Diesel boilers. Boilers for diesel fuel. Factory

A diesel-fueled boiler house is a unit with a heat generator and auxiliary equipment, designed to generate a hot coolant or steam.

It is used both for space heating and for the production of hot coolant or steam for industrial needs. Most often, water is used as a heat carrier.

Hot water or steam from the boiler house is supplied to the consumer through a heating main or steam pipeline.

Diesel boilers are often used as an autonomously operating heat generator at facilities that are not connected to gas networks or power networks of sufficient capacity.

Also, oil-fired boilers are often used for temporary heat supply, for example, during the construction phase or in the event of an accident.

Also, this practice of using diesel boilers is facilitated by the fact that their operation does not require complex coordination procedures and accompanying documentation, as, for example, for gas boilers.

Approximately 30% of orders for diesel boiler houses at the KotloAgregat Plant require the Customer to complete the boiler room module with a diesel generator, and acquire a completely autonomous source of not only heat, but also electricity for the facility.

Provision of diesel boiler house with fuel:

Fuel characteristics:

The efficiency of using diesel fuel is due to:

- convenience of its transportation and storage;

- the ability to ensure the efficiency of the boiler room up to 95%;

- emissions of less sulfur and ash from combustion compared to alternative liquid fuels for boilers.

Diesel fuel is supplied to the burner of the heat generator (boiler) at a temperature of at least + 12 ° C. Therefore, the supply tank is located inside. According to the standards, its volume cannot exceed 800 liters, therefore, if there is a need to ensure the operation of the installation for more than a few days, a diesel fuel tank is provided outside.

Diesel boiler room: fuel consumption

In modular diesel boiler houses manufactured by the KotloAgregat plant, fuel consumption has been significantly reduced. The efficiency of our boiler houses is 95% as a result of a set of measures that ensure more complete combustion of fuel.

Average diesel fuel consumption

Accordingly, organizations that purchase a diesel boiler plant from the KotloAgregat Plant with a burner capacity of, for example, 500 kW save about 9,000 liters of diesel fuel per month.

Approximate consumption of diesel fuel (when the boiler is operating at full capacity) can be “estimated” using a very simple formula: Fuel consumption (l / h) \u003d burner power (kW) x 0.1. Thus, the consumption of diesel fuel with a boiler power of 25 kW is approximately equal to 2.5 l / h.

Diesel boiler houses from ZAO Zavod KotloAgregat

Our plant manufactures modular diesel boilers with a capacity of 25 kW to 40’000 kW.

Advantages of our boiler rooms:

- increased efficiency

- a 12% reduction in fuel consumption compared to the industry average.

- reduction of the dimensions of the boiler house due to the use of an engineering system.

- fair prices due to serial production

- optimization of the price of the unit - the boiler house is designed exactly according to the needs of the Customer.

Versions of diesel boilers:

- block-modular design in separate transportable containers;

- stationary version with the possibility of erecting a building at the Customer's site;

- mobile execution on the chassis.

All types of diesel boiler houses of the Boiler Unit Plant can be designed for any type of coolant; designed as industrial or heating boiler rooms.

The most mass production of the Plant "KotloAgregat" in the line of diesel boilers are block-modular diesel boilers.

Modular diesel boiler room:

Modular boiler room for diesel fuel is a plant of complete factory readiness. All equipment is assembled on a frame in an insulated block container, which is easily transported by road or rail.

Inside the module there is the main heat generating equipment, as well as control and safety devices and utilities. The installations, as well as oil-fired boilers, include automatic fire extinguishing systems.

At the operation site, a block-modular diesel boiler house is connected to heat/steam lines. The boiler room in normal operation is controlled automatically without maintenance personnel.

The price of a diesel boiler house is calculated based on the technical specifications of the Customer.

Liquid fuel

Liquid fuels are substances of organic origin. The main constituent elements of liquid fuels are carbon, hydrogen, oxygen, nitrogen and sulfur, which form numerous chemical compounds.

Carbon (C) is the main fuel element: combustion of 1 kg of carbon releases 34,000 kJ of heat. Fuel oil contains up to 80% carbon, which forms various compounds.

