Calculation of heating of a private house

Arrangement of housing with a heating system is the main component of creating comfortable temperature living conditions in the house

The piping of the thermal circuit includes many elements, so it is important to pay attention to each of them. It is equally important to correctly calculate the heating of a private house, on which the efficiency of the thermal unit, as well as its economy, largely depends. And how to calculate the heating system according to all the rules, you will learn from this article

And how to calculate the heating system according to all the rules, you will learn from this article.

- What is the heating element made of?

- Heating element selection

- Boiler power determination

- Calculation of the number and volume of heat exchangers

- What determines the number of radiators

- Formula and calculation example

- Pipeline heating system

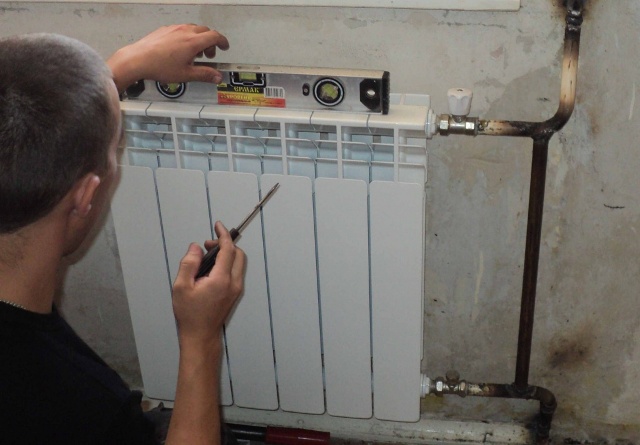

- Installation of heating devices

1 Calculation of the area of heaters in single-pipe heating systems

Surface

heating appliances in

single pipe heating systems

calculated with temperature

coolant at the inlet to each device

tin

, WITH,

the amount of coolant passing

through the device Getc,

kg / h, and the magnitude of the heat load

instrument Qetc,

Tue

Payment

area of each heater

carried out in a certain

sequences:

a)

The calculation scheme of the riser is drawn,

the type of heater is accepted

and installation location, supply scheme

coolant into the device, design

device node. On the calculation chart

pipe diameters, thermal

device load equal to heat loss

this room, Qetc.,

Tue

b)

The total amount of water is calculated

kg/h circulating through the riser, according to the formula:

(4.1)

where

—

additional

heat flow, (for this type

heating appliances=

1,02);

—

additional loss factor

heat of heating devices at external

fences, taken according to table 4.1;

With

\u003d 4.187 kJ / (kg.оС)

specific mass heat capacity of water;

–total

heat loss in rooms served

stand-up, W.

table

4.1 - Accounting factor for additional

heat losses of heating devices

at the outer fences

-

Name

heaterCoefficient

accounting,

at the outer wall, including under

light openingsRadiator

cast iron sectional1,02

Featured

heating unit pipeline diameters

devices are shown in Table 4.2.

table

4.2 - Recommended pipeline diameters

heater assembly

-

Name

riser nodeDiameter

pipes Dat,

mmriser

closing

siteeyeliners

1

3

4

5

floor riser

with offset bypass15

20

25

15

20

20

15

20

25/20

floor riser

with axial closing section and stopcock

KRP type15

20

15

15

15

20

floor riser

flowing15

20

—

—

15

20

That

same15

20

15

20

15

20

Knot

upper floor with lower wiring

and crane type KRP15

20

15

15

15

20

That

same15

20

15

20

15

20

Thermal

load Qst,

W and total water Gst,

kg/h, circulating in the riser, reduced

in table 4.3.

For instance:

Qst1

determined by the summation of heat losses

in rooms 101, 201, 301; Qst2

- in rooms 102, 202, 302.

table

4.3 - Summary table for calculating the flow rate

water in risers

-

No. st

Qst,

TueGst,

kg/h1

2

3

…

Qst

Gst

V

this course project we carry out

estimated calculation of heating

appliances.

