natural gas demand calculation

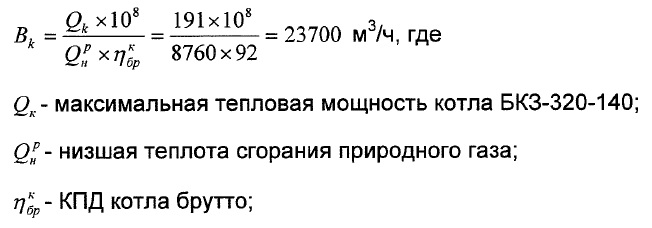

- Hourly gas consumption per boiler:

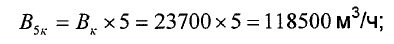

- Hourly gas consumption for five boilers

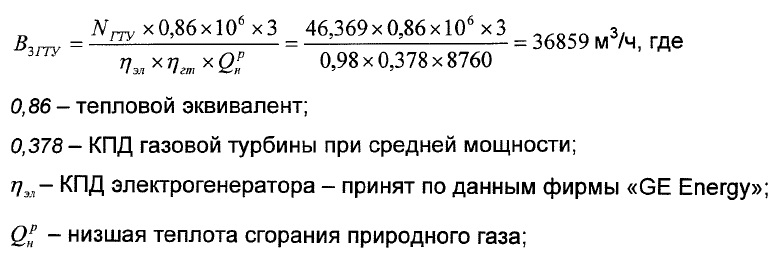

- Hourly gas consumption for GTU:

In accordance with the technical and commercial proposal of GE Energy, the hourly consumption of natural gas per GTU is 8797 kg/h. Thus, for three gas turbines, this flow rate will be 26391 kg/h, or 32700 m3/h;

- The total hourly gas consumption at Yuzhno-Sakhalinskaya CHPP-1 will be: 1118500+32700=151200 m3/h

Annual gas consumption

- In accordance with the technical and commercial proposal of GE Energy, the rated power of the gas turbine under ISO conditions is 46.369 MW, the efficiency is 40.9%;

In accordance with the daily load schedule of the Sakhalin energy system, the average electric power of three gas turbines in winter will be 95.59 MW, and in summer - 92.08 MW.

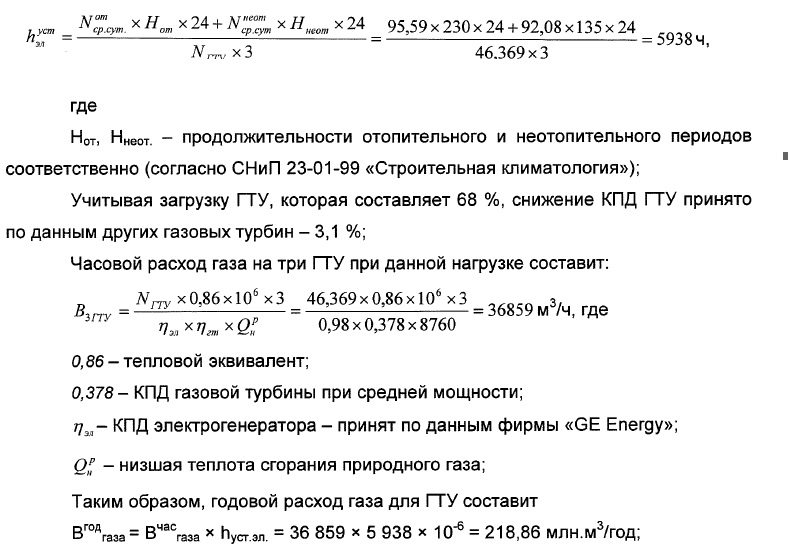

Taking into account the GTU load, which is 68%, the decrease in GTU efficiency is taken from the data of similar gas turbines - 3.1%;

The hourly gas consumption for three gas turbines at a given load will be:

Thus, the maximum gas consumption at the Yuzhno-Sakhalinskaya CHPP for 6500 hours of use is:

(118500+36859)х6500=1010 million m3/year;

- In accordance with the technical report on the operation of CHPP-1 for 2007, the annual consumption of equivalent fuel at CHPP-1 was 651,058 thousand tce/year.

At the same time, during the commissioning of the 4th power unit, the load will be redistributed between the existing steam-power equipment and the gas turbine unit in terms of removing part of the thermal and electrical load from the existing equipment of CHPP-1.

