Furnace models

Vologda

- The principle of operation is reminiscent of a gas generator, such a stove for a long-burning greenhouse is cost-effective in operation and has a high heat transfer.

- It is enough to lay firewood two or three times a day. Depends on the volume of the furnace and the overall size of the device.

Thanks to this, the equipment has received a great advantage, since there is no need to constantly be near the firebox and monitor combustion. Efficiency "Vologda" - about 80%.

The coolant enters from behind through specially installed flexible hoses that connect the device to the water tank. Up to 60 degrees from zero, the liquid heats up in 40 minutes.

There are models that can simultaneously heat a greenhouse and a residential building, in which heat will be distributed through water heating radiators. The instruction that comes with the model describes this process in detail.

A plus

It should be noted the easy process of switching from the gas generating state to the normal mode of the heater. Therefore, the equipment can also be used for baths.

Minus

Periodic rain is required.

Buleryan

For greenhouses and greenhouses is used quite rarely. Convection type oven, can maintain the desired temperature for a long time.

Works on conventional firewood and woodworking products. Naturally, the price of such a device is higher than the usual "potbelly stove".

"Bulleryan" in the greenhouse

Minuses

- Temperature controller not installed.

- Not very easy to install.

- It is often necessary to monitor the firebox.

In appearance, it resembles a horizontal barrel, with exhaust pipes located above and below. The smallest model is capable of passing through itself up to 5 m3 of air per minute, but the body, covered with a special paint, does not heat up.

Slobozhanka

The design is well suited for a small room. It can be done with your own hands without the involvement of assistants.

Pre

- Take a thick-walled pipe, make longitudinal grooves in it with a "grinder" or "autogenous". This will be a special device for uninterrupted air supply and activation of fuel combustion.

Air duct from pipe 100 mm

- Install a metal pin made of 5 mm steel from the bottom of the device, which will act as a gate, and it will be possible to regulate the supply of oxygen to the furnace.

Furnace air control device

- Make a chimney in the upper part of the furnace from a piece of pipe with a diameter of 100 mm to remove combustion products.

- Take a thick-walled metal cylinder with a diameter of 250 mm.

- Cut a 100 mm hole in the center of the steel thick-walled sheet and weld it to the pipe of the future air duct.

- Make a heat-dissipating disk from a sheet of metal 10 mm thick, which will be installed inside the device.

Making a do-it-yourself oven

The choice of the project of the future device mainly depends on the existing conditions and the desired functions. If heating is required in a small greenhouse, the device will only work periodically, for example, to ensure earlier sowing of seeds in the spring, a small potbelly stove of a simple design will do.

With the constant use of heating, for heating large areas, a significant amount of fuel consumption, economical designs based on pyrolysis combustion will be the most suitable option. Compactness and ease of installation are important - a small steel device is easier to install and put into operation, a brick structure, due to its massiveness, will require laying the foundation, and construction work will be more time-consuming and lengthy.

Fuel selection and materials preparation

Before you buy or make a stove for a long-burning greenhouse with your own hands, you need to decide what type of fuel you will use for kindling.The most expensive to maintain are electric and gas models, as resources for them are not spent economically and are expensive.

Heating, a stove and a greenhouse with which they will be heated economically, rationally, fully, can be carried out using the following materials:

Traditional fuel, which is used in most cases.

Firewood should be well dried before being used, they should be of the same size, should not be very large or, on the contrary, small.

Processed products or sawdust, shavings, are sure to be found in large quantities in almost every home.

This type of fuel is especially beneficial for those who make repairs, are engaged in construction, and cut wood.

A more expensive type of fuel, but it will cost much less than harvesting or buying firewood.

Peat burns well and economically in furnaces, provides the necessary temperature, the level of heat.

Fuel can be sold both in bulk and cost less, and compressed elements, in the form of coins, sausages. The second option is more convenient to use, it is portioned and economical.

Husk, straw and other fuels are processed products and therefore have a low cost.

Some give away these practical materials for next to nothing or for free.

Husk can be bought inexpensively at special enterprises that sell shelled nuts, seeds, etc.

It is important to choose the right type of heating unit, which depends on your budget. The most expensive and difficult to perform are Buleryan and Butakova, they are of course very good in terms of heating, but they will pay off only if they are installed in the house

You can assemble a convection or gas-generating oven with your own hands according to the schemes that are left by professional stove-makers and amateurs on the relevant sites and forums. However, the best, best option would be to order an individual project from a designer, a stove-maker.