Estimated

outer surface area of the heating

device, m2,

is determined by the formula:

(4.2)

where Qetc

– thermal load on the device, W,

Qetc=Qpom;

qnom

- the average value of the nominal

heat flux density, W/m2:

—

for cast iron radiators - qnom=595,W/m2.

Estimated

number of radiator sections per room

(riser) is determined by the formula:

(4.3)

where

a1

- the area of one section of the brand radiator

M140-AO (GOST

8690-75),

m2,a1

= 0.254 m2;

3

is a correction factor that takes into account

number of sections in one radiator; 3

=;

4

is a correction factor that takes into account

how to install a radiator in a room;

4

= 1.

table

4.4 - Correction factor values

β3,

taking into account the number of sections in one

radiator brand MS 140-AO

|

Number |

before |

15-20 |

21 |

|

β3 |

1,0 |

0,98 |

0,96 |

At

rounding a fractional number of elements

devices of any type up to the whole is allowed

reduce their calculated area Aetc

no more than 5% (0.1 m2).

Otherwise, the nearest

heating device.

results

calculations of heating devices of each

riser of the water heating system

summarized in table 4.5.

table

4.5 - The results of the calculation of heating

hot water heating devices

|

№ premises |

Qetc, Tue |

Aetc, m2 |

, section |

, |

Heating appliances

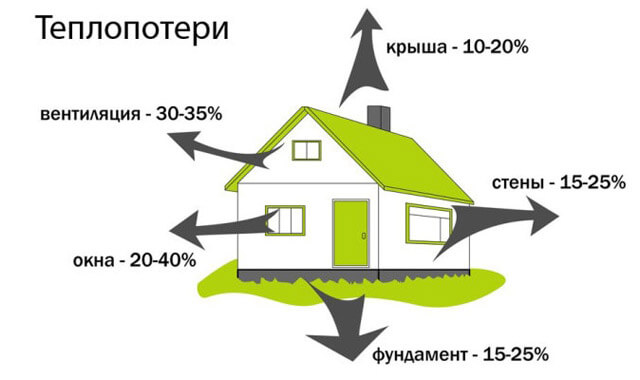

How to calculate the heating in a private house for individual rooms and choose the appropriate heating devices for this power?

The very methodology for calculating the heat demand for a separate room is completely identical to that given above.

For example, for a room of 12 m2 with two windows in the house we described, the calculation will look like this:

- The volume of the room is 12*3.5=42 m3.

- The basic thermal power will be equal to 42 * 60 \u003d 2520 watts.

- Two windows will add another 200 to it. 2520+200=2720.

- The regional coefficient will double the demand for heat. 2720*2=5440 watts.

How to convert the obtained value into the number of radiator sections? How to choose the number and type of heating convectors?

Manufacturers always indicate the heat output for convectors, plate radiators, etc. in the accompanying documentation.

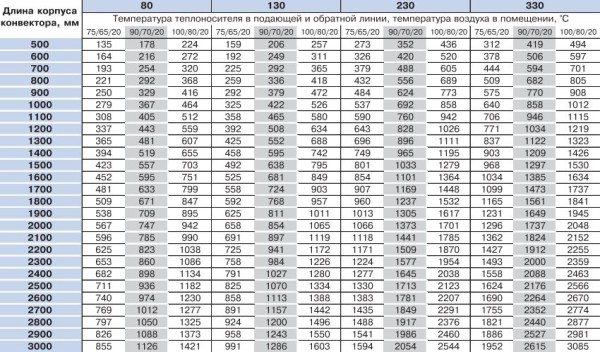

Power table for convectors VarmannMiniKon.

- For sectional radiators, the necessary information can usually be found on the websites of dealers and manufacturers. In the same place, you can often find a calculator for converting kilowatts in a section.

- Finally, if you are using sectional radiators of unknown origin, with their standard size of 500 millimeters along the axes of the nipples, you can focus on the following average values:

Thermal power per section, watts

In an autonomous heating system with its moderate and predictable coolant parameters, aluminum radiators are most often used. Their reasonable price is very pleasantly combined with a decent appearance and high heat dissipation.

In our case, aluminum sections with a power of 200 watts will need 5440/200=27 (rounded).

