Currently, self-tapping screws are used almost everywhere. This is the most popular fastener: self-tapping screws are used in construction, repair, and decoration. They fasten anything: wood, metal, plastic, drywall, gypsum boards. However, universal self-tapping screws do not exist, and in order for fasteners to perform their function efficiently, they must be selected in accordance with the characteristics of the material. Let's see how self-tapping screws for GVL differ from other fasteners, what characteristics they have and how to choose them correctly.

What is a self-tapping

Many beginners in repair do not understand how self-tapping screws differ from other types of fasteners. However, the differences are very significant. The name speaks for itself: these fasteners cut their own threads. To screw in a self-tapping screw, you do not first need to make a hole for it, it can cut through the material itself and select it so that a thread is obtained inside.

So, self-tapping screws are fasteners that have a threaded rod and a hat (head). Outwardly, they resemble screws (not for GVL), but they differ significantly in design. The main difference is in the carving. In self-tapping screws, it is very sharp, has a triangular shape. The thread rises along the rod to the very cap. The end is also very sharp, there are varieties with a drill end. Screws usually have a more frequent thread pitch and are not as sharp. Also, often their thread does not reach the cap, and a smooth rod remains under it.

Outwardly, the self-tapping screws differ very little. However, each type has its own characteristics. That is why a self-tapping screw for GVL is not suitable for metal or wood and vice versa.

Differences of self-tapping screws for GVL

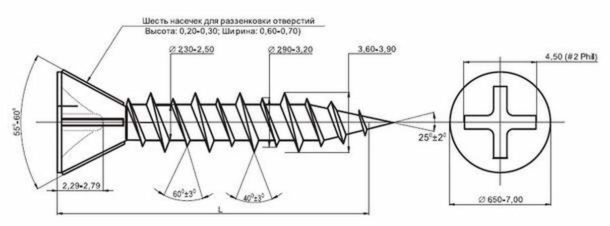

Self-tapping screws for GVL differ from their counterparts. External features are clearly visible in the photo. They have a smaller head diameter, but at the same time it has an elongated conical shape and has a countersinking ability. Thanks to this feature, fasteners can be completely drowned in the sheet (i.e., the head will be below the surface level) and reliably mask them.

On self-tapping screws designed to work with gypsum-fiber sheets, there are 2 rows of threads that run parallel to each other. It is called a two-row or two-way. It is noteworthy that one row of threads is almost 2 times higher than the other. This design feature is a necessity: gypsum fiber sheets are easily destroyed, and the threads of different heights prevent this. In addition, the self-tapping screw is more securely and firmly fixed in the material, which significantly reduces the risk that it will fall out. A two-row is also indispensable when attaching one type of material to another, for example, when finishing a room, GVL is mounted on a wooden crate or attached to a metal profile. Thanks to this thread, the fasteners always turn out to be strong and reliable, even if they are mounted directly on concrete.

Self-tapping screws for GVL are made of steel. At the same time, the surface is oxidized, which gives the products a characteristic matte black color. The tip of the rod is sharp, but without a drill.

The head has a figured (cross-shaped) slot - No. 2 according to the Knauf marking - which makes it possible to use a hand tool (phillips screwdrivers) or an electric one (a screwdriver with the appropriate bits). There are also notches for countersinking.

To increase speed installation of GVL it is advisable to buy self-tapping screws in the tape, which are used with screwdrivers, supplemented with nozzles for automatic feeding. Self-tapping screws in the tape will not crumble and will not be lost, they will not have to be held in your teeth.

Scope of application

Self-tapping screws for GVL are used when working with conventional and moisture resistant gypsum boards. Due to their design features, they provide reliable fastening of sheets to surfaces made of any materials. Self-tapping screws can be used both for finishing work, for example, for wall cladding, and for construction, for example, when erecting a partition in a bathroom. They also provide sufficient connection strength when installing GVL on ceilings, when performing a dry floor screed using the Knauf Superpol technology. Fasteners of other types are not able to guarantee that over time the fixed sheet will not collapse around the rod and the self-tapping screw will not fall out of the socket.

Size range

The diameter of self-tapping screws for GVL is standard. It is 3.9 mm. Thanks to such a small hat, self-tapping screws are easy to disguise.

The length of the screws may vary. They produce products with a length of 19, 25, 30, 45 mm.

More often than others, short self-tapping screws are used, 19 mm long. This size is considered optimal for mounting sheets in 1 layer. This is due to the fact that gypsum fiber board can be from 9 to 12 mm thick. A rod 19 mm long is enough to fasten 2 sheets together or fix 1 sheet on any base. In this case, there is no risk that the tip will go too far and come out from the back or rest against something hard. It makes sense to buy longer self-tapping screws if there is a need to fasten 3, 4 or more sheets together or to mount plates on specific bases.