Building materials are constantly being improved, and manufacturers are striving to give some products new properties, expanding their scope. The materials of the new generation include a unique development of the Knauf company - acoustic GKL. Let's find out what features and characteristics this type of drywall has, and where and how it can be used.

Features of acoustic drywall

The words "acoustic" and "acoustic" in relation to building materials usually tell us that the material has soundproofing or sound-absorbing properties. For example, acoustic mineral wool, soundproof wall panels or rolled soundproofing material in the form of a membrane can reduce the noise level in the room, preventing sounds from outside and from neighboring apartments. But acoustic drywall is not on a par with these materials.

Important! The task of acoustic drywall is not soundproofing, but sound absorption. If you decide to shield yourself from noisy neighbors, acoustic drywall will not help you!

This error has crept into many construction sites and portals and misleads people, however, if you open the section on Knauf-Acoustic slabs on the official website, you will not see a word that this is a soundproofing material.

Why then do you need acoustic drywall? This material is used to improve the acoustic characteristics of the room. This means that he:

- reduces the level of background noise that occurs in the room itself;

- reduces loudness;

- eliminates the effect of "echo";

- improves speech comprehension.

Thus, according to the Knauf company itself, Knauf-acoustics drywall allows you to create a comfortable acoustic environment in any room, which is especially important for objects with increased requirements for it:

- in recording studios;

- in music classes, concert and rehearsal halls;

- in cinemas;

- in meeting rooms;

- in classrooms.

There is a place for an acoustic variety of GKL in the apartment. It will help solve the problem of boominess inherent in some rooms, and will be appreciated by music lovers, musicians who play at home, as well as home theater owners.

Main characteristics

And now let's find out, thanks to which the Knauf-acoustics plates have the above properties.

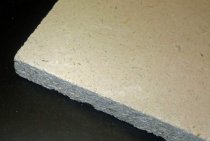

- Perforation on the surface. Many through holes act as resonators, providing sound absorption. As a result, sound waves quickly decay, falling into a kind of trap.

- The non-woven fabric on the back also has sound-absorbing properties. Depending on the design, you can choose GKL with black or white non-woven fabric.

Acoustic GKL "Knauf" has several options for the location and shape of the holes, which determine the model of the material:

- Fully perforated. On this model, the holes are distributed evenly over the entire surface.

- With block perforation. The holes are located on the plane in separate groups.

- With round perforation in the form of holes with a diameter of 0.8 cm.

- With square perforation, where the holes are made in the form of a square with a side of 1.2 cm.

- With scattered round perforation - the holes on the surface are arranged in a chaotic manner and have different sizes - 0.8 cm, 1.5 cm and 2 cm.

The shape of the holes, as well as their location, have a great influence on the design of the GCR and on the sound absorption characteristics.

Edge shapes

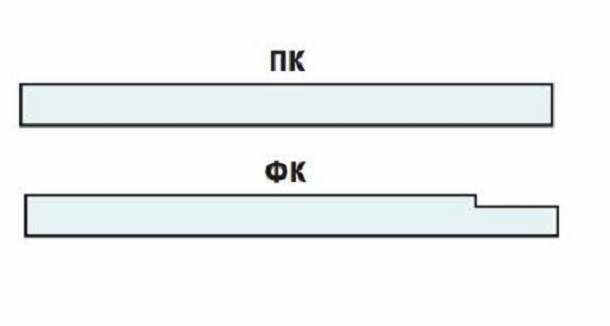

Models of acoustic GCR also differ in the shape of the edges. They can be:

- With curly or folded edges, made in the form of steps.Such models have the abbreviation "FC".

- With straight edges with the designation "PC".

Sheets of material can have edges of the same type, or they can be different:

- Sheets of grade 4PK have all four edges straight.

- Sheets 2PK/2FK have two straight and two seam edges.

- Sheets marked 4FK have four seam edges.

On opposite sides, only edges of the same type can be located. Sheathing of one plane should be done with sheets that have the same perforation and the same edges.

Dimensions

The dimensions of acoustic GKL differ from standard sizes:

- Width - 118.8 cm, 119.7 cm, 122.4 cm, 120 cm.

- Sheet length - 199.8 cm, 200 cm, 244.8 cm, 240 cm.

- The thickness of one sheet is standard - 12.5 mm.

- The weight of one sheet varies from 8.8 to 9.6 kg.

Advantages of Knauf-Acoustics plates

Acoustic drywall has many advantages over similar materials:

- The price matches its quality.

- Safe eco-friendly material can be installed in residential premises.

- Perforation of various shapes and sizes makes it possible to choose a material with the required level of sound absorption.

- Various types of edges of soundproof drywall allow you to finish walls and ceilings with an invisible joint.

- The material can be used to create curved surfaces.

The interesting and spectacular appearance of acoustic slabs makes them a valuable material in terms of design.

In addition, acoustic GKL from Knauf:

- Lightweight and plastic.

- Easy to process and install.

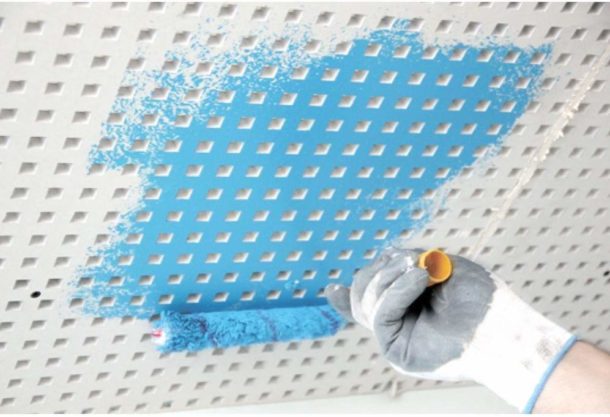

- Allows you to apply paint of any color.

- Eliminates the need for wet work.

Installation

You can install sound-absorbing drywall with your own hands. To do this, you need a standard set of tools for working with plasterboard, finishing material, fasteners.

Paint is used as a finishing material for acoustic slabs.

All work is carried out according to the following scheme:

- Carry out the marking and cutting of the material.

- A frame of metal profiles is mounted, on which they are pre-glued sealing tape.

- If necessary, additional sound insulation is laid.

- Sound-absorbing drywall is attached to the frame with self-tapping screws, just like ordinary sheets.

Important! Acoustic plates, unlike conventional plasterboards, are attached to the frame without displacement.

Features of working with panels "Knauf-Acoustics"

When working with acoustic GCR, you need to remember some important points:

- The joints of 4PK panels are puttied without the use of reinforcing tape. The edges are pre-cut with a slight bevel, the panels are mounted with a gap of 3–4 mm. The seams will fill putty "Uniflot", recesses from self-tapping screws are puttied. after drying, the seams are puttied with finishing putty and polished.

Important! The surface of acoustic drywall does not require continuous puttying.

- The connection of 4FK panels does not require additional processing, since the joining is carried out by means of folds.

- The execution of arched structures is carried out by the method of dry and wet bending using plywood templates.