Differences by type of fuel

Next, you should decide which model of the furnace will be better if you choose by type of fuel. Of course, everyone chooses an option for himself according to ease of use and economy. In this regard, there is no ideal. How to choose a stove for a bath, a person decides for himself and proceeds from his specific situation, comparing the advantages and disadvantages of each model. Today, stoves are significantly different from the previous ones. The appearance is more aesthetic, they have become lighter and more compact. Now let's think about how to choose by type of fuel if you need a stove for a bath.

wood stoves

Wood stove

Many people think that there is nothing better than a traditional wood-burning stove (see Which wood is better). Properly selected firewood gives a good heat and creates a unique aroma in the steam room, which manifests itself when some types of wood are burned. Moreover, the materials for the firebox are always available and the price is quite low. In this design, there is no need to supply new pipes and increase the cross-section of wires when power is supplied. But there are also some disadvantages. The steam room takes a long time to warm up. Maintaining the temperature falls on the shoulders of the owner. The need to clean the hall is also a disadvantage. In addition, wood stoves require a chimney, which will have to be periodically cleaned of soot. Especially a lot of soot is formed during the combustion of firewood from coniferous trees. At the same time, firewood from pine needles, when burned, releases essential oils that are beneficial to health.

electric oven

Furnace with power supply

The largest range of furnaces is probably presented among electrical structures. Let's see why this option is better than others:

- There is no problem with firewood. Cleanliness after use;

- Ease of settings. Modern stoves are easy to operate and are equipped with special control panels that help, through settings, to be aware of the microclimate in the steam room;

- Many work in different modes and can be suitable for both a sauna and a steam room filled with moisture;

- The built-in steam generator can create different vaping modes: from wet to dry;

- Takes up little space. As a rule, it is placed near the door so that it does not interfere with the location of the shelves and has an air flow from under the door;

- Maintains the set temperature in the steam room. You just need to choose a comfortable mode and relax.

You immediately thought how to choose an electric sauna stove? It is quite simple, the choice is made according to a simple calculation, 1 kW of electric furnace power for a bath falls on 1 m³. This is, of course, an estimate. Each model has its own characteristics, which are described in the instructions.

Gas oven

Gas oven

Any seller will tell you how to choose a gas sauna stove. But whether you give preference to her or not, depends only on you. These are quite mobile options that do not require chimneys. It has its own advantages:

- No need to stock up on fuel;

- Ease of controls:

- Maintains the set temperature;

- Does not require ash cleaning;

- Compact (space saving);

- Fireproof;

- When touched, no one will get burned.

But it has a very significant drawback, which can overpower many pluses: a gas supply is required. Sometimes this is quite difficult. We need a project that also costs money to do.

Cold and hot sauna stoves

Furnaces also have such a classification. It depends on the heating of the outer wall of the furnace.

Hot, warm up to 100ºС, this provides warmth in the steam room. It is often installed where there is no heating all the time. In winter, it will freely raise the temperature in the room quickly enough to the desired level.This will be difficult to do in a cold oven. Of course, there is also a drawback. You cannot control the temperature in the steam room. There is a risk of overheating the room and this will turn the bath into a sauna.

Cold also found a use. If there is no need to rush anywhere, it will show its advantages. It is heated for a long time, but the walls warm up to 50ºС. The heating of the steam room is provided by special channels, they take air from the floor and return it already in a warm form. By this they ensure the stability of the thermal regime in the bath. You can select the desired temperature and humidity.

To enjoy your time in a steam room, there are many factors to consider. The comfort of the state will depend on the correct approach to this issue. The stove is the heart of the sauna, which warms and provides pleasure. And the better you choose the heart, the more stable it will work.

Varieties of models

Depending on the material of manufacture of the stove, there are cast iron, steel and brick. Some varieties contain cast iron and steel parts.

Depending on the functional characteristics, the following types of wood-burning heating devices are distinguished:

- Models that perform only heating functions.

- Heating and cooking stoves cope with the tasks of heating buildings and cooking. In some appliances, in addition to the hob, there is also an oven.

- Units with a tank for heating water for domestic purposes.

- There are also devices that combine all of the above functions.

Depending on the location of the stove, there are wall and corner ones. The latter variety is compact and suitable for installation in a small room. More often these are combined models of cast iron and steel. Wall ovens have a rectangular configuration. They are multifunctional or designed only for heating. The power, lining and dimensions of such devices differ.

Specifications

Dimensions of a home-made heating and cooking stove:

- 1020 mm - width along the back wall and facade;

- 890 mm - the length of the side walls;

- 2240 mm - height from the first row to the beginning of the pipe (32 brick rows).

