One of the fastest simple and budgetary ways to update the ceiling in an apartment is foam finishing. At a cost, this method of decorating the ceiling can be compared with ordinary whitewashing, but unlike it, it allows you to implement a variety of design solutions. Styrofoam ceiling tiles can be decorated with embossed patterns, have a different color, imitate a variety of surfaces and materials from wood to stucco.

Pros and cons of ceiling tiles

If you are considering the option of decorating the ceiling with polystyrene and polystyrene tiles, then you can finally decide by getting acquainted with the positive and negative sides of this material.

Advantages of ceiling tiles:

- foam can be glued to any surface;

- the light weight of the material and the ease of cutting ensure ease of installation;

- sound and heat insulation properties;

- material safety - the absence of substances harmful to health;

- low cost of tiles and adhesive for installation;

- properly selected finishing material has a long service life;

- the large dimensions of the individual elements make it possible to clad the ceiling in a short period of time;

- installation of foam tiles practically does not reduce the height of the ceiling;

- the possibility of multiple staining - up to 7 times;

- easy dismantling.

Flaws:

- brittleness of the material;

- vapor tightness - the ceiling is unable to absorb excess moisture;

- difficulties in masking the seams between the individual elements of the ceiling;

- cheap styrofoam quickly turns yellow.

Attention! It is not recommended to combine a foam ceiling with vinyl wallpaper on the walls in one room. Air- and vapor-tight materials will create a “thermos effect” in the room, which will lead to the formation of an unfavorable microclimate and an increase in the risk of developing mold.

Types of ceiling tiles

Foam tiles are divided into three types, depending on the method of manufacture and its inherent properties.