Hydrogen (H) is the second most important element of liquid fuel: combustion of 1 kg of hydrogen releases 125,000 kJ of heat, i.e. almost 4 times more than when carbon is burned. Liquid fuels contain ~10% hydrogen.

Nitrogen (N) and oxygen (O2) are contained in liquid fuel in small amounts (~3%). They are part of complex organic acids and phenols.

Sulfur (S) is usually present in hydrocarbons (up to 4% or more). It is a harmful impurity in fuel.

Liquid fuel also contains moisture and up to 0.5% ash. Moisture and ash reduce the percentage of combustible components of liquid fuel, which reduces its calorific value.

Marine fuels

Marine fuels are intended for use in marine power plants (SPP). According to the method of production, marine fuels are divided into distillate and residual.

Marine fuels of foreign production must meet the requirements of the international standard ISO 8217:2010 “Petroleum products. Fuel (class F). Technical requirements for marine fuels”. In order to unify foreign and domestic standards, to ensure the convenience of bunkering foreign vessels in domestic ports, GOST R 54299-2010 (ISO 8217:2010) “Marine fuels. Specifications". The standard provides for the release into circulation of two types of marine fuels:

- marine distillate fuels of DMX, DMA, DMZ and DMB grades;

- marine residual fuels RMA 10, RMB 30, RMD 80, RME 180, RMG 180, RMG 380, RMG 500, RMG 700, RMK 380, RMK 500 and RMK 700.

The main characteristics of the quality indicators of marine fuels are given in tables 2 and 3.

Fuel grades DMX, DMA, DMZ must be clean and transparent, if they are tinted and opaque, then the water content in them should not exceed 200 mg / kg, when determined by coulometric Fischer titration in accordance with ISO 12937:2000 " Oil products. Determination of water content. Coulometric titration method according to Karl Fischer.

The requirements of TR TS 013/2011 for marine fuels set the limit values for the mass fraction of sulfur in % and the flash point in a closed crucible. Until 2020, the mass fraction of sulfur should not exceed 1.5%, and from January 2020 this figure will be limited to 0.5%. The flash point in a closed cup for all grades of marine fuels should not be less than 61 °C.

table 2

| Name of indicator | Norm for stamps | Test method | |||

|---|---|---|---|---|---|

| DMX | DMA | DMZ | DMB | ||

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1 Kinematic viscosity at 40 °С, mm2/s, | 1,400-5,500 | 2,000-6,000 | 3,000-6,000 | 2,000-11,000 | GOST 33 or GOST R 53708 |

| 2 Density at 15 °C | – | ≤ 890,0 | ≤ 900,0 | GOST R 51069, GOST R ISO 3675, ISO 12185:1996 | |

| 3 Cetane index | ≥ 45 | ≥ 40 | ≥ 35 | ISO 4264:2007 | |

| 4 Mass fraction of sulfur, % | ≤ 1,0 | ≤ 1,5 | ≤ 2,0 | GOST R 51947, GOST R EN ISO 14596, ISO 8754:2003 | |

| 5 Flash point, determined in a closed crucible, °С | ≥ 61 | GOST R EN ISO 2719

GOST 6356 |

|||

| 6 Hydrogen sulfide content, mg/kg | ≤ 2,0 | GOST R 53716, IP 570/2009

IP 399/94 |

|||

| 7 Acid number mg KOH/g | ≤ 0,5 | ASTM D 664-2006 | |||

| 8 Total precipitate by hot filtration, % mass | – | ≤ 0,10 | GOST R ISO 10307-1,

