The final stage of the process of installing modern windows is finishing the slopes. A thick profile, multi-chamber double-glazed windows and reliable fittings provide excellent thermal insulation, but the interface between the window frame and the apartment wall remains a cold and unattractive place. If you do not provide due attention to this area, then condensation, mold and wall destruction may occur. Therefore, let's find out which slopes are best suited for plastic windows.

What requirements must slopes meet?

Before considering window framing options, their advantages and disadvantages, let's decide what is required of these elements.

Slopes should:

- Not inferior in terms of window design durability. Modern double-glazed windows are designed for at least 15-20 years of operation. Slopes are required to withstand no less time without loss of basic qualities. Few people like to redo them every two or three years.

- Correspond to the general style of the window, to form a single whole with it.

- Maintain or even improve the performance of plastic windows.

- Withstand mechanical loads and impacts of the sashes.

- Be repairable if possible.

Slope finishing options

When repairing an apartment in a new building or when replacing windows, you will have to choose how to finish the openings after installing modern structures with double-glazed windows.

You can finish the window slopes using the following materials:

- plaster;

- drywall (GKL);

- gypsum fiber (GVL);

- plastic panels.

Recommended

Roller blinds open type.

Attaches directly to the frame, no drilling required.

Perfectly save from the sun and heat.

They don't take up space.

Many colors and sizes.

Price from 600 rubles for a complete set. Delivery is free from 3 days.

Plaster slopes

The manufacturing technology consists in installing beacons, plaster corners and applying plaster. After drying, the slopes are puttied, sanded and painted. It is extremely difficult to make high-quality insulation, since the connection between the solution and the wall is lost.

Finishing a window opening with plaster has the following advantages:

- Versatility. This material is used in rooms with different indicators of humidity and temperature.

- Democratic price. Plaster is an inexpensive material, and it is also possible to save money by doing the work yourself.

- Strength. Plaster slopes are more resistant to mechanical stress compared to other types of finishes.

- No seams. Perhaps the main argument of the supporters of such a coating: it is not necessary to additionally process the joints and interfaces of the opening planes.

- Possibility of renewal and repair.

But a number of serious shortcomings have led to the fact that plaster is less and less used in this kind of work:

- The duration and complexity of the process. Finishing takes considerable time: each layer of the plaster mixture needs to dry.

- A large amount of dust and dirt, the risk of scratching the window.

- Low thermal insulation properties of plaster. Such slopes are prone to freezing in winter, the appearance of condensation. In addition, during their installation, it is necessary to cut the foam one or two centimeters inward, weakening the heat-insulating seam.

- Detachment from the frame. It is impossible to firmly connect the plaster and the PVC frame. There are no sealants with equally good adhesion to both materials. This leads to the formation of cracks between the window block and the plaster layer.

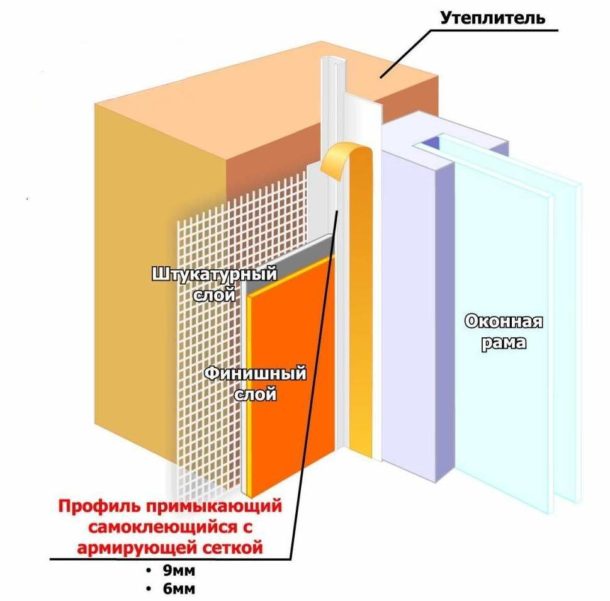

The last two drawbacks can be eliminated by insulating the opening with foam plastic before plastering and using an adjacent window profile with a reinforcing mesh.

Drywall slopes

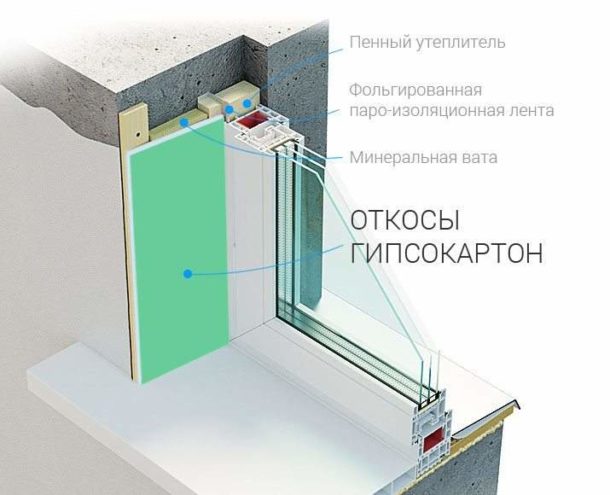

For their manufacture, pieces of plasterboard of the required size are used, which are screwed to the profile frame or glued to the sides of the opening. Then the surface of the drywall is primed, puttied and painted. In the case of laminated GKL, further finishing is not required. The space between the wall and the new slopes is insulated with mounting foam and insulation.

