Choosing an adhesive for extruded polystyrene foam

Building

Penoplex plates vary in density. This indicator largely determines how high-quality the insulation will be glued to the surface of the facade. Certain variants of extruded polystyrene foam can only be fixed with facade cement adhesive or exclusively with bituminous mastic. Other types of penoplex require the use of special glue or foam.

How to glue extruded polystyrene foam

From the foregoing, it follows that choosing the right glue for polystyrene foam is not easy. Adhesive compositions themselves usually contain many components. For example, it can be bitumen with a solvent. Another option is a one-component adhesive foam. The representative of the first group is Bitumast. The second includes ST 85 Ceresit.

Be that as it may, it is desirable to use substances that do not contain acetone or gasoline to create a reinforcing adhesive layer. Such components are able to dissolve the heat-insulating materials themselves. In addition, the adhesive can be universal or specialized. If the first can be used for almost any insulation, then the second is designed specifically for polystyrene foam.

Choosing the best glue for polystyrene foam

There are many facts from which it is necessary to build on the process of choosing an adhesive. In addition to such aspects as the cost of the material and the principles of its use, the purchase should also determine the purpose of the adhesive composition. It can be used in internal and external procedures.

Bituminous adhesive for styrofoam

The basis of the composition of bituminous glue is bitumen. Plasticizers and a solvent are also added to it. The peculiarity of bituminous glue is that it increases the waterproofing capabilities of the working base. The material allows you to fix the insulation plates both to the surface and to each other. In order for the result of applying Bitumast glue to be good, the base under it must first be dried and sanded. It will be possible to further increase the fixing of the material if the surface is covered with a primer, which will rid the base of unnecessary pores.

Cement-polymer adhesive

The composition called ANSERGLOB BCX 39 is designed for laying on materials such as concrete, brick and even wood. It can be used for outdoor and indoor activities. Mixtures of this kind consist of a complex of elements such as Portland cement and a plasticizer. Other additional components are also added to them. A deep primer is required prior to application.

Water- and frost-resistant adhesive AQUALIT SK-106P ensures reliable laying of insulation boards on the facade of the building from the outside. The product, which is called ECOMIX on the market, is in demand for interior work and is used to create a covering layer of insulation. Another solution is "MASTER SUPER". It is intended for laying a heat insulator on a bearing base.

Adhesive foam for foam

A separate category of adhesive materials for expanded polystyrene is polyurethane foam. The most famous representatives of this group are Ceresit CT 84, TechnoNIKOL and Tytan Styro 753. Features of adhesive foam in its fast setting, which occurs in 10 minutes. One cylinder of such material is enough to do the job, which requires 25 kg of a conventional mixture. This volume of polyurethane foam is enough to cover an area of 10 m2.

It will be possible to achieve a good result with the use of adhesive foam if the surface is prepared very well.But despite the laboriousness, the result is fully justified. Therefore, it is the use of polyurethane foam to fix the penoplex that is considered the best option, because it is possible not only to securely fix the insulation, but also to provide decent thermal insulation in general.

Application area

Polyfoam is used in various spheres of life. A large number of materials and products are made from it. Also, the material retains heat well, so it is often used for wall insulation.

Areas of application of expanded polystyrene:

- Construction works. In construction, it is used for thermal insulation of structures, houses, buildings, garages, hangars. It is also used for outdoor insulation.

- In shipbuilding. Life belts, lifeboats, light boats are made from it. Also used to fill the compartments of small boats.

- In medicine. In this area, foam containers are used to transport organs and medicines.

- In furniture production. It is added to the composition of the material, from which various pieces of furniture are then made.

- For the manufacture of packaging materials. They are added to the composition of various packages, packages, wrappers and so on.

- For the production of outdoor advertising. It is added to the composition of advertising structures - banners, signs.

- in the production of clothing. It is added to the composition of many fabrics. Styrofoam content is very warm.

Fastening foam to the wall methods and options

Styrofoam, or rather, expanded polystyrene, has excellent thermal insulation characteristics. Very often it is compared with mineral wool, emphasizing the shortcomings - it burns, is short-lived, fragile ... However, with a closer acquaintance with the materials, one can find flaws in everyone. For example, in comparison with the same foam, mineral wool has a very significant disadvantage - over time it becomes caked, from which such a sheathing loses its thermal insulation qualities, and if it gets wet, the insulation effect is completely lost.

Styrofoam is not threatened by wetting or caking, and if insulation is carried out according to technology, protecting the material from ultraviolet radiation and mechanical damage, then for the next 25–50 years you can forget about cold and damp walls in your house. In addition to protection from external factors, a very important point in the technology of foam insulation is the correct fixing of the plates on the base surfaces (walls, ceilings, slopes). In general, all methods can be divided into three groups:

- on dowels with an umbrella hat;

- for plaster mixtures;

- for adhesives.

