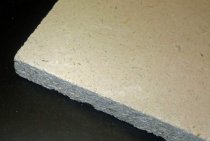

Drywall is an easy-to-use material that allows you to quickly finish the apartment. This achieves the necessary evenness of the walls and even the ceiling. But at the joints of drywall sheets, seams are formed, on each element there are many recesses from self-tapping screws. In order for the surface to become perfectly flat in the end, putty for drywall is used. Let's try to figure out the choice and technology of applying this material to plasterboard walls.

Choosing putty for drywall: dry mix or ready-made?

Putty mixes may be dry and cooked. If the question is which mixture is better, then when answering it, you need to consider several factors:

- With the same level of quality, finished putty is more expensive.

- Dry putties last longer and are less demanding on storage conditions. At the same time, it should be borne in mind that they enter stores, passing through many warehouses, as a result, the finished mixture may be unusable after a couple of months after purchase.

- The dry mix must be properly prepared, achieving the desired consistency and lack of lumps, beginners may have difficulty with this process. In addition, you will need a special tool - a mixer or a drill with a nozzle.

- Dry putty can be made thinner or thicker, depending on the application. For example, joints and seams are easier to cover with a thicker mortar; for the finishing layer, the putty should be more liquid than for the starting one.

- Ready putty, which has stood for some time in an open container, is not subject to storage.

Advice. To save the finished putty until the next cycle of repair work, you do not need to scoop it directly from the bucket, but set aside the amount necessary for work in another container. The bucket with unused residue must be tightly closed. In this case, the finishing material can be stored for another six months or even more.

Thus, ready-made putty is more convenient to work with and does not require preparation, therefore it is well suited for beginners, but dry putty has a lower cost and allows you to adjust the consistency depending on your needs.

Start or finish?

For high-quality finishing of a plasterboard surface, one type of putty is indispensable. For sealing joints and continuous puttying, different mixtures are used:

- For joints and seams, a mixture is used specially designed for these purposes - "Knauf Uniflott", "Knauf Fugen”,“ Volma Seam ”, - or, at worst, the usual starting putty of good quality.

- To putty the entire surface of the GKL, a starting and then a finishing mixture is used, or a universal one that can replace these two types.

Therefore, if you are wondering which putty to choose for drywall, the best solution would be to buy a universal mix and a special mix for joints.

The basis of the putty mixture

Also putty are:

- Cement. This type of finish is best suited for bathrooms, toilets and kitchens, as cement can easily withstand moisture.

- Gypsum. Gypsum mixes, on the contrary, are better to choose for dry living quarters, since gypsum does not tolerate high humidity.

- Polymer. This type of putty is the most versatile. It is best to use it for finishing drywall sheets. Polymer mixtures have high plasticity and rather low consumption.

Under no circumstances should alkyd putty be used on drywall. This will destroy the top layer of drywall sheet.

Such characteristics of various putties as frost resistance, fire resistance, etc. are not of particular importance for the interior decoration of an apartment.

The procedure for puttying plasterboard walls

Like any other type of finish, putty has a special application technology, which consists in the procedure and observance of certain rules.

Training

First you need to prepare the walls for the putty process. The wall should be flat, without protruding self-tapping screws (they need to be screwed 1 mm deeper than the sheet level). It is also necessary to check the GKL joints: the paper layer should not peel off from the inner filling of the drywall sheet. If this happens, carefully cut off the peeled off area and sand the surface. Otherwise, drywall from such joints may eventually fall off or go blisters.

Next step - priming drywall. This is best done with an acrylic-based primer mixture. It should be applied in two coats, using a wide soft roller to evenly cover the surface. The final layer of primer is applied only after the first has dried.

For ease of application, you can purchase a primer painted in a specific color. Then you will definitely see which part of the wall is already covered with a primer layer.

Joint processing

Plastering plasterboard walls should begin with filling joints, which are glued with reinforcing tape. Stir the dry mixture to the state of thick sour cream.

A layer of putty is applied so that all seams and joints are completely filled with it. The excess is carefully removed with a spatula. After applying the first layer, you need to wait until it dries, and apply another layer of the mixture to the joints. And after the putty has completely dried, it can be gently sanded.

If in some places a drywall sheet adjoins a plastered wall, the seams between them are glued with a separating polymeric self-adhesive film.

Here you can putty the caps of the screws - this is done with crosswise movements in order to fill the holes as tightly as possible.

Putty corners

This is the most time-consuming work that is done in two stages.

First, one side of the corner is puttied. The surface must be carefully leveled, especially in the part that is closer to the corner. After applying the second layer and drying it, you can start working on the second side of the corner. Thus, you need to create a perfectly even drywall joint. Here the putty is placed in a thinner layer.

In order to create a perfectly even corner, you can use a special corner spatula.

An aluminum construction corner must be attached to all slopes of windows and doors to create an even and fairly rigid corner. You can attach it to the wall with a small amount of putty mixture. The corner must be cut to fit the slopes and installed along the perimeter of openings or other external corners.

After installing the corners, they are smeared with putty so that the mixture penetrates into all holes. With a wide spatula, the applied layer is leveled over the corner and surface of the gypsum board.

Surface putty

After you have processed all the joints of the drywall sheets and the corners of the room, you can proceed to the finishing putty of the entire surface of the wall.

How to putty walls? The first layer of the mixture should not be made too thick, the wider the spatula, the better. After the first layer dries, the second one is applied, and then it is important to sand the surface of the entire wall well with a sandpaper-zero.

At the last stage, the puttied wall is treated with a primer in two layers in the same way as for the first time.

This method will allow you to level the plasterboard walls before finishing them.

The nuances of putty for different finishes

There are several nuances when processing plasterboard sheets with putty, on which the quality of the final finish will depend:

- If you plan to stick paper wallpaper on the walls, then you need to stir the putty with special care. You also need to take care of eliminating all possible flaws in the wall, since all the bumps and cracks will show through the wallpaper.

- When used in the decoration of heavy wallpaper, on the contrary, it is necessary to create a rough layer of putty. This will make it easier to stick wallpaper and not be afraid of peeling off due to better adhesion of materials.

- The most difficult thing is to putty the walls for their further painting. In this case, the surface must be perfectly flat. To achieve this effect, you can examine the wall under the light of a lamp (the shadow will reveal small irregularities).

Finishing plasterboard walls with putty will allow you to prepare the room for finishing with any material. The main thing is to follow the technology and act as carefully as possible. Then you can not worry about the durability and beauty of your walls!