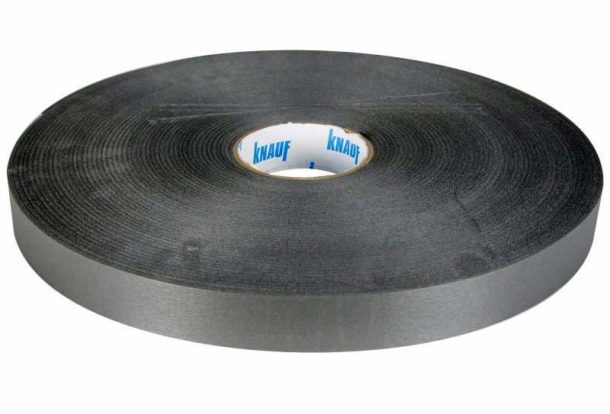

As is known from the course of physics, sound can be transmitted through solid objects. Therefore, the apartment can be well heard what is happening with the neighbors. Even in a room sheathed with drywall - a material with excellent soundproofing properties - extraneous sounds can be heard. The sound is transmitted from the wall to the metal profile and enters the room. Therefore, experts recommend that in no case do not forget to glue the sealing tape for GKL profiles on the frame elements before installation.

Description

The sealing tape is made from flexible polyethylene foam. It is a strip with a cellular structure, on one of the surfaces of which a self-adhesive layer is applied. It is protected by paper, which is peeled off before use. The product is sold in rolls of various lengths.

The sealing tape differs in thickness, width, length and brand of polyethylene foam. There are three types of this material:

- physically crosslinked PPE;

- chemically cross-linked PPE;

- non-crosslinked gas-filled NPE.

The width of the sealing strip varies from 30 to 95 mm, the most common thickness is 3 mm.

Application

The tape is necessary to ensure a tight joint between the metal profile for drywall and the supporting structures - the floor and walls. Most importantly, the product provides not only sealing, but also sound insulation and vibration reduction, which can be transmitted to the frame from the walls.

Often, novice builders try to save on building materials and neglect sealing tape. But this is a gross violation of construction technology. Installation of drywall is carried out according to a well-defined scheme using all the necessary components, from which you should not deviate. Rolled soundproofing material should be glued to profiles that are attached to the ceiling, floor and walls. It significantly improves sound insulation properties. drywall partition wall.

A plasterboard partition, which is mounted without a sealing tape, will not only not protect against extraneous noise, but will also become a kind of screen that attracts and amplifies all sounds and vibrations coming from neighboring rooms.

Sealing material must be glued to the guides, it is through them that sound is transmitted from room to room. Rack profiles that are attached to the walls should also be pasted over with soundproof tape.

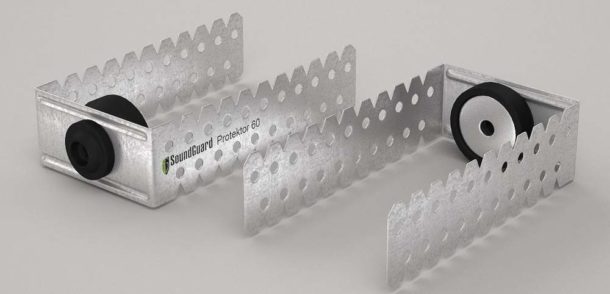

Important! To improve the sound insulation of the rack, it is necessary to mount it on special vibration suspensions.

Advantages

The tape is made of an elastic material on an adhesive basis, so it is convenient to use it, and installation does not take much time.

The advantages of this material:

- good sound insulation;

- does not absorb water, which means it does not spoil the drywall sheet;

- elasticity and low weight of polyethylene, ease of installation;

- resistance to fungus, alkalis and acids;

- resistance to temperature changes;

- environmental friendliness;

- durability.

The most popular on the Russian market are Knauf Dichtungsband, PES EUROBAND and Sound Guard products.

Working with sealing material

Some masters who make repairs in the apartment on their own believe that you can do without tape. But it is necessary for the correct fastening of the drywall profile and compliance with the technology. It should be remembered that the tape for the profile is best glued at a temperature of +10 degrees. It is desirable that after the end of work the temperature remains the same for another 1-2 days.

Working with self-adhesive tape is very simple. You need to choose a material that suits you in terms of characteristics and width.After you have marked the profiles and cut them, you need to degrease them, remove the protective paper from the sealing strip and stick it on. After that, you can attach metal profiles to the walls.