Slopes of window openings play an important role in shaping the interior decoration of the room. If they are crooked or peeled, then they can hopelessly spoil the whole impression of the installed double-glazed windows. Not always firms engaged in installation of plastic windows, provide such a service as putty slopes. And if you have to install modern structures with double-glazed windows with your own hands, then you will also have to putty the slopes and paint them yourself. What does a home master need for this?

What materials and tools will you need to stock up on?

The choice of putty carried out depending on the microclimate in which the window slope is to be located:

- Facade putties are perfect for external slopes. They have good resistance to moisture and low temperatures.

- For interior decoration of window slopes in rooms with high humidity, cement or polymer putty mixtures are used.

- For normal conditions, gypsum-based putties are suitable.

It is necessary to estimate the scope of work that will have to be done:

- For smooth slopes without strong defects, finishing putty will be enough.

- If a significant leveling layer is required to eliminate irregularities, then you will also have to purchase a starting putty mixture.

- If the slopes are removed for the first time, they are first leveled with a plaster mortar, and then putty is applied.

The construction market offers ready-made raw putty solutions, but professionals advise preparing putty yourself from dry mixes. This will allow you to create a solution consistency that is best for you.

Stock up in advance:

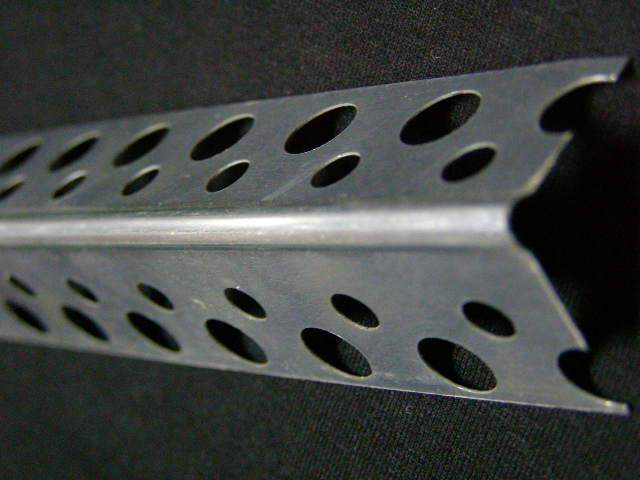

- perforated corners;

- masking tape;

- silicone-based sealant;

- deep penetration primer.

Of the tools you will need:

- a pair of spatulas - narrow and wide;

- sharp knife;

- building level and roller for priming the surface.

If in the future it is planned to cover the slopes with acrylic paint, then it is necessary to prepare the painting tool required for painting.

Preliminary work

The surface adjacent to the window must be prepared before applying the leveling layer.

window sill installation it is desirable to carry out before leveling the slopes. This will allow you to carry out all the work more efficiently at one time.

- The mounting foam protruding beyond the surface of the window structure is carefully cut off with a clerical or construction knife. In this case, it is recommended to go a little deeper behind the window block: in this case, the cut can be filled with sealant. It will close the open pores in the foam and prevent unwanted moisture from getting there.

- Masking tape protects the elements of the window opening from contamination. If there are surfaces that masking tape can ruin, then they are covered with ordinary paper.

- The entire surface is cleaned of old wallpaper, paint and dirt.

- Poorly adhering pieces of plaster or brick are removed and the surface is primed.

It is desirable that the primer mixture has pronounced antifungal properties.

How to apply putty correctly?

Before starting work, it is important to know that for the use of gypsum mortars, the temperature in the room should not be lower than + 10 ° C. Cement mortars can be used at temperatures up to +5˚С.

Work progress:

- The window opening is measured with a tape measure, after which segments are cut from the perforated corner of the desired size. To do this, you can use scissors for metal or a small grinder.

- Using a construction mixer, the putty mixture is stirred.It is better to cook it in small portions in order to have time to use up the putty before it hardens. It would be useful to read the manufacturer's recommendations. The finished solution should have the consistency of thick sour cream without any lumps.

- After evaluating the curvature of the surface with the help of a level, a starting solution is applied with a thickness of not more than 7 mm. With a narrow spatula, putty is applied to a wide one and applied to the surface from the bottom up with wide sweeping movements. Excess solution is removed by transverse movements of the spatula from the window.

- At the outer corners, until the putty mortar has hardened, pre-prepared segments of the perforated corner are attached. The corner is set according to the level. Excess solution that has come out through the perforation holes is removed with a spatula.

- If leveling the window slope requires a significant layer of putty, then each subsequent layer is applied only after the previous one has hardened. To increase the strength, a thin fiberglass reinforcing mesh can be used.

Important! To prevent cracking of the putty caused by thermal expansion of the window elements, a thin groove is made in the fresh putty between the slope and the window block. In the future, it is filled with a sealant, which will serve as a kind of damping layer.

- After leveling and drying, the surface is treated with a sandpaper. For convenience, it can be stuffed on a wooden block. As soon as all the irregularities and traces of the spatula are removed, the finishing putty is applied. Its layer should not be thicker than 1 mm.

- After letting the surface dry, it is once again treated with sandpaper, after which you can walk on it with paint.

At the final stage, all protective elements are removed from the window block and window sill: masking tape and paper.

Thus, it is not at all difficult to putty the slopes on your own. If everything is done correctly and accurately, then this will not only give a finished look to the window opening, but will also save significant money.