Placing so many sections in one room is not a trivial task.

As always, there are a couple of subtleties.

- When a multi-section radiator is connected sideways, the temperature of the last sections is much lower than the first; accordingly, the heat flux from the heater decreases. A simple instruction will help to solve the problem: connect the radiators according to the “bottom down” scheme.

- Manufacturers indicate the heat output for a temperature delta between the coolant and the room at 70 degrees (for example, 90 / 20C). As it decreases, the heat flow will decrease.

A special case

Often, self-made steel registers are used as heating devices in private homes.

Please note: they attract not only by their low cost, but also by their exceptional tensile strength, which is very useful when connecting a house to a heating main. In an autonomous heating system, their attractiveness is negated by their unpretentious appearance and low heat transfer per unit volume of the heater.

Let's just say - not the top of aesthetics.

However: how to estimate the thermal power of a register of known size?

For a single horizontal round pipe, it is calculated by a formula of the form Q \u003d Pi * Dn * L * k * Dt, in which:

- Q is the heat flux;

- Pi - the number "pi", taken equal to 3.1415;

- Dn is the outer diameter of the pipe in meters;

- L is its length (also in meters);

- k is the thermal conductivity coefficient, which is taken equal to 11.63 W / m2 * C;

- Dt is the temperature delta, the difference between the coolant and the air in the room.

In a multi-section horizontal register, the heat transfer of all sections, except for the first, is multiplied by 0.9, since they give off heat to the upward flow of air heated by the first section.

In a multi-section register, the lower section gives off the most heat.

Let's calculate the heat transfer of a four-section register with a section diameter of 159 mm and a length of 2.5 meters at a coolant temperature of 80 C and an air temperature in the room of 18 C.

- The heat transfer of the first section is 3.1415*0.159*2.5*11.63*(80-18)=900 watts.

- The heat output of each of the remaining three sections is 900 * 0.9 = 810 watts.

- The total thermal power of the heater is 900+(810*3)=3330 watts.

The choice of coolant

Most often, water is used as the working fluid for heating systems. However, antifreeze can be an effective alternative solution. Such a liquid does not freeze when the ambient temperature drops to a critical mark for water. Despite the obvious advantages, the price of antifreeze is quite high. Therefore, it is mainly used for heating small buildings.

Filling heating systems with water requires preliminary preparation of such a coolant. The liquid must be filtered from dissolved mineral salts. For this, specialized chemical reagents that are commercially available can be used. Moreover, all air must be removed from the water in the heating system. Otherwise, the efficiency of space heating may be reduced.

Calculation of the volume of water in the heating system with an online calculator

Each heating system has a number of significant characteristics - rated heat output, fuel consumption and coolant volume. Calculation of the volume of water in the heating system requires an integrated and scrupulous approach. So, you can find out which boiler, what power to choose, determine the volume of the expansion tank and the required amount of liquid to fill the system.

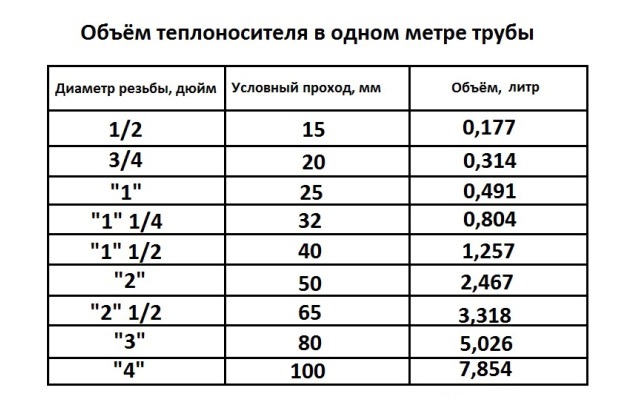

A significant part of the liquid is located in pipelines, which occupy the largest part in the heat supply scheme.

Therefore, to calculate the volume of water, you need to know the characteristics of the pipes, and the most important of them is the diameter, which determines the capacity of the liquid in the line.

