What is the meaning of balancing

Hydraulic heating systems are rightfully considered the most complex. Their effective work is possible only if there is a deep understanding of the physical processes hidden from visual observation. The joint operation of all devices should ensure the absorption of the maximum amount of heat by the coolant and its uniform distribution over all heating devices of each circuit.

The mode of operation of each hydraulic system is based on the relationship of two inversely proportional quantities: hydraulic resistance and throughput. It is they who determine the flow rate of the coolant in each node and part of the system, and therefore the amount of thermal energy supplied to the radiators. In the general case, the flow calculation for each individual radiator reflects a high degree of unevenness: the farther the heater is from the heating unit, the greater the influence of the hydrodynamic resistance of pipes and branches, respectively, the coolant circulates at a lower speed.

The task of balancing the heating system is to ensure that the flow in each part of the system will have approximately the same intensity even with temporary changes in operating modes. Careful balancing allows you to achieve a state where the individual adjustment of thermostatic heads does not significantly affect other elements of the system. At the same time, the very possibility of balancing should be provided for even at the design and installation stage, because both special fittings and technical data for the boiler room equipment are needed to set up the system. In particular, it is mandatory to install shut-off valves on each radiator, commonly called chokes.

Problem symptoms

It should be said right away that you don’t need to climb to the valves just for the love of art. Many technical specialists have a favorite phrase: "It works - don't touch it." Here, too, it can be applied. If you do not notice any negative signs in the operation of the heating system, then let it function in the current mode. If you randomly turn the taps, you can, on the contrary, unbalance everything, and then you have to fix it.

Let's look at those phenomena that are clear signs of a lack of balance:

- temperature difference in the rooms. As mentioned above, with poor-quality balancing or its complete absence, some rooms will be much colder than others. The rooms closest to the boiler will torment you with suffocating heat, and in the farthest you will freeze;

- one of the radiators is constantly murmuring. Such noise indicates a malfunction in the coolant current;

- a warm floor filled with a concrete screed heats the surface unevenly.

If you have just installed a new heating system, then it a priori needs to be balanced, regardless of the presence of any signs.

It should be noted that not every problem in the operation of the heating system is associated with its balancing. On the contrary, there are cases when it is absolutely pointless to carry out this operation:

- airiness of the system;

- leakage;

- blockage formation;

- malfunction of the expansion tank.

All these factors can lead to uneven heating of the premises. Balancing won't help here. It is necessary to eliminate the cause of the system malfunction. For example, to deal with airiness, use Mayevsky taps, which are usually installed on radiators. With their help, you can easily and quickly expel air from the place where it should not be. As soon as you deal with the air lock, the coolant current will immediately recover.You can learn more about how to use the Mayevsky crane from the articles on our website.

As for other reasons, everything is obvious. The leak must be repaired (or the damaged element replaced with a new one), the blockage must be eliminated, the expansion tank must be repaired (as a rule, the problem is a rupture of the membrane). Only after that, if problems with the distribution of the coolant still persist, can balancing be carried out.

If you live in an apartment building, then the question of how to balance the system is not worth it. On the contrary, you can’t climb there at all with your own hands, since any wrong actions will negatively affect not only your apartment, but also the neighbors. If you notice problems with heating in such a dwelling, then contact the management company - the solution to such situations is solely within their competence.

As for a private house with an autonomous heating system, some owners believe that they can simply regulate the flow of coolant in radiators using conventional shut-off ball valves. Actually, it is not.

That is, if you open such a tap only halfway, then the volume of incoming liquid will, of course, decrease, thereby changing the temperature in the room. But problems will soon arise with the locking equipment. The ball valve is not designed for such manipulations, its life principles are simple: it must be either fully open or fully closed. Any half-measures worsen its performance, and then completely disable it.

Therefore, balancing must be carried out, as they say, wisely. And now we will tell you in detail how to do this.

Working with radiant wiring and underfloor heating

As mentioned above, a slightly different procedure is used for collector wiring. It is suitable for both radiators and underfloor heating - in general, for balancing the entire system connected to one node.