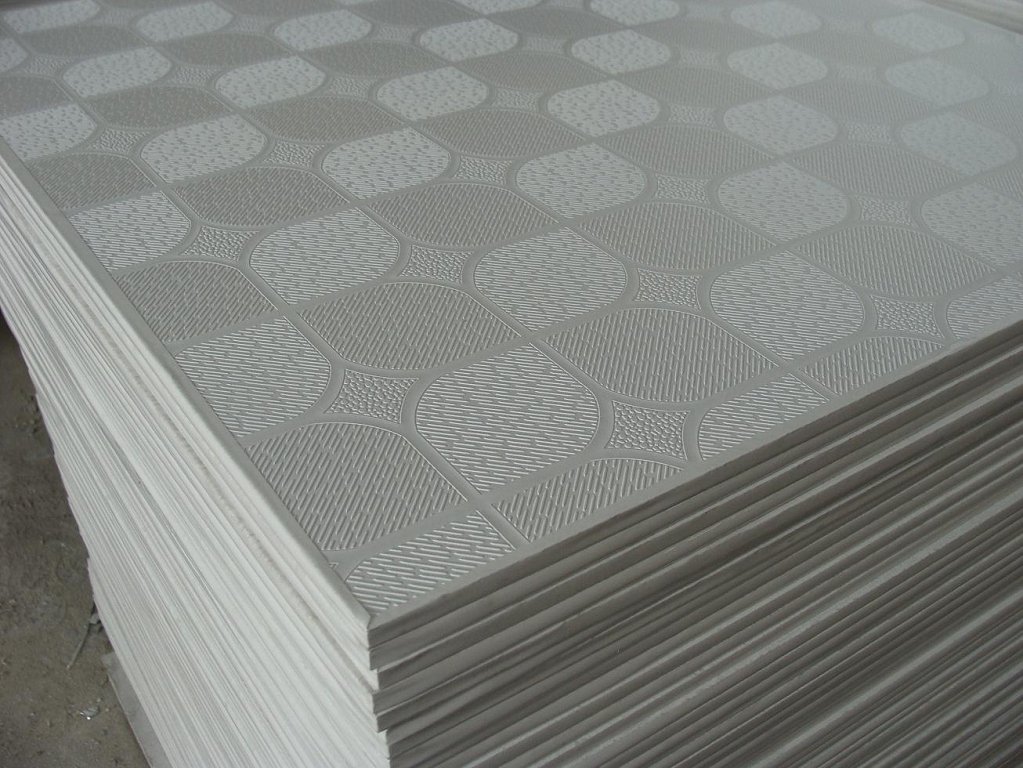

- Stamped tiles are made by stamping from polystyrene blocks. It has a low density, low weight and a thickness of 6-8 mm, has a relief pattern. This is the cheapest type of ceiling tiles, which does not have the most outstanding properties. The material is characterized by the absence of a protective coating, fragility and fear of water, so the ceiling of such foam cannot be washed, only dry cleaning or wiping with a damp sponge is allowed. Stamped products may not be well-defined, which can lead to gaps during installation.

- Extruded tiles are obtained by pressing polystyrene mass. It has a fairly high density, 3 mm thick and is covered with a film that provides it with protection from dust and detergents. The smooth surface of such tiles can imitate marble, wood and other materials. Its advantages include high strength, durability and attractive appearance, the disadvantages are noticeable connecting seams, an uneven back surface and the impossibility of staining.

- Injection tiles, which are made by baking polystyrene in molds, are superior in their properties to other types. It is distinguished by the clarity of the geometry of the relief pattern, a thickness of up to 14 mm and high strength. Ceilings made of this type of foam look solid thanks to high-quality joints that are almost invisible. Injection plates do not burn, they can be washed using any detergents and can be painted in any color, they can be glued even in the bathroom.

Calculation of the number of plates

It is easy to calculate the required number of products for finishing the ceiling - for this it is enough to know the area of \u200b\u200bthe ceiling. Since standard EPS ceiling tiles are 50 cm square, 4 pieces are required to cover one square meter of ceiling. Accordingly, to find out the required number of plates, you need to multiply the area by 4.

If the slabs have a non-standard size and shape, you need to find out how many slabs fit on one square meter, and then multiply the resulting number by the area.

Tip: after making the calculations, do not forget to add another 2-3 pieces to the amount received in case of marriage, damage to the tile, or the need to glue small pieces to correct the surface. With a diagonal arrangement of elements, material consumption also increases.

The choice of composition for gluing

If the ceiling is well leveled, the following adhesives are recommended for tiling:

- special adhesive for ceiling tiles "Titan";

- universal glue "Eco-Naset" - has sufficient viscosity, dries quickly;

- "liquid nails" - a thick consistency allows you to apply glue in a thick layer, which can compensate for some surface irregularities;

- "Moment" - quickly seizes, but requires the use of a pistol;

- PVA - odorless, but dries slowly.

For an insufficiently even ceiling, instead of ordinary glue, it is better to use finishing putty, with which you can level the ceiling and glue the finishing material at the same time. When using dry putty, along with the required amount of water, add 200 grams of PVA glue per 1 kg of the mixture.

Surface preparation

Depending on the condition of the surface and the type of previous finish, the following preparatory work is carried out:

- if there are differences of more than 1 cm, the ceiling must be leveled;

- if the ceiling is covered with wallpaper, they must be removed and a primer applied to the surface;

- whitewashed ceiling - whitewash is washed off, the surface - primed;

- Oil paint - wash with soapy water, remove swollen paint;

- water-based paint - the surface is abundantly wetted, dried with a draft or a heater, after half an hour the peeled paint is removed with a spatula.

