Finishing the ceiling with drywall can serve several purposes at once. This is surface leveling, and masking of various elements of communications, and the construction of complex multi-level structures. Insulation, sound insulation, lighting elements can be placed in the space above the plasterboard. But to create a strong and durable structure, it is necessary to correctly make a frame for drywall on the ceiling.

Wooden or metal?

There are several options for the implementation of the crate for mounting the GKL on the ceiling.

It can be made from wood or metal. The main advantages of a wooden frame are environmental friendliness, availability of material and ease of assembly. But there are also many disadvantages:

- As a rule, such a frame is used only with a flat base surface. Aligning walls or ceilings with it is a real torment.

- Before assembly, all structural elements must be carefully treated with an antiseptic solution. Otherwise, a long service life cannot be guaranteed.

- Wooden crate is not used in rooms where humidity exceeds 12%. At high rates, structural elements will swell and warp.

- During installation, it is required to leave gaps between the wall and the bars, compensating for the displacement of the geometry of the latter under the influence of temperature and moisture.

- A wooden frame is considered less durable than a metal profile structure.

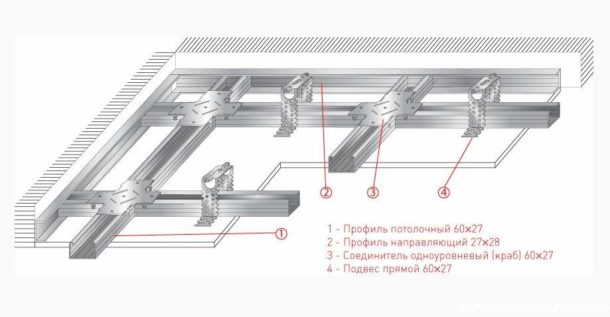

The metal frame is devoid of these shortcomings. It is resistant to the influence of the external environment and microorganisms, durable and practical. With minimal building skills and the necessary tools, it is easy to assemble it yourself. Mounting a frame from a profile will require careful calculation of the necessary material and various auxiliary elements: suspensions, crabs, connectors.

Ceiling frame types

The crate is of two types:

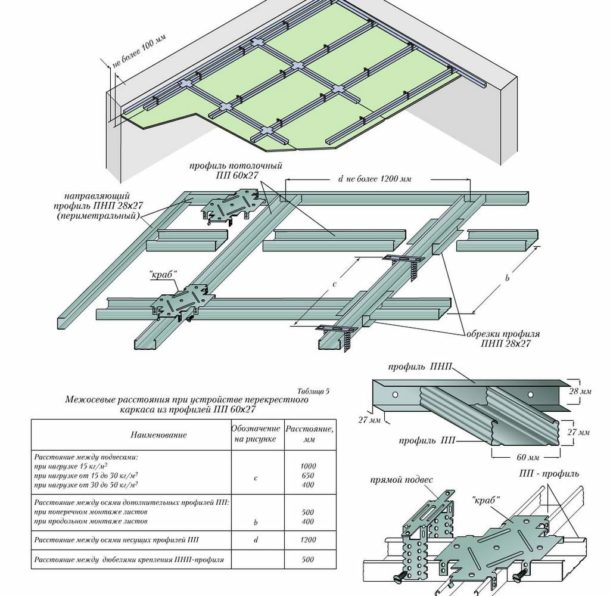

- Cellular, when load-bearing profiles or beams create a kind of lattice (see the next photo). As a rule, it is used in most cases of leveling the ceiling with drywall.

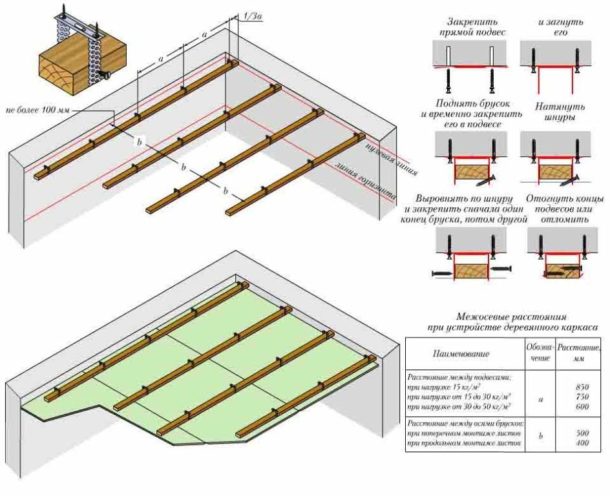

- Transverse. Profiles or slats are located only in one direction, and the GKL is attached to them across. This method is usually used by experienced craftsmen.

