Production of thick-walled pipes

Unlike electric-welded analogues, where the billet is produced by rolling a flat metal sheet of a given thickness into a cylinder, the starting material for the manufacture of a seamless pipe is a monolithic steel billet of a cylindrical shape. Industrial enterprises use two technologies that can turn a metal rod into a hollow product of the required section and length:

hot deformation

It is mainly used in the production of thick-walled products.

The manufacturing sequence here includes the following steps:

- A massive cylindrical steel rod is placed in a furnace and heated to a fixed temperature, at which the steel alloy becomes soft and ductile, but does not yet have fluidity.

- The heated billet falls on a powerful piercing press, which turns a monolithic blank into a hollow cylinder. Experts call it a sleeve. Outwardly, it already looks like a finished pipe, but does not yet have the ideal shape and required dimensions.

- Passing successively through groups of rollers that roll and draw the metal, the workpiece acquires the specified dimensions: length, diameter and wall thickness.

- Further, the product is cooled and subjected to final calibration, after which it is cut into segments of the required length and sent to the warehouse.

The manufacturing procedure is regulated by GOST 8732-78. The hot deformation method is poorly suited for the production of thin-walled products, since it gives an insufficiently high quality of the surface of the material and a higher error in wall thickness.

https://youtube.com/watch?v=bJlMDTRYvBY

cold deformation

The difference of this technology lies in the fact that the incandescent billet cools immediately after the piercing press, and it is passed through the molding rollers already cold. Then, before the final calibration, the pipe is heated up and cooled down again in order to remove areas of internal stresses from the metal, to make it more ductile and pliable. All stages of pipe manufacturing by cold deformation are regulated by GOST 8734-75.

Both technologies make it possible to obtain products with a constant wall thickness throughout their entire length, capable of operating under conditions of colossal pressure indicators. Each finished product must pass test tests, where it is carefully checked for bending, flattening, the chemical composition of the metal and the ability to successfully work with aggressive environments are evaluated.

Where is cold rolled profile pipe used

Cold rolled seamless shaped pipe is more expensive than hot rolled, but is corrosion resistant, so it is used only in high pressure and high temperature pipelines. Also, such products are used in cases where special requirements are placed on how high-quality the surface of the product and the geometric shape are.

Cold deformation has several fundamental differences, in particular, after processing on a piercing press, the workpiece is cooled, and its calibration is also performed cold. In order to avoid internal stresses, as well as to make the material viscous and plastic, the billet is heated to the state of metal recrystallization even before rolling.

Cold-rolled profile pipe can be made from several types of steel:

- Carbon.

- High carbon;

- alloyed;

- Highly alloyed.

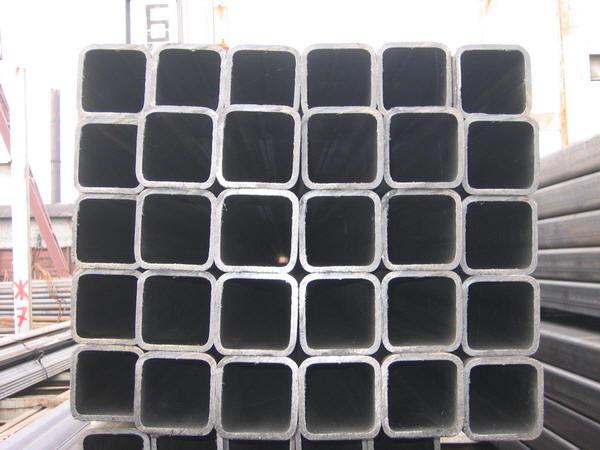

Cold Rolled Seamless Square Pipe

Only if the steel grades specified in GOST are used in the manufacturing process, high functionality and resistance to mechanical stress can be ensured.Unlike hot-formed, cold-rolled profiled seamless pipe can have thinner walls and its own smaller diameter, which significantly expands the scope of applications and ensures a low weight of the structure.

There are many situations when it is a small weight that becomes a critical factor, but the most popular now is a cold-rolled profile pipe with a diameter of no more than 14 cm.

What are cold formed pipes?

Cold rolled products are:

- especially thin-walled, with a wall thickness of not more than 0.5 millimeters, or if the diameter is related to the thickness by more than 40 units;

- thin-walled with a wall thickness of 1.5 millimeters, or the dh / s ratio is in the range of 12.5-40;

- especially thick-walled, if dh / s from 12.5 to 6;

- thick-walled if the ratio of diameter and thickness is less than 6.

There are situations when the ratios of thickness and diameter differ from the standard options, but such products are produced only if it is necessary to comply with special technical conditions. Special requirements are also imposed on the curvature of an arbitrary section, which cannot exceed 3 mm with a wall thickness of less than 8 mm, 2 mm with a thickness of 8 to 10 mm and 1.5 mm with a wall thickness of more than 10 mm.