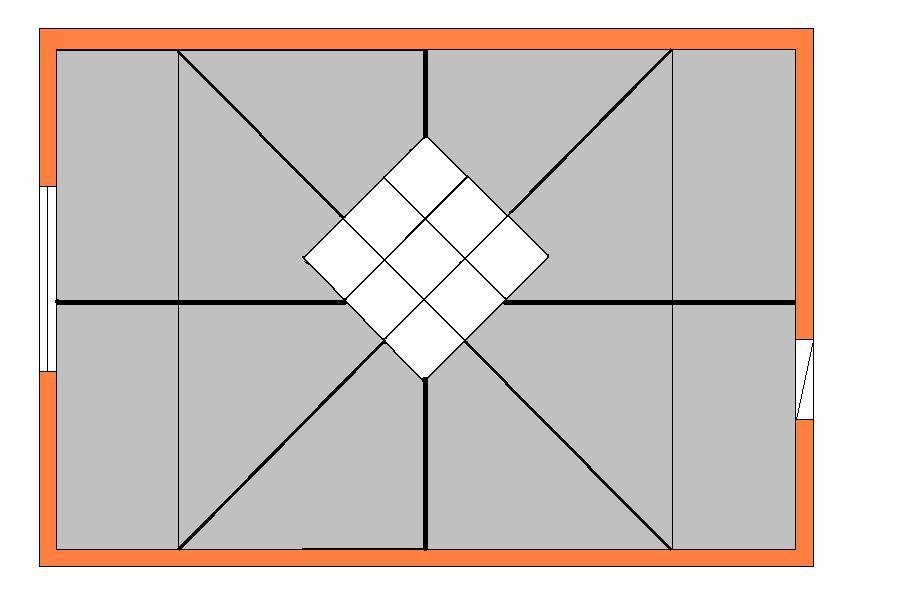

The choice of laying method and marking the ceiling

There are several ways to lay ceiling tiles:

- parallel;

- diagonal;

- with an offset, according to the principle of brickwork;

- combined options using tiles of different colors (staggered, along the perimeter of the ceiling, parallel or crossing diagonals, squares and other shapes).

To obtain beautiful foam ceilings with correctly arranged elements and even seams, it is imperative to apply markings.

It is most convenient to proceed as follows:

