Methods and rules of calculation

The calculation rules have their own tolerances, you need to know them before calculating the pipe diameter. There are several calculation methods, they depend on who and for what conditions they will be executed:

- High-precision, they are used in the manufacture of boilers and are carried out by the design departments of equipment manufacturers.

- Approximate calculations performed by non-specialists based on graphs, charts and tables.

- Automatic, obtained on the basis of online calculation.

Accurate calculations are understood as those in which many factors are taken into account:

flue gas temperature at the outlet of the boiler and from the pipe, the speed of movement of gases in the furnace and in sections of the smoke exhaust system, the loss of gas pressure along the movement in the gas-air path. Most of these parameters are obtained experimentally by manufacturers of boiler equipment and depend on the brand of the boiler, so this type of calculation is practically not available to users.

With regard to the approximate method, before calculating the diameter of the chimney, the characteristics of the volume of the combustion chamber are taken into account. To determine the geometric parameters of pipes, there are various tables and graphs

For example, with a firebox with dimensions of 500x400 mm, a round pipe from 180 to 190 mm is required.

The third method is based on the use of special online calculators. They take into account almost all important parameters, so they give very accurate results. In order to use them, the operator will need to know a lot of starting data.

exact method

Accurate calculations are based on a rather laborious mathematical base. To do this, you will need to know the fundamental geometric characteristics of the pipe, the heat generator and the fuel used. For such a calculation, you can use the following method for determining the diameter of a round pipe for a wood stove.

Input calculation parameters:

- Indications of T gases at the outlet of the boiler t - 151 C.

- The average velocity of the flue gases is 2.0 m/s.

- The estimated length of the pipe, which is standardly used for stoves, is 5 m.

- The mass of burned firewood B= 10.0 kg/h.

Based on these data, the volume of exhaust gases is first calculated:

V=[B*V*(1+t/272)]/3600 m3/s

Where V is the volume of air masses that are necessary for the completeness of fuel combustion - 10 m3 / kg.

V=10*10*1.55/3600=0.043 m3/s

d=√4*V/3.14*2=0.166 mm

Swedish method

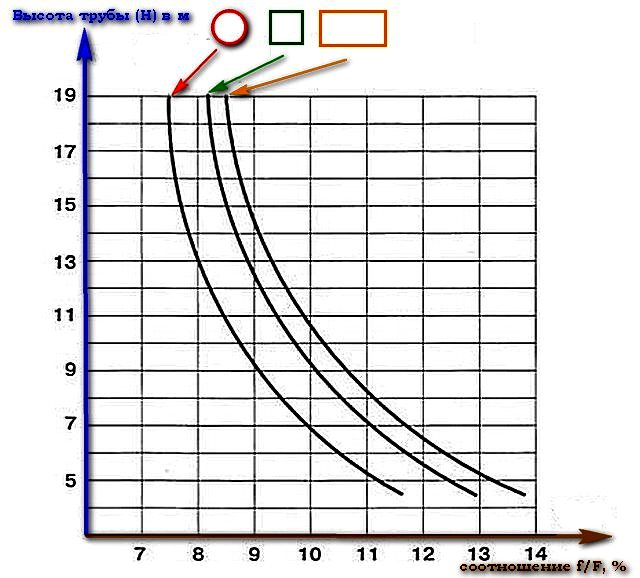

Chimney calculations are often performed using this method, although it is more accurate when calculating the flue systems of fireplaces with open fireboxes.

According to this method, the size of the combustion chamber and its gas volume are used for calculation. For example, for a fireplace with a portal 8 masonry high and 3 masonry wide, which corresponds to the size F = 75.0 x 58.0 cm = 4350 cm2. The ratio F / f = 7.6% is calculated and it is determined from the graph that a rectangular chimney with this size cannot work, perhaps the use of a circular section design, but its length must be at least 17 meters, which is not really high. In this case, it is better to make a choice from the reverse, according to the minimum required diameter section. It is easy to find it by the height of the building, for example, for a 2-storey house, the height from the fireplace to the chimney cap is 11 m.