GOST R 50837.6 |

||

| 9 Oxidation stability, g/m3 | ≤ 25 | GOST R EN ISO 12205 | |||

| 10 Coking 10% residue, % mass | ≤ 0,30 | – | ISO 10370:1993

ASTM D 4530-07 |

||

| 11 Coke residue, (micromethod), % mass | – | ≤ 0,30 | ISO 10370:1993

ASTM D 4530-07 |

||

| 12 Cloud point, °C | ≤ Minus 16 | – | GOST 5066 | ||

| 13 Pour point, °C

– in winter - summer |

≤ Minus 6

≤ 0 |

≤ 0

≤ 6 |

GOST 20287

ISO 3016:1994 ASTM D 97-09 |

||

| 14 Water content, % by volume | – | ≤ 0,30 | GOST 2477 | ||

| 15 Ash content, % | ≤ 0,010 | GOST 1461 | |||

| 16 Lubricity. Corrected Spot Diameter: at 60 °C, µm |

≤ 520 | GOST R ISO 12156-1 |

Table 3

|

Name

indicator |

Norm for stamps | Method tests |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RMA 10 | RMB 30 | RMD 80 | RME 180 | RMG 180 | RMG 380 | RMG 500 | RMG 700 | RMK 380 | RMK 500 | RMK 700 | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 1 Kinematic viscosity at 50 °С, mm2/s | ≤ 10,0 | ≤ 30,0 | ≤ 80,0 | ≤ 180 | ≤ 180 | ≤ 380 | ≤ 500 | ≤ 700 | ≤ 380 | ≤ 500 | ≤700 | GOST 33 or GOST R 53708 |

| 2 Density at 15 °C | ≤ 920,0 | ≤ 960,0 | ≤ 975,0 | ≤ 991,0 | ≤ 1010,0 | GOST R 51069, GOST R ISO 3675 | ||||||

| 3 Estimated carbon aromatization index CCAI, | ≤ 850 | ≤ 860 | ≤ 870 | |||||||||

| 4 Mass fraction of sulfur, % | ≤ 1,5 | GOST R 51947, GOST R EN ISO 14596 | ||||||||||

| 5 Flash point, determined in a closed crucible, ° С, | ≥ 61 | GOST R EN ISO 2719

GOST 6356 |

||||||||||

| 6 Hydrogen sulfide content, mg/kg | ≤ 2,0 | GOST R 53716, IP 570/2009

IP 399/94 |

||||||||||

| 7 Acid number mg KOH/g, no more |

≤ 2,5 | ASTM D 664-2006 | ||||||||||

| 8 Total sediment with aging, % mass | ≤ 0,10 | GOST R 50837.6 | ||||||||||

| 9 Coke residue (micro method),

% mass, no more |

≤ 2,50 | ≤ 10,00 | ≤ 14,00 | ≤ 15,00 | ≤ 18,00 | ≤ 20,00 | ISO 10370:1993

ASTM D 4530 |

|||||

| 10 Pour point, °С, not higher

– in winter - summer |

0

6 |

0

6 |

30

30 |

GOST 20287

ISO 3016:1994 ASTM D 97-09 |

||||||||

| 11 Water content, % by volume | ≤ 0,30 | ≤ 0,50 | GOST 2477 | |||||||||

| 12 Ash content, % | ≤ 0,040 | ≤ 0,070 | ≤ 0,100 | ≤ 0,150 | GOST 1461 | |||||||

| 13 Contents vanadium, mg/kg |

≤ 50 | ≤ 150 | ≤ 350 | ≤ 450 | IP501:2005

IP470:2005 ISO 14597:1999 |

|||||||

| 14 Contents sodium, mg/kg |

≤ 50 | ≤ 100 | ≤ 50 | ≤ 100 | IP501:2005

IP470:2005 |

|||||||

| 15 Content of Al, Si, mg/kg | ≤ 25 | ≤ 40 | ≤ 50 | ≤ 60 | IP501:2005

IP470:2005 ISO 10478:1994 |

|||||||

| 16 Waste lubricating oils (OSM): Ca and Zn, Ca and P, mg/kg | The fuel must not contain OCM. Fuel is considered to contain OCM if one of the following conditions is satisfied:

Ca content greater than 30 mg/kg and Zn greater than 15 mg/kg or Ca content greater than 30 mg/kg and P greater than 15 mg/kg |

IP501:2005

IP470:2005 IP500:2003 |

Views:

