After installing modern metal-plastic or wooden windows with double-glazed windows, it's time to take care of their framing - window slopes. Finishing the window opening is necessary not only to give the window a complete and neat appearance, but also to improve its thermal insulation qualities. The oldest, but to this day, the method of finishing window and door slopes that has not lost its popularity is plastering. We will try to figure out how to plaster the slopes on the windows with our own hands, and find out all the subtleties of this process.

Methods for finishing window slopes

When installing new windows in old buildings, unforeseen situations arise. Very often, the slopes of window openings themselves "strive" to collapse. Under them are voids or a very large layer of insulation. This is usually due to unsustainable norms during construction work.

You can make new window or door slopes with your own hands from different finishing materials: MDF, drywall, plastic. However, traditional plastering of slopes with mortars has a number of advantages, including:

- high impact strength;

- long service life;

- affordable price.

There are also disadvantages to finishing window slopes with plaster. First of all, this is insufficient thermal insulation and the possibility of cracking.

Plastering slopes in the openings of windows and doors is a rather painstaking work, but with some knowledge and a minimum ability to handle a spatula, it can be done by hand.

Tools and materials for plastering slopes

When doing the work with your own hands, for starters, you should decide on the selection of materials and tools with which you can plaster the slopes in the window opening. Their list includes:

- plaster mixture;

- putty;

- primer;

- brush;

- mounting foam;

- spatulas of two types - wide and narrow;

- Master OK;

- grater and half grater;

- short level up to 1 meter long, plumb;

- roulette;

- goniometer;

- containers for solution and water.

To remove an excess layer of old plaster from the window slopes, you will need a perforator, in the absence of which you can use a hammer and a chisel.

As a composition for plastering slopes, both a cement-sand mortar and a dry gypsum mixture are suitable. Gypsum-based stucco will cost you a little more, but it has some important advantages:

- high plasticity, providing convenience during work with slopes;

- the possibility of applying a thicker layer.

Preparatory work

Preparation includes several stages: protection of windows or doors, elimination of cracks and surface treatment of slopes.

Structural protection

Before finishing the slopes, it is necessary to take care of the safety of the window sill, as well as the windows or doors themselves. They need to be protected not only from mechanical damage, but also from the ingress of a solution, which is especially dangerous for wooden structures due to the possibility of swelling, deformation, damage to veneer or varnish.

- The surface of the window sill is covered with thick paper.

- Joints, frames of windows or doors are pasted over with construction tape.

- The door leaf can be removed or covered with oilcloth or film.

Do not forget also about the safety of fittings and heating batteries. It is easier to wrap them in rags or paper than to wash them for a long time.

Sealing gaps

Wide gaps between the window and the opening are sealed by the installation team, but small gaps may remain. In this case, you can fill them with mounting foam with your own hands.After it hardens, the excess is carefully cut off with a knife so that a small recess is obtained up to 2–3 cm deep, which will subsequently be filled with a solution.

Slope surface preparation

This stage consists of the following steps:

- Remains of old plaster, paint or oil stains are removed from the surface of the window opening.

- If there are smooth places, notches are made on them.

- After cleaning, the slopes are primed, which is necessary to increase adhesion - adhesion of two dissimilar materials. Processing is done with a wide brush.

- After the composition has dried, you can proceed to the next part of the work.

opening marking

There is the concept of "dawn angle". To get more light into the premises, the angle that is formed between the plane of the window or door opening and the plane of the wall must be more than 90 degrees. In order to take into account the angle of dawn, you need a goniometer. With its help, a line is drawn on the windowsill from the corner of the window frame so that 1 cm of deviation corresponds to 10 cm of the opening depth. So, with a wall thickness of 30 cm, the line will go to the side by 3 cm.

Installation of beacons

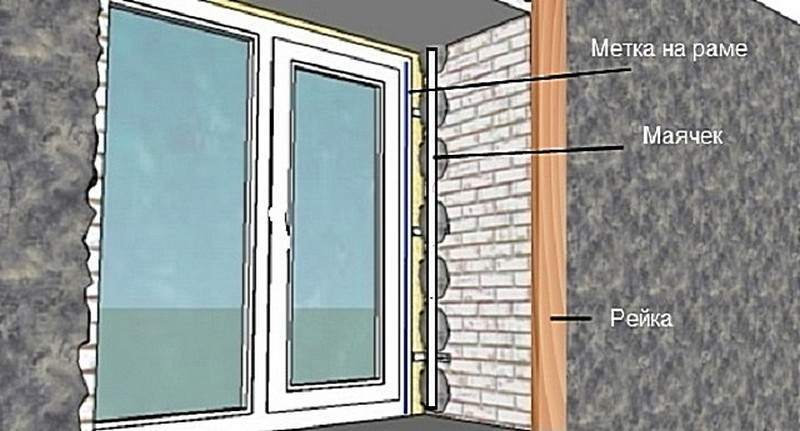

Professional builders perform plaster work on lighthouses made of wood or metal. If a small layer is required, then the slopes can be plastered according to the marks from the gypsum mixture.

If you are going to plaster slopes with your own hands, having absolutely no experience in leveling surfaces with building mixtures, then it is better to purchase ready-made plastering beacons in the store. In extreme cases, you can use strips of plywood.

- Along the outer wall along the entire plane, the beacons are fastened with nails or screws. The vertical is set with a plumb line, and the horizon level with a level.

- The second beacons must be installed so that they are adjacent to the window frame or door block. They are fastened with a mixture with the addition of gypsum, into which the profile is pressed. To do this, you can also use a clean, quickly solidifying alabaster.

alignment

After all the preparatory work, a sketch begins, and then the alignment of the prepared mixture or mortar onto the plane of the opening. When all the space between the beacons is filled, the entire surface is smoothed from bottom to top with a trowel. Thus, work is done on all three sides of the window: right, left and top.

After the solution dries, it is necessary to remove the beacons. To do this, using a spatula, the profile connection with the new plaster is trimmed. The vacated space is also filled with the mixture and leveled.

Tip: to prevent cracking of the plaster due to thermal expansion of PVC window frames in a solution that has not yet hardened, a groove is made with a spatula between the frame and the slope 3-5 cm wide. Silicone sealant is poured into the recess, which will act as an elastic gasket.

Slope grouting

After a few hours have passed and the mixture hardens, plywood beacons are removed - guides. The voids of the side edges are sealed with putty or mortar. Then, using a grater, the slopes are grouted in a circular motion. The surface is pre-wetted with a brush.

When pits or cracks appear, a little solution is thrown into problem areas.

Work continues until the plane becomes flat.

After the plastering of the window slopes is completed, it remains only to wait until the surface is completely dry, which can last from 6 to 11 days, depending on the thickness of the plaster layer. Now you can apply putty, then paint the slopes with traditional white.