parts (by weight) of Portland cement grade 500 and above, from 12 to 20 parts of asbestos, mostly low grades, are consumed. Due to the reinforcing effect of asbestos fibers, Asbestos cement, before the cement sets, has sufficient tensile strength and plasticity, allowing products of various shapes to be molded from a sheet 5–10 mm thick. In the hardened state, Asbestos cement has high physical and mechanical properties: ultimate strength in bending up to 30 MN/m2 (300 kgf/cm2), in compression up to 90 MN/m2 impact strength in the range of 1800–2500 J/m2 (1.8–2 .5 kgf cm/cm2). Asbestos cement is durable, frost-resistant (loss of no more than 10% of strength after 50 freeze-thaw cycles), practically waterproof, fire-resistant, has an increased (compared to concrete products) chemical resistance. Density Asbestos cement - 1550-1950 kg / m2 Disadvantages: Asbestos cement: susceptibility to brittle fracture and deformability with changes in humidity, the reduction of which is achieved by hydrophobization and additional reinforcement. Asbestos cement is produced at factories on sheet-forming machines (continuous rolling methods, semi-dry molding, etc. are promising). Asbestos cement is usually produced without additional coloring (gray), sometimes coloring is used in bulk or from the surface, as well as coatings with protective films

For the manufacture of drinkers, an asbestos-cement pipe with a diameter of 12.5 cm is also used (length ... different feeders, it is not possible to describe all of them - ..polaromat.ucoz /load/0-0-0-27-20

After that, feed is poured into the feeders and placed on the feeding space. ..centrszhat /…/mnogocelevye-stroitelno-otdelochnye-kotorye-byli-ispolzovany -

errare humanum est:

no. Asbestos is poison. It has long been forbidden to use it even when laying stoves ...

Boris N. Eroshkin:

Asbestos is a carcinogen. You don't have to do it.

Olga:

Not worth it. Asbestos is not good!

George Kroitor:

Water pouring from taps, in most cases, flows through asbestos-cement pipes. If we drink water from such a pipe, why shouldn't a pig feed from a half?

How to fasten asbestos pipes

Hello! We bought a house outside the city and encountered strong condensate from the chimneys of a gas boiler. The boiler is low temperature. The same story with asbestos ventilation pipes.It turned out that the former owner built up these pipes with galvanized pipes. From afar (a 3-storey house), they looked like completely asbestos-cement. During the replacement of the roof, this was discovered. Now we want to install asbestos-cement pipes instead of galvanized pipes, but on the slate base we were told that the industry does not produce clamps or couplings for non-pressure pipes, and those that are produced for pressure pipes are not suitable, because. they have rubber gaskets inside that are not suitable for chimneys. And without gaskets, the couplings will be too loose and there will be no good connection. Tell me, some way out: how to properly connect two asbestos non-pressure pipes? And where can it be purchased? Shells for asbestos pipes?

Elena, Voronezh.

Hello Elena from Voronezh!

On the Internet, find the telephone numbers of the sales department of the Bryansk plant for asbestos-cement products (located in the city of Fokino, Bryansk region). Call and specify the range of asbestos-cement couplings produced by him of the diameter you need.

If they don’t tell you anything comforting, then there are possible options for using asbestos-cement pipes in which one of the ends has an extension into which the usual end of the asbestos-cement pipe is inserted. Since there will still be a small gap-backlash between the inner surface of the pipe with expansion and the outer surface of the pipe with a regular end, it is usually filled with cord asbestos, asbestos-cement fabric. Or they are sealed with an ordinary mortar (cement-sand with a proportion of 1 part of cement - three parts of sand).

Another option - two asbestos-cement pipes are joined together. A shell is preliminarily put on one of the pipes, which has a significantly larger inner diameter than the outer diameter of the asbestos-cement pipe, a plaster or masonry mesh is inserted into the gap (rigidity and cell size of medium parameters).

To prevent the mesh from jumping down, it is fixed in any possible way (usually with a soft wire). The pipes and the shell are centered (they are aligned). Then carefully fill everything with the same cement mortar, which was mentioned above. From below, a temporary miniature formwork is made from boards, plywood, and other materials. The task of the formwork is to prevent the solution from falling down.

As a shell, you can then take the most suitable coupling for pressure asbestos-cement pipes, remove the rubber gaskets and do the indicated manipulations.

Hard? No, not really, it is quite within the power of an ordinary person to do.

Ask a question to Semenych (the author of the materials)

Installation rules

When installing non-pressure asbestos-cement systems, the following options for joining individual sections are used:

- With polyethylene couplings. First, the parts should be heated by immersing in hot water. Then the hot sleeve is put on the first pipe until it rests against the internal partition. After that, a second pipe is inserted into the connecting part from the other side.