In addition, at the last stage of production, the cold-rolled profile billet must be subjected to annealing, and its geometric shape and wall thickness must be within the established standards.

Allowed deviations in product dimensions for especially small diameters up to 1.5%, for ordinary diameters 0.8%, deviations in wall thickness for small diameters up to 12%, for ordinary ones up to 10%. Only if the customer has special requirements can annealing be omitted.

In accordance with GOST, a cold-rolled profile pipe is made of steel grades - 10, 20, 35, 45, 20X, 40X, 15XM, 30XGSA. Seamless profile pipe is supplied, both cold-rolled and hot-formed, in batches not exceeding 70 tons, which can be packed in bundles. If the diameter of the product exceeds 159 mm, it must be individually marked.

Classification

Seamless steel pipes are classified according to:

- production method;

- temperature parameters;

- cutting method, etc.

According to the type of section, the models are divided into:

- round;

- oval;

- square;

- rectangular;

- trapezoidal, etc.

Length classification includes products:

- measured;

- unmeasured;

- multiples of any measured length.

The most common classification of metal products is that produced by cold or hot rolling.

The length of the cold-working pipes is standardly produced 4.5-9 m. The parameters of the steel thickness of the products vary from 8 mm.

Hot-rolled structures are produced with a cross section of 25-700 mm, with a steel thickness of 2.5-75 mm, depending on the functional purpose. Seamless seamless pipes are made from cast billets that provide high strength.

Dimensions and Features

Hot-formed products have a diameter of 20 to 550 mm with a wall thickness of 2.5-75 mm. The minimum length of a pipe section is 4 m, the maximum length is 12.5 m, the permissible dimensional error is 5 mm. Another important indicator is the maximum bending value. For pipes with a wall thickness of 20 mm or less, the bend should not exceed 1.5 mm per linear meter of length, for wall thicknesses from 20 to 30 mm - no more than 2 mm, over 30 mm - 4 mm.

Cold-formed pipes have a smaller assortment. The wall thickness here varies from 0.3 to 24 mm, the external section - from 5 to 240 mm.

Whether a pipe belongs to a thin- or thick-walled variety is determined by calculating a coefficient showing the ratio of diameter to wall thickness. When the calculated value is in the range of 6-12.5, the product is classified as thick-walled.Over 12.5 - to thin-walled. Products with a coefficient below 6 are already considered to be especially thick-walled. They are extremely expensive to manufacture and are only made to order.

Features and purpose

Seamless thick-walled pipes are a special kind of pipe material manufactured industrially, hot or cold rolled. Certain grades of steel are used for manufacturing (ferrous, stainless, sometimes with impurities of non-ferrous metals), which allows them to be successfully used in various areas of the national economy, up to aircraft construction and the chemical industry.

The main advantages of steel seamless products are as follows:

- High tensile strength.

- Corrosion resistance.

- Small thermal expansion of the material.

- Resistant to most chemically active media.

- Long service life, calculated in tens of years.

Types of seamless pipes

Depending on the manufacturing technology, the industry offers consumers two types of products: hot-rolled and cold-rolled.

Hot rolled

You can also come across the term hot-pressed or hot-worked. Are issued in accordance with GOST 9940-81. The technology of hot rolling does not allow making pipes of small diameters. In addition, in this case it is not always possible to obtain a perfectly smooth pipe surface and guarantee dimensional accuracy.

Cold rolled

Otherwise, cold-drawn or cold-formed. Their production is regulated by GOST 9941-81. They differ from hot-rolled ones, first of all, in a smaller cross section and thin walls. The surface of pipes with this method of production is smoother. When producing products with a section type other than round (rectangle, star, oval, hexagon, etc.), only the cold deformation method is used.

Thick-walled and thin-walled pipes

Another criterion is the wall thickness of the product. This indicator largely determines the scope of the pipe material. Separate thick-walled and thin-walled steel pipes:

- Hot-rolled seamless pipe has a diameter of 28-426 mm, with a wall thickness of 3-40 mm.

- Cold rolling allows the manufacture of pipes with a diameter of 0.3-450 mm and a wall thickness of 0.06-12 mm.

Pipe cutting is carried out at a right angle. The saw cut area is necessarily cleaned of bumps and burrs. The surface of the product must have a uniform structure, without cracks, dents or sunsets.

Advantages of seamless pipes

The absence of a seam on a metal pipe makes them very durable compared to welded products. The physical characteristics of steel + a special technology for the manufacture of pipe materials endows them with the following characteristics:

- The ability to operate at high temperatures and pressures inside the pipeline makes them indispensable in the energy sector.

- Rigidity, resistance to external deformation and internal pressure is used in hydraulics, mechanical engineering.