If the calculations are made incorrectly, the system will not work efficiently, the room will not warm up at the proper level. An online calculator will help you make the correct calculation of the volumes for the heating system.

Calculator of liquid volume in the heating system

The heating system can use pipes of various diameters, especially in collector circuits. Therefore, the volume of liquid is calculated by the following formula:

The volume of water in the heating system can also be calculated as the sum of its components:

In sum, these data allow you to calculate most of the volume of the heating system. However, in addition to pipes, there are other components in the heat supply system. To calculate the volume of the heating system, including all important components of the heat supply, use our online heating system volume calculator.

Advice

Making a calculation with a calculator is very easy. It is necessary to enter into the table some parameters regarding the type of radiators, the diameter and length of the pipes, the volume of water in the collector, etc. Then you need to click on the "Calculate" button and the program will give you the exact volume of your heating system.

You can check the calculator using the above formulas.

An example of calculating the volume of water in the heating system:

Values of the volumes of various components

The volume of water in the radiator:

- aluminum radiator - 1 section - 0.450 liters

- bimetallic radiator - 1 section - 0.250 liters

- new cast iron battery 1 section - 1,000 liters

- old cast iron battery 1 section - 1,700 liters.

The volume of water in 1 linear meter of the pipe:

- ø15 (G ½") - 0.177 liters

- ø20 (G ¾") - 0.310 liters

- ø25 (G 1.0″) - 0.490 liters

- ø32 (G 1¼") - 0.800 liters

- ø15 (G 1½") - 1.250 liters

- ø15 (G 2.0″) - 1.960 liters.

To calculate the entire volume of liquid in the heating system, you must also add the volume of coolant in the boiler. These data are indicated in the accompanying passport of the device, or take approximate parameters:

- floor boiler - 40 liters of water;

- wall-mounted boiler - 3 liters of water.

The choice of a boiler directly depends on the volume of liquid in the heating system of the room.

The main types of coolants

There are four main types of fluid used to fill heating systems:

- Water is the simplest and most affordable coolant that can be used in any heating systems. Together with polypropylene pipes that prevent evaporation, water becomes an almost eternal heat carrier.

- Antifreeze - this coolant will cost more than water, and is used in systems of irregularly heated rooms.

- Alcohol-containing coolants are an expensive option for filling the heating system. A high-quality alcohol-containing liquid contains from 60% alcohol, about 30% water and about 10% of the volume are other additives. Such mixtures have excellent non-freezing properties, but are flammable.

- Oil - as a heat carrier it is used only in special boilers, but it is practically not used in heating systems, since the operation of such a system is very expensive. Also, the oil heats up for a very long time (warming up to at least 120 ° C is required), which is technologically very dangerous, while such a liquid cools down for a very long time, maintaining a high temperature in the room.

In conclusion, it should be said that if the heating system is being modernized, pipes or batteries are being installed, then its total volume must be recalculated, according to the new characteristics of all elements of the system.

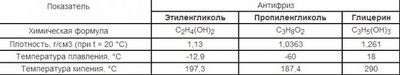

Antifreeze parameters and types of coolants

The basis for the production of antifreeze is ethylene glycol or propylene glycol. In their pure form, these substances are very aggressive environments, but additional additives make antifreeze suitable for use in heating systems. The degree of anti-corrosion, the service life and, accordingly, the final cost depend on the additives introduced.

The main task of additives is to protect against corrosion. Having a low thermal conductivity, the rust layer becomes a heat insulator. Its particles contribute to clogging of channels, disable circulation pumps, lead to leaks and damage in the heating system.

Moreover, the narrowing of the inner diameter of the pipeline entails hydrodynamic resistance, due to which the coolant velocity decreases, and energy costs increase.

Antifreeze has a wide temperature range (from -70°C to +110°C), but by changing the proportions of water and concentrate, you can get a liquid with a different freezing point. This allows you to use intermittent heating mode and turn on space heating only when needed. As a rule, antifreeze is offered in two types: with a freezing point of no more than -30 ° C and no more than -65 ° C.