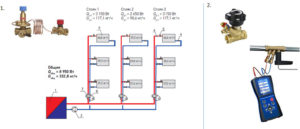

The setting can be done in two different ways. For the first of these, rotameters must be available on the collector. These elements are transparent flasks and are flow meters. To balance you will need to do some calculations. This uses the following formula:

The letter G in this case denotes the mass flow rate of the heated coolant that flows along the circuit. The unit of measurement is kg/h. The letter Q indicates the amount of heat energy that should be released by the heating circuit, it is measured in watts. As for Δt, this is the temperature difference obtained at the entrance to the loop of the circuit and at the exit from it. The calculated value of this parameter is 10 degrees.

Thus, you can calculate how many liters of heated coolant should pass through a certain section of the circuit per minute. The required amount of heat generated can be calculated based on standard values. According to them, 100 watts are needed for each square meter of area.

Let's give an example of calculation. Let's say the area of your room is 20 m 2. This means that 2 kW of thermal energy is needed to heat it. We substitute the obtained value into the formula above, and we get the following result:

On the flowmeters, the values are indicated in l/min, so you need to convert the value by dividing the resulting figure by 60. It turns out approximately 2.87 l / min.

After the calculations, the balancing procedure is carried out as follows.

- Fill and pressurize the heating circuit. The heating boiler may not be turned on. But the circulation pump must be started.

- Close the thermostatic valves on the second part of the manifold, this is done manually using special caps.

- Now open the first valve. Adjust the rotameter that corresponds to it using the lower ring - you need to rotate it.Thus, set a certain level of coolant flow.

- After you have dealt with the first valve + flow meter group, close this valve and move on to the second pair.

- Thus, adjust each rotameter in turn. Finally, open them all and check if each device correctly shows the coolant flow.

If there are no rotameters, then the process is carried out according to the results of temperature measurement in the circuit loops. The procedure in this case will be quite dreary and long.

If you need to balance not a warm floor, but radiators connected using beam wiring, then everything is done in exactly the same way. For greater confidence, you can focus on collector rotameters and temperature measurements. We are sure that after reading today's article, you will not have problems with balancing. Good luck!

In accordance with applicable law, the Administration disclaims any representations and warranties, the provision of which may otherwise be implied, and disclaims liability in relation to the Site, the Content and its use. More: https://seberemont.ru/info/otkaz.html

Was the article helpful? Tell your friends

Why carry out hydraulic adjustment of CO

The main goal of balancing the heating system is the correct distribution of the amount of coolant to the radiators (batteries) per unit of time, directing the required amount of heat to places where there is a shortage of it.

For a more complete understanding of the picture, let's imagine that in a certain section of the CO it is divided into two circuits, each of which leads to different rooms. Since the volume of the premises is different, the length of the contour may vary. A circuit with a longer length (or more heaters) has more hydraulic resistance. As you know, water (coolant) always follows the path of least resistance. In other words, according to physical laws, more heat will get into a shorter circuit than distant radiators. The figure clearly shows the distribution of thermal energy in two identical systems.

It should not be forgotten that in an unconfigured CO, the heat generator operates at maximum, which negatively affects all structural elements.

Summarizing the above, CO balancing is carried out for:

- Uniform heating of batteries, regardless of their location in the heating system.

- Economical operation of the boiler plant.

Advice! Balancing a two-pipe heating system (performed with preliminary hydraulic calculations), of small length (no more than 4 heaters) - optional. In all other cases, for efficient and economical operation of CO, hydraulic adjustment is necessary!

Balancing the heating system in a private house

After the installation is completed, it is necessary to adjust the heating system or balance it. This allows you to identify, correct, eliminate inconsistencies in the operation of the boiler unit and other devices, ensuring high efficiency and heat transfer.

Contrary to popular belief, the heating system needs to be balanced not only in a large multi-storey building, but also in a small private house, up to a small-sized summer cottage. Unbalance is the cause of improper heat distribution, when some rooms are very hot, while others are not warm enough.

In this regard, it is recommended to carry out balancing before the start of each heating season.