For more efficient and rational heating, it is best to make or buy for a greenhouse not a brick oven, but a metal one, it heats up faster, accumulates thermal energy well, and evenly distributes it throughout the greenhouse.

At the first stage of work on the manufacture of the heating unit, it is necessary to assemble its main part - the body, this can be done using one of the following options:

- A body having a cylindrical shape is welded from sheet steel;

- As a base, empty propane gas cylinders are often used, which are cut off the fruit of the required shape and size;

- From a pipe with a very large diameter;

- The classic option is to assemble the frame of a greenhouse stove from a metal barrel that has no cracks and is completely sealed. If a large barrel is taken as a base, as an addition to it for making the base, it will be necessary to buy and prepare a medium-length pipe, which is necessary for making a chimney. For fastening and fixing the box, it is necessary to acquire a steel corner, fittings, strip or channel.

Heating boilers based on a potbelly stove

To heat a multi-room house, you will need a flow-through water heating circuit with a long-burning solid fuel boiler. Such a system can be set up in two ways. The principle laid down in the potbelly stove is taken as a basis.

The first method or boiler number 1

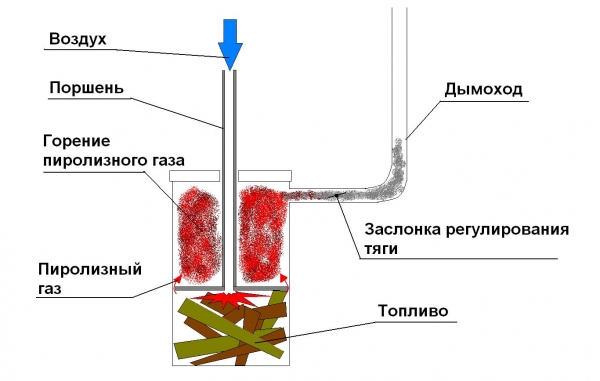

The natural vortex is replaced by forced air, and pyrolysis is divided into two stages in space: the pyrolysis chamber, the nozzle (nozzle), which forms the flow of pyrolysis gases, and the combustion chamber. The nozzle is made so that there are no parasitic turbulences behind the mass of fuel. Through blowing is required for full process control.

Features of once-through and heat storage pyrolysis boilers:

- The temperature in the combustion chamber is a parameter necessary to control the process.

- Heat dissipation optimization is directly proportional to the boost intensity.

- The insensitivity of the system to the temperature of the walls of the combustion chamber, so the water heater can be built in a technically convenient way.

- Additional loading is possible at any stage and in any allowable quantity.

The efficiency of once-through boilers can be over 90%. They require power to operate. When shutting down, to further start the system, it is necessary to rake out the caked mass and make a new bookmark in the furnace.

The second method or boiler number 2

A pyrolysis boiler with a water heater, which does not require electricity and automation, works on the principle of counteraction of two square-cube laws. This refers to the laying of fuel and the lining of fireclay bricks. The algorithm of the brick oven:

- At the beginning, the intensity of the pyrolysis process is provided by the sublimation of the lightest volatiles. The "first heat" goes through the smoke circuits, being absorbed by the lining.

- At the stationary stage, the lining serves as a thermal buffer: in case of excess pyrolysis heat, it absorbs it, and releases it when it cools down.

- Upon completion of fuel carbonization, gradual heat transfer by the lining occurs, preventing the temperature from dropping below the critical point.

in or coal into the boiler with thermal buffer is produced gradually. Sharp fluctuations in temperature are contraindicated for her. If too sluggish fuel is used, it may stall. If there is too much fuel, there is a risk of an accident. If the first heat is not suppressed, the efficiency will not exceed 76-78%, since the instantaneous heat transfer by the lining to the outside is excluded.

Greenhouse stove manufacturers

You can make a stove for a greenhouse yourself, or you can buy it in specialized stores, decide for yourself.

Currently, manufacturers offer many different options for greenhouse stoves:

- Buleryan.

- Butakov oven.

- Slobozhanka.

- Vologda.

Let's consider these models in detail.

You can regulate the process of air supply to the combustion chamber using a damper. Thanks to it, it is possible to increase or decrease the volume of oxygen supplied, which affects the final burning rate.

Buleryan

Residents rarely choose such stoves for heating greenhouses, but at the same time, these units guarantee long-term fuel burning and maintain a comfortable temperature.