In industrial refrigeration and air conditioning systems, as well as in technical systems with no special environmental requirements, antifreeze based on ethylene glycol with anti-corrosion additives is used. This is due to the toxicity of the solutions.For their use, expansion tanks of a closed type are required; use in double-circuit boilers is not allowed.

Other possibilities of application were received by a solution based on propylene glycol. This is an environmentally friendly and safe composition, which is used in the food, perfume industry and residential buildings. Wherever it is required to prevent the possibility of toxic substances entering the soil and groundwater.

The next type is triethylene glycol, which is used at high temperatures (up to 180 ° C), but its parameters have not been widely used.

Heat transfer requirements

You need to immediately understand that there is no ideal coolant. Those types of coolants that exist today can only perform their functions in a certain temperature range. If you go beyond this range, then the quality characteristics of the coolant can change dramatically.

The heat carrier for heating must have such properties that will allow for a certain unit of time to transfer as much heat as possible. The viscosity of the coolant largely determines what effect it will have on the pumping of the coolant throughout the heating system for a specific time interval. The higher the viscosity of the coolant, the better its characteristics.

Physical properties of coolants

The coolant should not have a corrosive effect on the material from which the pipes or heating devices are made.

If this condition is not met, then the choice of materials will become more limited. In addition to the above properties, the coolant must also have lubricity. The choice of materials that are used for the construction of various mechanisms and circulation pumps depends on these characteristics.

In addition, the coolant must be safe based on its characteristics such as: ignition temperature, release of toxic substances, vapor flash. Also, the coolant should not be too expensive, by studying the reviews, you can understand that even if the system works efficiently, it will not justify itself from a financial point of view.

A video on how the system is filled with coolant and how the coolant is replaced in the heating system can be viewed below.

Calculation of water consumption for heating Heating system

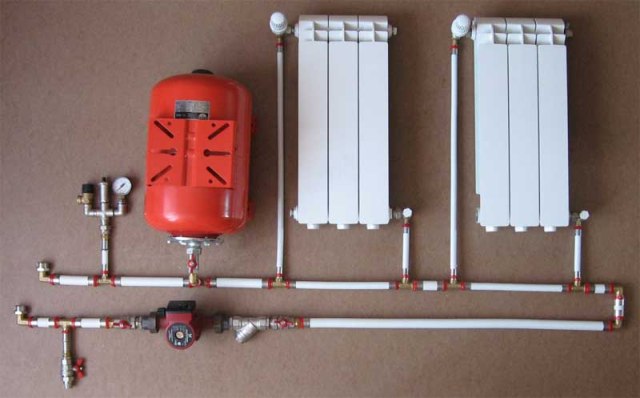

The heating structure includes a boiler, connection system, air vents, thermostats, manifolds, fasteners, expansion tank, batteries, pressure increasing pumps, pipes.

Any factor is definitely important. Therefore, the choice of installation parts must be done correctly. On the open tab, we will try to help you choose the right installation parts for your apartment.

Mansion heating installation includes important devices.

Page 1

The estimated consumption of network water, kg / h, to determine the diameters of pipes in water heating networks with high-quality regulation of heat supply, should be determined separately for heating, ventilation and hot water supply using the formulas:

for heating

(40)

maximum

(41)

in closed heating systems

hourly average, with a parallel scheme for connecting water heaters

(42)

maximum, with a parallel scheme for connecting water heaters

(43)

hourly average, with two-stage schemes for connecting water heaters

(44)

maximum, with two-stage schemes for connecting water heaters

(45)

Important

In formulas (38 - 45), the calculated heat fluxes are given in W, the heat capacity c is assumed to be equal. The calculation according to these formulas is carried out in stages, for temperatures.

The total estimated consumption of network water, kg / h, in two-pipe heating networks in open and closed heat supply systems with high-quality regulation of heat supply should be determined by the formula:

(46)

The coefficient k3, which takes into account the share of the average hourly water consumption for hot water supply when regulating according to the heating load, should be taken according to table No. 2.

Table number 2. Coefficient values

r-Radius of the circle, equal to half the diameter, m

Q-water flow m 3 / s

D-Inner pipe diameter, m

V-coolant flow rate, m/s

Resistance to the movement of the coolant.