F/f ratio= 8.4%. f = Fх 0.085 = 370.0 cm2

D= √4 x 370 / 3.14 = 21.7 cm.

Is there a universal chimney

How to calculate a chimney for a fireplace and other heating systems? Is it possible to install such a channel that would correspond to any type of fuel, if its material is always selected exactly in accordance with the type of a particular fuel? At the moment, such a universal mechanism has not been invented. There are some systems that work pretty well with some types of fuel. However, they are far from quality.

Internal section

The calculation of the cross section of the chimney is a mandatory requirement for the quality of the exhaust system.

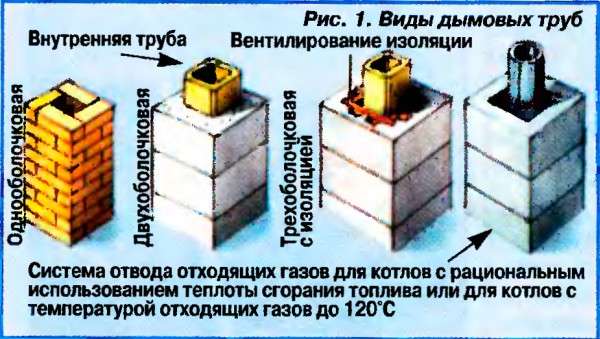

Cylindrical shape. The heating of the gas heating system is uneven, because of this, the movement of smoke through the pipe is carried out in a spiral. Therefore, the optimal shape of the pipe will be cylindrical. It is she who will provide the perfect traction.

If you design a square-shaped chimney, eddies cannot form due to lack of draft, and smoke will collect in the corners. And the quality of the exhaust system and your health depend on the speed of the exhaust force.

Also, the cylindrical shape of the chimney channel is suitable for new generation boilers (stop strat).

We watch the video, the calculation of a square chimney:

The principle of operation of such heating devices is created taking into account the high-speed heating of the heating system.

The nuances of planning and factors affecting the parameters of the chimney

To design an impeccable option, it is unimaginable to manage only with calculations and diagrams. The flue intersects with important structural parts of the house, which means that it certainly affects the plan. In the case when the owner wants to install closer to the ridge, he may face many difficulties. Therefore, it is better to place the chimney at a great distance.

The height must be selected taking into account the design features:

- Apartment design;

- chimney geometry;

- number of residential floors;

- ease of installation of chimney channels;

- potential accessibility for maintenance of the boiler unit and smoke ventilation unit;

- type of building material used during the construction of partitions and truss systems;

- the number of heat sources connected to a single chimney.

It should be noted that, in accordance with the norms for the installation of heat supply systems in individual dwellings, it is allowed to connect only one boiler to one flue. In special versions, it is allowed to carry out the removal of boiler gases through one chimney from 2 units. For the proper functioning of heat engineering equipment, a cut should be placed in the middle of such a design. Furnaces in multi-storey buildings up to 3 floors are placed one on top of the other, and their chimneys in a similar manner, so that flue gases can escape through one shaft.

The vast majority of designers prefer the use of channels that are mounted at the time of the erection of the walls of buildings in brickwork - they can significantly save money on building materials.

A chimney that cannot be installed in a main wall is installed with smoke ventilation ducts as close as possible to the ridge run.

The construction of a wall chimney is carried out using a template-buoy, lined with brickwork on all sides. It is made in the form of a wooden box, with a cross section equal to the diameter of the chimney. Having reached the top of the template, it is moved higher, after which it is laid over again. The process continues until the construction of the bearing wall is completed.

Often, brick pipes are located on the inside of the main walls; in this case, the most efficient heating of the cottage can be organized, with low specific heating costs. Sometimes smoke ducts are placed in the outer walls, however, this method will be the most costly and will cause significant effort in maintaining the smoke ducts. In the option of laying the smoke ventilation system in the outer wall, the width of the pipe wall is greater.

The perfect calculation of the chimney increases the efficiency of the heating source of the house and guarantees the safe operation of the heating sources. Otherwise, toxic gases can enter the living space and harm the health of residents.

