It is known that gypsum plaster, putty and paint are applied only to the prepared surface, otherwise the materials will almost certainly crumble after drying and during further operation. Properly prepare walls, ceilings and other surfaces for subsequent finishing will help primer "Concrete contact". This universal tool improves the adhesion of materials and strengthens the treated surface, increases its moisture resistance and resistance to any mechanical stress.

Primer composition

It includes:

- quartz sand;

- styrene-acrylate dispersion, which is a binder;

- cement;

- various fillers.

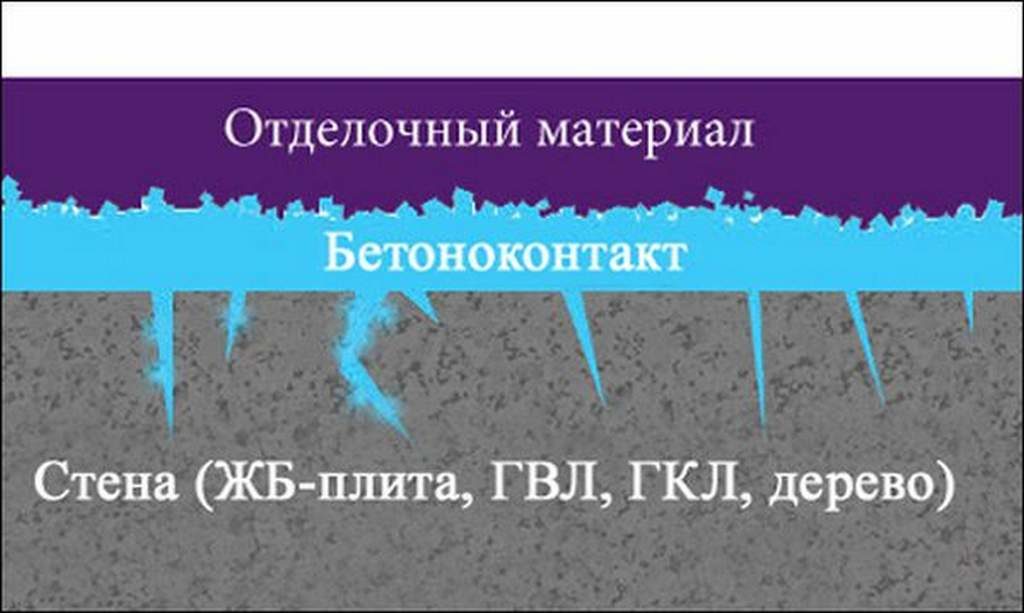

The water-dispersion primer "Beton-kontakt" was created primarily to solve the problem of adhesion of concrete and gypsum mixtures, which, when applied to an unprepared surface, simply slide along a smooth base.

Purpose and scope

Let us consider in more detail what a primer is for and where it is used:

- The primer composition plays the role of a link between the base and the applied finishing material. Even on a very smooth and slippery surface treated with this primer, anything will stick, because the quartz filler creates a roughness that resembles sandpaper, providing a quality grip.

- Due to the penetration of substances into the structure of the base material, "Concrete-contact" makes its outer layer more durable.

- The composition is suitable for both porous absorbent surfaces and smooth, non-absorbent surfaces.

- This primer is a solution to the problem of plastering monolithic concrete, on which gypsum plaster does not adhere well due to poor moisture absorption.

Important information! "Beton-contact" has one serious "contraindication". In no case should it be used before plastering with cement mixtures. The peel strength of the film created by this primer is 0.4 MPa, while the adhesion of any cement mortar starts from 0.5 MPa. In addition, cement mixtures shrink and the applied layer of plaster is slightly stretched. If the mortar was applied directly to the concrete, there would be no problems, but with the "Concrete-contact" it will lag behind the wall.

Due to the name of the primer, it often gives the impression that it is used only for the treatment of concrete slabs. In fact, "Betonokontakt" is universal, it is applied to almost any type of surface:

- on a brick;

- dense concrete;

- foam and aerated concrete;

- drywall, gypsum fiber sheets, cement-bonded and tongue-and-groove boards;

- tile;

- bases leveled with cement or gypsum mixtures;

- surfaces covered with oil paint;

- tree;

- metal.

If necessary, "Concrete-contact" can be applied even to plastic and glass.

Compositions from different manufacturers have some differences, so it is advisable to read the characteristics of the primer and its scope on the package before purchasing. So, for example, "Betokontakt" from Knauf, according to the manufacturer, is intended for processing smooth, slightly absorbent or non-absorbent substrates, which include concrete, plastered surfaces, expanded polystyrene, gypsum tongue-and-groove boards. It is applied under gypsum plaster, suitable only for interior work.

When buying, it is recommended to ask the seller for a certificate of compliance with established standards.

Specifications and application features

"Betonokontakt" has the following properties:

- Drying speed. This primer dries very quickly. Depending on the surface area, the "readiness" time is from 1 to 3 hours.

- Material consumption. The average value is 300 grams per 1m2. In fact, this indicator varies depending on the porosity of the surface and ranges from 150 to 500 grams per 1 m2.

- Moisture resistance. The coating has waterproofing properties due to the formation of a characteristic waterproof film.

- Life time. According to experts, the primer will not lose its properties for 70-80 years. However, this is only guaranteed if it is applied in accordance with the rules.