In the first case, fastening occurs solely by screwing dowels into the walls. Foam sheets are attached at five points - in the corners and in the center. Corner dowels also fix the junction of individual sheets. The joints themselves are additionally glued with a sealant, which improves the thermal insulation qualities.

First of all, using the starting profile, the bottom row of foam is attached, then the master moves from top to bottom along the entire perimeter of the wall

It is important to leave gaps between the individual boards of at least 3 mm, as the foam also expands and contracts with temperature changes. Dowels - the cheapest way to fix the plates

Stucco mixes are another very popular option for fixing foam, which is mainly used for insulating concrete and brick walls outside and inside the building. It goes without saying that a special plaster composition is used for this - ordinary cement plaster is unsuitable for this. Some companies produce universal mixtures that are suitable for both fixing foam boards and plastering, some divide the mixtures into two groups - one only for gluing, the second only for plastering.

Adhesives for polystyrene - not every adhesive is suitable for polystyrene foam, and many are even able to destroy its structure by reacting with it. Therefore, experiments are unnecessary here. Pasting concrete, brick and metal walls with foam is feasible using building PVA, universal liquid nails, mounting foam or special polyurethane glue. Each of the methods has its own characteristics, which we will discuss below.

Polyurethane foam adhesive

The use of a special polyurethane adhesive sold in cylinders helps to increase the speed and improve the quality of concrete surface insulation.

This fact is the main advantage of this type of adhesive.

The technology for the installation of foam plastic on concrete requires a 3-day technological break after gluing the polystyrene foam plates and until they are fastened with dowels. This, accordingly, increases the total duration of all works. Using polyurethane foam adhesive foam, you can reduce the technological break to 1 day.

Advantages of polyurethane foam:

Scheme of floor insulation with polystyrene foam.

- ideal for gluing foam to concrete;

- reduction of terms of performance of thermal insulation works up to 3 times;

- technological characteristics of adhesion of adhesive foam to a concrete surface are much higher than a simple dry adhesive mixture;

- moisture resistance indicators are higher than that of dry mixes;

- low consumption: only 1 cylinder is required per 10 square meters;

- the cost of such glue is similar or slightly more expensive than that of dry adhesives (depending on the manufacturer);

- simultaneously with the gluing of the plates, the joints are filled with foam, which effectively prevents the formation of cold bridges;

- polyurethane foam is sold ready for use, so the quality of gluing will not depend on the human factor (mistakes in the preparation of glue) and will be stable throughout the entire scope of work.

A little about the product

Extruded polystyrene foam is an analogue of foam plastic, consisting of small faces. Production involves foaming the material through agents, which can be freon or carbon dioxide. Numerous tests have confirmed the negative impact of the first on the Earth's ozone layer. In this regard, manufacturers are increasingly trying to produce expanded polystyrene using CO₂. The granules themselves are obtained by passing the mixture through a special matrix with small cells. As a result, finished sheets and panels are formed. This form was not chosen by chance, since it is much easier and more convenient to lay extruded polystyrene foam in the form of small plates.

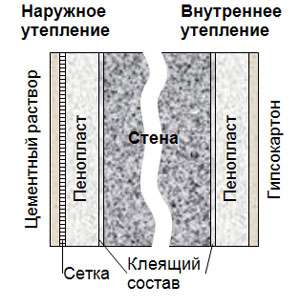

Insulation of buildings from the outside

Usually, sheets 100 mm thick with a density of 35 kg / m² are used for this.

They are fastened with special glue and plastic fungi (dowels). Performing such work at height is possible only with the use of special equipment or by the forces of industrial climbers.

In addition to the above, external insulation is also convenient in that it can be performed regardless of whether repairs are planned in the room itself or not. Unlike this method, internal insulation is possible only during a major overhaul.

Finishing work when insulating walls with foam

Installation of foam on the wall can be considered complete with various finishing works, the main of which are:

- sheathing with sheets of drywall;

- surface plaster.

In the first option, drywall sheets are attached to the crate, for this you can use nails with large hats.Then all the necessary work on drywall is carried out: sealing the seams, priming the surface and coating with facing material at your discretion.

In the case of fastening the foam under the plaster, after its installation, a layer of glue is applied to the entire surface with a spatula, on which the prepared plaster mesh is laid out. Aluminum corners are installed at the corners to create greater strength. Then another layer of special glue is laid on them, which is smoothed out with a spatula. For greater alignment, you can apply another such layer. Give it some time to dry. After complete drying, the surface is grouted, in which all irregularities are removed with a grater.

Now you can proceed to the final stage of work - applying plaster, leveling it and grouting.