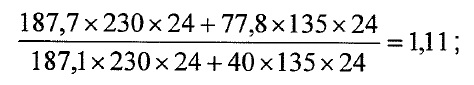

In accordance with the predicted version of the daily load schedule of the energy system, the average electric power of the existing steam power unit of CHPP-1 will be 187.1 MW in winter and 40 MW in summer. According to the typical daily load-bearing schedule of 2007, the average electric power of CHPP-1 was 187.7 MW in winter and 77.8 MW in summer. Thus, with the commissioning of the 4th power unit, the use of the installed capacity of the existing part of CHPP-1 will decrease by 11%:

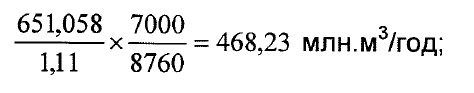

Then the annual gas consumption for the existing part of CHPP-1, taking into account the reduction in capacity by 11%, will be:

- The rated power of the gas turbine under ISO conditions is 46.369 MW, the efficiency is 40.9%;

In accordance with the daily load schedule of the energy system, the average electric power of three gas turbines in winter will be 95.59 MW, in summer - 92.08 MW. Then the number of hours of using the installed capacity of three gas turbines will be:

- The total annual gas consumption at CHPP-1 is: 468.23+218.86=687.09 million m3/year

(Visited 7 798 times, 3 visits today)

What you need to know when performing calculations

Knowing certain nuances will help you correctly select the right amount of fuel:

Modern furnaces have high power and can work on different types of solid fuel raw materials.

furnace equipment does not have a very high efficiency, since a significant part of the heat escapes through the pipe along with the combustion products. This must also be taken into account in the calculations. The standard value is entered in the program - 70%. But you can make your own, if it is known;

solid fuel, depending on the type, has a different heat transfer rate

Thermal parameters of different types of wood, peat, coal and briquettes are predetermined in the program;

if calculations are also performed for firewood, then it is important to indicate the degree of their drying. For example, for raw wood raw materials, the heat transfer value can be 15-20% lower

This will require more fuel;

final results can be issued in different ways. Firewood is measured in cubic meters, and bulk varieties of raw materials in weight equivalents - tons and kilograms. In this case, the result will be the same, but the number is defined as cubic meters for wood and as tons for other options.

The provided calculation is obtained taking into account the most unfavorable weather conditions, that is, according to the maximum value. In practice, very warm days occur in winter. This creates a reserve for unforeseen cases.In a few years it will be clear in what mode you need to heat a wood-burning stove and how much raw materials are needed even without special calculations.

traditional oven

If it is planned to build furnace equipment, then it is important to plan in advance a special place for storing raw materials. It is also worth studying the features of different types of wood, as some options are able to burn for a longer period, which allows you to save on fuel. . Save Time: Featured Articles Every Week by Mail

Save Time: Featured Articles Every Week by Mail

7 Removal of smell and taste. Calculation and selection of a coal column

Posted Feb 20, 2013 |

Tags: |

4.7 Removal of smell and taste. Calculation and selection of a coal column.

So, hardness salts are removed from the water. Theoretically, this water can already be used. But, as practice shows, water can also have a smell and a specific taste. To get rid of odors and tastes, water is passed through filters - adsorbents. Usually these are either cartridge or column type filters. These filters use specially prepared activated carbon as a backing material, which, as you know, has a huge absorbing capacity due to its large internal surface.

Consider now how to choose the right coal column.

The calculation of the coal column is carried out similarly to a mechanical sand filter.

The first step is to know what filter performance is required.

Suppose we need a filter with a bandwidth, like for all previous filters:

Vfilter= 2m3/h.

The linear velocity of water in the carbon filter is assumed to be

vlin=15m/h.

Based on these indicators, we can find the cross section of the required cylinder:

=2/15=0.133m2

From table 4.2 we determine which cylinder is most suitable for us according to the calculated section.

The closest balloon is 16x65 (section 0.130 m2). Total balloon volume Vballoon=184l.

The filling volume of the cylinder is 70% of its total volume. In our case, the total volume of backfill

Vbackfill=Vballoon x 0.7 \u003d 184x0.7 \u003d 128.8 l

As mentioned above, activated carbon is used in the carbon filter.

Based on the density of coal 0.8 kg / l, we obtain its mass:

Mcoal= Vbackfillx0.8=128.8x0.8=103.04 kg.

Two cycles are used to wash the filter: backwash and shrinkage.

Backwashing should be carried out with a flow of 20m/h for 20-30 minutes, and shrinkage should be carried out for 5-10 minutes at a speed of 8-12m/h.

Based on these data, it is necessary:

- pick up a restrictive sewer washer in the filter head (this washer limits the speed of water flow through the backfill during backwashing).

- check whether the pump capacity is sufficient to flush the filter.

- calculate how much water the filter will discharge when flushing into the sewer.

The restrictive sewer washer is selected in the following way:

Determine the required water flow for backwashing:

Vbackwash=Sballoonx20m/h\u003d 0.133x20 \u003d 2.66 m3 / h

The same value will be the minimum performance of the pump that supplies water to the filters.

Next, we calculate the diameter of the restrictive sewer washer:

dwashers= Vbackwash/0.227=2.66/0.227=11.71 gal/hour

No. limit washer is equal to:

№washers=dwashersx10=11.71x10=117

The amount of water discharged into the sewer:

When backwashing:

Vcan1= tbackwash x Vbackwash \u003d 0.5 hours x 2.66 m3 / h \u003d 1.33 m3

When shrinking:

Vcan2\u003d 0.17 hours x 2 m3 / h \u003d 0.34 m3

In total, when washing the filter, 1.33 + 0.34 = 1.67 m3 is discharged into the sewer