- In aircraft construction, the strength of a seamless pipe is in demand, combined with the lightness of the material due to an especially thin wall.

- Unconditional tightness ensures the safe transportation of aggressive, toxic substances in chemical plants.

- Environmental friendliness and safety, in terms of inertness to food products, is widely used in the food industry.

The only disadvantage of seamless steel pipes is their high cost. But in the combination of price and quality, when there are increased requirements for pipelines and structures, this material not only pays off in full, but also makes a profit in the short term.

Areas of use

The strength and durability of products allows the use of metal blanks in various areas of production and public services.

Seamless pipes are used for construction:

- cars;

- agricultural machinery (tractors, loaders, cranes, combines);

- aircraft and aircraft modeling;

- military equipment;

- different types of ships, etc.

Products are necessary for the installation of waterways, hydraulic systems, for laying gas pipelines, in the areas of extraction and processing of petroleum products, in chemical industries, energy complexes, in heavy industry, etc.

Thick-walled models are used in complexes with high pressure indicators, for the construction of supporting structures that can withstand heavy loads (frameworks, reinforcing grids, etc.).

Specifications

Characteristics of a seamless pipe meet the standards of GOSTs. Dimensions of products processed under thermal influence are regulated by GOST 8732-78. Popular pipes having an outer surface diameter of 25-700 mm, wall parameters are 2.5-75 mm. The length of standard pipes varies from 4 to 12.5 m.

Models with cold deformation are regulated by GOST 8734-75. The size of the diameter on the outside is 8-450 mm, the wall thickness is made 0.08-20 mm. The random length of the pipes is 1.5-11.5 m, the measured length is 4.5-9 m.

For pipelines without connecting seams, steel grades 10, st35, st40x, etc. are used.

The dimensions and weight of the seamless pipe depend on the manufacturing technology and the rolling method. The size range for models that withstand high pressure (precision) is fixed in GOST 9567-75, which complies with the requirements of European ISO standardization. The standards also apply to pipe fittings made of high strength steel.

Before delivery, products are tested for compliance with overall parameters, tightness, resistance to mechanical damage, etc.

Technological process of manufacturing seamless stainless steel pipes

The technology of industrial production of seamless pipe is extremely complex and time-consuming. Each stage requires a lot of energy and materials. Pipes are often used for the transport of sterile media, so the most stringent requirements are placed on their manufacture. The metal must be cleaned of impurities, and the production process itself must be carefully controlled at all stages:

- A metal billet made of alloy steel is heated in a furnace.

- Red-hot, it is fed to the pressing and piercing mill, where the forming elements give it the necessary configuration, penetrating the workpiece through and through.

- After that, the future pipe is rolled out with rollers to a predetermined length, with the required wall thickness, outer and inner diameters.

- The finished element cools down and undergoes final calibration in a special container.

- The final stage is the preparation of segments of the required length and the marking of products ready for sale.

Some grades of seamless steel pipes undergo a special post-hardening procedure. The product heats up and then cools down quickly. Repeated several times, the procedure rearranges the molecular lattice of steel, giving it new properties.

For the manufacture of seamless stainless steel pipes, various grades of steel are used:

- 12X18H10T. The most resistant to corrosion, is used more often than others. Alloy additives: nickel, titanium and chromium. Chromium enhances anti-corrosion properties, titanium enhances strength, nickel gives the alloy the necessary ductility.

- 10X17H13M2T. Great for transporting highly acidic chemicals. The main consumers of such products are chemical and medical enterprises, food production

- 06HN28MDT. It is successfully operated in the petrochemical and metallurgical industries.

- 10X23H18. A high-alloy steel grade with increased resistance to high temperatures and open flames. Pipes made of such steel are used in the construction of chambers for burning fuel, high-temperature boilers. Easily withstand prolonged exposure to temperatures up to 1100°C.

In general, the standards for the manufacture of seamless stainless pipes allow the use of 20 different alloys. This allows you to obtain products with a unique set of characteristics that are best suited to a specific task.

https://youtube.com/watch?v=bJlMDTRYvBY

Product varieties

- Since the seamless type of pipes is in great demand in the market, it has received its own name among the people - cast. Since casting from a special metal ingot is used for the process of its creation. This type almost does not have longitudinal types of connections.

- Depending on its dimensions, a seamless form can contain various measures of length.

- For any variety, certain sizes are established by state standards. So, if you follow the general standard, the hot-rolled pipe in the total diameter should vary from 25 to 700 mm (in the outer diameter), at this time the wall thickness should reach 2.5-75 mm. The production of parts can take place in a certain range from 4 to 12 mm.

- Seamless steel pipes in terms of the overall ratio of wall thickness to total diameter can be from six to thirteen millimeters. There are as many as four varieties, which, at this time, are also divided into four full-fledged groups. Thus, the gradation varies from the letter B to E. Group B characterizes forms whose chemical components are measured. Group E becomes their opposite. This type is made without the use of heat treatment in accordance with documentation standards.