Factors affecting performance

With regard to the parameters of the chimney, it is impossible to say that the higher it is, the more preferable. An extremely long or wide flue increases the cost of building chimneys. A boiler or furnace with a similar chimney will wear out with excess draft, the fuel will be burned quickly, and a significant part of it will uselessly escape into the atmosphere, reducing the efficiency of the heat supply system.

The size of the section only partially affects the length of the chimney pipe. In other words, the user will not be able to increase its diameter to improve efficiency. In this connection, experts do not advise experimenting with the dimensions of the sections of the stove pipes, adjusting them to certain height indicators, for example, making them below 5 m or above 7 m. The thrust will be the same throughout the structure, on the contrary, a very large pipe diameter can reduce - for turbulence, tearing off the torch from the gas nozzle.

The calculation of the length of the pipe depends more on the height of the object on which it is placed, and the type of roofing. The indicator above the roof level is a more important indicator for calculating the optimal pipe section.

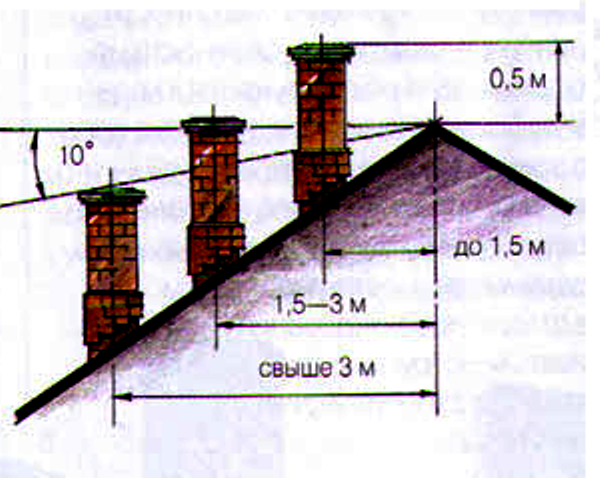

The length of the chimney pipe from the grate to the exit point must be at least 5 m. If the roof is made in the form of a flat structure, then the elevation of the pipe must be at least 50.0 cm. 1.5 m, it must rise at least 50.0 cm in relation to the extreme or enclosing parapet. If it is within 1.5–3.0 m from the ridge, then its top should not be lower than it or the parapet.

In some cases, the pipe is located further than 3 m from the ridge line, then its smallest height is calculated at an angle of 10 degrees relative to the horizon. In case there are large high-rise objects nearby, and the boiler or fireplace runs on wood, then the height of the chimney is selected above the roof of the nearby houses.

Recommendations for pipe placement and construction:

- It is not necessary to equip chimneys near the roof windows so that an accidental wind does not blow combustion products into the attic.

- Similarly, it is not recommended to erect exhaust pipes and ventilation ducts in the valleys, so that snow pockets are not created.

- When the outer section of the chimney exits, it is not necessary to rigidly strengthen it with the roof structure and rafters, since the entire roof will suffer if the pipe collapses with a hurricane.

A competent calculation of all the characteristics of the future chimney scheme is a guarantee of its performance and efficient operation of all boiler equipment. A flaw in the calculations, which can be made at the design stage, will lead to an emergency mode with subsequent destruction of the system. Simple calculations, based on many years of experience of specialists, enable the user to perform them qualitatively to determine the technical parameters of the chimney.

Types of chimneys

When choosing a stove system, one should take into account the material from which the house is built: wood or brick. A wooden mansion burns faster and is less reliable in terms of fire safety compared to a brick house

When installing a pipe, it is very important to correctly calculate so that the combustion products are drawn out of the room without harm to health.

When installing the pipe, it is necessary to correctly install the draft, which ensures the safe removal of carbon monoxide. The optimum height of the pipe is at least five meters.