Thus, thanks to the insulation of the house with foam plastic, you can not only create a unique atmosphere of warmth and comfort inside, but also significantly save on the energy consumed for heating.

TOP-5 brands of foam glue

So which styrofoam glue to choose? To answer this question, it is worth considering the popular brands that the modern construction market offers.

Before buying them, you should carefully consider the main features and qualities, it is important that the adhesive mixture is suitable for polystyrene foam

Ceresit

This is a well-known brand of styrofoam glue. In its assortment there are options that are great for gluing polystyrene foam and gluing it to different surfaces. The most suitable models are CT85 (dry adhesive) and CT84 (polyurethane adhesive).

Among the advantages it is worth highlighting:

- Fast drying. Hardening on average takes from 2 to 3 hours, it all depends on the type of glue;

- Adhesive foam Ceresit calmly withstands high and low temperatures. Can be used from -20°C to +40°C;

- Excellent moisture resistance;

- Suitable for outdoor and outdoor decoration;

- It adheres well to various surfaces - concrete, wood, plastic.

The manufacturer Ceresit produces different types of glue - liquid versions, in cylinders, in the form of foam, dry mixes. All of them have excellent quality and are suitable for various construction works.

Knauf

The manufacturer Knauf produces different types of glue that are suitable for expanded polystyrene sheets. They help to provide a strong and durable attachment that will not collapse under the influence of various negative factors.

The positive qualities include:

- high strength and durability;

- frost resistance;

- universality;

- fast freezing;

- moisture resistance.

Types of glue brand Knauf have long established themselves in the construction market. They are in high demand because they are suitable for absolutely all materials, including foam.

Tytan

This is a well-known manufacturer, in the assortment of which you can find different types of high-quality and durable glue. They are excellent for gluing polystyrene foam for exterior and interior decoration. The most popular is TYTAN STYRO 753.

Its advantages include:

- fast drying;

- convenient application;

- excellent resistance to low and high temperatures;

- high strength;

- affordable price.

TYTAN glue is always in high demand among experienced builders. This is due to its versatility and ability to be used at low temperatures.

Moment

This is a well-known brand that produces liquid, dry mixes for gluing different options, including foam. Also in the range there is mounting foam, which has a quick setting.

Moment brand adhesive mixtures have the following advantages:

- fast grasp;

- moisture resistance;

- resistance to high and low temperatures;

- affordable prices;

Moment is an affordable brand that is commercially available in many stores. Moreover, the glue of this manufacturer has a low cost, but at the same time it has good qualities.

TechnoNIKOL

For many, this manufacturer is unknown, but it produces an excellent adhesive-foam, which is great for styrofoam sheets, bricks, wood, plastic and other building materials. Mixes for winter and summer are on sale.

The benefits include:

- high degree of strength;

- increased resistance to moisture;

- Glue can be applied at different temperatures;

- universality;

- affordable price.

To choose glue for foam, you should find out its nuances of use. Do not miss the rules and recommendations that will help you figure out how to stick the foam to the foam and other surfaces. Almost any adhesive mixture is suitable for this purpose, but it must be used correctly.

Expert answers

Alex K:

Foam plastic is glued very well and quickly with mounting foam. Moreover, to each other and to any surface

1:

maximum pencil. And that can eat away.

Isabella W.:

Yes. Glue corrodes. Can be used with double sided tape

CONGO:

silicone sealant

sweet:

rubber or silicone

Masik_Dimasik:

Glue "titanium" They glue foam tiles on the ceiling.

Just Konstantin:

Today, expanded polystyrene is becoming an increasingly popular material used in construction, due to its high performance properties. It is environmentally friendly and has very high heat and sound insulation capabilities. Styrofoam is used in many types of structures, so dozens of its brands are now on the market. Depending on them, the main properties of the foam plastic change - density and rigidity, which directly affect the choice of the optimal method of fastening. By and large, almost any adhesive is suitable for this purpose: special foam adhesive, frost-resistant facade adhesive, tile adhesive mixture, silicone sealant, liquid nails, etc.

When choosing an adhesive for polystyrene, the main thing is to pay attention to the absence of organic solvents in its composition, such as gasoline or acetone, since these substances dissolve polystyrene foam very easily. Styrofoam can be glued to almost any surface, be it concrete, brick, drywall or galvanized iron.

At the same time, at least five places for applying glue should fall on one square meter of the surface. If the sides of the foam sheet are less than one meter long, then when mounted on adhesive solutions, it is usually fixed in the center and at the corners. To make the fastening more reliable, you can also additionally use dowel-nails.

Oleg Zhestov:

Ordinary stationery. First they glue paper on it, and then between themselves.

