The implementation of the screed is one of the most important stages in the installation of a warm floor with your own hands. This work must be approached with the utmost responsibility, since not only the appearance of the future floor depends on its quality. Underfloor heating screed performs several important functions:

- protects the heating system from mechanical damage, and in the case of an electric floor heating, also from air;

- acts as a floor radiator of an impressive area, distributing heat from the heater over the entire surface of the floor and heating the entire space of the room;

- Serves as a level surface for finishing flooring.

The composition of the screed for underfloor heating

unequivocal opinion on what type of screed better suited for arranging a warm floor with your own hands, does not exist. Lately there have been supporters dry screed, which is based on dry materials, allowing you not to waste time drying the solution, as with the wet version. But the most common type continues to be a wet screed.

For a warm floor, the following composition options are suitable:

- Cement-sand mortar, mixed in a ratio of 3:1. Suitable for both water and electric underfloor heating.

- Concrete mortar containing fine-grained filler. An excellent option for a water heating system to avoid surface cracking.

- Self-levelling compounds. In an independent version, they are suitable for pouring electric heating elements, they are convenient when doing do-it-yourself work.

- Special mixtures designed for underfloor heating. They have a different composition, are presented in stores in a large assortment.

- Tile adhesive. Plays the role of a screed when using electric heating elements.

Tip: to increase the strength of the flooring when doing do-it-yourself work, use a reinforcing mesh. The addition of various plasticizers and microfiber helps to increase the durability of the compositions.

Thickness and horizontality of the screed

One of the most important parameters of the screed for underfloor heating, which causes the most questions when doing do-it-yourself work, is its thickness. It has certain requirements:

- The screed must have the same thickness over the entire area of the room. Only if this condition is observed, uniform heating of the material and high-quality heat transfer is possible. Therefore, it is unacceptable to start work in the presence of irregularities and drops on the subfloor - in this case, it is pre-levelled.

- The coating should not be too thin, because in this case the heating will be uneven and only certain zones will be heated. A thin layer will not accumulate heat and will cool quickly. Too thin thickness can lead to cracking.

- The layer can not be made too thick, otherwise it will keep the heat inside, not letting it out.

For a warm water floor, the standard thickness of the screed is 6.5–7 centimeters, of which there is a layer 3–5 centimeters thick above the pipes.

For an electric underfloor heating using cables, the thickness should be 2.5–3 centimeters, for a film type heater, 1–1.5 centimeters.

The levelness of the surface is critical for a water heating system, when using electric heating elements a slight slope is acceptable.

Risk of cracking

When using a traditional wet type of screed, it is very important to prevent cracking. Their appearance can lead to many negative consequences:

- uniform heating of the room will become impossible, which will negate the advantages of a modern heating system;

- uneven heating of floor areas will lead to overheating of individual thermal elements and their subsequent failure;

- may suffer finishing flooring.

To prevent the occurrence of cracks in the manufacture of a screed with your own hands, you must:

- correctly observe the proportions of the solution, as well as the drying mode;

- use plasticizers to increase the elasticity of the composition;

- reinforce the structure with reinforcement or reinforcing mesh;

- install damper between wall and screed.

The damper can be damper tape or low density foam. Its main task is to compensate for the expansion and contraction of the material as a result of temperature changes.