From one furnace per day we get 2.6 kW or 2260 kcal / h, from two - 3.9 kW or 3400 kcal / h. The design of such a device has a cooking chamber, a drying grate, a ventilation hole, which ensures the removal of odor and steam, an oven, a samovar, a box for heating water. In addition, the unit is equipped with valves that regulate the movement of hot gases, thereby providing the possibility of heating the furnace in both summer and winter modes.

The summer version of this device passes heat under the stove, around the oven and hot water box, then sends it to the smoke channel. The winter type provides for the following: after the device for heating the liquid, heat is alternately supplied to two chambers, and already cooled smoke comes out into the pipe.

Due to its heavy weight (2.6 tons), the stove requires a solid foundation with pre-laid waterproofing. After that, we can proceed to the laying of the furnace, observing the dressing of the seams in the rows.

Popular varieties of long-burning units

Below are modern stoves for heating a house with wood with a long action:

- Okhta fireplace stove of domestic production is a multifunctional unit with a stove and glass doors. It can function as a conventional appliance or with a long burning mode, for which you just need to hermetically close all the doors. On one tab of firewood, the device will work for 3 hours. High-quality steel and imported components are used for production. The cooking surface is made of cast iron. The chimney is connected at the back. Below there is a niche for additional drying of firewood. Wall cladding - ceramics. Specifications:

- thermal power - 8 kW / h;

- heating area - up to 90 squares;

- hob with one burner made of cast iron;

- chimney - 15 cm;

- height - 87 cm;

- depth - 42 cm;

- width - 56 cm;

- Efficiency - up to 85%;

- weight - 131 kg;

- closed firebox.

- The La Nordica multifunctional fireplace stove has a single burner hob and an oven with a heat-resistant enamel coating for easy cleaning. The body is made of steel, and the internal elements are made of cast iron. Specifications:

- made in Italy;

- thermal power - 8.1 kW / h;

- hob with one burner;

- chimney - 15 cm;

- height - 85.1 cm;

- depth - 66.5 cm;

- width - 1.03 m;

- weight - 183 kg;

- Efficiency - up to 81%;

- closed firebox.

- Domestic-made Termofor furnace is inexpensive, has high productivity and attractive design. There are 4 models depending on the area to be heated. Their specifications:

- power - from 6 to 16 kW / h;

- heated volume - from 100 to 250 m³;

- width - 37 cm;

- length - from 55.5 to 93 cm;

- height - 76 cm;

- weight - 42-75 kg.

What should be the oven

To choose a stove that is best suited for a particular bath, you need to answer the question of what requirements it must meet. Good oven:

- It should create the desired temperature and humidity in the steam room, in the rest room and in the sink;

- Be economical;

- Heat water in the required quantities (heating must be regulated);

- Allocation of steam of the required quality for the required number of people;

- Must be warm. After the bath procedures are completed, the heat of the oven should be enough to dry the room, this will ensure a long service life of the bath and reduce the time for cleaning the room after taking the procedures;

- Have a sufficiently capacious water tank, this parameter depends on how many people will use the bath;

- Be non-volatile or have a backup power source (there may be power outages at the wrong time);

- A person should be warmed by heat from all sides, convection of heated air should be used;

- Safety in heat release (no soot and burning, low risk of fire).

brick ovens

For heating in the bath, it is better to use brick stoves, which are less susceptible to corrosion in conditions of high humidity. However, they are suitable not only for the bath room. A brick stove for heating a house with wood is used in regions with power outages and when other types of fuel are not available. Consider the main varieties of such heating structures.

Russian oven

This is a design with significant dimensions, but a large set of functions. Such a structure has an open firebox with a damper and extended smoke channels that run inside the entire structure and heat it well. In some cases, there may be another firebox, on top of which there is a hob.

These are universal designs with many functions:

- You can dry shoes and clothes on the Russian stove.

- The design is convenient in cooking. You can not only cook, but also bake, stew, fry.

- The entire room is heated, as well as a separate heated bed, which is used for rest or sleep.

The efficiency of such a device is only 60%. In winter, the furnace has to be heated constantly, not allowing it to cool, because when it cools down, condensation forms, which causes cracking of the brick.

The advantages of Russian stoves are in their functionality, uniform heating of the house and colorful appearance. The disadvantages include significant size and weight, as well as the need to build a foundation. The cost of such a design due to the large consumption of materials is rather big. Additional disadvantages are low efficiency and the need for regular cleaning.