Evgesha:

polyurethane foam checked

Rubanik Alexander Mikhailovich:

a fire in a discotheque - the polystyrene foam ceiling "warmed up" and released PHOSGENE .... All victims of the fire died a painful (!!!) death. for 2-3 days... More than 100 people… Eternal memory!

Nadezhda Trubnikova:

Mineral wool, for example, is very heterogeneous, even ordinary tile adhesive clings to it. She has her own nuances, the same weight. Everything is interesting and described in detail here UteplimVse /vidy/penoplast/chem-prikleit

20090114:

Glue foam rubber to foam plastic on PVA glue, it’s not the main thing here that adhesion, destruction ... the main thing is that all elements start with the letter P ... by the way, glue itself!

yadog@mail :

anything but wallpaper =)

Julia Sadkova:

try liquid nails!

Yuki:

Try double sided tape

dimazz517:

"88", "Moment-1" universal ("Hekel"), "FENSOL" (aerosol), although the glued surfaces will slightly "melt". The main thing is to follow the instructions, but do not degrease or clean. Apply glue to foam rubber. If strength does not matter - PVA from Henkel (red plastic bottle).

Ser X Photos:

Proven by my PVA experience !!! Reliable and simple !!!

How to properly and how to glue the foam

Styrofoam is a porous, lightweight white material.It is usually used in construction work, most often for insulation. It can also be used for packing goods or furniture, equipment during transportation and for handicrafts.

To make the desired design strong and not fall apart in a day, it is important to know how and with what to glue the foam correctly at home

Choosing the Right Adhesive

Glue the foam to paper, cardboard or wood with ordinary PVA glue. It is quite durable and tenacious. Ideally, PVA is suitable for use in the manufacture of small crafts, which will later be in a static position and will not be subjected to stress.

You can use special glue. It is designed to be in direct contact with foam. It is usually sold in specialized stores for needlework or in construction. This glue is more expensive than PVA and harder to find. Please read the information on the back of the tube carefully before purchasing. Some types are designed for gluing parts of the foam only among themselves, while others - with other materials. This glue is usually called Styroglue.

Aerosol glue is suitable for connecting pieces of foam to each other and to other materials. It is sold in large containers and is consumed quite sparingly. In addition, spray adhesive has a low price. You can find such products in a hardware or hardware store. Often it is multifunctional, so with one spray you can glue the foam to foam, paper, cardboard, wood, metal.

A glue gun is also suitable for gluing foam

Please note that it should work at the lowest possible temperatures. Too much heat will cause the styrofoam to melt, which will not only ruin the look of the work, but can also be hazardous to health.

In construction, more viscous and dense types of adhesives are usually used. Among them are epoxy or instant glue, as well as liquid nails.

Basic rules for gluing

After selecting the adhesive, prepare the surfaces. It is necessary to clean them so that grease, dust and other contaminants do not reduce the tenacity of the adhesive. If you are working only with foam, then it is enough to thoroughly wipe both sides with a dry cloth. In the event that you glue the foam to raw wood or very uneven material, sand it with sandpaper. It is also necessary if you are dealing with large pieces of material. This will increase the level of adhesion, and the foam will stick easily.

The next step is to apply glue. If you need a strong and durable fixation, then spread it over the entire area to be glued in a thin and even layer. If you do not need to glue so tightly, apply a few drops or strips of glue to the surface of the foam. In the event that you have to work with a large layer, pour the glue into a glass or plastic container and spread it with a brush with artificial bristles. Some adhesives may ooze out of the seams and even foam. In this case, wipe off excess material as soon as possible with a dry cloth. Remember that glue is difficult to wash off by hand, so it is best to work with rubber gloves.

After that, attach the surfaces to be bonded to each other and press firmly. Depending on the type of glue, you have about a minute to change the position of the pieces, after which the substance will begin to set. To strengthen the fixation, apply a thin layer of glue to the border of the two surfaces where they touch. In the next step, you will just need to wait for the glue to dry.

How to glue glass: detailed instructions

Rules for gluing plastic at home

How to store persimmon at home?

Recommendations

When working with foam, do not use types of glue that are designed for other surfaces, such as metal, wood, or fabric.It is likely that they will fulfill their function, but at an unreasonably high cost. In addition, they can ruin the foam. For this material, those types of glue that contain a solvent for plastics: acetone or alcohol are not suitable. For the same reason, do not use universal rubber glue.

Remember that Styrofoam is plastic stuffed with air. It is very light and fragile. Work with it carefully, do not press hard when gluing, as the craft may deteriorate. When working with adhesive at home, use personal protective equipment such as masks and gloves and keep the area well ventilated.

This is interesting: Replacing the electrical wiring in the apartment with your own hands step by step - how to change the wiring correctly