Any coolant moving inside the pipe tends to stop its movement. The force that is applied to stop the movement of the coolant is the resistance force.

This resistance is called the loss of pressure. That is, a moving coolant through a pipe of a certain length loses pressure.

Head is measured in meters or pressures (Pa). For convenience in the calculations, it is necessary to use meters.

Sorry, but I'm used to stating head loss in meters. 10 meters of water column create 0.1 MPa.

In order to better understand the meaning of this material, I recommend that you follow the solution of the problem.

Task 1.

Water flows in a pipe with an inner diameter of 12 mm at a speed of 1 m/s. Find expense.

Solution: You need to use the above formulas:

Advantages and disadvantages of water

The undoubted advantage of water is the highest heat capacity among other liquids. It requires a significant amount of energy to heat up, but at the same time it allows you to transfer a considerable amount of heat during cooling. As the calculation shows, when 1 liter of water is heated to a temperature of 95°C and cooled to 70°C, 25 kcal of heat will be released (1 calorie is the amount of heat needed to heat 1 g of water by 1°C).

Leakage of water during depressurization of the heating system will not have a negative impact on health and well-being. And in order to restore the initial volume of coolant in the system, it is enough to add the missing amount of water to the expansion tank.

The disadvantages include freezing water. After starting the system, constant monitoring of its smooth operation is required. If there is a need to leave for a long time or for some reason the supply of electricity or gas is suspended, then the coolant will have to be drained from the heating system. Otherwise, at low temperatures, freezing, the water will expand and the system will break.

The next drawback is the ability to cause corrosion in the internal components of the heating system. Water that is not properly prepared can contain an increased level of salts and minerals. When heated, this contributes to the appearance of precipitation and the growth of scale on the walls of the elements. All this leads to a decrease in the internal volume of the system and a decrease in heat transfer.

To avoid this disadvantage or minimize it, they resort to water purification and softening by introducing special additives into its composition, or other methods are used.

Boiling is the simplest and most well-known method. During processing, a significant part of the impurities will be deposited in the form of scale on the bottom of the tank.

Using a chemical method, a certain amount of slaked lime or soda ash is added to the water, which will lead to the formation of sediment. After the end of the chemical reaction, the precipitate is removed by filtering the water.

A smaller amount of impurities is contained in rain or melt water, but for heating systems, distilled water is the best option, in which these impurities are completely absent.

If there is no desire to deal with shortcomings, then you should think about an alternative solution.