Balancing Tools

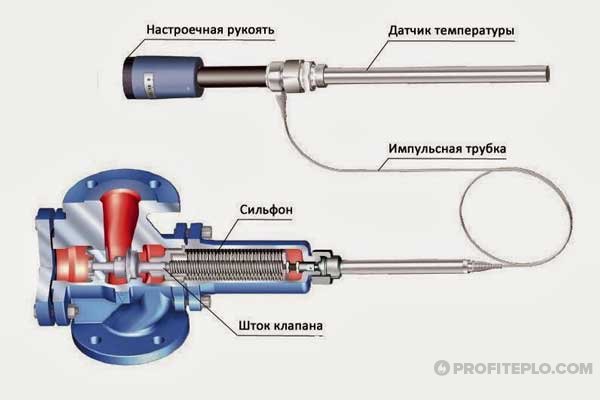

These include a balancing valve and a special measuring device.

A balancing valve is a type of shut-off valve for adjusting the hydraulic resistance in heating systems. The device solves the problem by changing the diameter of the pipe section.

Modern Y-type models are characterized by the possibility of presetting, which limits the flow rate marked on the dial with a scale. The design provides for the presence of two nipples for measuring pressure, temperature, coolant flow rate drop. The name is due to the shape of the case, where the cones are placed at an optimal angle to each other. This minimizes the influence of the coolant flow on the measurements, and increases the accuracy of the adjustment.

When to Install:

- The maximum load on the system does not provide a comfortable temperature.

- With a constant load in the room, significant temperature differences are observed.

- The normal heating power cannot be reached.

The advantages of installing this device are as follows:

- Reduced fuel consumption and heating costs.

- Increasing the efficiency of using the heating system and increasing comfort due to the ability to control the air temperature in each individual room.

- Makes it easier to start.

Installing a balancing valve involves the use of special fittings and adapters

It is important to pay attention to the presence of an arrow stamped on the body of the device and its direction. Some devices are mounted strictly in a certain direction of water circulation. By violating this manufacturer's recommendation, you will cause valve failure and system failure.

Upon completion of installation, measurements should be taken to determine the level of adjustment

Violating this manufacturer's recommendation, you will cause valve failure and system failure. Upon completion of installation, measurements should be taken to determine the level of adjustment.

It is possible to measure the pressure and temperature drops, as well as the flow rate of the coolant at the balancing valve, using a special device.

The multifunctional computer device is equipped with accurate sensors, and in addition to the measurement function, it is able to eliminate detected errors and carry out balancing. This device greatly simplifies and speeds up the process of fine-tuning the heating system.

Manufacturers of modern devices provide the ability to connect them to a computer. Installing a special program allows you to transfer data to a PC for further work with them.

It is important not only to buy modern equipment, but also to know how to use it. Otherwise, the setup process will be inefficient, which will lead to incorrect operation of the heating, lack of a comfortable microclimate, excessive consumption of thermal and electrical energy.

- With the help of partner valves, the hydraulic system is divided into modules.

- Next, all parts are balanced, starting from risers and collectors, ending with heating points. In this way, it is possible to achieve the design flow rates of all modules and valves with minimal pressure losses on the devices themselves.

- After balancing, the pump switches to the power that provides the calculated rate of water circulation in the system. This will allow you to adjust the flow on the main module located at the pump.

The result of adjusting the balancing valves is the received data on what values are needed and achieved. This information allows you to check the quality of the work performed and is its guarantee.

As a result of properly performed balancing, the injection equipment begins to consume a minimum of electricity, and the consumption of thermal energy is carried out rationally.

Another problem that one has to face in the absence of special devices is the inability to determine the quality of the heat supply when it is in operation. Y-type balancing valves with measuring nipples have a system self-diagnostic function, which is as follows:

- Fault detection while the heating system continues to operate.

- Checking the technical condition and operating parameters of the equipment.

- Making decisions when troubleshooting.

Thus, the search for errors and their quick elimination is performed.

What a homeowner needs to know about balancing heating systems

At first glance, it seems that there is nothing complicated in setting up. The temperature in the rooms can be adjusted without special measuring instruments, independently, guided by subjective feelings: make it warmer somewhere, and cooler somewhere. But often the result does not live up to expectations, since the average user does not take into account the laws of hydraulics: an increase in the flow area of the balancing valve of one radiator will lead to a decrease in flow on the other radiator

And here it is important to catch the same balance.