There are also single-level and multi-level structures. A ceiling of two or more tiers is rather complicated in calculation and installation, but all costs are more than paid off by the original appearance. To develop projects of such structures, it is better to resort to the help of a professional designer.

Necessary materials and tools

Since metal profile frames are most often used to align ceilings, we will list everything that is required for their installation.

From the tools you need to prepare:

- Levels. Bubble will also work, but laser is better. It makes no sense to buy it on purpose, if there are no plans to professionally engage in repair work. It is better to borrow from friends or rent. The hydraulic level is easy to do with your own hands.

- Perforator for making holes in the wall for dowels, on which the profiles will be attached.

- Drill and drill bits for metal.

- Screwdriver.

- Hammer, metal shears and tape measure.

To connect profiles to each other, it is convenient to use cutter. It provides better fastening than small metal screws (they are also called "fleas", "bugs" or "seeds").

From the materials you will need:

- Profiles - carriers and guides. Fasteners: suspensions, crabs, self-tapping screws for metal, dowel-nails.

- damper tape.

A correctly drawn frame diagram will help determine the exact amount of material.

Charting

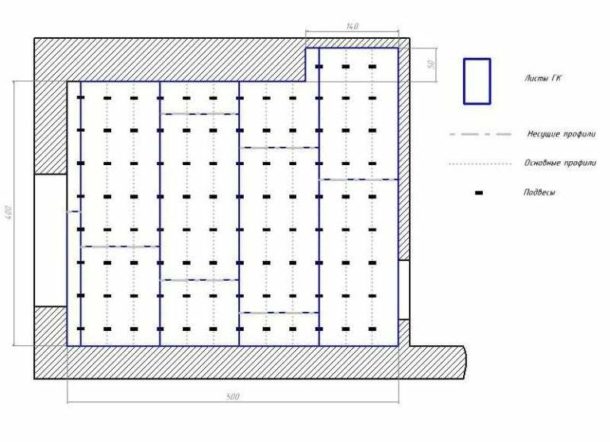

Depending on what type of frame is selected, the necessary measurements are taken. Then a diagram is drawn on a sheet of paper, taking into account the features of the chosen design.

For honeycomb frame:

- The length of each wall is measured. It is for each, since often opposite walls in apartments do not match in size.

- The distance from floor to ceiling is measured at the corners of the room and in its center.

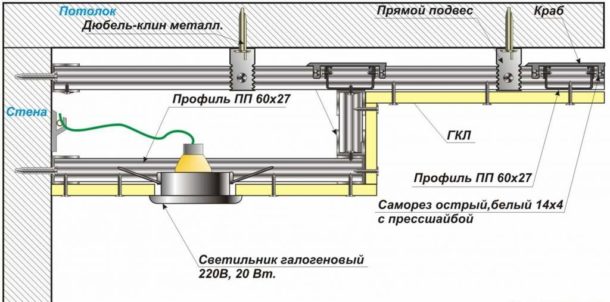

- From the lowest point of the ceiling, the thickness of the suspended structure is laid off. It depends on what will fit in the space between the base surface and drywall. It can be insulation, sound insulation, lighting elements, wiring or other communications. The minimum distance between the ceiling and drywall is 50 mm.

- The layout of the bearing profiles and crossbars is drawn. In this case, it is necessary to choose the optimal step so that the sheets must be joined on the profile. Usually the step is 60 cm.

- The result is a grid with cells of the same size. On it it is necessary to designate the attachment points of the suspensions with a step of 30-40 cm.

- It would be useful to draw on the diagram of all communications and the location of fixtures.

