How to insulate a wall in a brick bath

Finishing the steam room should be carried out using heat insulators that do not emit substances harmful to the human body. For this, heaters that are not susceptible to moisture from fiberglass or basalt are suitable. Bath insulation should be comprehensive and include insulation of elements such as the floor, foundation, roof and walls. Let us consider in detail how to properly insulate, and what methods are used for each element.

Foundation

The concrete that makes up the foundation is a strong conductor of cold. Before erecting a wall, it is insulated with roofing material so that cold and moisture from the ground do not get in. However, this is not enough. It is necessary to finish the foundation walls from the base to increase heat retention and minimize subsidence of the foundation

This is important, because in winter the earth expands under the influence of cold, while cracks form in the foundation, which destroy it. Of the materials, you should choose penoplex, it is cheaper than polyurethane foam, but its installation takes more time

The second material also works well and can be assembled in a day.

The floors in the bath

To protect the floor from earth moisture, before installing the plates, an expanded clay pillow is needed. The thickness of its layer depends on the thickness of the walls, and should be twice as large. A basement is not needed for a bath, so expanded clay is completely covered over the entire inner surface of the foundation. The floor in the bath is preferably made of concrete slabs. It handles moisture better than wood.

wall decoration

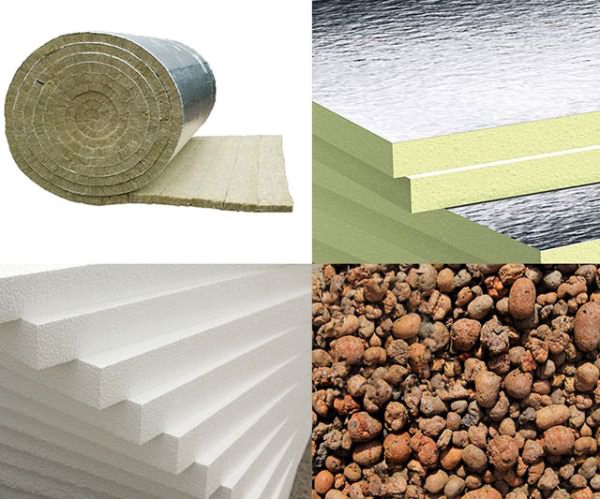

The insulation is fixed on a pre-fixed cobbled crate, it will prevent the material from slipping, protect it from compression, while retaining its original properties. When choosing a heater, you should consider what type is used: expanded clay, foam foam, isolon, or others. Scheme of thermal insulation of bath walls:

- Masonry is done in several passes, the brick is periodically poured with prepared lime mortar.

- Insulation boards are located from the inside, between the bearing wall and the finish.

- A lining or wooden panels are attached on top of the insulation.

Roof finish

Complex insulation of a steam room in a brick bath cannot do without a ceiling. Steam rises first of all, so the roof of the steam room is especially susceptible to high temperatures and high humidity. Therefore, he needs to pay no less attention than the walls. For the roof, specialists in insulating the bath from the inside recommend using mineral wool with a double-sided waterproofing coating. For these purposes, foil fiberglass is well suited. It is not recommended to use expanded polystyrene. At such temperatures, it releases substances dangerous to the body.

https://youtube.com/watch?v=wm1q_X5klK0

Insulation of a brick bath from the inside

How to insulate the walls of a brick bath from the inside? The inner surface of the walls of a brick bath is best insulated with natural heat-insulating materials that retain heat perfectly, but do not emit any harmful substances at high temperatures. In particular, mineral wool webs, available in the form of rolls or individual mats, are excellent for this purpose.

The only drawback of such a heater is the ability to absorb moisture, which, by definition, is always in abundance in any bath. Therefore, the heat-shielding layer will require additional waterproofing, which protects the mineral wool from steam and water.

The procedure for installing insulation on internal walls will be as follows:

- a supporting frame is erected on a brick wall of wooden slats;

- heat-insulating material is laid in the resulting cells. In addition to mineral wool, more modern materials can be used here with great success.For example, foil foam is not only absolutely insensitive to moisture and temperatures of several hundred degrees, but due to the shiny surface of the foil it is able to reflect heat back into the bath rooms;

- the entire structure is covered with a layer of waterproofing (polyethylene, foil, etc.). To ensure complete moisture resistance, the waterproofing material should be laid with an overlap of 10-20 cm. To give additional strength to the joints, all joints should be fixed with thin and flat wooden slats.

In order to improve aesthetics, thermal insulation is usually not left open, but covered with wooden clapboard.

In addition to walls, the internal thermal insulation of a brick bath should include measures to reduce heat loss through the floors. The sequence of actions here will be as follows:

- a layer of vapor barrier is laid on the subfloor cleaned of dust and dirt;

- thermal insulation mats are lined and fixed in one way or another;

- a layer of waterproofing is laid;

- the finishing floor is equipped with the widest possible boards with a thickness of at least 40 mm.

It is very important to consider the material from which the subfloor is made. If it is formed by boards, then they will need to be pre-treated with a means to prevent wood decay. The concrete subfloor itself can play the role of thermal insulation

Therefore, even at the stage of its arrangement, one should take care of giving heat-saving properties. This is achieved by the following floor laying technology:

The concrete subfloor itself is able to play the role of thermal insulation. Therefore, even at the stage of its arrangement, one should take care of giving heat-saving properties. This is achieved by the following floor laying technology:

- a layer of sand about 5-10 cm thick is poured into the pit;

- a solid heat insulator (polystyrene) is laid;

- a mixture of cement, sand and crushed foam is poured;

- sheets of roofing material are overlapped;

- the reinforcing mesh is lined;

- a concrete solution is poured with the addition of crushed stone of a fine fraction;

- at a height of 10-20 cm, a finished plank floor is created.