Dutch

The Dutch woman is a channel-type stove. It has vertical channels for good heating of the walls.If it is planned to heat the bath from a bath stove, then this design is suitable for this purpose due to its compactness.

Dutch benefits:

- compact dimensions;

- quickly warms up due to thin walls;

- after a long break in heating, it quickly reaches full power;

- suitable for home heating up to 70 m².

The disadvantages of such designs are low efficiency (only 40%). The device operates in the smoldering mode. For good traction, the structure needs regular cleaning. Proper operation requires skill and constant supervision.

Swedish

The difference between the Swede and the Dutch is in the universal design. With a compact size, it is more efficient. This is a multifunctional design with a hob, oven and niches for drying.

In fact, this is a channel-type furnace with partial use of the principles of bell-type devices (gases are burned under the furnace roof). The device is suitable for heating two adjacent rooms, therefore it is not used in spacious large houses.

Benefits of the Swedish:

- rapid heating of the room and efficient combustion of solid fuel;

- the lower part warms up well, which helps to heat the floor in the house;

- you can cook food, dry clothes and vegetables, and also just heat up food;

- if you additionally build in a heat exchanger, you can heat water for domestic needs.

The disadvantage of the design is its high cost, because only fireclay bricks are used for masonry. In the lower part, you need to make thermal insulation to avoid heat loss. Do not let the stove cool down during the cold season, because this will cause the destruction of the masonry.

Bell-type furnaces

Bell-type heating devices are the result of modern developments. They heat evenly on each side and retain heat well. In such structures there are no winding channels, so ash practically does not settle in them.

The principle of operation is as follows: the furnace smoke rises under the dome, where it cools down to a certain temperature. After that, it descends along the walls, causing them to heat up. The design usually provides for a cascade of caps, which increases the efficiency of the device.

Such devices are practically devoid of disadvantages. Their advantages include simplicity of design, reasonable cost and low consumption of materials. Additional advantages - fast heating of the room, due to the lack of back draft, the oven with an open damper does not cool down, the device can be supplemented with a heat exchanger and a hob. Even a novice master can assemble such a design.

Universal ovens

Uterna universal furnaces of the W series are designed for heat treatment of small-sized metal products in air at a maximum temperature of 900 °C, 1260 °C 1340 °C.

And also for firing products from ceramics and porcelain, stone mass.

Universal ovens are used in:

laboratories,

educational institutions,

Jewelry and pottery workshops,

dental offices,

In areas of heat treatment of metals.

Technical features of universal ovens

1.1 Furnace frame and doors of the universal oven Uterna W

The light and strong framework of the universal furnace is made of sheet and profile steel. The frame is painted with heat-resistant paint in black, the protective casing is painted with red powder paint.

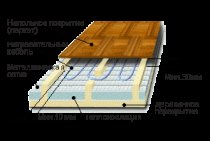

1.2 Thermal insulation of the chamber of the universal oven Uterna W

The insulation of the working chamber of the universal electric furnace is multilayered. The first layer is made of lightweight refractory bricks and evacuated blocks. For the second layer, cotton wool, mats, felt, boards and other fibrous materials are used.

The walls of the working chamber of the furnace are covered with heat-resistant felt, which protects the insulation of the walls from heat shocks.

The front of the chamber is made of fireclay bricks or heat-resistant concrete

1.3 Heating elements of the Uterna W universal oven

Heating elements made of high-quality resistance alloy by KANTHAL A-1 (Sweden), spiral type, open, mounted on refractory ceramic tubes.

1.4 Temperature control and regulation of the universal oven Uterna W

The thermal processes occurring in the universal furnace are controlled and controlled by the OMRON E5CN temperature controller (Japan).

Maximum temperature Up to 1700

digital screen

Visibility of the set temperature on the screen - Visible (green color)

Visibility of the temperature in the chamber on the screen - Visible (red color)

PID or ON-OFF control law

Setting Control Coefficients - Fuzzy / Auto

Visibility of the power received from the mains By indicator and percentage expression

Cycle mode - Keep warm

Possible types of thermocouples "J", "K", "L"

Self-monitoring - When the thermocouple is broken due to interruptions in the internal memory, internal circuit, calibration data.