- With the use of asbestos-cement couplings. In this case, two holes with a diameter of 20 mm should be drilled in the connecting part (they must be in line). The pipeline is laid so that the joint between the two components is as tight as possible. Then the prepared coupling is put on the joint. The gap between it and the collector is clogged with hemp winding, and glorified bitumen is poured into the prepared holes. It is possible to connect the joining sections only after it has solidified.

Asbestos-cement pipes BNT with a diameter of 300, 400 and others attract with their performance and reasonable price. This time-tested material has proven its worth in many areas of life. Let him help you too!

Add a comment

How to connect asbestos-cement pipes. Couplings.

Asbestos-cement pipes have found their application in ventilation systems, chimneys, ventilation and drainage systems. Sometimes they are used in sewer systems. These pipes do not rust, do not burn and are resistant to aggressive environments. Asbestos-cement pipes are connected to each other with special double-breasted couplings with a rubber seal. At the same time, at the place of installation of the coupling, it is possible to change the direction of the pipeline up to three degrees

This is essential for ease of installation.

Structurally, a double-breasted coupling is a piece of pipe with an inner diameter greater than the outer diameter of the connected pipes. Inside the coupling, closer to the edges are rubber sealing rings. It is due to them that reliable sealing of the connection is ensured. The connection itself is very simple. First, one end of the coupling is pulled onto the end of the pipe so that the end of the pipe is in the middle of the coupling. In order not to make a mistake, you should first make marks on both pipes. Then a second pipe is inserted into the coupling. The pipe surface under the coupling must be dry and clean. Due to the fact that rubber sealing rings provide significant resistance when installing the coupling, a screw jack is used to move it along the pipe. A small gap appears between the pipes and the coupling along the outer perimeter, which should be cemented.

Sometimes it is necessary to connect asbestos-cement pipes of different diameters, which are laid in the ground. In this case, non-pressure chrysotile-cement couplings should be used. This work is much more difficult than the one discussed above.

Initially, two holes with a diameter of 12 - 20 millimeters must be drilled in the walls of the coupling. They should be located in one line along the axis of the coupling. After that, markings are made on the surface of the pipes to be joined so that the coupling is located symmetrically to the pipe joint. The coupling is pushed onto the edge of one of the pipes so that the holes are on top. The next step is the alignment of the connected pipes. The gap between them should not exceed three millimeters. After that, the joint is wrapped with bituminous tape 60-70 mm wide and the sleeve is pushed exactly symmetrically to the joint. Using wooden blocks, the coupling must be fixed. To do this, such clamps are inserted between it and the inner wall of the pipes. When the coupling is installed tightly, it is necessary to fill the gaps between it and the pipes with tow. Now you can proceed to the final stage of work. Its essence lies in pouring molten bitumen into one of the holes in the coupling. It must be poured in a thin stream until it appears in the second hole. After the bitumen has completely solidified inside the coupling, a reliable and durable connection is obtained.

Asbestos-cement pipes are also used as a protective sheath for electrical cables. Pipe connections in this case are made using polyethylene couplings. It should be stated right away. Polyethylene couplings can only be used for pipes with a diameter of one hundred to three hundred millimeters. The connection technology is very simple. The coupling is simply heated in boiling water, and then put on one of the pipes. The second pipe is inserted without delay into the coupling. Here some skill is needed so that the clutch does not have time to cool. Otherwise, it will shrink and the pipe cannot be inserted.

Non-welded metal cuffs can also be used for similar purposes. They are put on a special sealing layer and tightened with screws. The gaps between the surface of the pipes and the coupling are sealed with cement mortar.

Material Specification

Such a building material is used in laying networks of external pipelines, installing furnace chimneys, irrigation, ventilation systems and constructing casing pipes for wells. The products are subject to the following technical requirements:

- They must comply with the requirements of GOST 1839-80 (this also applies to couplings).

- Asbestos-cement products must be smooth and have a strictly circular cross section.

- There can be no delamination of material, cracks and chips on the structures.

- It is assumed that on the outer surface there may be minor scratches up to 2 mm deep and prints from the cloth packaging.

Features of the operation of chimneys from an asbestos-cement pipe

One of the main difficulties in using asbestos-cement pipes is the need to remove soot in a timely manner. Due to the fact that only one inspection hole is installed in such a chimney, cleaning the pipes is difficult, so prevention should be done first.