74

List of oil refineries in Russia

| refinery | Controlling shareholder |

Processing capacity (million tons) |

Depth of processing, (un. units) |

federal district |

The subject of the Russian Federation |

Year intro for exploitation |

|---|---|---|---|---|---|---|

| KirishiNOS | Surgutneftegaz | 22 | 0.75 | Northwestern Federal District | Leningrad region | 1966 |

| Omsk Refinery | Gazprom Neft | 19.5 | 0.85 | Siberian Federal District | Omsk region | 1955 |

|

Lukoil-NORSI |

Lukoil | 19 | 0.66 | Privolzhsky Federal District | Nizhny Novgorod Region | 1956 |

| Ryazan NPK | TNK-BP | 15 | 0.72 | Central Federal District | Ryazan Oblast | 1960 |

| YaroslavNOS | Slavneft | 13.5 | 0.7 | Central Federal District | Yaroslavskaya oblast | 1961 |

| Perm refinery | Lukoil | 12.4 | 0.88 | Privolzhsky Federal District | Perm region | 1958 |

|

Moscow refinery |

MNGK (38%), Gazprom Neft (33%), Tatneft | 12.2 | 0.68 | Central Federal District | Moscow region | 1938 |

|

Volgograd Refinery |

Lukoil | 11 | 0.84 | Southern Federal District | Volgograd region | 1957 |

|

Angarskaya NHC |

Rosneft | 11 | n.a. | Siberian Federal District | Irkutsk region | 1955 |

|

Novokuibyshevsk Refinery |

Rosneft | 9.6 | n.a. | Privolzhsky Federal District | Samara Region | 1946 |

|

Ufimsky refinery |

AFK Sistema | 9.6 | 0.71 | Privolzhsky Federal District | Republic of Bashkortostan | 1938 |

| Ufaneftekhim | AFK Sistema | 9.5 | 0.8 | Privolzhsky Federal District | Republic of Bashkortostan | 1957 |

| Salavatnefteorgsintez | Gazprom | 9.1 | 0.81 | Privolzhsky Federal District | Republic of Bashkortostan | 1952 |

| Syzran refinery | Rosneft | 8.9 | n.a. | Privolzhsky Federal District | Samara Region | 1959 |

| Nizhnekamsk Refinery | TAIF (33%) | 8 | 0.7 | Privolzhsky Federal District | Republic of Tatarstan | 1980 |

|

Komsomolsk Refinery |

Rosneft | 7.3 | 0.6 | Far Eastern Federal District | Khabarovsk region | 1942 |

| Novo-Ufimsky Refinery (Novoil) | AFK Sistema | 7.1 | 0.8 | Privolzhsky Federal District | Republic of Bashkortostan | 1951 |

|

Kuibyshev Refinery |

Rosneft | 7 | n.a. | Privolzhsky Federal District | Samara Region | 1943 |

|

Achinsk refinery |

Rosneft | 7 | 0.66 | Siberian Federal District | Krasnoyarsk region | 1981 |

| Orsknefteorgsintez | RussNeft | 6.6 | 0.55 | Privolzhsky Federal District | Orenburg region | 1935 |

|

Saratov refinery |

TNK-BP | 6.5 | 0.69 | Privolzhsky Federal District | Saratov region | 1934 |

|

Tuapse refinery |

Rosneft | 5.2 | 0.56 | Southern Federal District | Krasnodar region | 1949 |

|

Khabarovsk refinery |

NK Alliance | 4.4 | 0.61 | Far Eastern Federal District | Khabarovsk region | 1936 |

| Surgut ZSK | Gazprom | 4 | n.a. | Ural Federal District | KhMAO-Yugra | 1985 |

| Afipsky refinery | OilGasIndustry | 3.7 | n.a. | Southern Federal District | Krasnodar region | 1964 |

| Astrakhan GPP | Gazprom | 3.3 | n.a. | Southern Federal District | Astrakhan region | 1981 |

| Ukhta refinery | Lukoil | 3.2 | 0.71 | Northwestern Federal District | Komi Republic | 1933 |

| Novoshakhtinsky Oil Refinery | South of Russia | 2.5 | 0.9 | Southern Federal District | Rostov region | 2009 |

| Krasnodar refinery | RussNeft | 2.2 | n.a. | Southern Federal District | Krasnodar region | 1911 |

| Mari Refinery |

Artur Perepelkin, Alexey Mileev, Nikolay Khvatov and Sergey Korendovich |

1.3 | n.a. | Privolzhsky Federal District | Mari El Republic | 1998 |

| Antipinsky Oil Refinery | n.a. | 2.75 | 0.55 | Ural Federal District | Tyumen region | 2006 |