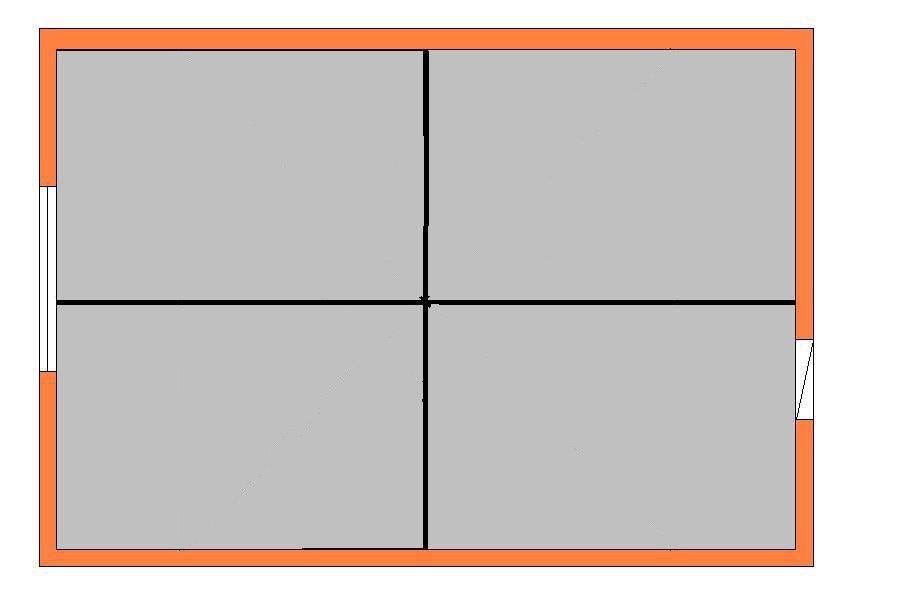

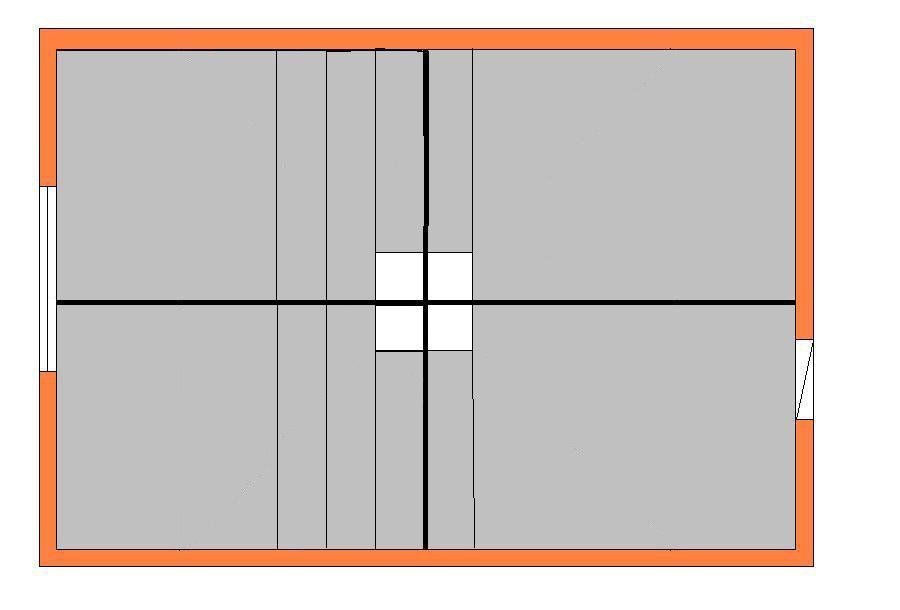

- Using a stretched paint cord, mark two perpendicular lines on the ceiling, each of which divides the wall in half. The point of their intersection is the geometric center of the ceiling.

- For a parallel laying method, you can limit yourself to this marking or, for reliability, draw parallel lines at a distance equal to the width of the tile.

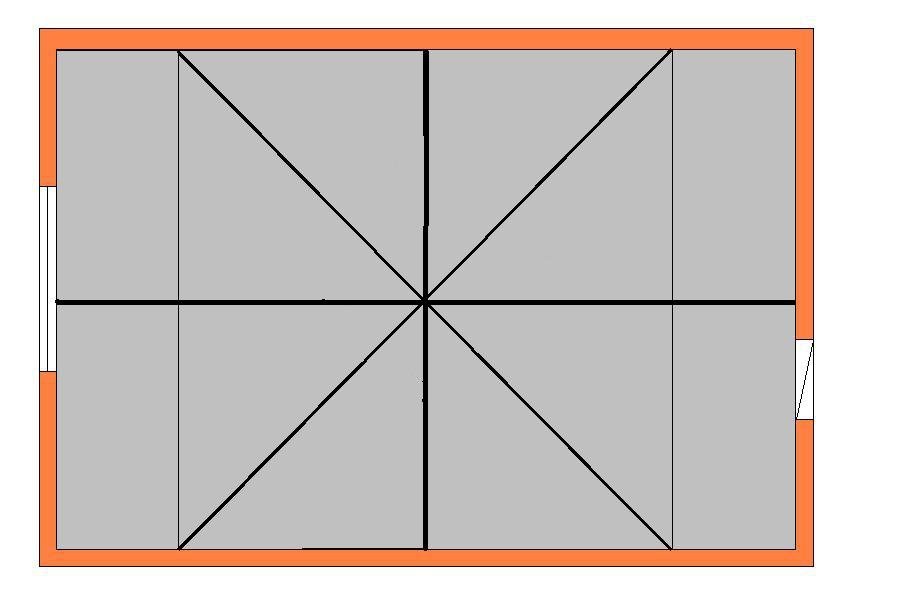

- If you are going to glue the plates in a diagonal way, make additional markings: from the center of the ceiling, draw lines to the walls of the room at an angle of 45 degrees to the perpendicular lines of the original markings.

- It is better to start gluing tiles from the center of the room, in some cases you can start from the most noticeable corner.

Gluing tiles

Gluing tiles to the ceiling is quite simple:

- A layer of glue or primer is applied to the center of the plate and along the edge. If necessary, you can apply glue to other areas.

- The tile is pressed against the ceiling and held for 15-30 seconds.

- If the glue has set and the tile is holding on to the ceiling, you can proceed to the next one.

- Near the walls, the size of the edge plates is adjusted by cutting with a sharp knife.

- After finishing the foam ceilings with tiles, the gaps between the elements are sealed with putty or acrylic sealant. If you glue foam products on putty, then you can seal the seams immediately during the gluing process.

- After the glue has completely dried, but not earlier than a day later, the foam plastic ceiling can be painted with water-based paint.