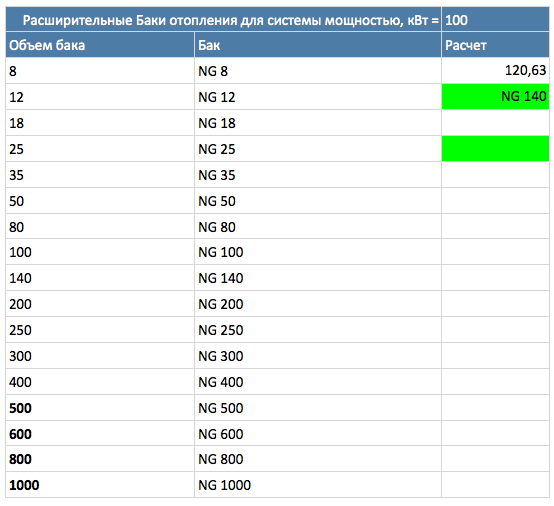

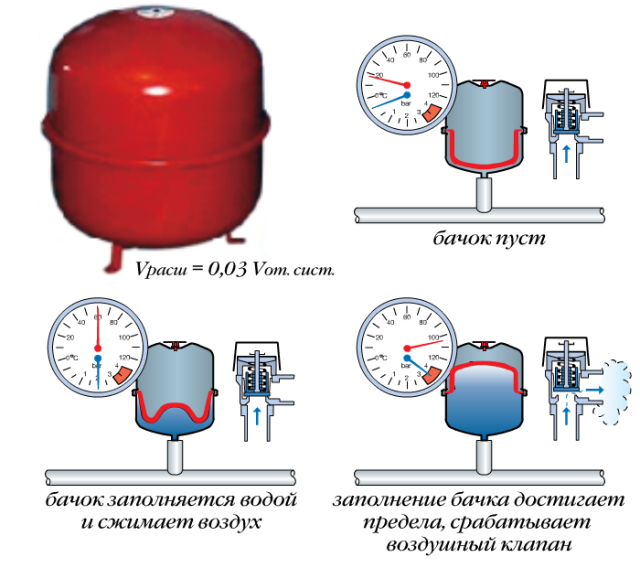

Expansion tank

And in this case, there are two calculation methods - simple and accurate.

simple circuit

A simple calculation is utterly simple: the volume of the expansion tank is taken equal to 1/10 of the volume of the coolant in the circuit.

Where to get the value of the volume of the coolant?

Here are a couple of simple solutions:

- Fill the circuit with water, bleed the air, and then drain all the water through the bleeder into any measuring utensils.

- In addition, roughly the volume of a balanced system can be calculated from the calculation of 15 liters of coolant per kilowatt of boiler power. So, in the case of a 45 kW boiler, the system will have approximately 45 * 15 = 675 liters of coolant.

Therefore, in this case, a reasonable minimum would be an expansion tank for a heating system of 80 liters (rounded up to the standard value).

Standard expansion tanks.

Exact scheme

More precisely, you can calculate the volume of the expansion tank with your own hands using the formula V = (Vt x E) / D, in which:

- V is the desired value in liters.

- Vt is the total volume of the coolant.

- E is the expansion coefficient of the coolant.

- D is the expansion tank efficiency factor.

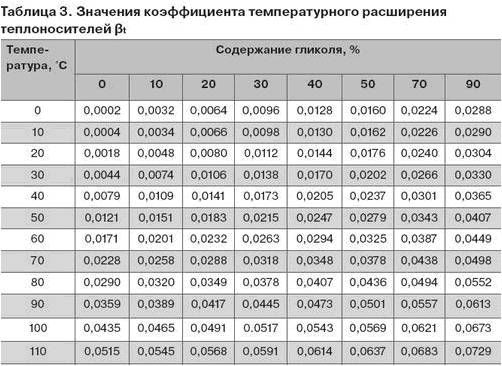

The expansion coefficient of water and lean water-glycol mixtures can be taken from the following table (when heated from an initial temperature of +10 C):

And here are the coefficients for coolants with a high content of glycol.

The tank efficiency factor can be calculated using the formula D = (Pv - Ps) / (Pv + 1), in which:

Pv is the maximum pressure in the circuit (setting pressure of the safety valve).

Hint: usually it is taken equal to 2.5 kgf / cm2.

Ps is the static pressure of the circuit (it is also the tank charging pressure). It is calculated as 1/10 of the difference in meters between the level of the tank and the upper point of the circuit (an overpressure of 1 kgf / cm2 raises the water column by 10 meters). A pressure equal to Ps is created in the air chamber of the tank before filling the system.

Let's calculate tank requirements for the following conditions as an example:

- The height difference between the tank and the upper point of the contour is 5 meters.

- The power of the heating boiler in the house is 36 kW.

- The maximum water heating is 80 degrees (from 10 to 90C).

- The tank efficiency coefficient will be equal to (2.5-0.5)/(2.5+1)=0.57.

Instead of calculating the coefficient, you can take it from the table.

- The volume of coolant at the rate of 15 liters per kilowatt is 15 * 36 = 540 liters.

- The coefficient of expansion of water when heated by 80 degrees is 3.58%, or 0.0358.

- Thus, the minimum tank volume is (540*0.0358)/0.57=34 liters.

Correct calculation of the coolant in the heating system

By the combination of features, the undisputed leader among heat carriers is ordinary water. It is best to use distilled water, although boiled or chemically treated water is also suitable - to precipitate salts and oxygen dissolved in water.

