Reinforcing mesh for floor screed is used to ensure the strength of the entire floor surface and serves to distribute the load. Reinforcement allows you to level the floor before laying the floor covering, giving it the necessary strength and resistance to various loads. The construction of floors with the use of mesh for reinforcing the screed eliminates the risk of cracking the base, maintains its shape during operation, preventing it from collapsing. In addition, reinforcement has a positive effect on the basic properties of the concrete pavement.

The main types of reinforcing meshes

Screed is a transition layer that connects the main surface of the floor with the final coating. It is performed not only for hardening, but also to ensure such properties as waterproofing, thermal insulation and soundproofing of the room. To reinforce the concrete surface, most often, two types of mesh under the screed are used:

- metal;

- Plastic.

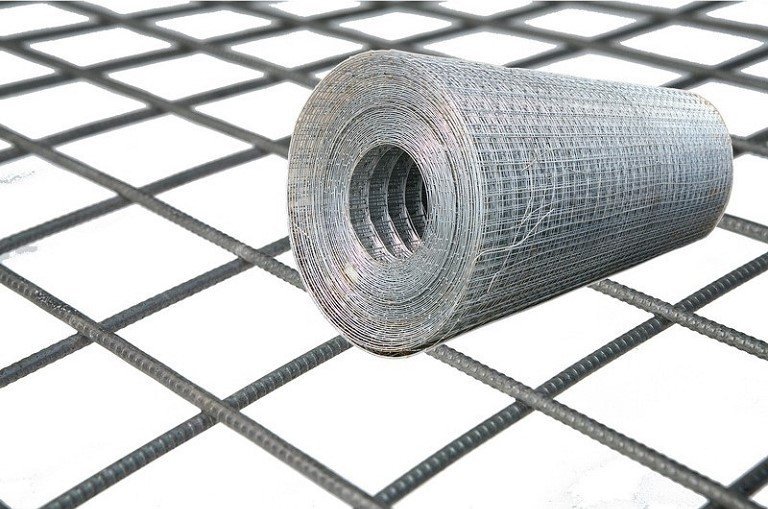

The mesh under the screed is laid at a height of about three centimeters from the floor, after which it is poured with a concrete mixture. Here you need to ensure that it does not touch the subfloor, remaining in the very thickness of the concrete.

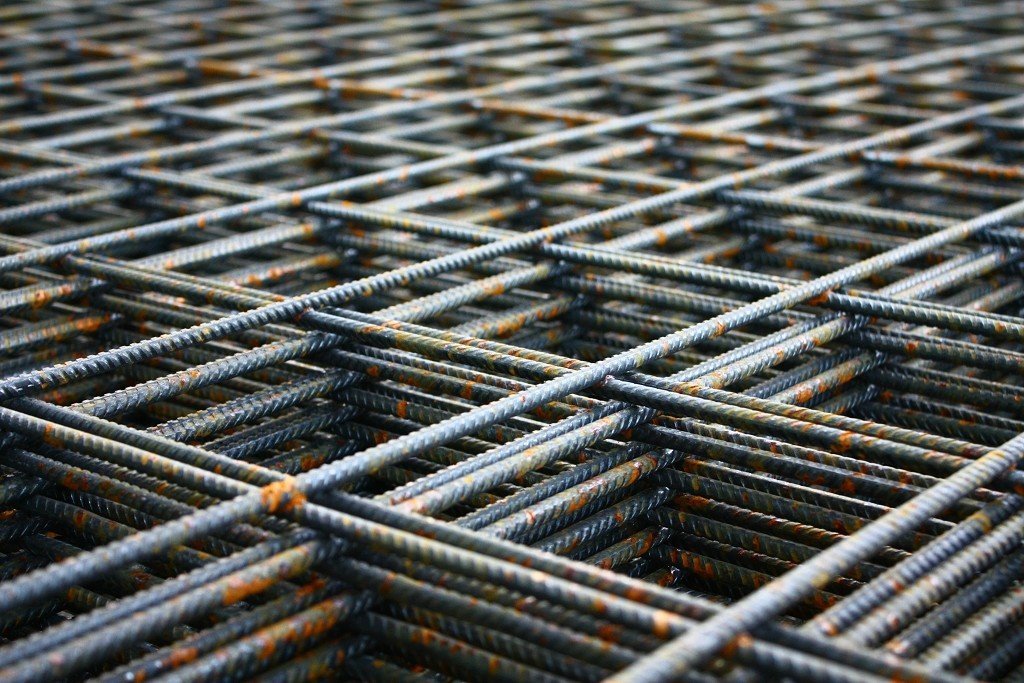

Reinforcement of the floor screed with a metal mesh ensures maximum strength of the base. This material is used for layer thickness fill no more than 80 mm. It is best to use a metal mesh in rooms subjected to fairly heavy loads - a hallway, a kitchen or when organizing a floor heating system.