- Select the appropriate material

- Calculate the height of the chimney

- Calculate the cross section of the chimney

- Calculate the diameter of the chimney

It is necessary to take into account the fuel with which the heater will be heated. Depending on it, you should choose the right material for the pipe:

- Brick

- asbestos-cement

- fireclay

- Iron

- Ceramic

The operational properties of the brick channel are small. The service life is no more than seven years, and the level of safety also fails. When laying, a reliable solid brick is important, which is then covered with a layer of putty for sealing.

Asbestos-cement pipe is very cheap, but not environmentally friendly. When heated, it exudes carcinogens. The most reliable, but also expensive material for the pipe is fireclay. It meets all fire safety requirements, is reliable and practical. The service life of fireclay is quite long.

We watch video types of chimney systems:

The steel chimney is the most durable of all thanks to its modular design. You can always replace the damaged pipe section with a new one. The steel channel is plastic, and any number of elbows can be created from it. The steel structure rotates and bends in any direction. This is a universal material for fireplaces and stoves of any modification.

A chimney made of ceramic material is installed in rooms with a large space. The most popular is the chimney, combined with two moves. It looks like a pipe with two chimney channels.

Errors in the construction of chimneys

The faster the heating occurs, the more economically the boiler works, switching to standby mode.

Square shape. But for wood-burning heating systems, a square sectional shape will be just better. To calculate the cross section of the chimney, the type of fuel is fundamental. Wood fuel does not require a lot of traction, like gas, so the round section will simply contribute to the weathering of heat from the house.

Inner diameter

The correct calculation of the diameter of the chimney will ensure the smooth functioning of the entire heating system at home. You can calculate the diameter of the chimney according to the enclosed manufacturer's instructions. But if you don't have one, follow these rules:

- To calculate a square-type chimney, the diameter of the blower should not exceed the diameter of the pipe.

- For a heating system with an open firebox (fireplace), the calculation of the chimney is 1:10 relative to the firebox.

Height

What should be the height of the chimney? It is impossible to determine an unambiguous chimney height for all types of heating systems. Here the following principle applies: the wider the diameter of the pipe, the sooner the cooling of the combustion products of the fuel occurs. As a result, condensate settles on the walls of the pipe, which blocks the functional smoke exhaust.

Watch the video on how to correctly calculate the height:

That is, an increase in diameter at a height of 5 meters does not contribute to an increase in traction. And if we increase the height of the chimney and reduce its diameter, then by doing so we will increase the volume of warm air and reduce its cooling. And that means we will increase traction. That is, when calculating the chimney, this feature must be taken into account. It is the increase in height with a decrease in the volume of the pipe that will create strong traction. But how economical it is in terms of fuel costs, you decide.

If you want to calculate the chimney in favor of fuel economy, and decide to make the chimney height as high as possible with the minimum amount of pipe, the draft in the system will decrease dramatically. A decrease in draft can lead to the penetration of carbon monoxide into the room. Therefore, the calculation of the chimney cannot be brought into line with financial savings, this will lead to carbon monoxide poisoning.

How to calculate the height of the chimney correctly:

- Use special programs to calculate the height of the chimney

- The height of the chimney above the roof should not be arbitrary

- The height of the chimney above the ridge must be more than 0.5 meters

The height of the chimney will depend on the design of the roof itself.

The calculation takes into account the distance between the chimneys, as well as:

- Roof thickness

- Roof pitch angle

- Distance from the vertical axis of the ridge

But when calculating the height of the chimney, the height of the umbrella covering the pipe is not taken into account.

How to calculate thrust

The calculation of the height of the chimney depends on the required draft. It is she who ensures the correct operation of your heating system. The draft is formed due to the spread of temperatures and pressure in the pipe itself and the surrounding space.

Due to the pressure shift, warm air goes up and cold air goes down. Cold air tends to displace hot air. Accordingly, in cold weather, traction increases.

- Hc stands for chimney draft;

- Hd - pipe section from the branch pipe to the boiler;

- Pw is the air density;

- Pg is the density of the combustible substance.

1 mm. water. Art. = 0.0001kgf/cm2

Insufficient draft in the pipe can be caused by the short length of the pipe itself. This means that the height of the chimney must be increased. And yet, you need to consider a reasonable limit. In practice, the total length of the chimney should not exceed six meters. The question of how to build a chimney pipe can be solved independently.