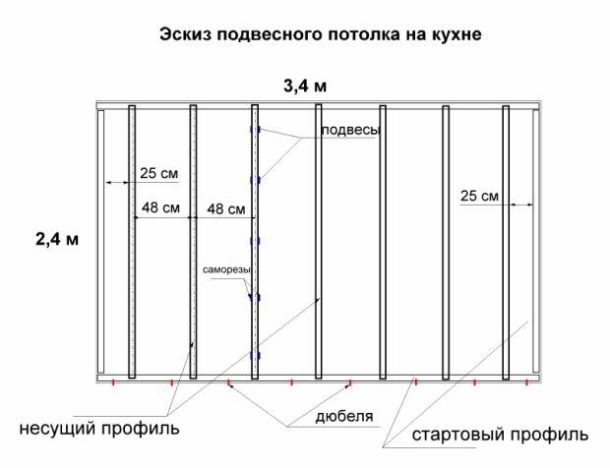

For the cross frame:

- The height of the structure is selected according to the same principle.

- The step of the bearing profiles is 0.5 meters.

- The locations of the suspensions are determined in the same way as for the cellular frame.

For multilevel structures, there is no clear algorithm. The order of work depends on the number of levels, the location of the boxes and other features of the design ceiling. But the general principles for placing fasteners remain the same.

Preparatory work, transferring the scheme to the ceiling

Preliminary preparation consists in the elimination of the old coating. All elements are removed, the strength of which is in doubt. Large cracks are sealed with cement, and then puttied.

At this stage, you also need to get rid of stains of fungus or mold, if any. It is better to treat the entire base surface of the ceiling with an antiseptic to prevent their occurrence in the future.

After preparing the base, you can proceed to the markup according to a pre-compiled scheme. It is convenient to carry it out with a chopping cord or paint thread. The scheme drawn on paper is transferred to the walls and ceiling. Not only the position of the profiles is noted, but also the attachment points of the suspensions.

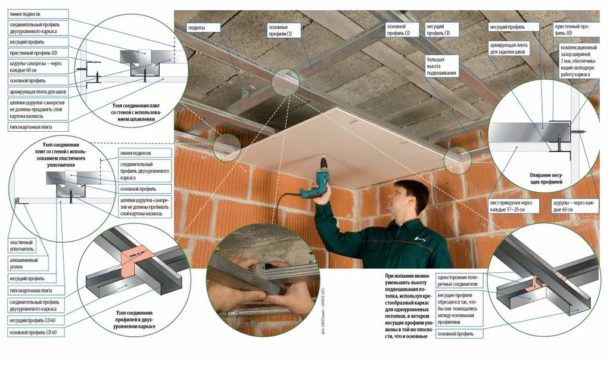

Frame installation

Work order:

- In the guides, holes are pre-drilled for dowel-nails with the intended pitch (sometimes they are made at the manufacturing stage by the manufacturer).

- A damper tape is glued to the side adjacent to the wall. It is needed so that sound vibrations are not transmitted from the wall to the frame.

- Guides are attached to the wall. The bottom edge of the profile must match the line on the wall.

- Hangers are being installed. The step between them is 60 cm. If the frame is of a cellular type, they should fall between the jumpers.

- The carrier profiles must be cut by about a centimeter. This is necessary so that the structure does not deform with the possible expansion of the metal under the influence of temperature.

- The installation of the profile begins from the place where it is paired with the guides. For fixing, self-tapping screws for metal are used.

- Having aligned the carrier rails with a level, attach them to the suspensions. All profiles must be strictly in the same plane.

- If the structure consists of cells, crossbars are attached. It is preferable to arrange them in a checkerboard pattern. The joints are reinforced with crabs.

Some experts recommend assembling multi-level ceilings, starting from the lower level: this way the structure will be more durable and rigid. The necessary bending of the guides is achieved by notching them at certain intervals.The stronger the bend, the more often the incisions.

First, vertical racks of the desired size are attached to the guides, and then the lower edges. All elements are interconnected with screws or with the help of a cutter.

Drywall fixing

Pieces of drywall pre-cut to size are mounted on the finished frame. The ceiling is a prominent place, so you should not save on the quality of the material. It is better to choose a product from a well-known manufacturer, for example, Knauf.

- Fasten the GKL with self-tapping screws in increments of 10–20 cm, sinking the heads into the material by 1 mm.

- After that, the seams are processed: sealed with putty and reinforced with reinforcing tape. Joint processing technology is described in detail here.

- The entire surface is primed and, as it dries, is ready for further finishing.

Any questions regarding the drawing up of the scheme and the installation of the frame, ask in the comments. An experienced master will answer them.