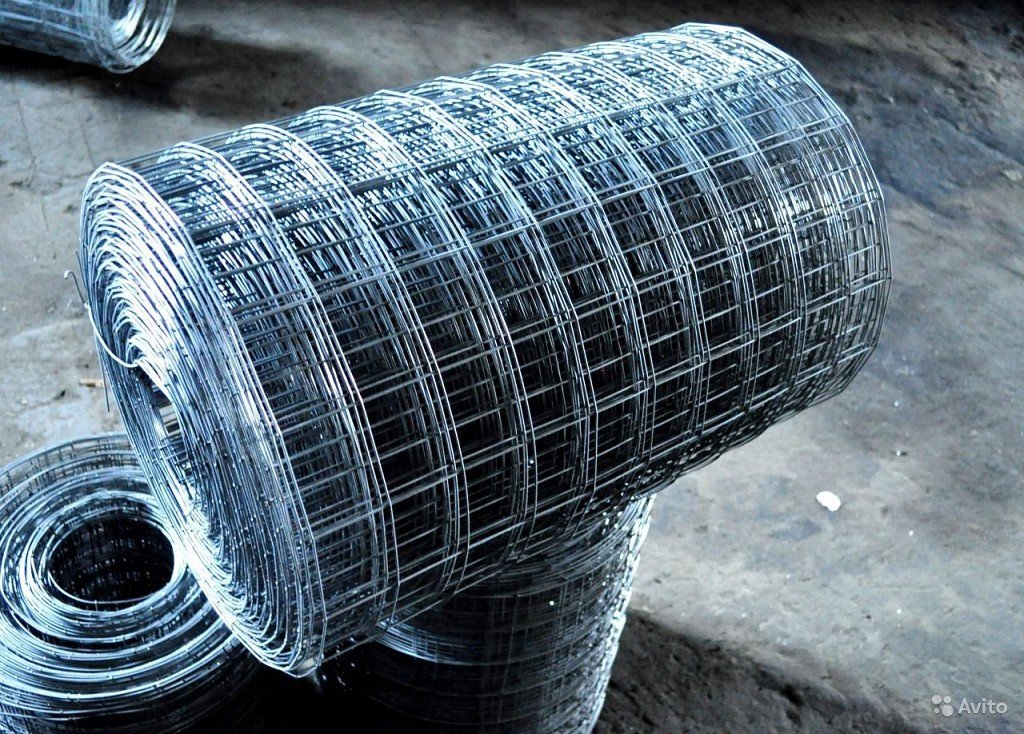

The metal mesh can be made from individual wire elements that are twisted together. It can also be a welded product.

Plastic structures for reinforcing the concrete floor are made of modern material - polypropylene. Due to their excellent elasticity, they are widely used for reinforcing floor surfaces in newly built houses. After all, they are subject to strong shrinkage, and the elastic mesh prevents the appearance of splits and cracks. Plastic mesh for floor screed, unlike similar products made from other materials, does not corrode, has a long service life, low weight and is characterized by ease of installation. In addition, it is able to withstand very strong loads, both in longitudinal and in cross section.

The modern way of arranging the screed

Reinforcement of the floor screed can be performed not only by laying the grid. Dispersion reinforcement, which uses fiber made of glass, steel or other materials, is gaining great popularity today. However, such a reinforced screed is not suitable for rooms with increased loads, and therefore, in some cases, it is used as an addition to the first method of strengthening the floor. Fiber provides the most rapid maturation of concrete and the manifestation of such properties as plasticity.

The use of fiber for reinforcing a concrete floor is a new, modern method. It allows you to reduce the consumption of concrete during pouring and does not allow it to crack.

How to lay the grid?

- A metal mesh for durable reinforcement of the floor screed is laid on a concrete floor cleaned of dirt and dust. Thoroughly clean the base of debris, dirt and even paint stains.

- In order for concrete to best adhere to the rough surface, it is necessary to prime the base with a special compound.

- Installation of metal or wood lighthouses along the upper boundary of the grid placement will provide you with a flat bay.

- To soundproof the room you will need penofol, which must be attached to the wall.

- The mesh is laid under the screed, and the solution is poured into the resulting distance between the beacons, after which alignment is performed.

- As soon as the concrete dries a little, about thirty minutes after the bay, the surface must be rubbed.

- The beacons are removed about seven days after the bay, and the voids are sealed with mortar.

- To prevent the surface from drying out and cracks, the screed should be regularly wetted with water.

- It will take a month for the concrete to dry completely.

- Maintain a constant temperature during work and drying of concrete at twenty degrees Celsius. Avoid drafts and try to lay the screed mesh of the same level in one day.

Floor screed nets make it possible to significantly reduce the thickness of the concrete layer and make it stronger and more stable. It is especially indispensable for organizing floors in wet rooms, as it is able to keep their shape even when completely flooded with water. To make the floor even more even and smooth, after the composition has dried, make an additional layer by applying self-levelling compound.