The device of the furnace Buleryan

Buleryan is a convection-type device in the form of a barrel with extended pipes, the fuel for which is firewood. It also contains:

- door for loading firewood;

- smoke damper;

- traction regulator.

Outwardly, the Buleryan stove resembles a classic "potbelly stove", but the principle of operation is different.

Heat exchange is carried out by:

- thermal radiation;

- heat transfer;

- convection.

In fact, it contains three devices with different functional purposes:

- heater;

- bake;

- gas generator.

They function as follows: firewood smolders in the chamber, pyrolysis gas is produced and burned, thanks to which the heat transfer process is carried out.

These furnaces were developed in Canada, and the German company Energetec Gmbh has a patent for the production of such devices. In Russia, CJSC Laoterm produces Buleryan under the name Breneran; in terms of technical parameters, the Russian rebranding is no different from the original.

Despite the convenience of using such equipment, it has some disadvantages:

- are not equipped with regulators for adjusting the temperature;

- not easy to install;

- their work must be constantly monitored.

Their price varies from 8,000 to 25,000 rubles.

https://youtube.com/watch?v=3egYpX2IPns

https://youtube.com/watch?v=3egYpX2IPns

Butakov oven

These are conventional ovens, which got their name in honor of the professor who developed them.

The device of Professor Butakov's furnace

The body of the furnace is a parallelepiped, it contains air pipes and a two-chamber firebox. In addition, the device is equipped with:

- ash pan;

- damper;

- chimney.

The principle of operation of this type of furnace for greenhouses is absolutely identical to the Buleryan furnace.

The price of such devices: 10,000 - 35,000 rubles.

Slobozhanka

Slobozhanka is characterized by high quality and efficiency. This type of stove is also called "super potbelly stoves".

Oven Slobozhanka

Structure:

- the combustion chamber;

- air supply and distribution channel;

- convection shirt.

In this furnace, the ignition system is top, respectively, logs are also loaded through the top, a special cylinder is additionally used, which puts pressure on combustible materials.

There are three main types of furnace data:

- With L-shaped pipe for lateral supply of oxygen to the combustion chamber.

- With air supply through the central part with the help of a guide pitoid.

- With air supply from the lower side part.

Regardless of how air is supplied to the combustion chamber, the heat exchange process will be carried out with maximum efficiency.

You can connect a water circuit to Slobozhanka and create a heating system with radiators.

Slobozhanka is a profitable solution for heating greenhouses, since various materials can serve as fuel, from firewood to cones.

https://youtube.com/watch?v=DHXc7EKmD30

Vologda

Furnace Vologda

This model of long-burning stoves for heating greenhouses has a number of advantages:

- high heat transfer;

- high efficiency 80 - 90%;

- it is necessary to lay firewood several times a day;

- low price.

If you opt for such an oven, you will not need to monitor how it functions all the time. To supply the heat carrier, flexible hoses are used, which are attached to the rear of the boiler and lead to the tank with the heat carrier. It will take 30-40 minutes for the water to heat up to a temperature of 60 ° C.

Cost: 4,000 - 6,000 rubles.

The manufacturer of the Vologda brand produces models that can be used simultaneously for heating both greenhouses and private houses, for this you will need to connect a water circuit and install radiators.

Infrared heaters and heating boilers can also be used to heat the greenhouse.

Bubafonya

Potbelly stoves have low efficiency and the need for frequent reloading of fuel. The craftsman Bubafonya came up with a home-made design that differs in the principle of fuel combustion.

Features and device

The main difference in the Bubafoni oven is the upper intake of the air mass, which led to such positive properties as:

- longer burning of fuel;

- there is no need for frequent loading of the furnace;

- better heat retention;

- profitability, because such a furnace can be made from improvised materials: barrels made of iron or metal; as fuel, you can use not only firewood, but also boards, chips, cardboard or shavings. And also the Bubafonya oven works autonomously, that is, without the use of electrical energy.

There are also disadvantages of this design:

- outwardly looks unpresentable;

- average heat transfer;

- carbon formation on the walls of the furnace;

- condensation forms, which freezes in winter and blocks the main pipe;

- during air intake, fire sometimes appears from the duct;

- with the installation of such a stove, it is necessary to take care of ventilation in the greenhouse.

To make Bubafonya yourself, you need to know the device and the principle of operation of the furnace. Air enters through the top tube, and the fuel starts to burn. When burned, the ash will accumulate on the surface of the fuel and prevent it from burning. Because of this, care must be taken to install the press in the form of a metal pancake, the diameter of which is slightly smaller than the barrel. A hole is drilled in the middle of the pancake for an oxygen pipe.