In the section of seamless pipes, seamless pipes will become the most durable and of high quality.

A pipe that does not have seams has a large number of different modifications. So, the main differences will depend on the steel grade that is used during creation, the parameters of the walls (thickness and length). In total, about ten different steel grades should be used to create such pipes without seams. Such a colorful composition helps in any case to choose the most suitable option in accordance with the situation and needs.

Hot rolled can be produced using a large number of different devices. All of them are able to noticeably differ from each other both in the overall size of the parts and in the methods of their creation. Ultimately, you can get a variety of types of products.

The main differences between seamless and other pipes will be mainly especially in the external parameters.

Seamless rolling is obtained after rolling one ingot of metal using a specialized device that helps to complete the process of creating holes in the center of one ingot. You can also use a completely different way of producing seamless products - drilling a hole inside a cylindrical object.

Hot-rolled without seams, depending on the diameter of the walls, can be both thick-walled and thin-walled. The dimensions in this case will vary depending on the outer diameter.

Advantages of Steel Seamless Pipe

- Of course, the greatest advantage of solid rolled metal will be the almost complete absence of seams on the product, after which they begin to become almost completely invulnerable. The absence of the main welding seam can increase their strength and resistance to the outside world by several times.

- The product, which is created using a thick sheet of metal, differs from others in its anti-corrosion property. But this can also adversely affect the flexibility of the product during repair work or assembly work. Also, during the installation work, it is imperative to take into account the overall diameter of the hot-formed pipes used. This is considered very important, as editing may not give the desired effects to the user.

- Also, the seamless type can be made from various forms of steel, it has a high heat conductivity and a low temperature level, which characterizes the linear expansion parameter.

A hot-rolled pipe will become an almost ideal means for creating communications. Using various forms of connections, you can create new forms of structures and buildings.

https://youtube.com/watch?v=ypzKyB_xrRo

Where is hot rolled pipe used

The main task performed by such products is the safe delivery of the working medium without leakage, even if this medium is in a gaseous state.

Due to the fact that carbon and alloy steel is used in the production process, finished products can be used to deliver a chemically active environment, as they have high anti-corrosion characteristics.

Depending on what kind of material is used in the manufacturing process, hot-rolled products are divided into several categories:

- Having normalized mechanical properties.

- Having a normalized chemical composition.

- Products with rationing and chemical compositions and mechanical properties.

- Having rationing of test hydraulic pressure.

- Rationing of the control of mechanical properties on samples and chemical compositions.

Various technical specifications also determine the scope where hot-rolled seamless pipes are used. It is the absence of any seams that ensures high functionality and durability of such products.

The technical requirements for hot-rolled products are determined by GOST 8731-74, and the assortment - GOST 8732-78. In turn, the assortment of cold-rolled products is determined by GOST 8734-75, and the technical requirements of GOST 8733-74.

How is it produced?

For the manufacture of seamless hot-rolled pipes, a solid hot-rolled or forged billet is used, which is heated to a temperature of +900º-1200º. The exact temperature readings depend on which steel grade is used in this case.

The production process takes place on the so-called pipe mills. As a result, a product is obtained that has very low rates of rolled accuracy, as well as significant tolerances for wall thickness. And the quality of its surface is quite low.

Hot Rolled Round Seamless Pipe

For these reasons, hot rolling technology cannot be used in the manufacture of steel products with thin walls and small diameters. Theoretically, in accordance with the standards, the parameters of hot-rolled pipes should be from 25x2.5 mm to 530x75 mm, but practical indicators are from 32x3 mm to 426x30 mm. This is due to the fact that factories do not have the appropriate equipment, or production is impractical.

Hot-formed products are produced in several stages:

- the workpiece is heated to a temperature that slightly exceeds the crystallization threshold of steel;

- using a piercing press, a hollow cylinder or sleeve is obtained from the workpiece;

- with the help of rolling, the correct shape and appropriate size, wall thickness, outer and inner diameters are given;

- the steel profile pipe is cooled and calibrated with the help of rollers;

- products are cut to the required dimensions, which can be standard and non-dimensional.

Steel grades used for the manufacture of hot-rolled products

Such a pipe is made of steel grades:

- 10.

- 20.

- 35.

- 45.

- 15HM.

- 30HGSA.

- 09G2S.

Permissible pressure indicators do not exceed 20 MPa, and the permissible deviations of the diameter are up to 1.25%, wall thickness up to 12.5%. Hot-rolled seamless products can be either thin-walled 6-12.5 mm or thick-walled: 12.5-40 mm. Also, these products can have an increased accuracy of manufacturing the outer diameter and the usual one.