The resulting design is advantageous in that it is ventilated. And this means a significant increase in the service life of both the finished floor and the heat-insulating concrete base underneath.

How to insulate the floor in the bath? You will find out the answer to this question by reading this article.

And in this article, read about the insulation of the roof of the bath.

Ceiling insulation

Through the ceiling with poor-quality thermal insulation, up to a quarter of all the heat generated by the furnace can go

Therefore, to reduce losses, ceiling insulation should be given no less attention than in the case of walls. The most suitable insulating material for this purpose is lightweight and non-combustible fiberglass

Work on the insulation of the ceiling in the bath is carried out as follows:

- fiberglass canvases or mats are laid out on the ceiling boards;

- a mixture is poured on top, consisting of equal parts of sawdust, sand and clay. The optimal thickness of this layer is 20-25 cm;

- after the previous layer has dried, foam sheets are laid out on it;

- the entire surface is poured with a small layer of cement screed.

In addition, ordinary expanded clay is able to provide excellent thermal insulation. With a backfill thickness of about 30-40 cm, it will be able to reliably retain precious heat.

Insulation of a bath from foam blocks. Read about it here.

And this article talks about the insulation of a wooden bath.

Here https://ru-house.net/stroitelstvo/ you will find many more informative articles about building a house.

Insulation of the walls of the bath features of the process

When you have completed the process of floor insulation, we begin the insulation of the walls from the inside.

Please note that it is not necessary to loosen or process the brick tub from inside the bath room, since this wall surface will later disappear behind the wood sheathing for the steam room

The only thing that will need to be done is to impregnate the brick wall in order to protect it from bacteria, but this procedure is only relevant for rooms such as the steam room and shower room.

The walls of the bath should be insulated in exactly the same way as other rooms, and not only baths. However, there are a number of process features that are characteristic exclusively for this type of work:

- to reduce the number of possible heat losses, close the gaps between the wall and windows with polyurethane foam; the frame for mounting the cladding must be made of wooden beams, then attach it directly to the brick tub; it is highly undesirable to use metal hangers and profiles for work, since they tend to conduct heat; insulation in the form of mineral wool or polystyrene plates is placed in the cells of the crate: the insulation is attached to the tub with dowel umbrellas or with a special adhesive; if you are going to stick a heat insulator, then it is better to treat the brick wall of the bath with a penetrating primer.

So, when the main insulation has already been applied to the walls, it is necessary to apply a layer of vapor barrier, which can be used as kraft paper, glassine or foil film, which, by the way, will be the most optimal material for the steam room and shower room. For example, the same kraft paper, when used in places of high humidity, can get wet over time and become unusable.

If necessary, stuff the counter-batten onto the battens of the batten. This will create a gap between the outer skin and the vapor barrier. Then the lining should be attached to the counter-lattice using thin planks of wood.

When your bath or sauna has a large area and occupies several floors, it is not necessary to insulate the walls from the inside everywhere in order to prevent strong heat loss during its operation. If a loggia is attached to the bath, it is also subject to insulation. You should also install good entrance doors equipped with at least two sealing circuits.

Warming outside

Before starting to insulate a brick bath from the outside, it is necessary to carefully analyze the issue of bricklaying:

- The mortar must fill the entire space between the bricks evenly, at the same thickness; The first row of brickwork should be made only from solid elements; Beams rest on the bond row; As for clay bricks, before laying them, it is necessary to thoroughly moisten the brick, especially if the bath is arranged in the summer season.

In order to insulate the bath from the outside of the building, it is necessary to lay expanded clay between the walls with a thickness of 40-50 centimeters. You can also use slag, fluff of lime, sawdust and sand for this.

But it would be more rational to insulate the walls of the bath from the outside with slab insulation. Direct fixation of the layers of insulation occurs with the help of a synthetic binder. The plates are placed in spacers at a distance of half a meter from each of the plates. Read the instructions on which stove to choose for a bath.

Mount the slab insulation in such a way that there are small gaps between the elements. They are necessary for the ventilation of the facade, because otherwise, the entire surface during the rainy season will be covered with mold formations.

How to insulate a steam room

The procedure for insulating the ceiling in the steam room will be as follows.

- The entire surface of the ceiling is covered with roll paper.At the joints, you need to create overlaps of 10-20 cm.

- Wooden bars with a section of 5x5 cm are nailed to the ceiling. These bars will have a dual purpose: they will fasten the paper by themselves and become the basis for fastening the outer covering.

- The entire ceiling is sealed with metal foil. To fix it, it is best to use a special adhesive tape, on one of the surfaces of which a layer of aluminum is applied. There should be no gaps between sheets or strips of foil, as penetrating hot steam will wet the ceiling. This is fraught with a deterioration in thermal insulation qualities and can lead to the development of putrefactive processes.

- Over the bars, wooden slats are stuffed, to which, in turn, the main ceiling covering from a wooden lining will be attached.

Similarly, the foil is fastened to the surfaces of the walls in the steam room.

As a sheathing material in the steam room, it is best to use pine lining. Pine perfectly resists both high temperatures and the effects of hot steam from the heater. In addition, due to the presence of a certain amount of resins, distillation from pine will add a special aroma to the atmosphere of the steam room.

In general, the process of warming a brick bath does not cause any particular difficulties even for masters without extensive experience in such work.

The most important thing is to choose a suitable insulation that is resistant to high temperatures and high humidity. In the case of using thermal insulation that is afraid of moisture, it should be carefully isolated from the bath atmosphere or from precipitation in case of outdoor work.