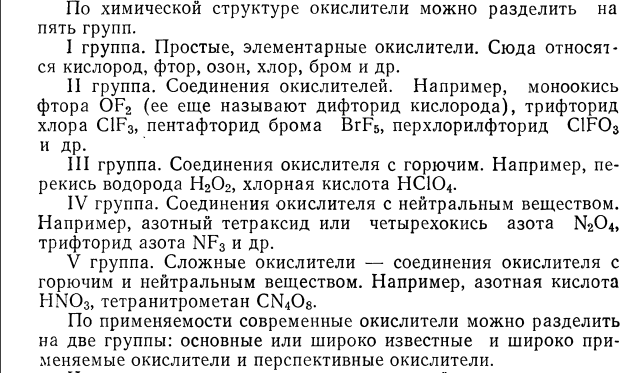

Oxidizers

OxygenChemical formula-O2 (dioxygen, American designation Oxygen-OX). The LRE uses liquid, not gaseous oxygen-Liquid oxygen (LOX-briefly and everything is clear). Molecular weight (for a molecule) -32g/mol. For precision lovers: atomic mass (molar mass)=15.99903; Density=1.141 g/cm³ Boiling point=90.188K (−182.96°C)

In the photo: shutters of the protective devices of the kerosene filling auto-junction (ZU-2), 2 minutes before the end of the sequence diagram when performing the operation CLOSE ZU not fully closed due to icing. At the same time, due to icing, the signal about the exit of the TUA from the launcher did not pass. The launch was carried out the next day.

The RB tanker unit with liquid oxygen was removed from the wheels and installed on the foundation.

"ANALYSIS OF THE EFFICIENCY OF USE OF OXYGEN AS A COOLANT OF THE CHAMBER OF A LIQUID ROCKET ENGINE" SAMOSHKIN V.M., VASYANINA P.Yu., Siberian State Aerospace University named after Academician M.F. Reshetnev

Imagine: instead of H2O, imagine LCD (LOX).

Note: In defense of Elon Musk's pasta monster, let's put in a word. Part 1 In Defense of Elon Musk's Spaghetti Monster, Let's Say a Word

Part 2 Ozone 3 Molecular weight = 48 amu, molar mass = 47.998 g / mol The density of liquid at -188 ° C (85.2 K) is 1.59 (7) g / cm³ The density of solid ozone at -195.7 ° C (77.4 K) is equal to 1.73 (2) g / cm³ Melting point -197.2 (2) ° С (75.9 K)

Nitric acid 3 State - liquid at n.o. Molar mass 63.012 g / mol (it does not matter that I use molar mass or molecular weight - this does not change the essence) Density \u003d 1.513 g / cm³T. fl.=-41.59 °C, T

bp=82.6 °C

3

Nitrogen dioxide (NO2) is added to the acid to increase the impulse. The addition of nitrogen dioxide to the acid binds the water that enters the oxidizer, which reduces the corrosive activity of the acid, increases the density of the solution, reaching a maximum at 14% dissolved NO2. This concentration was used by the Americans for their combat missiles.

Interesting fact: Soviet rubles were almost 95% made of this alloy. Nitrogen tetroxide24 Molar mass=92.011 g/mol Density=1.443 g/cm³

324 Fluorine 2 Atomic mass \u003d 18.998403163 a. mu (g/mol) Molar mass F2, 37.997 g/mol Melting point=53.53 K (−219.70 °C) Boiling point=85.03 K (−188.12 °C) phases), ρ=1.5127 g/cm³

"fluor"

Super? Bummer, not "super" ...

22Starting position after the launch of such a "vigorous engine"? 222

Walter HWK 109-507: advantages in the simplicity of the LRE design. A prime example of such a fuel is hydrogen peroxide.

Hydrogen peroxide for luxurious hair of "natural" blondes and 14 more secrets of its use

Note: if you want to convert one specific impulse option to another, then you can use a simple formula: 1 m / s \u003d 9.81 s.

"fill up"