Layer sequences

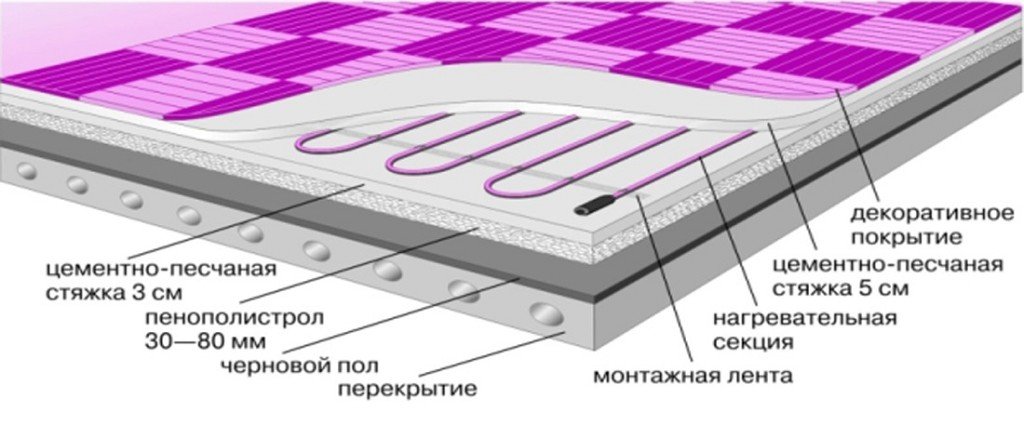

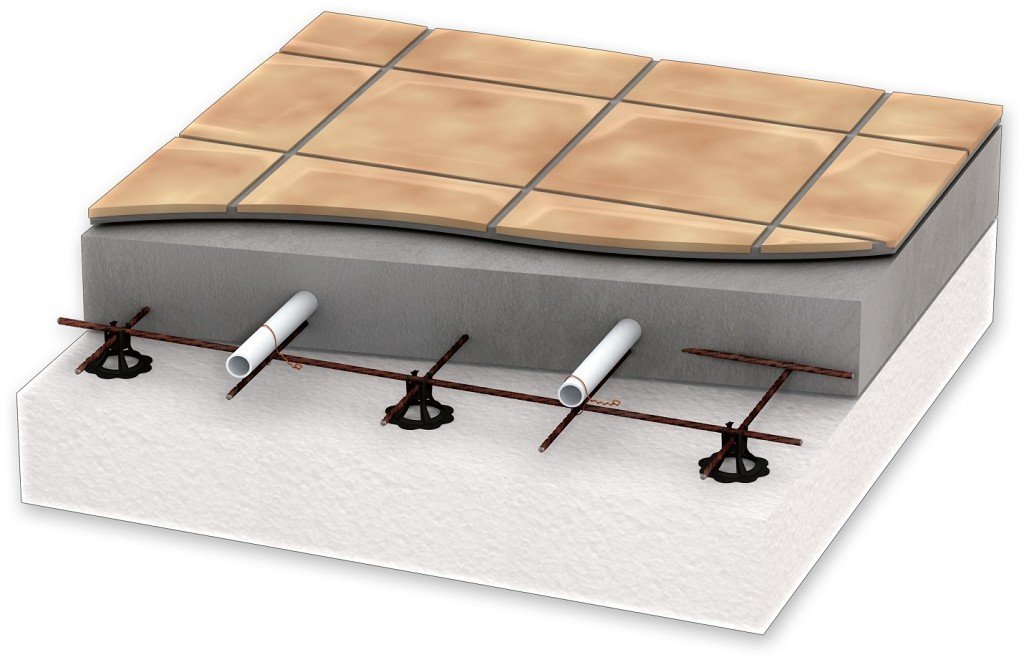

The underfloor heating screed is not poured onto a bare floor, the design is a multi-layered “pie”, each of the layers of which performs its own tasks. When installing a screed with your own hands, it is very important to follow the correct sequence of laying the layers.

"Pie" for a water floor

For a water heated floor, the following laying option is considered the most common:

- Layer waterproofing. A waterproof film is needed not only so that the liquid solution does not leak to the neighbors from below. Waterproofing prevents the penetration of moisture from the floor, and the heat of the heating system is not spent on drying.

- Thermal insulation. The main task of the heat-insulating layer is to direct the maximum amount of heat into the room and create an obstacle to its spread to the floor slabs. The best effect is achieved when using two types of materials:

- polystyrene from 3 centimeters thick, which does not allow concrete to draw out heat;

- reflective thermal insulation coating that directs the heat flow upwards.

- reinforcing layer. For reinforcement, a special mesh is usually used, which reinforces the screed. This layer is important to prevent cracking of the material due to deformation of the soft underlayers or thermal expansion.

- Pipe system.

- Screed. This layer is performed according to standard technology using lighthouses.

Tip: so that the pipes do not float during the pouring of the solution, they must be fixed on the insulation boards or on the reinforcing mesh.

Features of laying layers for electric floor

The “pie” arrangement when using cable heating and a system of heating mats will be the same as with a water system. However, it must be remembered that the cable should not touch the thermal insulation, therefore it must be attached to a reinforcing mesh suspended between the lags. Film heating elements can be placed on top of the screed or a minimum fill layer of up to 2 centimeters can be used.

Important: infrared heating film in no case should be placed under the screed. The final flooring is placed directly on the film or on GVL boards laid on top of the film.