Advice

- If the ceiling height does not allow installing a chimney 5 meters high, an electric smoke exhauster should be connected.

- Remember that excessive height of the chimney is additional heat loss.

- If the draft in the pipe is strong, install a limiter

- When determining the height of the chimney, take into account the main direction of the wind

- If the maximum height of the brick chimney is not sufficient, back draft may occur.

- The formation of thrust in the channel is influenced by horizontal sections of the pipe and bends - the more of them, the less pressure

Before installing a chimney, carefully read the rules and study the parameters of your heating system. Calculation of all parameters of the chimney is a complex engineering task. Therefore, it is better to entrust everything to a competent specialist and not risk your well-being.

Chimney for potbelly stove

Chimney material

Before proceeding with the manufacture of the chimney pipe, which will be installed on the potbelly stove, it is necessary to determine the material that will be used.

Taking into account the fact that the potbelly stove is a portable stove, we immediately refuse brick chimneys. In this case, we have few options: either asbestos-cement or metal pipes

Most heating experts still recommend the use of metal chimneys: they are both lighter and easier to manufacture. It is about them that we will talk in more detail.

Cast iron stove with steel chimney

Making a metal chimney for a potbelly stove

So, we decided on the material - we will make a chimney from a metal (stainless steel) pipe. However, it is not enough just to stick the chimney pipe into the corresponding hole in the potbelly stove - the chimney must be correctly installed and optimally located.

Potbelly stove on the street

As a rule, a simple chimney for a potbelly stove installed indoors consists of two parts - internal and external. These parts are connected in the attic or at the level of the roof space.

Such a "double-knee" design makes it relatively easy to replace the lower burned-out segment of the chimney without dismantling the entire system.

By the way, you can not buy steel pipes, but bend them from a steel sheet, but this will require certain skills from you. On the other hand, then you can make a pipe for a potbelly stove of exactly the diameter that you need.

Pipe installation

To install a chimney of standard dimensions, we need the following materials:

- Knee 100x1200mm (1 pc.)

- Knee 160x1200 mm (2 pcs.)

- Butt elbow 160x100 mm (3 pcs.)

- Tee 160 mm with plug

- Mushroom 200 mm

Also, depending on the characteristics of the room in which the potbelly stove with our chimney will be installed, you may need a passage glass, a rain visor, thermal insulation, etc.

Also, to seal the joints between pipes, we may need an asbestos cord or a special sealant.

After all the materials are ready, we proceed to assemble the pipe for the potbelly stove:

- We fix the first section of the pipe on the chimney or the furnace pipe.

- We build up the pipe elbow to the overlap.

Chimney hole

- In the floor slab we make a hole with a diameter of at least 160 mm for the chimney outlet. We remove the thermal insulation along the edges of the hole to prevent its ignition.

- We insert a passage glass into the hole, and then we pass the potbelly stove pipe through it.

- We join the pipe with an external chimney.

- To ensure optimal operation of the chimney, we provide thermal insulation of the outer part of the chimney, wrapping it with thermal insulation and coating it with bitumen.

Chimney outlet through the window

We strengthen the fungus on top of the chimney, which protects the pipe from precipitation and small debris getting inside.

Pipe Care

In order for the chimney (and with it the potbelly stove itself) to work properly, it must be looked after:

- At least once a year, we check the outer surface of the pipe for defects - burnouts, rust, cracks.

- Similarly, the pipe must be cleaned annually. To do this, you can either use special chemical compounds that are burned in the furnace along with firewood, or simply burn a few aspen logs in a potbelly stove. Aspen gives a very high temperature, which perfectly burns out soot.

- It is unlikely that it will be possible to use mechanical cleaning agents (ruff, weight, etc.), because the chimney of the potbelly stove is not very durable.

The manufacture and arrangement of both the furnace itself and the pipes for the potbelly stove is a difficult task only at first glance. Of course, you will have to sweat and carefully study the proposed instructions - nevertheless, it is quite possible to do this without resorting to the help of specialists. So keep it up!