Features of handling the composition:

- The primer is applied at air temperature from +5 to +30 degrees Celsius. In this case, the humidity should not exceed 80%.

- Despite the rapid drying, the paint is applied only 12 hours after the primer treatment.

- Finishing material should be applied no later than a day later, since dust reduces adhesive properties.

- The primer can be diluted with water.

- On sale there are packs weighing 3, 5, 6, 10, 14 and 20 kg.

"Concrete-contact" is valued for the fact that it does not have an unpleasant odor. In addition, it is allowed to carry out processing indoors, without the need for personal protective equipment.

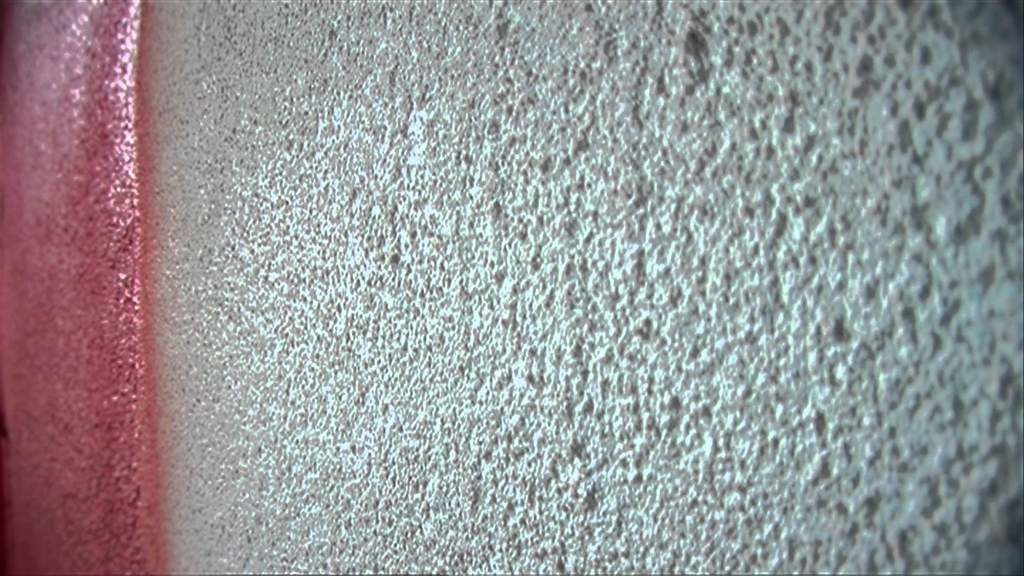

"Concrete-contact" does not have its own color. But in most cases, pink dye is added to it in production so that poorly processed areas can be seen when coating the surface. On sale it is already in a usable condition, which eliminates the need for kneading, applied by brush or roller. Following the example of other primer manufacturers, some firms have brought the product to the market in spray cans that spray the material onto walls or ceilings.

Manufacturers produce "Concrete-contact" with different grain sizes, on which the purpose of the primer depends. The composition with a fine filler is suitable for the subsequent application of putty, paint, with a larger one - for plastering.

Application features

Before applying "Concrete-contact", it is necessary to pre-treat the surface. To do this, you need to clean the wall or ceiling from dirt, wipe the dust and scrape off the elements that will flake off.

After the preparatory work, you can start applying the primer.

- First, a solution is prepared. It must be thoroughly mixed, as the heavier particles (sand and cement) go down and need to be balanced with the rest of the composition.

- When applied, use a brush or roller. The technical characteristics of the primer allow you to limit yourself to just one layer. But if there is a need, for example, the wall is too uneven, you can apply a second one.

The second layer of "Concrete-contact" is needed if the primer is completely absorbed, gaps are visible on the surface or the coating is easily removed by hand.

- While the material is setting, you can begin preparations for further finishing.

Any primer dries about 2-3 hours. In rare cases, the time may be reduced to 60 minutes. To check the condition of the surface, you can run a metal spatula over it. If traces remain, the soil is not ready for further processing.

How much "Concrete-contact" is required depends on the type of surface.

- For porous bases (concrete slabs, bricks), soil consumption will be 300–500 g/m2.

- For surfaces with medium porosity (monolithic concrete, self-leveling floors), the consumption will be 250–300 g/m2.

- For smooth substrates (hardened concrete, tiles, walls painted with oil paint) - 150–250 g/m2.

To reduce the consumption of "Concrete-contact" on porous substrates, you can pre-impregnate the surface with a deep penetration primer.

Price

The cost of a primer depends on its quality and the name of the manufacturer.

- The cheapest primer can be found from 30 rubles per kg. So, "Concrete-contact" brand "Rainbow" costs 25-45 rubles. per kg.

- If we consider a not too famous brand, then you will have to pay about 60–90 rubles. per kg. This price category includes primers of the Prospectors, Osnovit, Pufas, Bolars brands.

- When buying the most expensive material, the cost can be 100–160 rubles. per kg. For example, the average price for Betokontakt from Knauf in Moscow is 125 rubles. for 1 kg. At the same time, high-quality soil of the famous Ceresit brand is cheaper - 70 rubles. for 1 kg.

You need to choose according to your financial capabilities and how many square meters you plan to process. When all rooms of the apartment are to be finished, you can use a primer of the middle price category. If water-repellent properties and durability are important, then you should pay attention to more expensive and high-quality products.

You can clearly understand where and how Concrete Contact is used by watching the video.