Accuracy 0.1

Panel dimensions, mm 45×45

Technical characteristics of universal ovens Uterna W

Universal Uterna W-series ovens are custom-made

Some variants of serial universal ovens Uterna series W

| Model | Working chamber mm, (width, height, length) | Power, kWt

|

Volume, L | Тmax, °C | Voltage, V |

| Universal electric oven Uterna W 8

|

190x160x260 | 2.5 | 8 | 1260 | 220 |

| Universal electric oven Uterna W 25

|

250x250x400 | 3.4 | 25 | 1260 | 220 |

| Universal electric oven Uterna W 50

|

400x300x400 | 4.2 | 50 | 1260 | 220 |

| Universal electric oven Uterna W 80

|

400x600x400 | 6 | 100 | 1260 | 220 |

Choosing the right oven

Let's figure out how to choose the right stove for a bath. First of all, you should decide on the volume of the bath itself, the steam room and its thermal insulation, what should be the humidity of the premises, the estimated warm-up time and the number of visitors who will be present at the same time. We get the volume simply: we multiply the length, width and height. In a comparative analysis, it should be taken into account that uninsulated surfaces (without insulation) will require an increase in the power of the coolant, which is equivalent to an increase in the size of the steam room by 1.2 m³. If the steam room is made of wood, the volume of such a room should be increased by 1.5 times.

Furnace mode

The next step in solving the problem of how to choose a stove for a bath is to determine the operating mode of the heating unit.

To understand which model is better, you should familiarize yourself with the principle of operation of such units. The variety of models can lead to confusion and wrong choice. First, clearly imagine what kind of furnace you would like to have, how the furnace should be fired. According to the mode of operation, they can be divided into two classes:

Continuous action. Here, a box made of metal or cast iron is heated by fire, in which stones are placed (they serve to accumulate heat in themselves). These stoves are good because it is possible to start steaming almost immediately when the stones are heated. Such stoves are safe, it is impossible for carbon monoxide to enter the steam room. water falls on the rocks. They have a small wall thickness and small volumes of backfill heating elements. Here, an iron plate separates the stones from the flue gases, the surface temperature of the heater is up to 350ºС. There is no soot on the stones. It is possible to heat the stove repeatedly, even during bath procedures. Such stoves use more fuel, but you can stay in the steam room for any amount of time. Such a furnace needs to be heated constantly due to the low heat capacity. As a result, low efficiency, a lot of furnace material is consumed. But in the steam room there is no formation of soot and carbon monoxide.

Batch ovens. Here the stones of the heater are directly heated. Public baths operate on this principle, in which the firebox is fired with gas all night, warming up cast-iron stoves so that they give off heat during the next day. It takes several hours to heat such a structure in order to warm up the array of stones. The stones are heated by an open flame, the temperature can reach up to 1000ºС. At a lower temperature, the heated elements are covered with soot, which, together with the steam, rises into the air if the stones are poured with water. This is a simple oven design.The big disadvantage is the inability to bathe until the stones and the steam room are completely warmed up. When you open the damper from the stones, carbon monoxide will immediately begin to enter the room. After complete warm-up, the valve in the pipe closes, and the accumulated heat warms up the room, and does not fly out into the pipe. The efficiency of such furnaces is much higher than with constant action. And fuel costs are lower. But on the other hand, giving steam, connoisseurs can catch the pleasant aroma of smoke. Their safety is lower than that of the previous design.

Varieties of long-burning devices

A wood-burning stove for a home can be with or without a water circuit. The first variety is suitable for heating buildings of a large area. But at the same time, it is necessary to install heating radiators and lay pipelines. To heat a small country house, a device without a water circuit is enough.

conventional oven

The design of a conventional long-burning stove is as follows:

- firewood is laid in the combustion chamber of a large volume;

- below is a channel for supplying primary air, which is needed to ignite the fuel;

- above the furnace there is a chamber for secondary combustion of pyrolysis gases;

- two main chambers are separated by a special partition;

- in the upper part of the device there is a pipe for connection to the chimney;

- the glass door of the furnace allows you to use the device as a fireplace.

Water circuit device

Heating wood stoves for a house with a water circuit have the following design:

- In the central part of the unit is the main and largest combustion chamber. It is completely filled with firewood.

- Around the furnace is a pipe with water.

- A grate is installed immediately under the combustion chamber. In many models, its functions are performed by pipes of the water circuit. Due to this, heat extraction begins even at the primary stage of combustion.

- At the very bottom of the unit is an ash pan, which is closed by a separate door.

- At the back there is a horizontal branch pipe for connecting the appliance to the chimney.

- At the bottom on the rear surface there is a flange or a threaded socket for connecting the return heating circuit.

- Nearby is a flange for connecting the supply pipeline of the house heating system.

- Some models have an additional heat exchanger that functions as a cooling circuit.

- Inside the furnace body there are containers with a coolant, where it is heated before being fed into the pipelines.