“In an unbalanced heating system, to heat all the rooms in the house, the circulation pump has to work with an increased load, which accelerates its wear and sometimes causes noise in the pipes. In such cases, you will have to forget about thermal comfort, as well as savings, - says Maxim Nemkov, head of the installation department of the World of Comfort Samara company, which provides services for the design, installation and maintenance of engineering networks. - As practice shows, it is undesirable to arrange a heating system on your own - the probability of errors is too high. These, for example, include the selection of boilers and pumps with an unreasonable margin due to the unaccounted for heat capacity of the rooms. Professionals do not allow such inaccuracies in their work.

To minimize risks, the homeowner must have the necessary information and constantly monitor the work of installers. So, if the master assures that it is enough to design the heating system and configure the equipment in accordance with the calculations of the engineer, then it is better to contact another company. Real conditions always differ from theoretical ones: for example, methods for calculating heat losses do not take into account the specific features of the building, which causes deviations in the required coolant temperature from the design values. This is a common situation, but if left unattended, the system will not work correctly.

Balancing itself can be done in two ways. "Classic" implies the presence of a heating system project, according to which, by twisting the balancing valves, the required design flow through each radiator is adjusted. But the presence of a project made without errors is now a rare phenomenon. And the real system may differ from the calculated one. In the event that there is no project documentation, they resort to the "emergency" method. In such cases, an electronic thermometer is used to measure the temperature on any surface. With its help, the same outlet temperature of all heaters is adjusted by means of balancing valves. “The general disadvantages of existing methods include the lack of a universal approach and high time costs. On average, balancing takes about one working day, it is carried out by at least two people,” Anatoly Korsun, a professional installer, shares his experience. It is clear that such time costs are not profitable for a team of specialists, therefore, in an effort to work out as many objects as possible, they make ridiculous mistakes. And as a result, the accuracy of balancing suffers, which eliminates the savings, for the sake of which, in fact, everything was started.

Required Tools

If you ask a plumbing professional what tool you need to perform a balancing operation, you will most likely hear about a thermal imager. It is used to determine the level of heating of all elements of the heating system. But the cost of such a "machine" is quite high.It makes no sense to buy a device for the sake of one operation. In principle, you can try to rent it if you find it. But let's still try to get by with simpler and more affordable means.

For example, the following things will be enough for you:

- electronic contact thermometer. Required to measure the heating temperature of heating equipment;

- screwdriver;

- hex key, with which the balancing valve stem is rotated;

- paper and marker or pencil.

Ideally, it would be necessary to stock up on the wiring diagram according to which the heating system was assembled. But often the project documentation is simply absent, because the assembly was carried out according to temporary sketches and practically “on the knee”.

In this case, you will have to fill in the missing. You need to make on paper at least a rough sketch of how all the elements of the heating system are located. On this plan, it is necessary to indicate in what order the radiators are connected to the circuit and how far they are from the boiler room.

The second stage of preparation is flushing the sump located at the inlet to the heating boiler. Then heat up the heater to maximum power. As a rule, the temperature of the coolant should be approximately 80 degrees. This process does not depend on the weather outside - you still need to warm up.

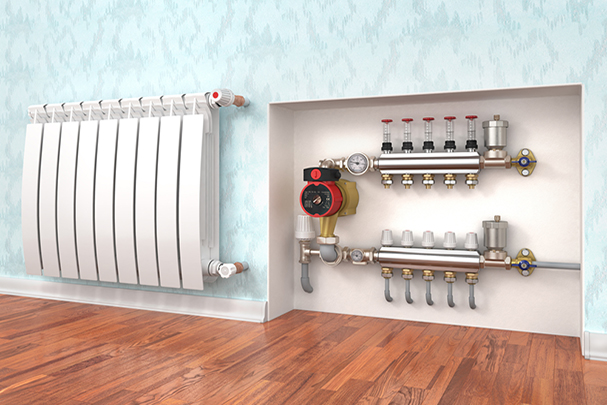

Tying simple heating systems

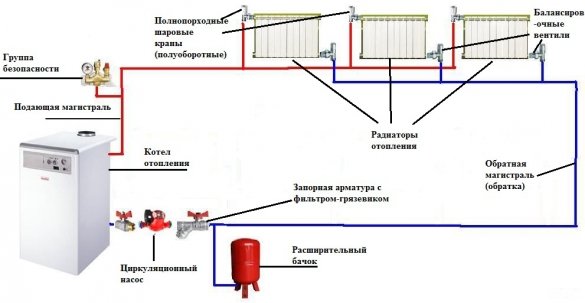

A heating system can be called simple if it contains one direct circuit. A direct circuit means a line into which the coolant is supplied from the boiler without changing the initial temperature. Some radiator heating systems are simple. They can be single-pipe, two-pipe and mixed. The most practical type of simple radiator heating is a two-pipe system based on the supply and return lines.