The fuel burns out, and the press lowers, squeezing out the ash between the pancake and the wall. Such ash cools down and leaves through the chimney with the rest of the combustion products.

Manufacturing

Having studied the drawings and diagrams of the furnace, understanding the principle of operation, you can make Bubafonya with your own hands. An important point is the choice of capacity.A large-diameter pipe, a barrel, an empty gas cylinder can be used as it.

Whatever it is, you will have to complete the design:

- get rid of the cover;

- to obtain a container with an open top, it is necessary to weld the bottom;

- press preparation: a metal sheet circle is suitable for this;

- drill a hole for the pipe in the center and attach the pipe by welding;

- a pipe with a large diameter is also welded onto the lid so that the first pipe can slide freely;

- to create a gap so that air passes between the surface and the fuel, fasten a metal profile to the pipe;

- for the firebox, make a door from an iron sheet and attach it;

- make a hole for the chimney on top of the container and connect the pipe;

- make legs for the stove, if the bottom is not “worth it”.

In the manufacture of the chimney, it is necessary to take into account the need to create resistance, which will allow a longer retention of heat.

Before installing the furnace, it is necessary to make a foundation of bricks and a substrate of galvanized sheet under it. This will help to avoid heating the bottom of the stove, which leads to the death of closely growing crops. The foundation also retains and distributes heat.

After installing the furnace, it is necessary to overlay with bricks to improve heat transfer.

Wood burning stoves for greenhouse heating

The choice of options for heating devices for the greenhouse is as diverse as for the home. Most often, factory models are used, which are purchased in stores, but it is possible to make such a device with your own hands.

Furnaces differ both in the type of fuel - wood, gas or electric, and in the material of manufacture - metal or brick.

Most often, a solid fuel apparatus is chosen for self-construction, which is heated with firewood, pallets of wood chips, husks, and dry pieces of peat.

Ordinary greenhouse stove

A device of this type can be made of metal or brick.

A metal potbelly stove is quite simple to build, it is recommended to weld it from an old barrel or gas cylinder, 1.5 m x 0.5 m in size. .

The uneven heating is important - the stove has a high heat transfer due to the metal case, so the air in the immediate vicinity of it is very overheated, which negatively affects the soil and plants.

The construction of a brick oven will allow you to get a longer, gradual heating of the room, as well as long-term heat transfer after the firewood has already burned out. The construction of an elongated horizontal smoke channel will significantly increase these figures.

The dimensions of such a device can be different, depending on the area of \u200b\u200bthe room, the smoke channel is usually laid out for the entire length of the greenhouse - being located in the center, it contributes to high-quality, uniform heating of the air.

Important! The task of the greenhouse stove is primarily to warm the soil, so the smoke channel and the device itself are located as close to the ground as possible

Scheme of a long-burning device

To increase the efficiency of the stove, they often equip a double combustion chamber - this allows you to extend the effect of one bookmark of firewood by 12-18 hours. This is achieved through the pyrolysis process - due to the controlled entry of air into the furnace, firewood does not burn in an open flame, but smolders very slowly, releasing a large amount of smoke and hot gases. The second chamber of the furnace serves for the final combustion of the evolved combustion products.

Photo 1. Scheme showing the device of any long-burning furnace with a limited supply of oxygen.

With this method of heating, it is necessary to add fuel much less frequently, and pyrolysis combustion leaves almost no waste, so you do not have to often clean the furnace from ash. Saving fuel and time required for maintenance makes this option the most popular.The dimensions can be quite small - 1.5 m x 1 m, more efficient heating of the air will be provided by the installation of a horizontal smoke channel.

Long burning furnace

Long-burning units operate according to the gas-generator principle, which results in a reduction in fuel consumption and a low heating temperature of the walls of the device (read: “Long-burning heating furnaces - choose the best option”).

The all-welded design has an internal compartment consisting of two compartments:

- combustion chamber (oxygen access to it is limited, so the fuel smolders, and does not burn, which results in an increase in the combustion time of firewood);

- afterburner chambers (combustion products burn in it).

Under the steel casing of the device are convective pipes. They provide an outlet for the flow of heated air and its distribution throughout the greenhouse. Since the temperature throughout the building is almost the same, condensation does not occur. One of the advantages of long-burning stoves is the fairly rapid heating of the air. Also, quite often, home-made long-burning potbelly stoves are used for heating greenhouses.

