Plasticizers for floor screed are special substances that are added to the composition of the floor pouring solution, concrete and other mortars, to impart plastic properties, as well as to significantly improve the existing technical characteristics. The plasticizer of the screed accelerates and facilitates the mixing of the solution, contributing to the fastest dissolution of liquids, reducing solid particles, the speed and strength of the interaction between them.

When pouring a warm floor, it must be taken into account that the heating agent is located unevenly on the floor, only in those places where people walk. When the heating is turned on, the floor in some places is very hot, while in others it remains cold. The temperature changes quickly when the heating is turned on and off.

During operation, the floor:

- should not crack, crumble;

- must be perfectly even, not pressed through and not wiped;

- should heat up evenly.

What is a plasticizer for?

The plasticizer for underfloor heating screed, when added to the composition, gives the mixture the following properties:

- up to 30% increases the strength of concrete, as well as its ability to stretch in a frozen state;

- prevents cracking;

- increases resistance to mechanical stress;

- up to 30% reduction in the amount of water used for mixing;

- the amount of spent cement is saved;

- increases resistance to abrasion;

- facilitates the process of pouring the floor;

- the composition becomes much more dense, homogeneous, adheres more thoroughly and stronger to the heating elements;

- self-levelling of the screed occurs;

- thermal conductivity increases;

- water absorption is reduced by minimizing air pores;

- the resistance to aggressive media, humidity, fungi, salt deposition, and corrosion is greatly increased.

What are the requirements for plasticizers?

These substances must have good compatibility with the selected brand of cement, so that when interacting, the mixture acquires the necessary plastic qualities. The additive should have low volatility and be odorless. The plasticizer must have a high chemical inertness. Also, the plasticizer should not be released from the polymer under the influence of liquids, oils.

Plasticizers for underfloor heating are used in the manufacture of:

- floors warm and self-leveling;

- screeds;

- industrial floors;

- floor slabs.

In addition, these additives are used for interior and exterior surfaces.

The inclusion of a plasticizing additive in the composition of concrete allows construction work to be carried out both at sufficiently low and high temperatures. The addition of plasticizers makes it possible to carry out work at temperatures from + 5 C to +35 C.

Screed for underfloor heating prepared with the use of liquid, powder additives, emulsions. A plasticizer is introduced into the composition of the tile adhesive in the amount necessary for the preparation of a warm floor.

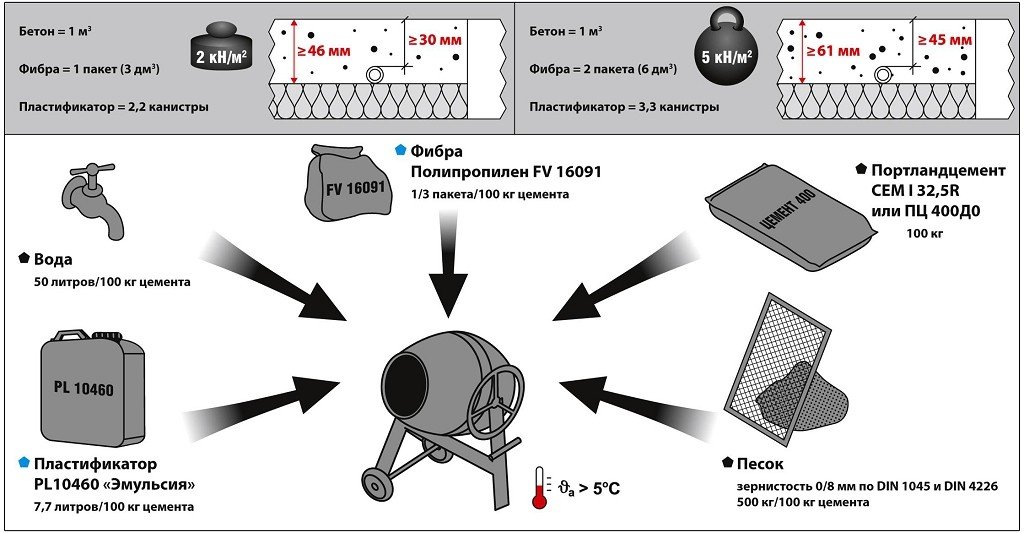

The composition of the screed for underfloor heating includes: one part of cement, three parts of coarse sand (from 0.5 to 0.8 mm in size) or fine gravel. Cement and filler are pre-mixed. The plasticizer is added to half the recommended volume of water, carefully poured into the mixture of sand and filler, mixed. The rest of the water must be added to the composition in portions, until a thick viscous consistency is obtained. The average consumption of liquid plasticizer is from 400 to 800 milligrams per 1 m2 of surface.

A screed for a warm floor using a powder plasticizer has the same composition as with a liquid plasticizing additive, but with the addition of reinforcing polyamide fibers.

Today, mixtures for pouring underfloor heating, as a rule, are sold in hardware stores ready-made. The purchase of ready-made building mixtures will allow you to quickly and easily fill the floor, but will significantly increase the cost of work.

If necessary, plasticizers for pouring warm floors may have additional features:

- the presence of an accelerator for hardening cement mixtures;

- an additive that increases the density of concrete during freezing and thawing (can increase the strength of concrete by 20 - 30%);

- additive for surfaces that will be used in environments with increased corrosive load, such as swimming pools;

- antifreeze hardening accelerator, increases the early grade strength of concrete, accelerates hardening and allows you to work at temperatures down to minus 15 C;

- anti-shrink effect.

Safety rules when working with plasticizers

These construction additives can irritate the mucous membranes of the eyes and respiratory organs. When using them, it is necessary to use personal protective equipment. Use a respirator to protect your lungs, goggles to protect your eyes. Wear rubber gloves to avoid contact with the skin.