However, if there is a possibility that the temperature in the room with the heating system will drop below zero for some time, then water will not be suitable as a heat carrier. If it freezes, then with an increase in volume, there is a high probability of irreversible damage to the heating system. In such cases, an antifreeze-based coolant is used.

Circulation pump

Two parameters are important for us: the pressure created by the pump and its performance.

In the photo - a pump in the heating circuit.

With pressure, everything is not simple, but very simple: a circuit of any length that is reasonable for a private house will require a pressure of no more than the minimum 2 meters for budget devices.

Reference: a difference of 2 meters makes the heating system of a 40-apartment building circulate.

The simplest way to choose the performance is to multiply the volume of coolant in the system by 3: the circuit must turn around three times per hour. So, in a system with a volume of 540 liters, a pump with a capacity of 1.5 m3 / h (rounded) is sufficient.

A more accurate calculation is performed using the formula G=Q/(1.163*Dt), in which:

- G - productivity in cubic meters per hour.

- Q is the power of the boiler or section of the circuit where circulation is to be provided, in kilowatts.

- 1.163 is a coefficient tied to the average heat capacity of water.

- Dt is the temperature delta between the supply and return of the circuit.

Hint: for a standalone system, the standard settings are 70/50 C.

With the notorious boiler heat output of 36 kW and a temperature delta of 20 C, the pump performance should be 36 / (1.163 * 20) \u003d 1.55 m3 / h.

Sometimes performance is indicated in liters per minute. It's easy to count.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms.Exceeding the permissible volume can lead to increased wear of the heater, as well as significant energy consumption.

The required amount of heating medium is calculated according to the following formula: Total volume = V boiler + V radiators + V pipes + V expansion tank

Boiler

The calculation of the power of the heating unit allows you to determine the boiler capacity indicator. To do this, it is enough to take as a basis the ratio at which 1 kW of thermal energy is sufficient to efficiently heat 10 m2 of living space. This ratio is valid in the presence of ceilings, the height of which is not more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the volume of equipment in the passport data.

Therefore, if the correct power calculation is performed, there will be no problems with determining the required volume.

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross section of the pipeline according to the formula - S = π × R2, where:

- S - cross section;

- π is a constant constant equal to 3.14;

- R is the inner radius of the pipes.

Having calculated the value of the cross-sectional area of \u200b\u200bthe pipes, it is enough to multiply it by the total length of the entire pipeline in the heating system.

Expansion tank

It is possible to determine what capacity the expansion tank should have, having data on the coefficient of thermal expansion of the coolant. For water, this indicator is 0.034 when heated to 85 °C.

When performing the calculation, it is enough to use the formula: V-tank \u003d (V syst × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-syst - the total volume of liquid in the remaining elements of the heating system;

- K is the expansion coefficient;

- D - the efficiency of the expansion tank (indicated in the technical documentation).

Currently, there is a wide variety of individual types of radiators for heating systems. In addition to functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first calculate their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the technical data sheet of the product. In the absence of such information, you can navigate according to the average parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 l per section;

- aluminum - 0.4 l per section.

The following example will help you understand how to correctly calculate the value. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make the calculation: 5 × 6 × 0.4 \u003d 12 liters.

As you can see, the calculation of the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in the system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, the system is filled by about 90%, after which the performance is checked. Then bleed the accumulated air and continue filling.

During the operation of the heating system, a natural decrease in the level of the coolant occurs as a result of convection processes. In this case, there is a loss of power and productivity of the boiler. This implies the need for a reserve tank with a working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it.

Selection of heat meters

The selection of a heat meter is carried out on the basis of the technical conditions of the heat supply organization and the requirements of regulatory documents. As a rule, the requirements are for:

- accounting scheme

- the composition of the metering unit

- measurement errors

- the composition and depth of the archive

- flow sensor dynamic range

- availability of data acquisition and transmission devices

For commercial calculations, only certified heat meters registered in the State Register of Measuring Equipment are allowed. In Ukraine, it is forbidden to use heat energy meters for commercial calculations, the flow sensors of which have a dynamic range of less than 1:10.