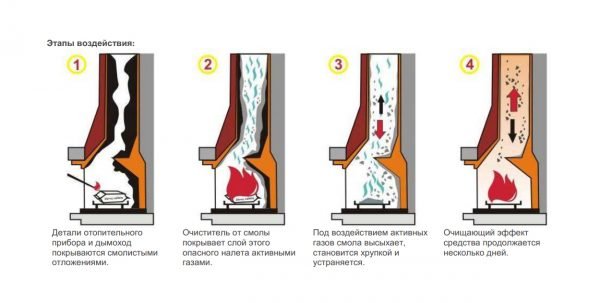

Chemical cleaning of the chimney

Under the brands Hansa (Lithuania), Spalsadz (Poland), Chimney Sweep (Russia) they produce cleaning products in powder form (a mixture of copper chloride, phosphates, ammonium salts, etc.). When pouring 1-2 measuring spoons of the composition onto burning wood, the chemicals react with slag and soot on the walls of the chimney. Under the action of a catalyst, pollutants are converted into combustible gases and a solid substance. The gaseous component leaves the chimney with smoke, the rest of the particles fall into the furnace and are cleaned out along with the ash. Manufacturers recommend using the product every 4-5 ignitions to keep pipes clean. The effect of the drug is easy to notice by the whitish smoke emitted. A tool with the same effect is also available in the form of a log impregnated with the necessary chemicals.

The action of a chemical chimney cleaner is very simple.

Users confirm that this method of cleaning and prevention is very effective and greatly simplifies life in the absence of inspection hatches in the chimney

But given that asbestos-cement pipes are sensitive to temperature rise, soot powder should be used with caution. If the manufacturer does not indicate the dosage for such a chimney, it is better to start with half of the standard serving.

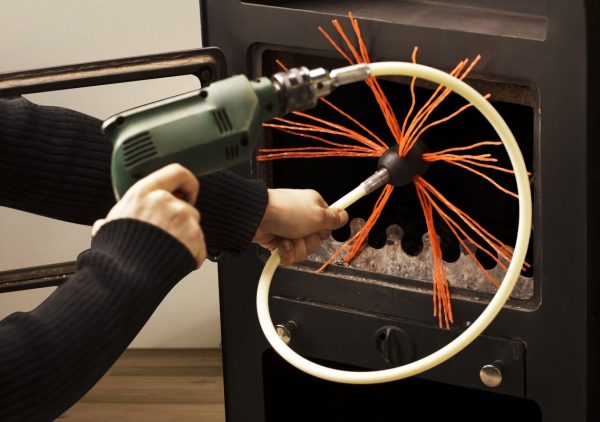

Mechanical cleaning of the chimney

Manual removal of soot is carried out using round brushes and scrapers with long handles. They are best selected with a diameter slightly larger than that of the pipe, and with a pile of metal wires. Since the inner surface of asbestos-cement chimneys is initially rough, and the soot can sit deep, cleaning with plastic brushes will not bring the desired result.

If the roof of the building is very high, there is a reason to entrust the cleaning to professionals.

Brushes can be placed on rods or rods, but even the longest handles do not allow you to properly clean a 5-meter chimney. Therefore, they can only be used for partial cleaning of the pipe in the accessible area. But if a convenient inspection hatch is equipped, you can scrape the chimney first from the bottom and then from the top.

To clean long pipes, you can also use a cable with a brush and weight. Its end with a cleaning tip descends from above and, under the action of gravity, sinks to the very foundation of the chimney. Since the chimneys from asbestos-cement pipes are always mounted strictly vertically, almost all dirt can be removed in 1-2 passes.

Rotary chimney cleaning method

The rotary method is a kind of mechanical cleaning. At the heart of the same scraper brush on a long flexible rod, only the holder itself can be connected to a drill or a powerful screwdriver. The mechanism will provide such high revolutions of the brush that it is impossible to provide manually. Therefore, cleaning is carried out much faster and better. Rotary cleaning kits like TORNADO are easy to find on sale, but some craftsmen make such devices on their own.

For rotary cleaning, you can make the device yourself

If cleaning the chimney is not difficult for you, otherwise asbestos-cement pipes will not bring much trouble.

Scope of products

With the participation of non-pressure structures made of asbestos cement, which comply with technical standards, the following work is performed:

- External networks of non-pressure sewerage are being laid.

- Irrigation systems and channels for laying communication cables are being arranged.

- Vaulted foundations are created (the BNT 100-200 pipe is reinforced and filled with concrete before this).

- Pile foundations are being installed. In this case, BNT 150-500 pipes are used (the diameter depends on the weight of the material from which the walls are built).

- Chimneys are made (asbestos-cement material is used when the temperature of the exhaust gases does not exceed 3000 ° C).

- Various elements of landscaping are created - flower beds, poles, flowerpots, columns, decorative elements of fences.

- Gutters are constructed from sawn asbestos-cement cylinders.