It is easier and faster to fix the GKL than to display a flat plane with plaster. But do not forget that after installation, a fine finish is required, which will take several days. If you use laminated GKL, then the installation of slopes is done in one day.

Advantages of using drywall:

- Low cost.

- Ease of installation. Requires the most basic skills in construction.

- The ability to easily create perfectly flat surfaces.

- Additional insulation.

- If preparation for staining and painting was carried out, then a simple repair, suitable for repeated repainting.

- If you use a good semi-gloss and glossy paint, you can repeatedly wash the slopes.

- When finishing and painting, it does not require the installation of plastic corners.

Recommended

Closed roller blinds.

Attaches directly to the frame, no drilling required.

Perfectly save from the sun and heat.

They don't take up space.

Many colors and sizes.

Price from 1,700 rubles for a complete set. Delivery is free from 3 days.

Flaws:

- The impossibility of firmly bonding the slope material and the PVC frame (as with the plaster version). This leads to the appearance of cracks at the mates.

- Fear of moisture. If the windows “cry”, under the influence of condensate drywall, even moisture resistant, gradually collapses, swells near the frame. Regardless of the GKL laminated or painted. Judging by the reviews, this is the main reason for not using GKL in the manufacture of slopes.

- Risk of deflection, dents and bursting. Still, drywall is a rather fragile material.

To avoid the stage of fine finishing, you can take laminated plasterboard instead of the usual one. But in this case, you will have to use special corners to close the ends of the sheets.

Gypsum fiber slopes (GVL)

The technology for mounting slopes from gypsum-fiber sheets is practically the same as mounting drywall, the advantages will be the same. At the same time, GVL is devoid of the disadvantages of GKL: it is much stronger and tougher, and its moisture-resistant variety is not at all afraid of a wet environment.

Advantages of gypsum fiber slopes:

- Fairly simple installation.

- High strength and rigidity.

- The possibility of high-quality insulation.

- Ideal construction geometry.

- Long service life - more than 10 years.

- Maintainability: a damaged element can be easily puttied and tinted.

- Moisture resistance.

- The paint is easy to clean.

- Any decorative coatings can be mounted on GVL: from wallpaper to tiles.

- Making a slope from gypsum fiber

- GVL installation process

Flaws:

- Relatively high price (compared to GKL and plastic).

- The need for finishing.

- Cutting gypsum fiber is more difficult than drywall.

If, after priming and puttying, the GVL slopes are painted with high-quality latex paint, then they can be washed fearlessly. And re-painting will be required no earlier than in 5-8 years.

Repair of slopes from GVL

In this case, the slopes were installed more than 8 years ago. In the process of cosmetic repairs (with the division of the room into two parts), the slopes were partially puttied, sanded and painted.The work on the slopes took 2 days, the cost of the work is negligible (compared to the installation of new slopes - even when compared with budget plastic ones). The walls were also painted, so no corners were needed.

- The slope was missing a whole corner. Crumbled from window blows for 8 years.

- The slope is completely restored and painted in 2 layers.

Plastic slopes

Another way to get aesthetic and reliable slopes is to sheathe the opening with double-sided sandwich panels. They have not only good thermal insulation properties, but also sufficient rigidity.

Not recommended use one-sided sandwich panels and decorative wall panels made of thin cellular plastic to finish the window opening. They do not have the necessary strength, wear resistance and thermal insulation qualities. It is better to use special panels for the manufacture of slopes.

It is plastic finishing that is gaining more and more popularity. The material of the slopes not only visually harmonizes with the window frame made of PVC, but is also securely fastened to it by means of special sealants. This method of finishing the opening has other advantages:

- Low price.

- A smooth surface that retains its properties for many years and does not require additional finishing and regular maintenance.

- No gaps and temperature differences due to the use of the same material from which the frame is made.

- Additional thermal insulation that reinforces the weak point of the window opening - the seam between the frame and the wall of the room.

- Installation speed. Plastic slopes are mounted faster than drywall and even more plaster.

- The minimum amount of dirt and dust when facing with plastic.

- 100% moisture resistance.

- It is possible to replace part of the slope in case of damage.

- The frame covering the outer contour reliably protects the junction of the wallpaper and the window opening.

Minuses:

- Susceptibility to mechanical damage.

- Impossibility of local repair. In case of breakage, you will have to change the whole panel.

- Poor quality of additional elements, such as corners. Often these small parts are made of recycled plastic, which turns yellow over time and stands out ugly against the background of snow-white slopes.

- Interior incompatibility. Glossy plastic will look unnatural in a classic-style room, as well as in any other design direction that uses natural materials.

So that others do not add to these shortcomings of plastic slopes, you need to correctly choose the material, guided by two main rules:

- Panels must be made from virgin plastic. Only such products are absolutely harmless even when heated in the sun and will not turn yellow after a year.

- The PVC layer must be thick enough. This will help avoid damage to the slopes.

When choosing between matte and glossy plastic, you need to consider that smudges and fingerprints are more visible on a glossy surface. Matte panels look more natural and look like classic painted slopes.

- Glossy plastic

- Matte plastic