Such a unit is sufficient for heating greenhouses, the use of which is not expected in winter (read: "Heating a greenhouse in winter - basic principles"). If there is an intention to use the building in the winter, then in addition to installing the stove, you also need to lay water pipes to heat the greenhouse in winter. For this purpose, devices with a built-in boiler are suitable.

Heating systems that use long-burning stoves have many advantages over other methods of heating greenhouses:

In addition, long-burning stoves can be effectively used at any time of the year.

Wood stoves are not the best option for heating greenhouses, but they are still in great demand. Modern heating systems are more efficient, but their use is not always possible. If there is no access to the gas pipeline, and there are often interruptions in electricity, wood stoves will be the only way out of this situation.

Solid fuel stove potbelly stove

Outside the cities, firewood is the most affordable, so the most popular long-burning stove is wood-burning. They drown it not only with firewood from the ridge, but also with waste wood - shavings, sawdust, waste Fiberboard and chipboard, small brushwood, straw, etc. There are many heating systems on wood and wood waste. Consider the most efficient, the efficiency of which is more than 70%.

A potbelly stove is an economical stove that appeared in Russia after the revolution, during the time of war communism, when many had to endure hardships. The genius of the potbelly stove is that it instantly warms up, as well as the simplicity of its device, the prototype of which was the Russian stove. The upper door is for laying firewood, the lower one is for regulating combustion by supplying air through the ajar door.

The task of the potbelly stove is to keep the heat in at least one room at minimal cost. When using coal, the grate is removed, and the air from the blower is directed to the furnace

It is important not to stuff it chock-full - the volume of the bookmark should be no more than a quarter of its volume. The afterburner is a long horizontal or slightly inclined part of the chimney

Made of metal, it keeps the heat in the room.

When fired, any potbelly stove is red-hot, so its upper surface can be used as a hob. A screen should be installed on the sides at a distance of 40-60 mm from the oven. It protects the room from infrared rays and maintains the temperature at an optimal level.

On the basis of a potbelly stove, you can make a home-made boiler for long burning on wood. To do this, instead of the screen, a U-shaped metal water heater is installed. The distance between the furnace body and the boiler must be the same as the screen offset.

Sources

- https://eteplica.ru/otoplenie-i-ventilyaciya/kak-sdelat-pech-dlitelnogo-goreniya-dlya-teplicy.html

- https://teplofan.ru/pechi-i-kaminy/pech-dlya-teplic

- http://kotel-otoplenija.ru/pechi-dlitelnogo-goreniya-dlya-otopleniya-zimnix-teplic-kratkij-obzor-modelej

- http://teploguru.ru/pechi/pechi-dlitelnogo-goreniya.html

- http://KaminGid.ru/pech-slobozhanka-svoimi-rukami

- http://SdelayPechi.ru/vidy/firmennye/pech-slobozhanka.html

- https://kaminguru.com/pech/slobozhanka.html

- https://oteplicah.com/kommunikacii/otoplenije/76-pechi-dlya-teplic-dlitelnogo-goreniya

Types of heating and types of stoves

Greenhouses are heated in several ways:

- biological;

- electric;

- air;

- gas;

- furnace.

Stove heating is the most economical heating option, which allows the use of most types of fuel. They can run on wood, coal, gas and even pellets.

Stove heating has one significant drawback - overdrying of the air due to the rapid heating of the equipment.

Furnace heating on sawdust, which are waste woodworking enterprises. Therefore, the purchase of this fuel does not require large expenditures. To build a sawdust stove, you need to purchase a tin barrel, preferably a couple of barrels, a gas cylinder and a pipe segment.

- A waste oil stove is an economical heating option with long burning. Those subject to oil waste are disposed of from any vehicle fleet, so fleet workers will gladly share the oil.

- To heat the greenhouse in the cold season, potbelly stoves are used, which provide good heating.

- Kuznetsov's brick heating stove is of particular interest to gardeners due to its high efficiency (80%). However, the body of the brick stove must be insulated with basalt material.

- Miracle oven on diesel fuel is an excellent solution for a greenhouse where there is no connection to a central heating system. The stove is used both as an additional and as the main source of heat.

There are many types of stoves for heating greenhouses, which differ from each other:

- the principle of heat transfer;

- convection;

- radiation;

- main and additional details;

- fuel combustion chamber;

- pipes for air supply.