And if its balancing is done correctly, such a system will ensure uniform heating of the radiators around the entire heating perimeter.

Consider the main elements of the system and their functions.

Expansion tank

Expansion tank of a closed type - a tank equipped with a rubber membrane that divides the device into two parts (the coolant is in the lower half, and the inert gas is in the upper half). When the temperature in the heating system rises, part of the coolant enters it, thereby smoothing out the pressure difference in the supply and return lines.

The tank can be installed in the immediate vicinity of the heating boiler. An additional shut-off valve (ball valve) installed in front of the tank inlet will make it easy to disconnect the tank from the system if it needs to be repaired or replaced.

Artificial intelligence wins in the fight for the right settings

So far, the picture is emerging little clear: and I want to save money - a fifth of utility costs for heating! - and there are too many subtleties. Even if everything is done correctly, the result, alas, is not guaranteed. “Usually, balancing is carried out before the heating season, but in severe frosts it turns out that the rooms have different thermal protection, which, as it turned out, the owner forgot to warn about. The homeowner, at his own discretion, increases the coolant flow in cold rooms, after which all work on setting up the system goes down the drain,” says Sergey Orlov (installer).

To correct this shortcoming, special computer programs for calculating heating systems allow, which, unlike manual methods, take into account the vast majority of factors. They determine the required flow rate of the coolant with high accuracy. It remains only to set the recommended adjustment of the balancing valves.It is clear that for this method of balancing it is necessary to have the skill of using such calculation programs, as well as to have special balancing valves with graduation in the system. If balancing valves without special calibration were installed in the system, when adjusting these valves, it will be necessary to measure the flow with special flow meters in order to achieve the calculated flow rates in each radiator. All this, coupled with the need for special shut-off valves or special measuring equipment, makes the procedure for "beginners" very difficult.

But with the development of wireless communication and the transition from push-button mobiles to smartphones, the computer balancing method has become simpler and more accessible: no special training is required. The engineers of the GRUNDFOS Concern were the first to implement it: they offered the market the ALPHA3 circulation pump with the ALPHA Reader communication module and developed the GRUNDFOS GO Balance application for smart phones and tablet computers.

As homeowners who have tried the novelty assure, now balancing can be done independently and with high accuracy. The whole process takes about an hour (for houses up to 200 square meters) and is carried out in several stages. First you need to mount a new pump in the system and equip it with a communication module. Then you should download, install and run a free application in the immediate vicinity of the communication module so that the smartphone and the pump "find" each other. Then it remains only to follow simple and understandable instructions: the program will ask you to enter data about the existing system and measure the exact flow rate of the coolant on each radiator. After entering the required information, the utility will calculate the required consumption for each battery, and two values will appear on the screen: current and recommended. It remains only to adjust the balancing valve until the actual flow rate matches the calculated one.

“The need for such a tool has been long overdue, and GRUNDFOS specialists were the first and only ones to offer such a solution. Even before the start of sales of the new product, pre-orders were placed for the entire next delivery of ALPHA3 and Alpha Reader, says Ekaterina Semyonova (GRUNDFOS). - And this is not surprising, because, as I noted earlier, a well-functioning system allows you to save up to 20% of fuel (gas, coal, firewood). In addition, the GRUNDFOS ALPHA3 series pumps themselves are characterized by low energy consumption: they are 87% more economical than conventional units, for which they are recognized as the most energy efficient in their class.”

Mobile technologies are the engine of progress. They help us not only to cope with quite ordinary household issues, but also to save money. And who knows, perhaps in the future, engineers will delight homeowners with even more intelligent solutions.