The device and features of the boiler

Japanese-made boilers "Rinnai" are closed-type appliances. These are turbocharged units in which a fan operates to force the removal of combustion products. The coaxial chimney supplies combustion air and removes smoke.

The ignition block is located in the center of the structure. The burner cuts the flame into three parts, so the heat exchanger warms up evenly. At the same time, the flame can be modulated in three modes. For example, in the summer you can turn on only one part, saving on fuel.

The product includes two copper heat exchangers: one for heating, the other for hot water supply (DHW). A three-way valve switches the heating from one system to another. Inside is an expansion tank of 8.5 liters.

Below is a circulation pump. Its rotor is dry, which contributes to the long-term operation of the unit. It ensures the circulation of the coolant through the system. Remote control or keyboard. In the presence of a display that reflects the temperature and other indicators.

Product Description

According to consumer reviews, the following models are considered the most popular:

Wall-mounted gas boilers are considered the most economical in terms of resource consumption. They can be connected in a chain, providing heat and hot water, both in small apartments and in large houses. The power of Rinnai in space heating mode is 11.6-42 kW with an efficiency of 96%. The area of the serviced space is 30-120 m2, the gas consumption is 0.3-1.15 m3/hour, the hot water supply is 12 l/min. The volume of the expansion tank is 8.5 liters. If you need to work on liquefied fuel, you need to change the nozzles.

The Rinnai design includes a modulating fan-type burner with an automatic function of resource consumption in proportion to pressure. This feature is aimed at saving within 20%, provides a long service life of the heat exchanger and the control system of the gas double-circuit boiler. As a result of complete combustion, there is a low level of toxic waste, which does not allow carbon deposits and soot to settle on the nozzles. The series includes models: RB-107, 167, 207, 257, 307, 367.

An improved version of wall-mounted gas double-circuit boilers from the manufacturer Rinnai. With increased functionality, the equipment makes less noise. The remote control is equipped with a color display, there is a voice control mode, weather-dependent sensors. When heating, you can reduce the power of the device by 20%. An adjustment unit is used to achieve the optimum water temperature. Thanks to periodic heating, an instantaneous supply of hot water is ensured. The Rinnai operates at a minimum head of 2.5 l/min and shuts off at 1.5 l/min pipe pressure. A remote control is included as standard, which, according to user reviews, simplifies the coordination of all systems.

Gas boilers with a closed combustion chamber Rinnai have a capacity of 19-42 kW, heat an area of 190-420 m2. The efficiency is 90%, the volume of the expansion tank is 8 liters. The device is equipped with an ECO program (environmental mode). Has two additional sensors: control of protection against freezing and temperature of the heat carrier. The series includes models: RB-107, 167, 207, 257, 307, 367.

Rinnai gas boilers operate on mains and liquefied fuels, subject to the change of nozzles. The main advantage of this subgroup is absolute environmental friendliness, which is due to the minimum emission of toxic waste into the atmosphere. The automation unit is three-level, the adjustment of the burner flame and heating of the coolant is determined depending on the season and climate. Error diagnostics are displayed on the monitor in text and digital code. Adjustment of the fan operation protects against lack of air for purge.

The power of the wall-mounted gas boiler is 12-42 kW, the heated area is 120-420 m2. The minimum consumption of hot water supply is 2.7 l / min, a centralized resource is 1.1-4.2, liquefied is 1-3.5 m3 / hour. The volume of the expansion tank is 8.5 l, the maximum temperature of the coolant is 85, DHW is 60 ° C. A coaxial chimney is used to remove combustion products. Series models: RB-166, 206, 256, 306, 366.

Gas boilers manufactured by Rinnai are designed to service premises from 100 to 400 m2. Equipped with two heat exchangers, the first is made of copper, the second is fast and produces up to 14 l / min. In the combustion chamber, the fuel-air mixture is smoothly regulated, proportional to the volume of gas. This is achieved by an integrated turbocharged burner. Optimum functionality does not depend on weather conditions. Emission of toxic substances is minimized, which prevents the formation of soot and scale.

The boiler power is 18-42 kW with an efficiency of 90%. The minimum water flow is 2.7 l/min. The temperature range for heating is 40-80 °C, for hot water supply - 35-60 °C. The device has an electronically controlled pump. The microprocessor constantly analyzes the readings of the sensors and sends information to the working nodes. The air intake is forced, from the street. The series includes models: RB-166, 206, 256, 306, 366.

The device of heating boilers Rinnay

All these three points are reflected in the company's line of heating equipment. The following modifications are presented:

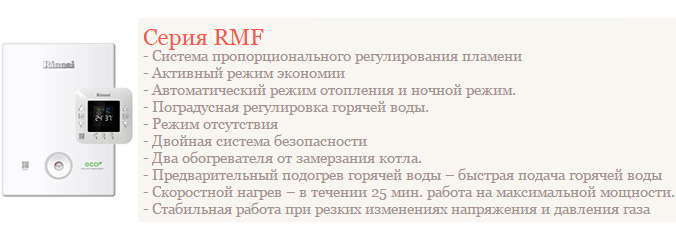

- Rinnai RMF Series

- the modification includes equipment with the ability to connect to the "smart home" system. The main difference of the model range is the active gas saving mode. When hot water is turned on, the burner can operate in three modes, providing the necessary heating. Additionally, a high-speed heating unit is provided that allows you to get hot water immediately after opening the tap. Another innovation that Rinnai RMF hinged heating gas double-circuit boilers have is that two microprocessors control the heating of the coolant at once, correcting each other's work. It is possible to set the daily mode of operation of gas equipment, taking into account the characteristics and preferences of the consumer. Room thermostats connected to the control unit help to further reduce gas consumption for heating. - Rinnai EMF

- economical gas consumption is achieved due to the proportional adjustment of the flame, with the aim of low emission of nitrogen oxide, which makes it possible to prevent heat loss. Traditionally, the possibility of maintaining the temperature of warm water is used. The 3-way valve provides stable heating, regardless of the number of users and pressure. The Rinnai EMF individual wall-mounted double-circuit gas boiler has the function of simultaneously connecting both the main and additional heating systems (warm floor). -

Double-circuit gas condensing hinged heating boilers Rinnai CMF

equipped with an advanced control system to automatically adjust the volume of the flame and heat the water to a certain temperature. The control unit helps to select the optimal operating mode of the boiler for the next 24 hours in order to avoid excessive fuel consumption. Rinnai household condensate wall-mounted double-circuit gas heating boilers, CMF series, remove combustion products through a coaxial chimney, which speeds up the installation process and makes it possible to install stations in multi-storey buildings .

All models of Rinnai boilers are volatile and stop working when there is a power outage. Microprocessors used in automation are sensitive to voltage drops in the network. For stable operation, you will need to install an uninterruptible power supply, a generator or a battery.