Chimney Height Calculation Methods

All individual houses must be equipped with heating with gas, liquid or gaseous fuel sources. Such devices are equipped with chimneys to remove carbon monoxide gases resulting from the combustion of fuel.

Such boilers are able to work only when there is the necessary draft for supplying blast air and removing flue gases. Calculation of flue parameters is carried out exclusively by highly qualified professionals, the results of the calculations are drawn up in the form of tables and are recommended for use during the manufacture of the chimney system from boilers.

Graphic method

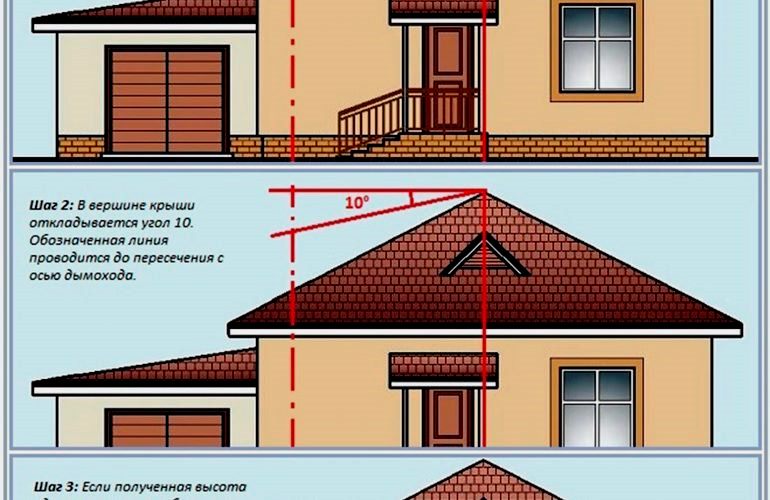

The method for determining the height of the chimney relative to the ridge is based on the Pythagorean theorem. The scheme is built in compliance with the dimensions and ratios of the structure on an accessible scale:

- On the finished sketch, 2 symmetrical axes are applied: the ridge and the designed pipe location.

- A horizontal line is drawn through the top of the roof and, using a protractor, to the bottom of it, a slope equal to 10 degrees is laid.

- The planned line is drawn to the axis of symmetry of the pipe.

- A truncated line will give the required value.

- It must be measured and calculated in accordance with the accepted scale.

- A certain size will determine the height.

- It will be necessary to find out whether the accepted value meets the state regulations.

- The plan of the building, if necessary, is slightly adjusted. Why the axis of the chimney is smoothly moved horizontally until the optimal location of the chimney is determined.

mathematical method

This procedure for determining the height of the chimney relative to the ridge is based on the use of trigonometry. The calculations are performed in the following order:

- Draw a sketch of the front of the building in the desired scale. For technicians without engineering skill, the most appropriate scale is 1:100.When translating the plan into natural dimensions, it is considered that 1 cm is equal to 1 m.

- The diagram fixes the symmetrical axis of the chimney. Through the top of the roof, an additional line is made and then lead to its intersection with the pipe axis.

- In the same way, as in the process of graphic reception, an acute-angled triangle of 10 degrees is drawn, attached to the edge of the ridge.

Having information about one of the legs, it is possible to calculate the other, according to the formula a = b * tgL. In this case:

- a - length from the rib to the outlet of the chimney;

- b - length from the axis of the building to the symmetrical axis of the chimney;

- L is an angle equal to 80 degrees, making up 10 degrees to 90.

The described methods are used in the calculation of domestic chimneys, which specifically serve a single source of heating. For industrial boilers with a heating capacity of more than 80 kW, or several such installations, it is recommended to contact specialists. Proper thrust size can only be ensured with the use of detailed thermal and aerodynamic calculations of the boiler equipment.

The height of the chimney from the ridge of a pitched roof can depend not only on the rules of SNiP, but also on the external and internal configuration of the channels, their cross section and other data that specifically determine the efficiency of the heating unit and its efficiency. To organize the most detailed calculations, online calculators will be used on specialized websites.